Circular braiding machine

A circular knitting machine and cam technology, which is applied in the field of circular knitting machines, can solve the problems of jacquard influence, insufficient spring force, unstable function of rotor metal parts, etc., and achieve the effects of stable function, half impact sound and simplified clutch mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described below with reference to the drawings.

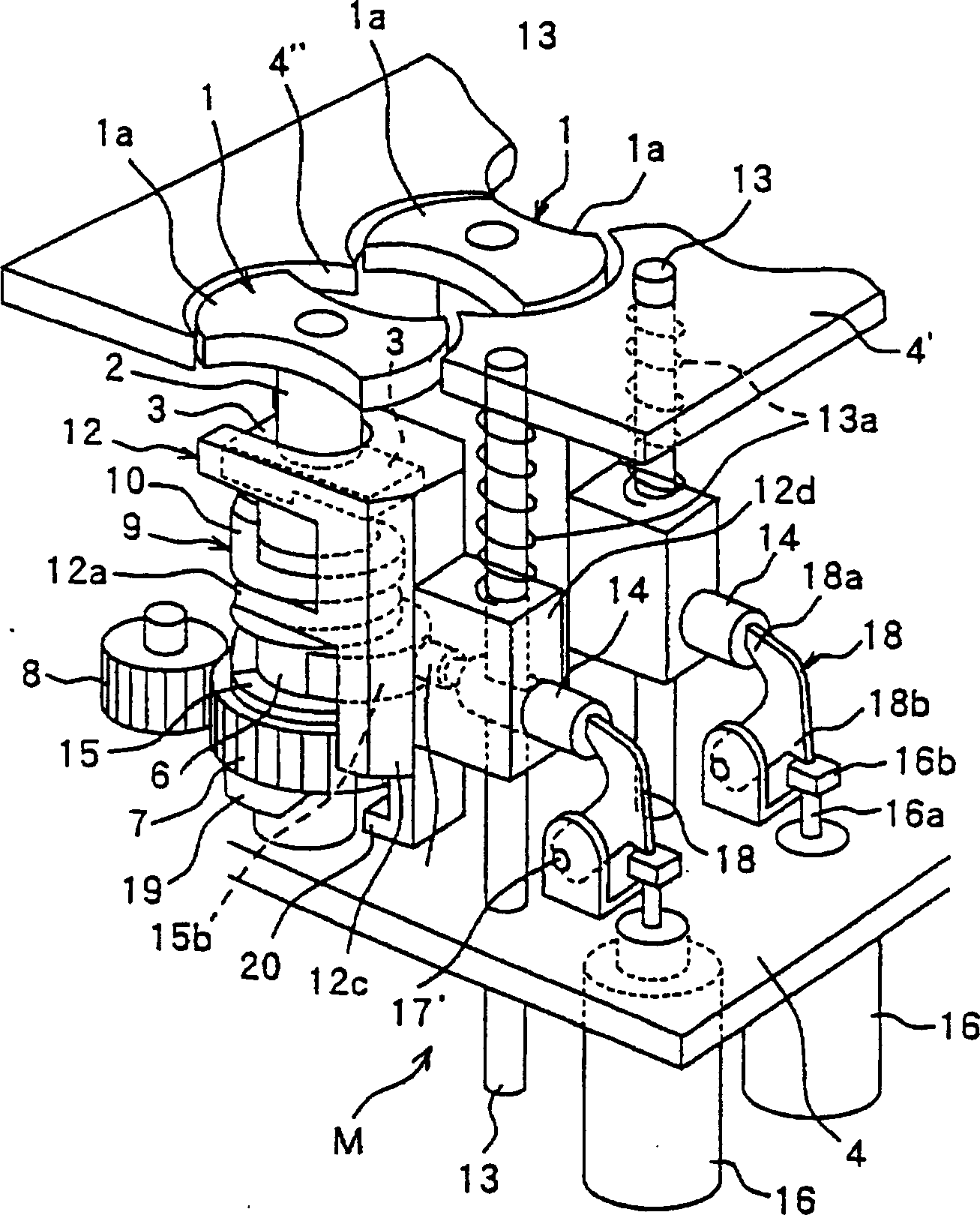

