Machine and method for manufacturing reinforced net and reinforced net

A technology for strengthening nets and machines, applied in building reinforcements, wire nets, applications, etc., to solve problems such as inability to use cables or high-strength wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

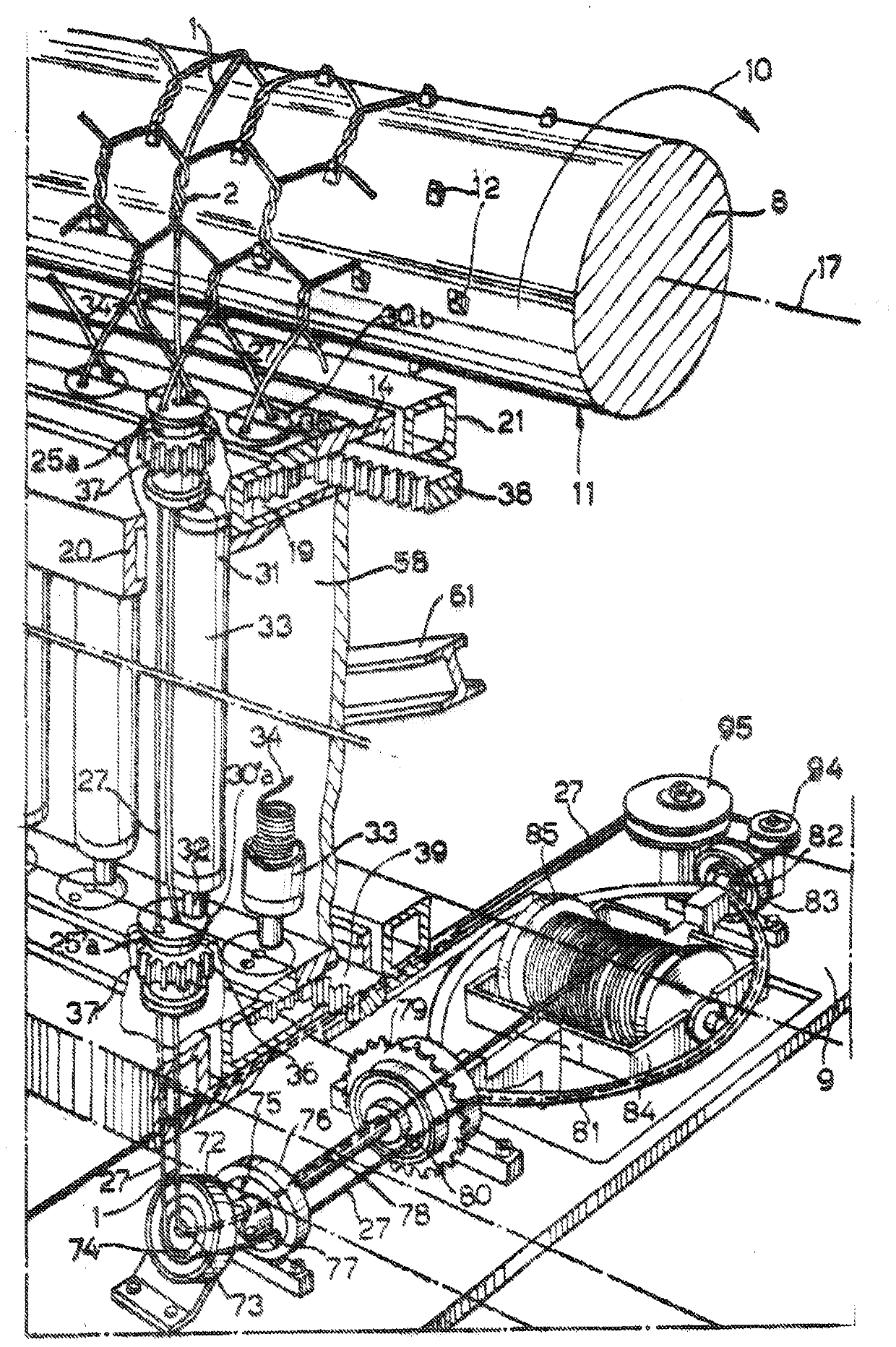

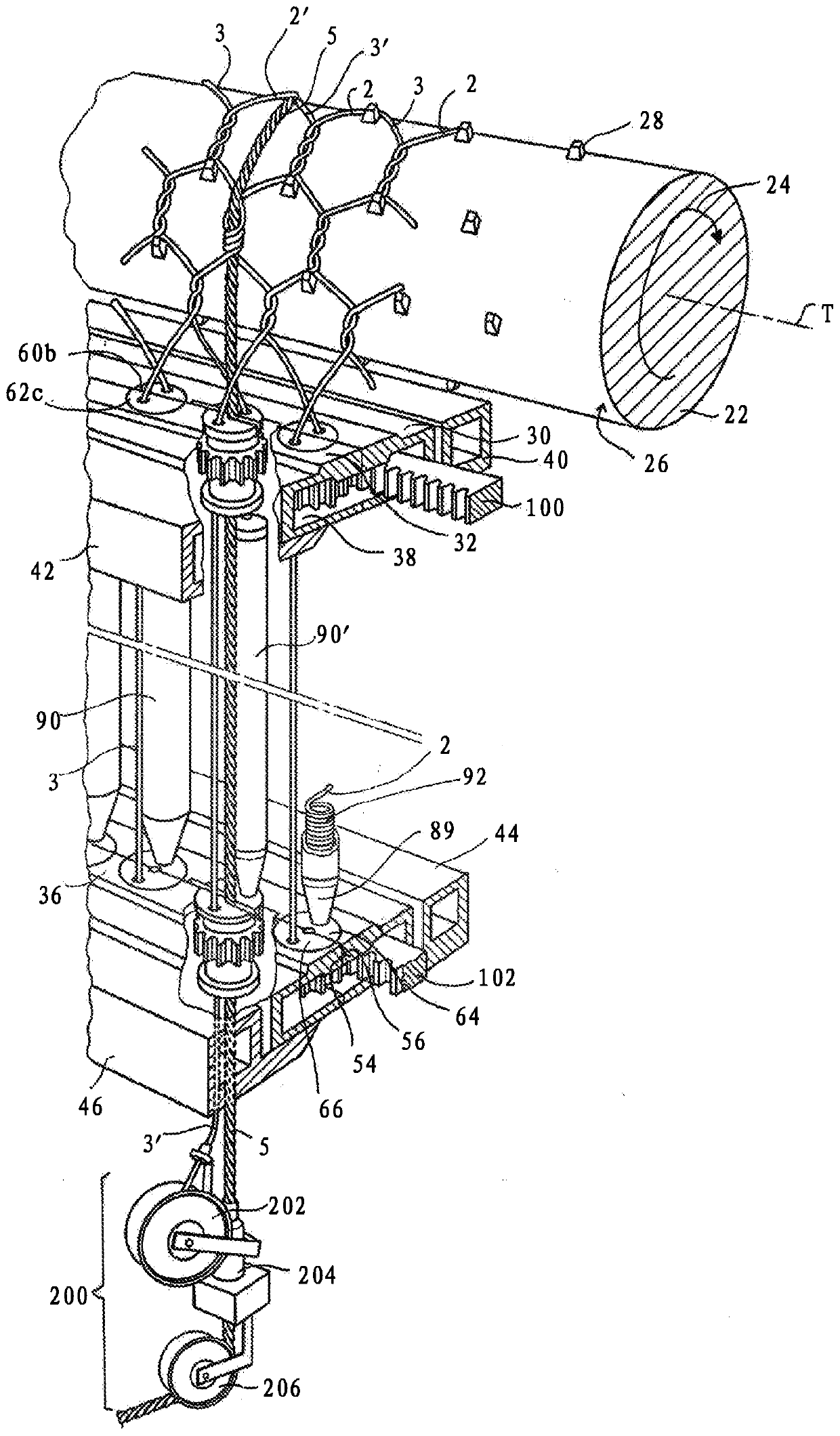

[0017] exist Figure 2-9 In , the same elements are designated by the same reference numerals; the numbering of the reference numerals is different from that of FIG. 1 which is the prior art.

