Leavers machine and pushing rod for the same

A Levis lace machine and push rod technology, applied in the field of push rods, can solve the problems of expensive equipment, long replacement time, reduced productivity, etc., and achieve the effects of reducing burden, reducing noise, and achieving light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

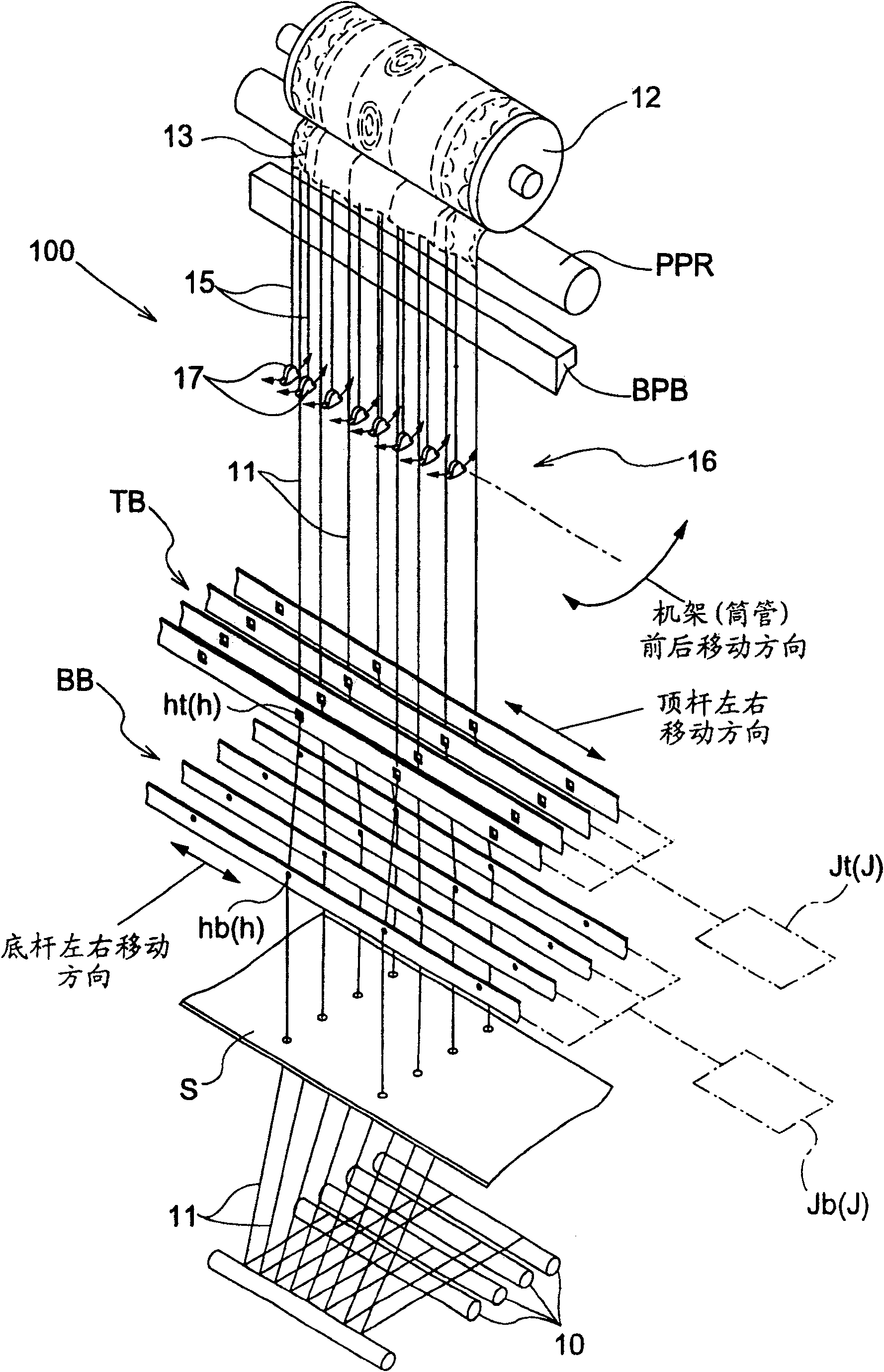

[0040] Next, the Reves lace machine 100 provided with the push rod related to the present application will be described.

