Patents

Literature

69results about How to "Spacing controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

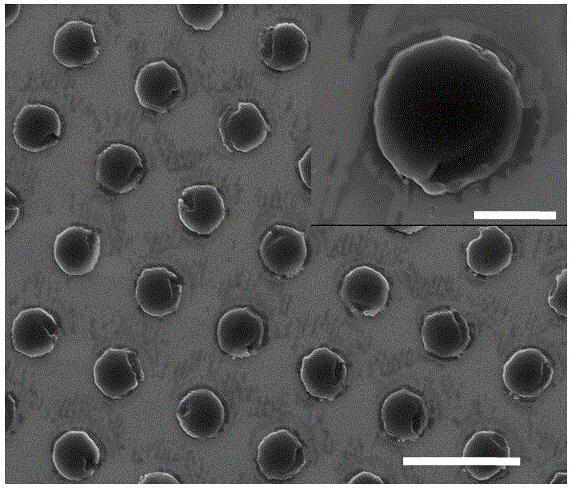

Preparation method of wafer-grade spherical micro-lens array

InactiveCN102491258AReduce roughnessReduce adhesionDecorative surface effectsChemical vapor deposition coatingAdhesiveMicro lens array

The invention discloses a mould for a spherical micro-lens array, and a preparation method thereof. The method is characterized in that the method comprises steps that: a lens mould micro-groove array and self-aligning silicon mould micro-grooves are respectively etched on a silicon wafer; micro-channels are etched among the lens mould micro-groove array, and are used for connecting the lens mould micro-grooves; a certain amount of heat-released aerosol power is placed; a borosilicate glass wafer is bonded with the silicon wafer under a vacuum condition; the bonded wafers are heated; under the effect of vacuum negative pressure, softened glass is automatically filled into the self-aligning silicon grooves, such that self-aligning glass convex blocks are obtained; the materials are cooled and annealed; silicon is removed, such that a glass mould is obtained; corresponding self-aligning grooves and mould grooves used for controlling lens spaces are etched; anti-adhesion treatments are carried out on the surfaces of the glass mould and the silicon mould; a UV curable adhesive is filled in a spherical glass micro-cavity of the glass mould, such that the lens-molding silicon wafer is self-aligned with the glass mould; the UV curable adhesive in the mould is cured, and the wafer-grade spherical micro-lens array can be obtained after demolding. The method provided by the invention is advantaged in simple technology, low cost, and good reliability.