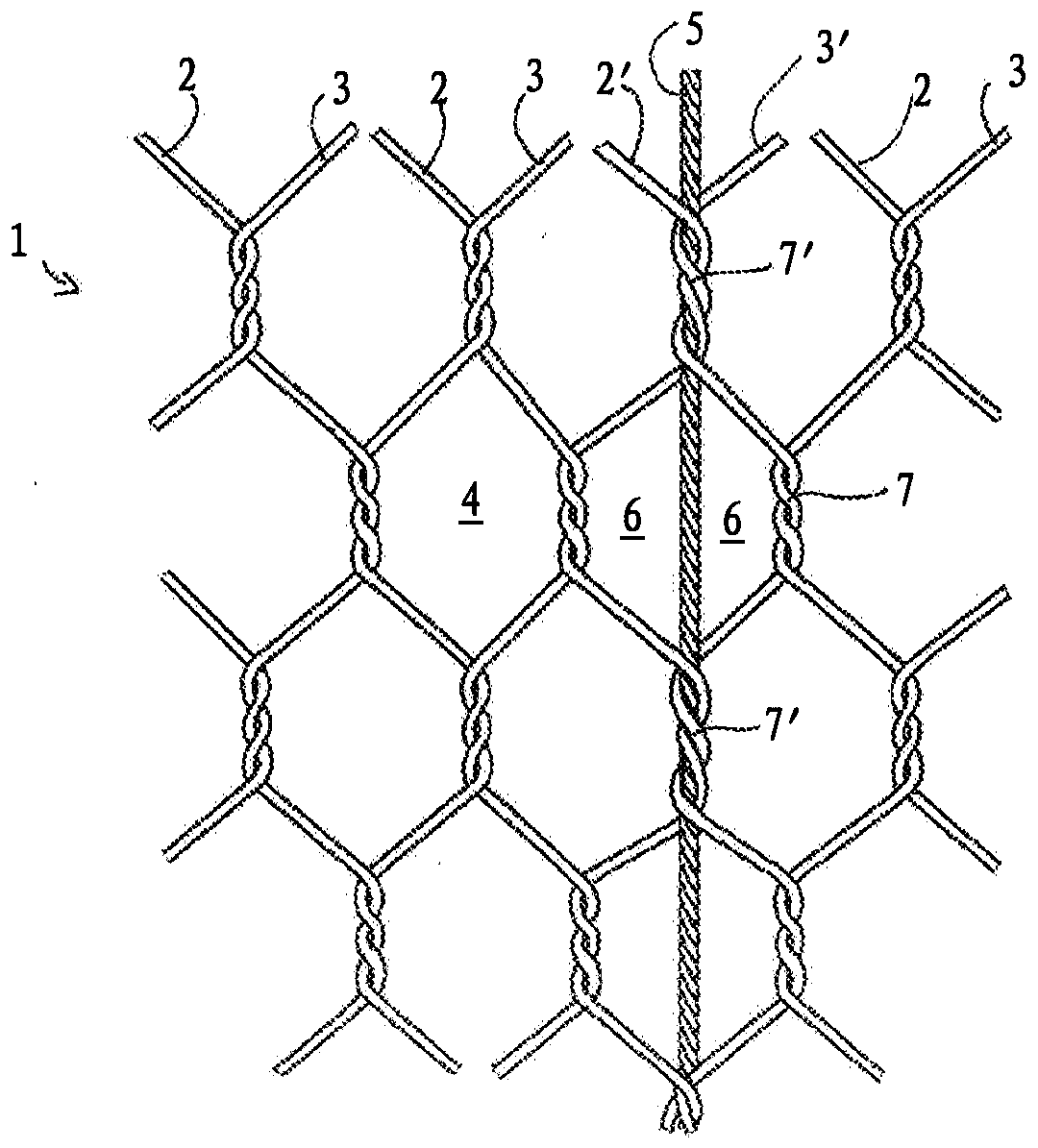

[0018] image 3 The part of the mesh 1 in is a twisted pair mesh, which includes hexagonal mesh and reinforced cables. The net comprises a plurality of filaments 2, 3, 2', 3' coiled around each other in twisted sections 7, 7' to form a hexagonal mesh 4, and at least one of the filaments is longitudinally inserted through a selected twisted section 7' Strengthen the cable 5. Between two consecutive twisted sections 7' in the longitudinal direction, the reinforcing cord forms two trapezoidal meshes 6 arranged side by side. Here and in the following, the term "cable" will be used for the sake of simplicity; however, it will be understood that any strengthening element having a strength greater than that of the wires forming the mesh may be used. For example, the reinforcing element may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com