[0041] figure 1 The schematic structure of the Reves lace machine 100 is shown, and it is a figure which looked at the Reves lace machine 100 obliquely from front.

[0042] The Reves lace machine 100 guides the warp threads 11 wound on a plurality of warp beams 10 from the lower position of the machine table to the comb tooth part 16 through the sley S, and forms the Leves lace by winding the warp threads 11 and the bobbin line 15 The formed Reves lace 13 is alternately combed and held by the rear dividing reed BPB and the front dividing reed (not shown), and simultaneously lifted by the pin roller PPR on which the card clothing is wound on the upper part. The produced Reves lace 13 has a structure that is wound on the winding roll 12 that is in contact with the needle roll PPR.

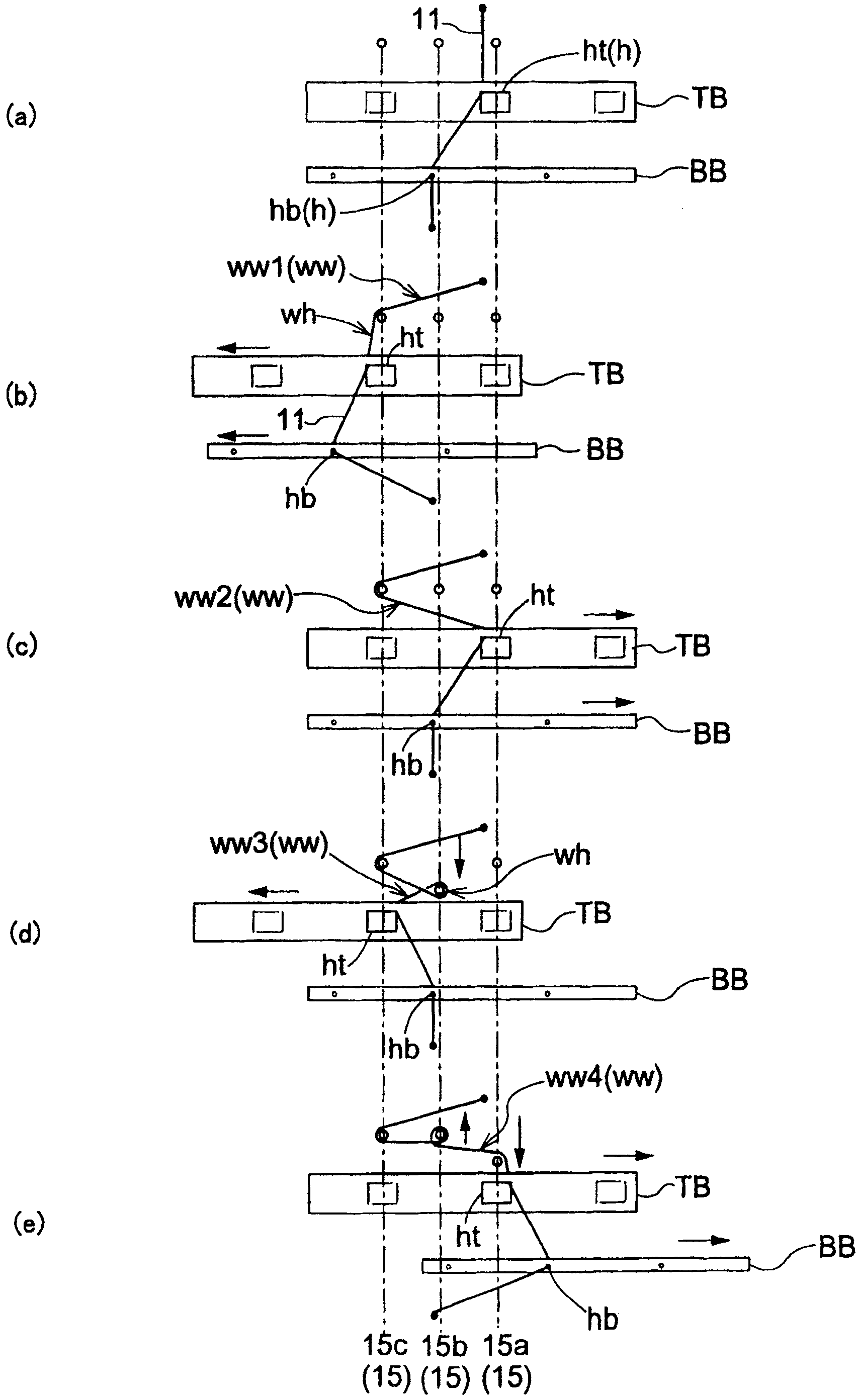

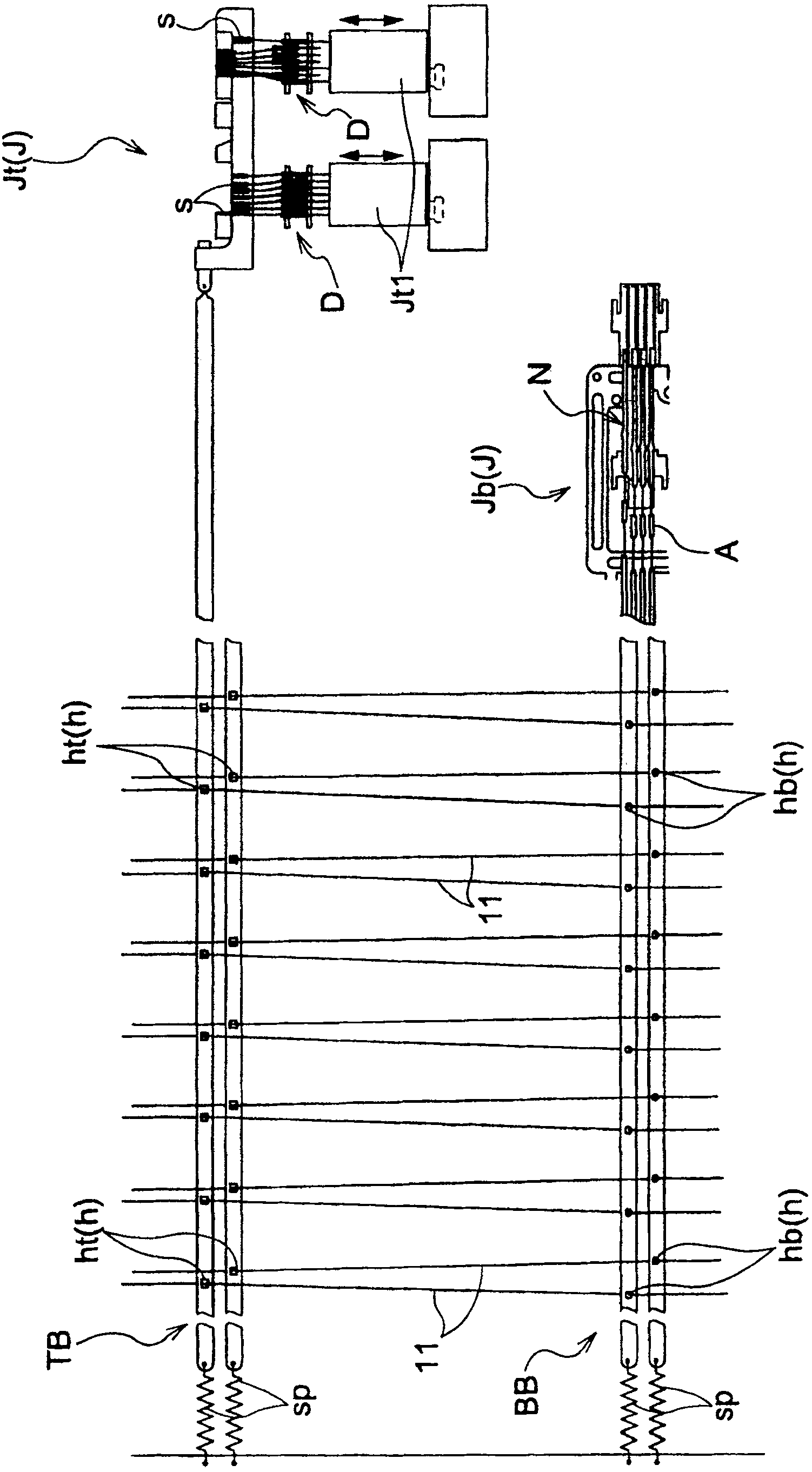

[0043] In the Reves Lace Machine 100, use Figure 4 , Figure 5 , Ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com