Owner:SOUTHEAST UNIV

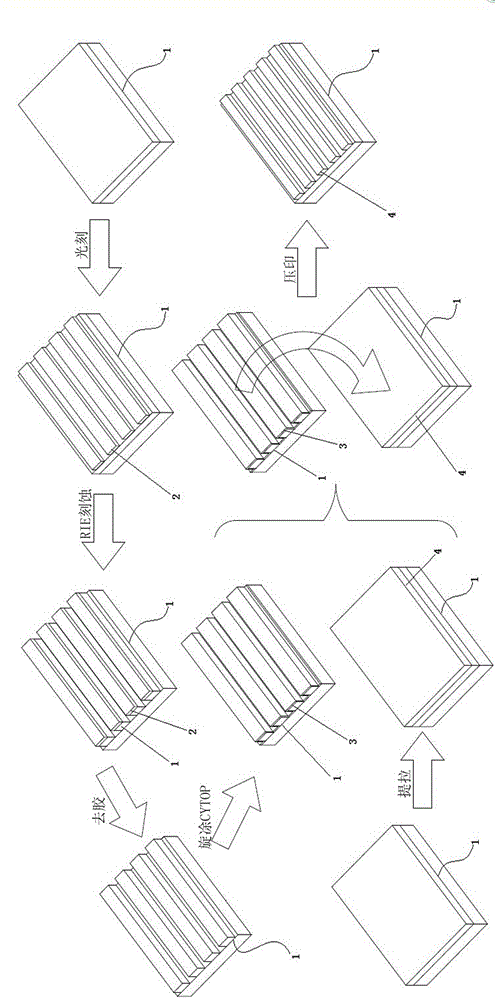

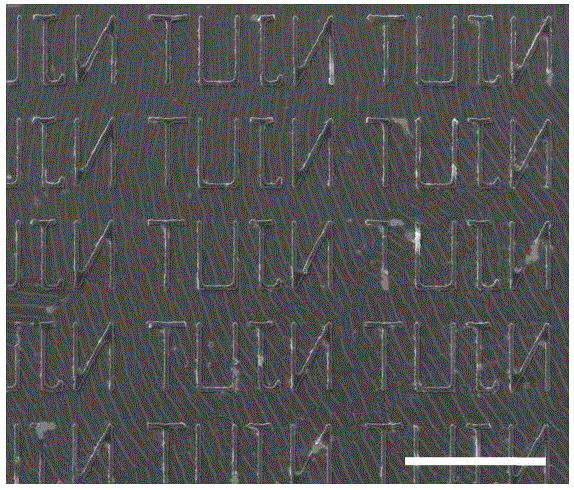

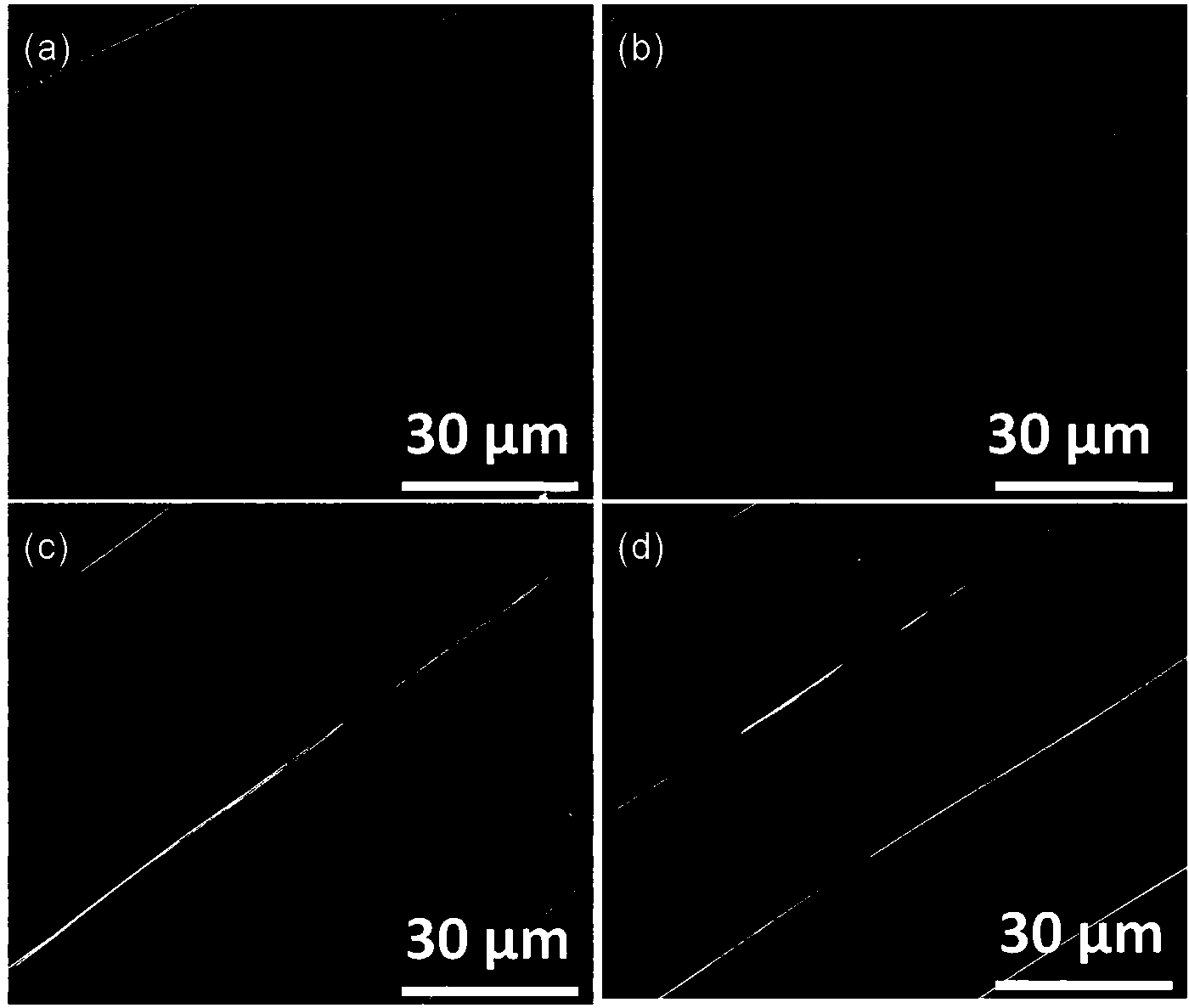

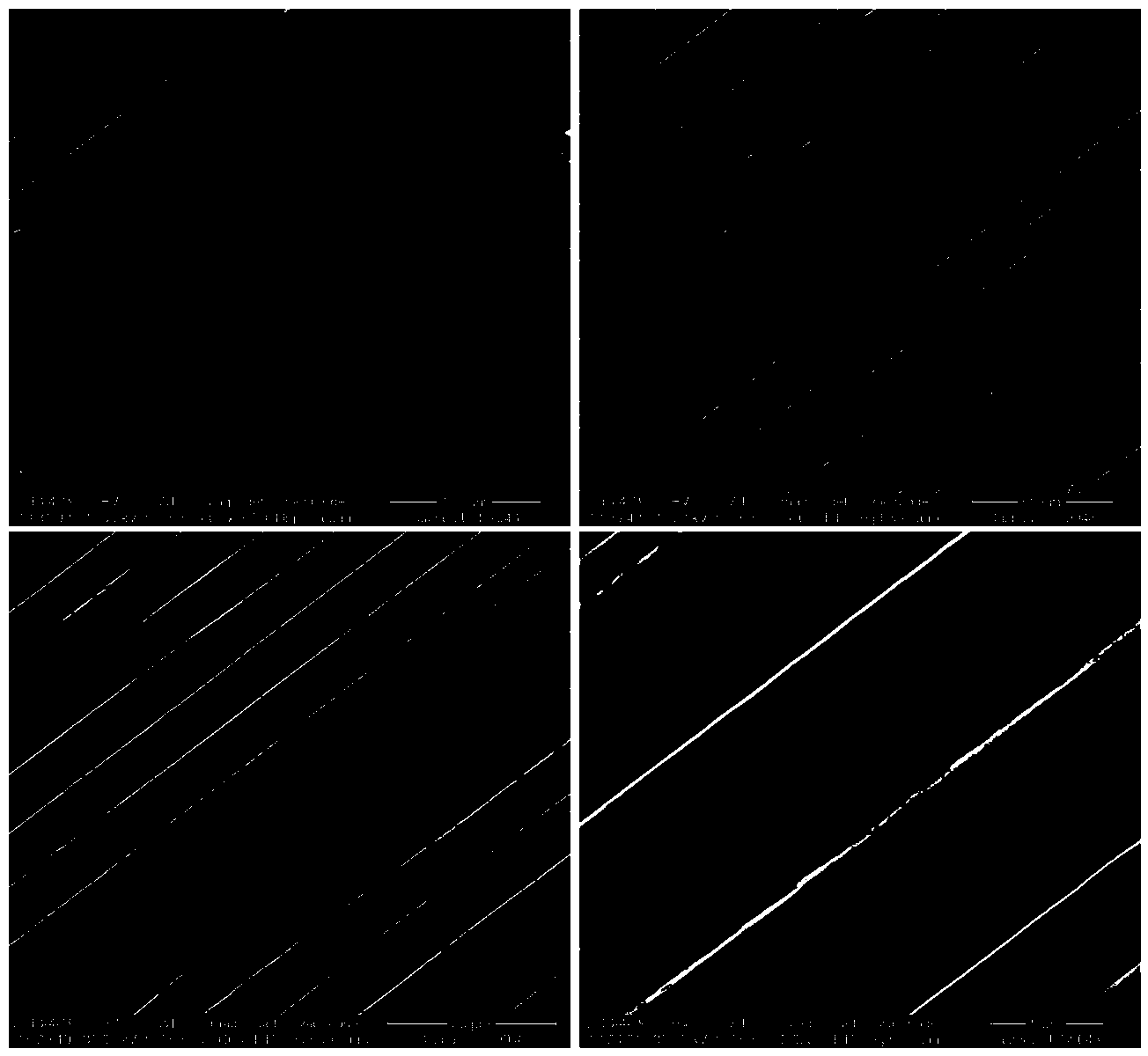

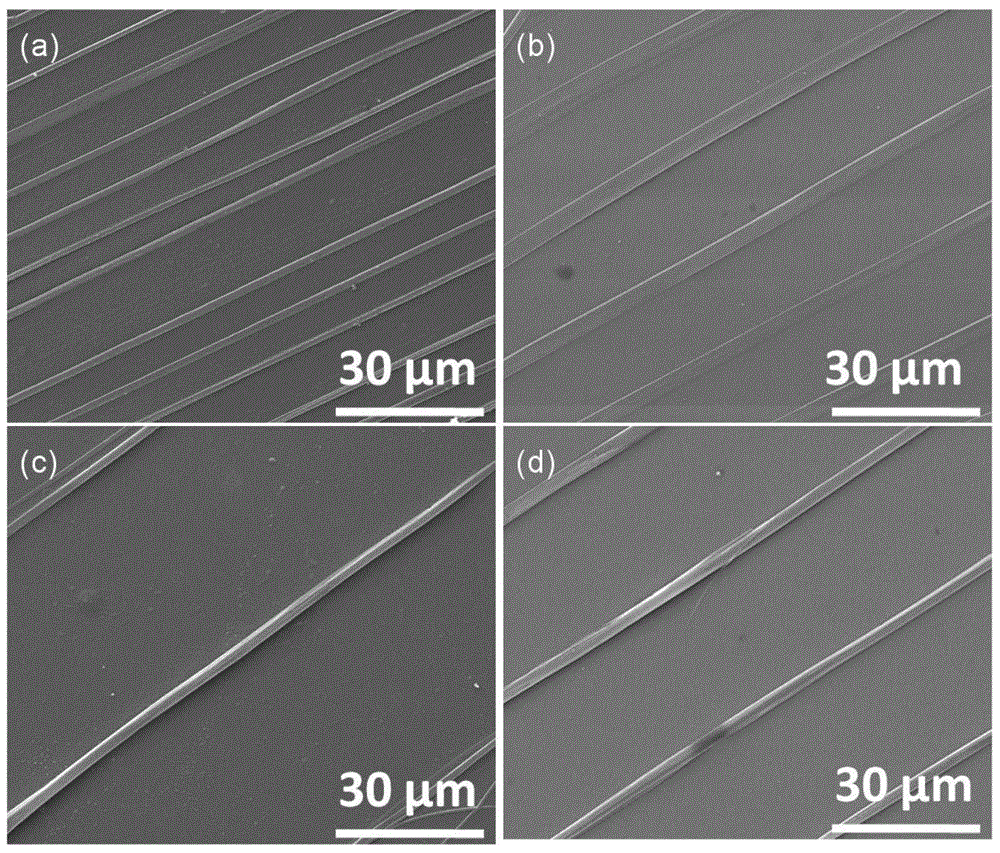

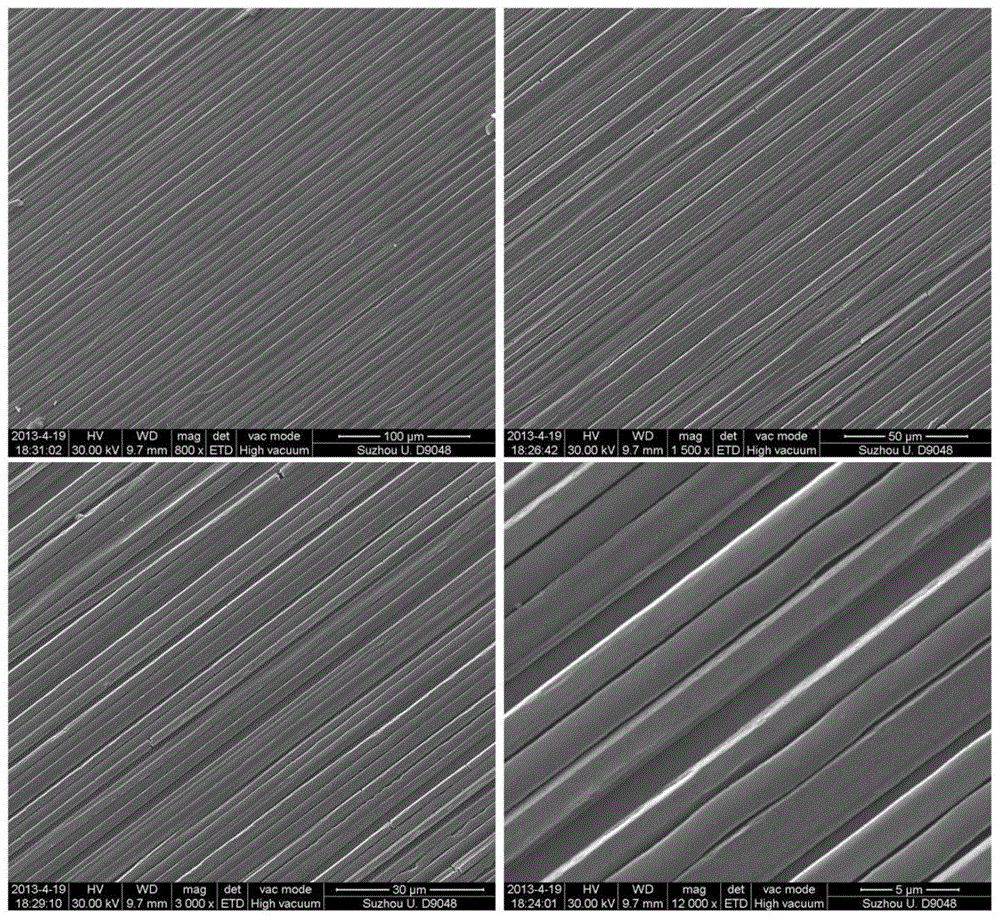

Method for constructing organic liquid crystal molecule single-crystal micro-wire patterned array by nanoimprint technology

The invention discloses a method for constructing an organic liquid crystal molecule single-crystal micro-wire patterned array by a nanoimprint technology. The method is divided into two parts; one part is a preparation of an imprint template; the other part is a preparation of an imprint base; the preparation of the imprint template comprises the following steps: firstly, cleaning a SiO2 / Si wafer base; secondly, carrying out positive photoresist photoetching and developing on the base to obtain an array pattern; thirdly, etching the photoetched SiO2 / Si wafer base by a reactive ion etching machine; fourthly removing the photoresist and obtaining an uneven template periodically arranged; fifthly spinning perfluorinated resin on the SiO2 / Si wafer base; and finally heating to finish the preparation of the imprint template; the preparation of the imprint base comprises the following steps: firstly, taking one cleaned SiO2 / Si wafer; secondly, lifting an organic small molecule membrane from the base on a step-by-step precision lifting platform to finish the preparation of the imprint base; the imprint template covers the base; certain pressure is applied; the imprint template is heated to the melting points of organic small molecules; heating is stopped after the temperature is kept constant for 15 minutes; the imprint template is cooled to room temperature; and the base is taken out, so as to obtain the periodic large-area organic small-molecule single-crystal micro-wire patterned array.

