Plastic shuttle of netting machine

A net weaving machine and plastic shuttle technology, applied in twisted lace looms, textiles, shuttles, etc., can solve the problem that the plastic shuttle of the net weaving machine cannot work normally, shorten the service life of the plastic shuttle of the net weaving machine, and affect the normal operation of the net weaving machine Work and other problems, to achieve the effect of reasonable and ingenious overlapping design, improved service life and strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

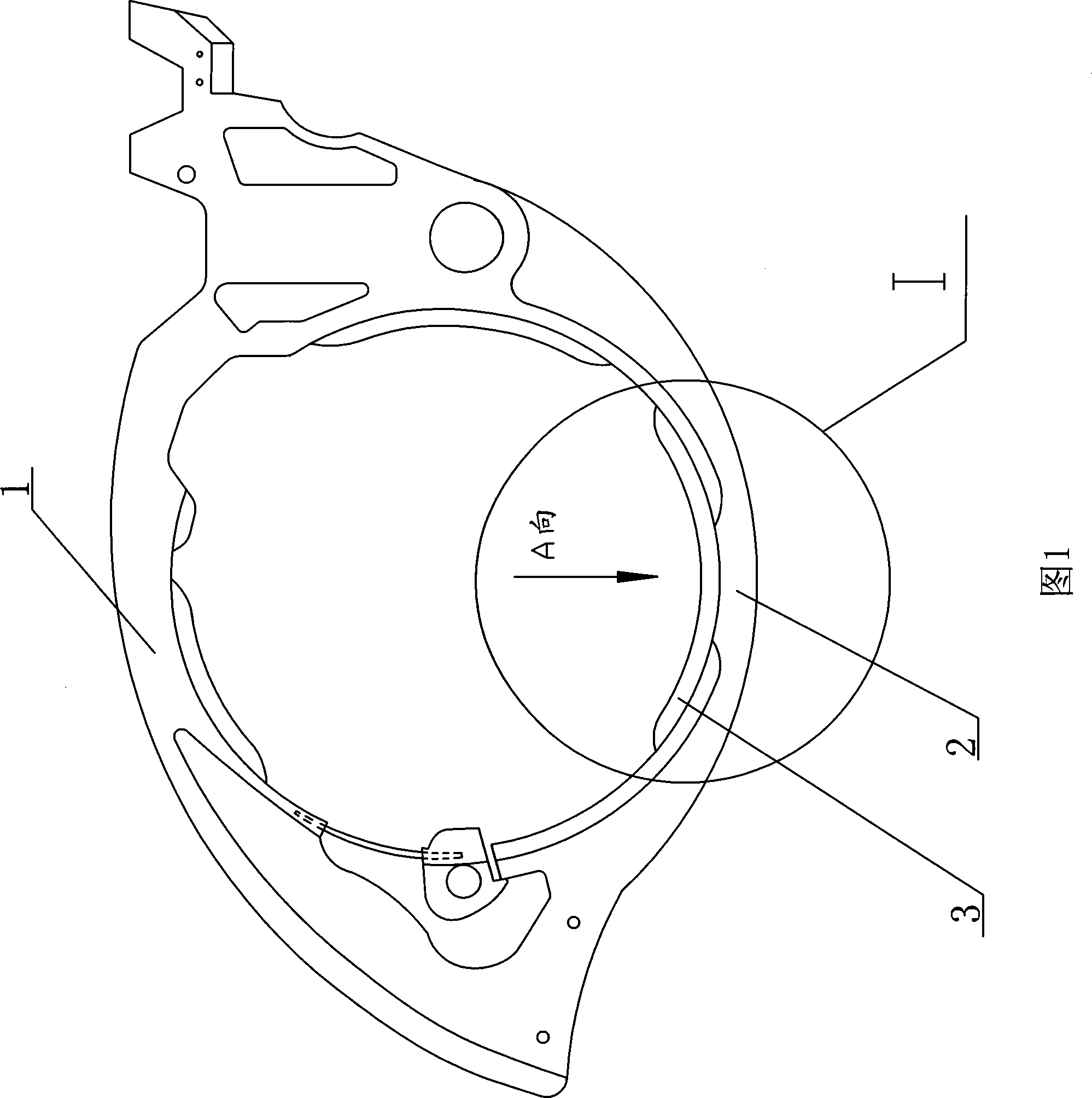

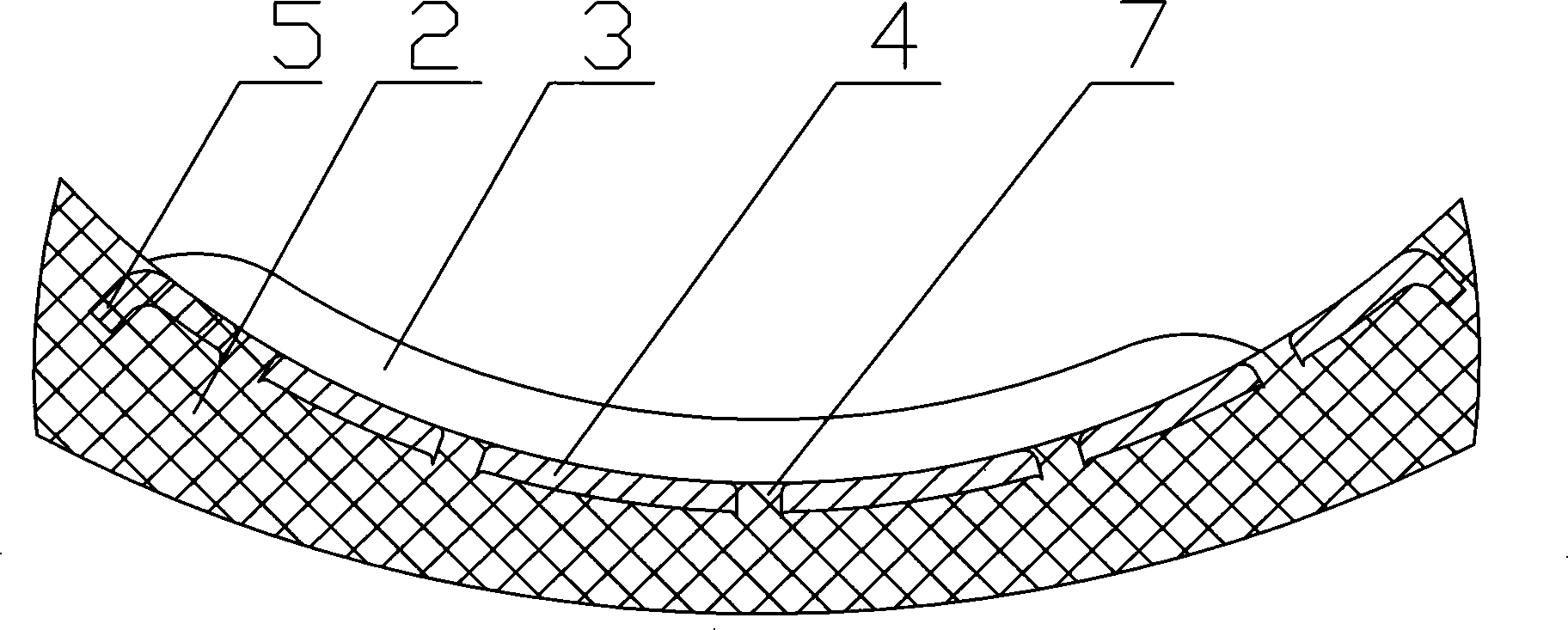

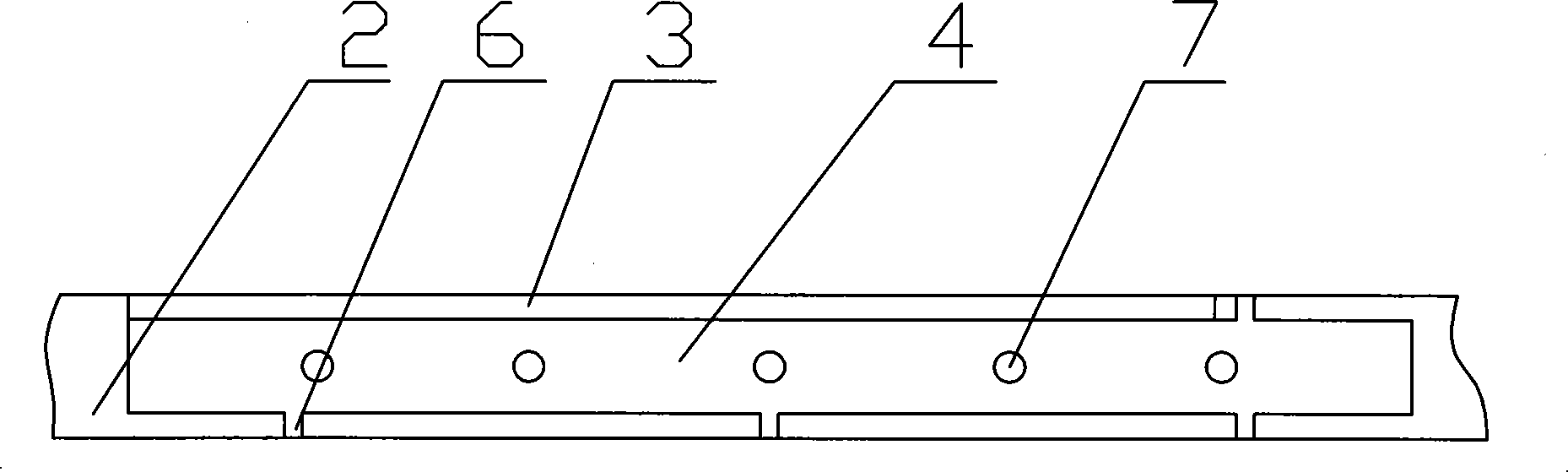

[0018] Below in conjunction with accompanying drawing, the structure of plastic shuttle of net weaving machine of the present invention is described in further detail.

[0019] Such as figure 1 and 2 As shown, the plastic shuttle of the weaving machine includes a shuttle body 1 formed by injection molding of high-strength and wear-resistant plastic, and an arc-shaped bottom support section 2 arranged at the bottom of the shuttle body 1 for supporting the wire reel. The wire reel is not shown in the figure, one side of the arc-shaped bottom support section 2 is provided with a shuttle edge 3, and the inner surface of the arc-shaped bottom support section 2 is embedded with a layer of arc-shaped metal sheet 4, which can be It is made of wear-resistant metal material, usually made of steel sheet or iron sheet. When making it, the arc-shaped metal sheet 4 is set in the mold, and it is injection-molded together with the plastic shuttle. In the formed shuttle, the arc-shaped The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com