Shuttle collision preventing device of netting machine

A net weaving machine and anti-collision technology, applied in the field of net weaving machines, can solve problems such as reducing work efficiency, affecting the quality of mesh sheets, and jumping off copper shuttles, achieving the effect of simple structure and ensuring normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

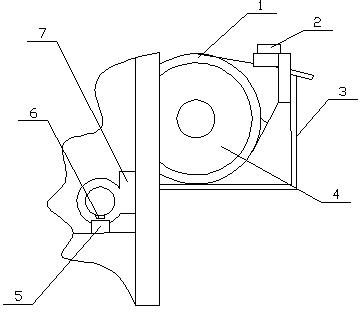

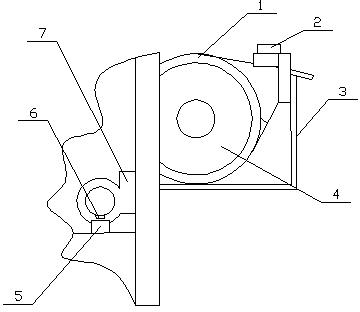

[0008] Depend on figure 1 It can be seen that a kind of anti-collision shuttle device for weaving netting machine includes an edge box 3, the edge box 3 is installed on the frame 7, the copper shuttle 1 is installed on the edge box 3, the shuttle disc 4 is installed on the copper shuttle 1, and the light receiver 2 Installed on the top of the edge box 3, the position is higher than the end of the edge of the copper shuttle 1, and the light projector is located at the other end of the edge box 3, and its position corresponds to the light receiver 2.

[0009] When the present invention is working, because the warp thread shading time of the weaving machine is advanced, the approach point 6 of the time-limited proximity switch 5 is adjusted accordingly, so that when the warp thread is light-shielded, the time-limited proximity switch 5 is in a working stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com