Owner:SUZHOU UNIV

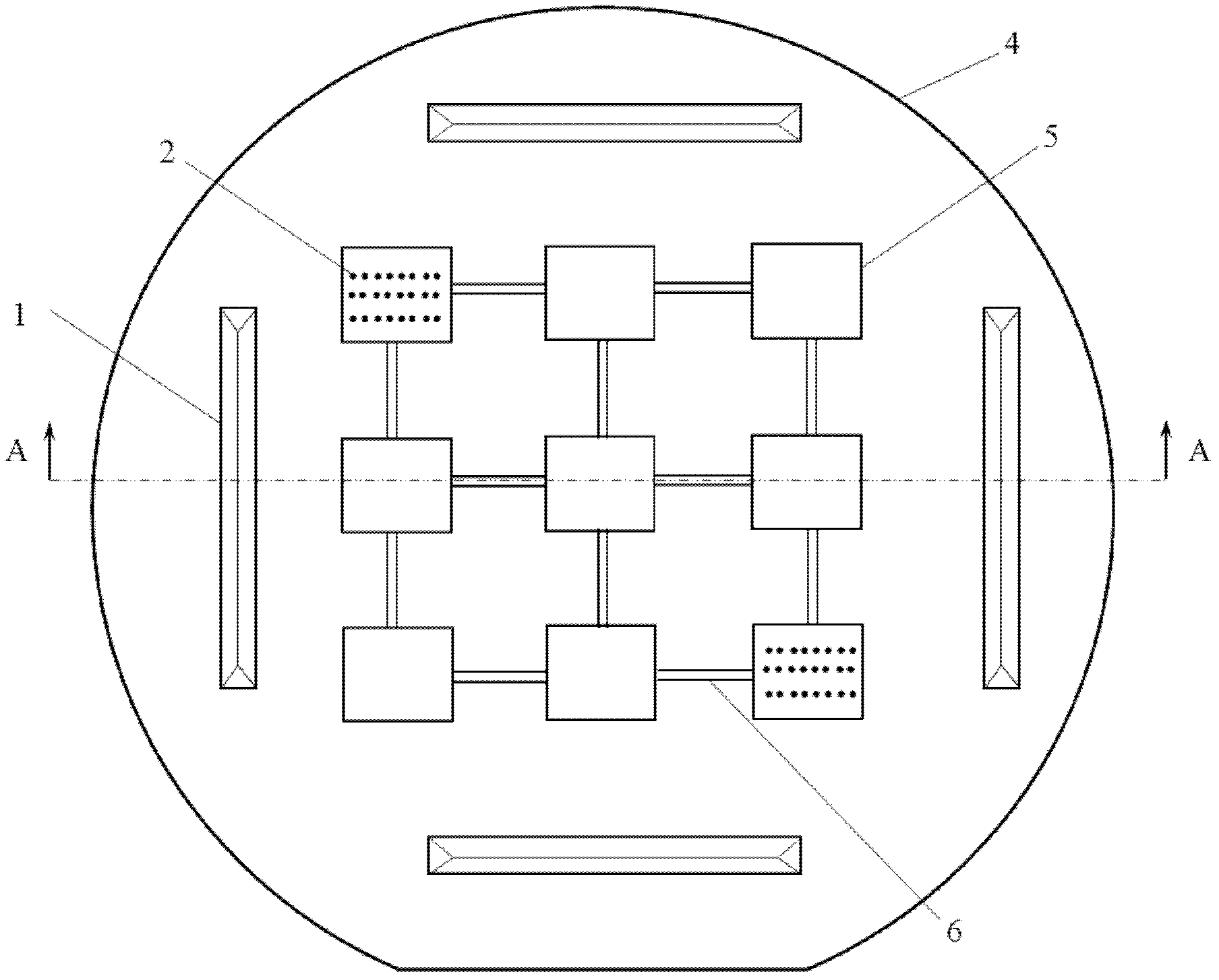