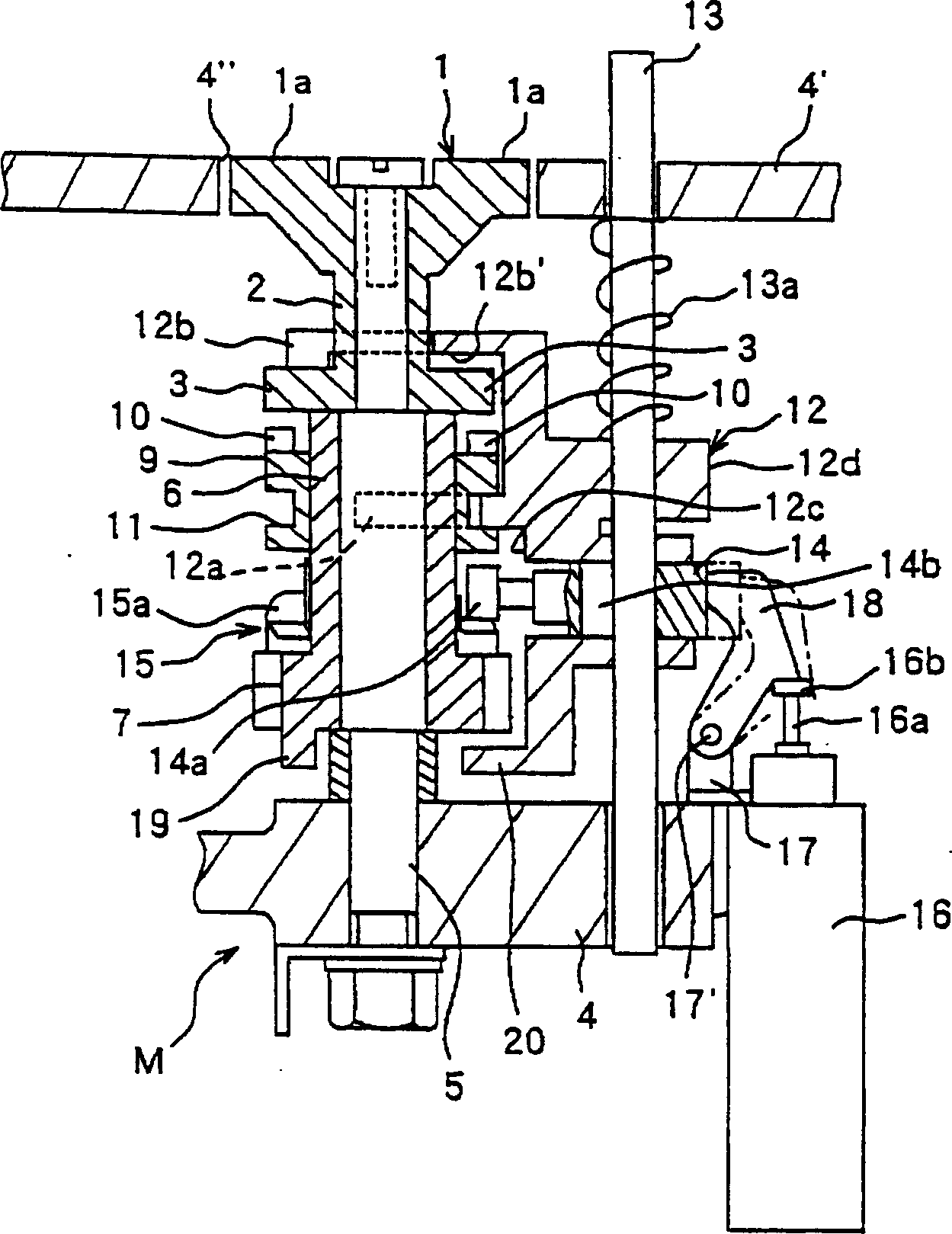

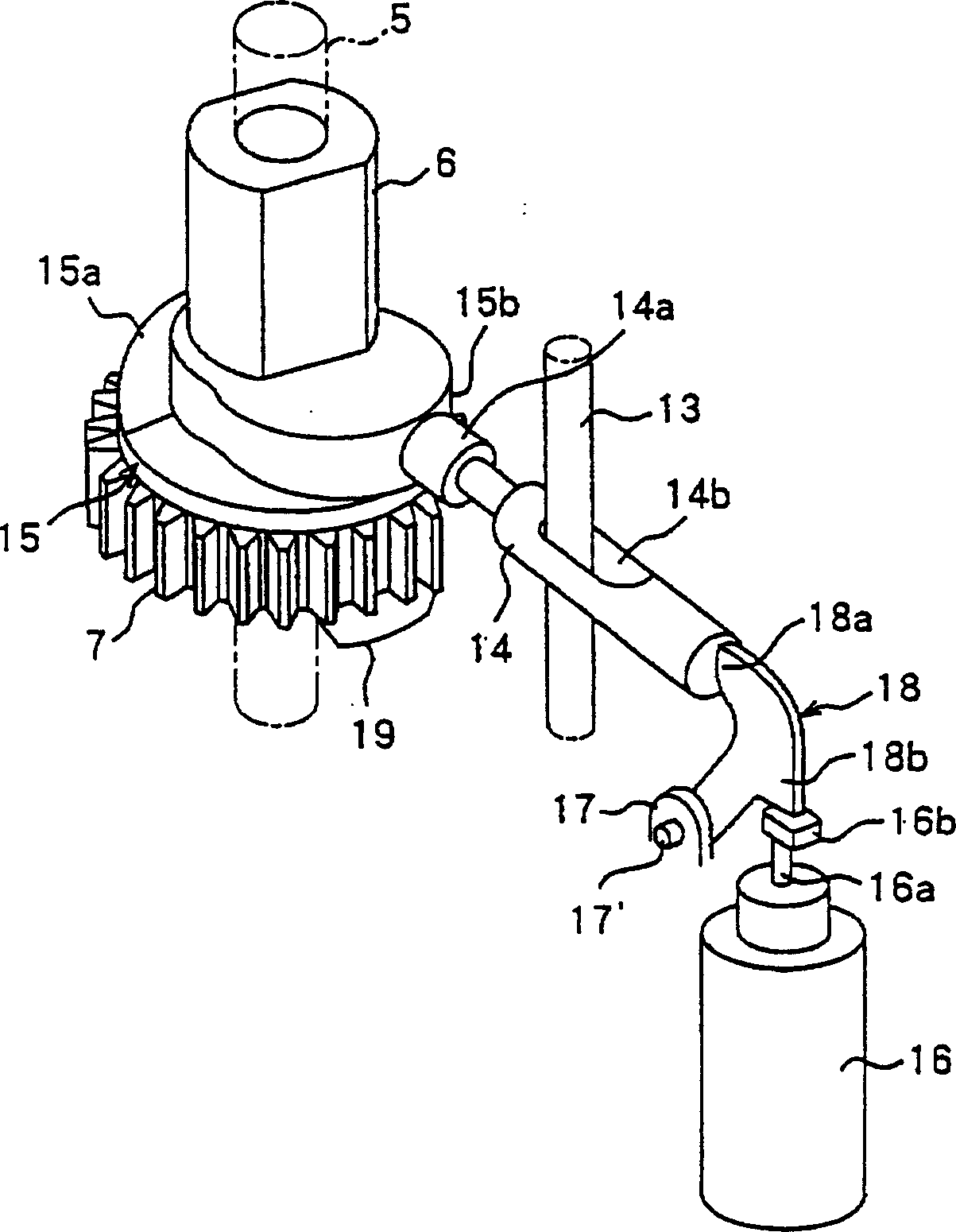

[0017] figure 1 It is an external perspective view of the main parts of the circular knitting machine according to the present invention. figure 2 It is a cross-sectional view when the slide shaft is pressed. image 3 It is a perspective view showing the relationship between the second cam and the slide shaft. Figure 4 It is a perspective view showing the relationship between the third cam and the fork.

[0018] In the figure, 1 is a rotor metal part (ロタタメタル), which is composed of a hollow shaft 2 and fan-shaped portions 1a, 1a extending outward symmetrically from the upper end of the hollow shaft 2, and the hollow shaft 2. The lower end is composed of claw pieces 3, 3 extending in the same direction as the fan-shaped parts 1a, 1a.

[0019] The rotor metal part 1 is rotatably loosely fitted in the horizontal direction on the upper part of a plurality of (64, 94, etc. eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com