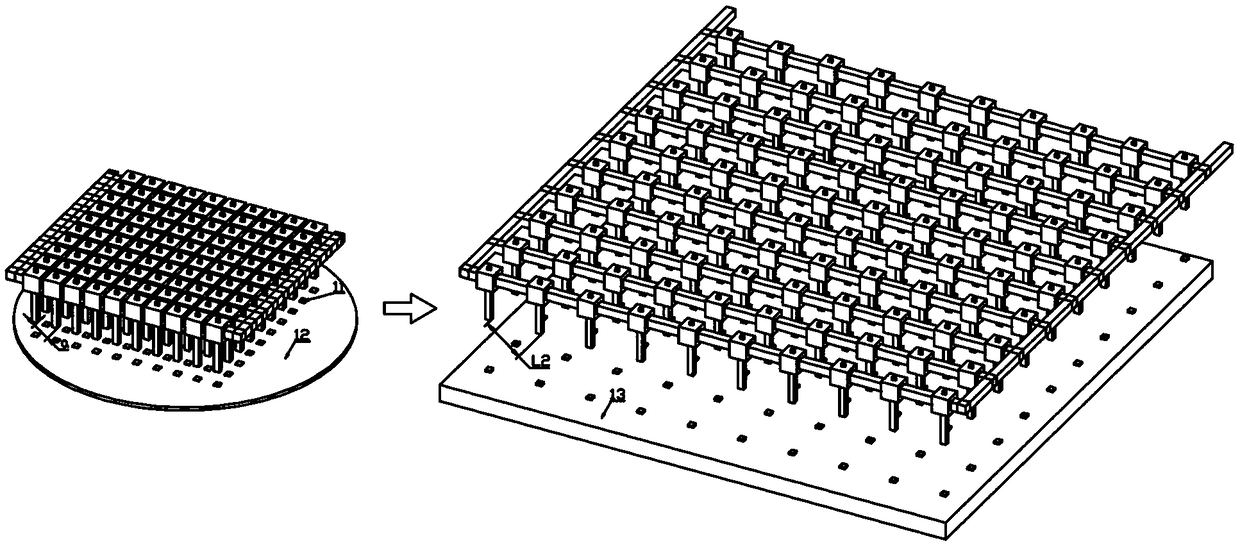

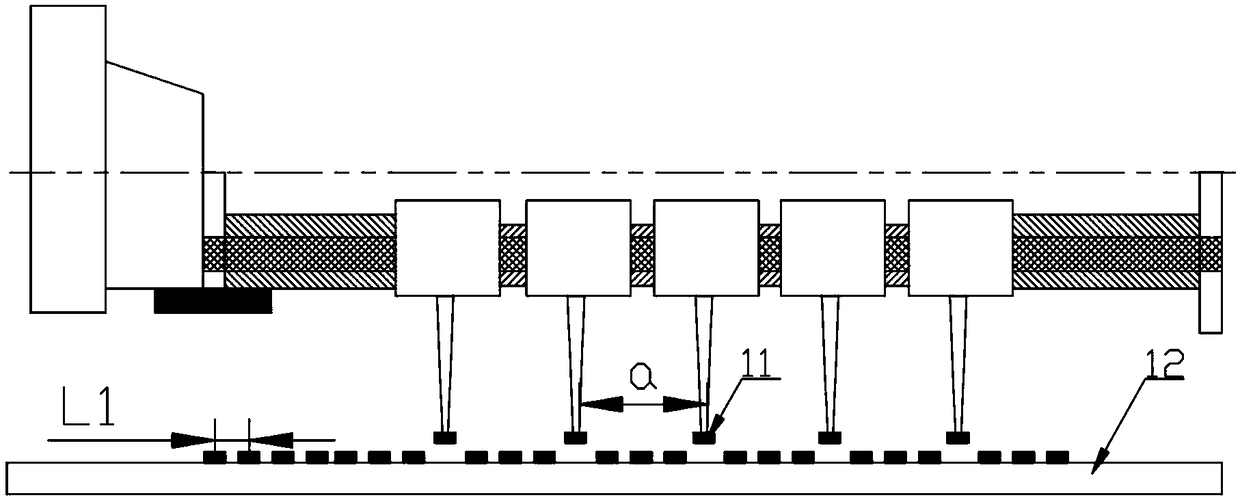

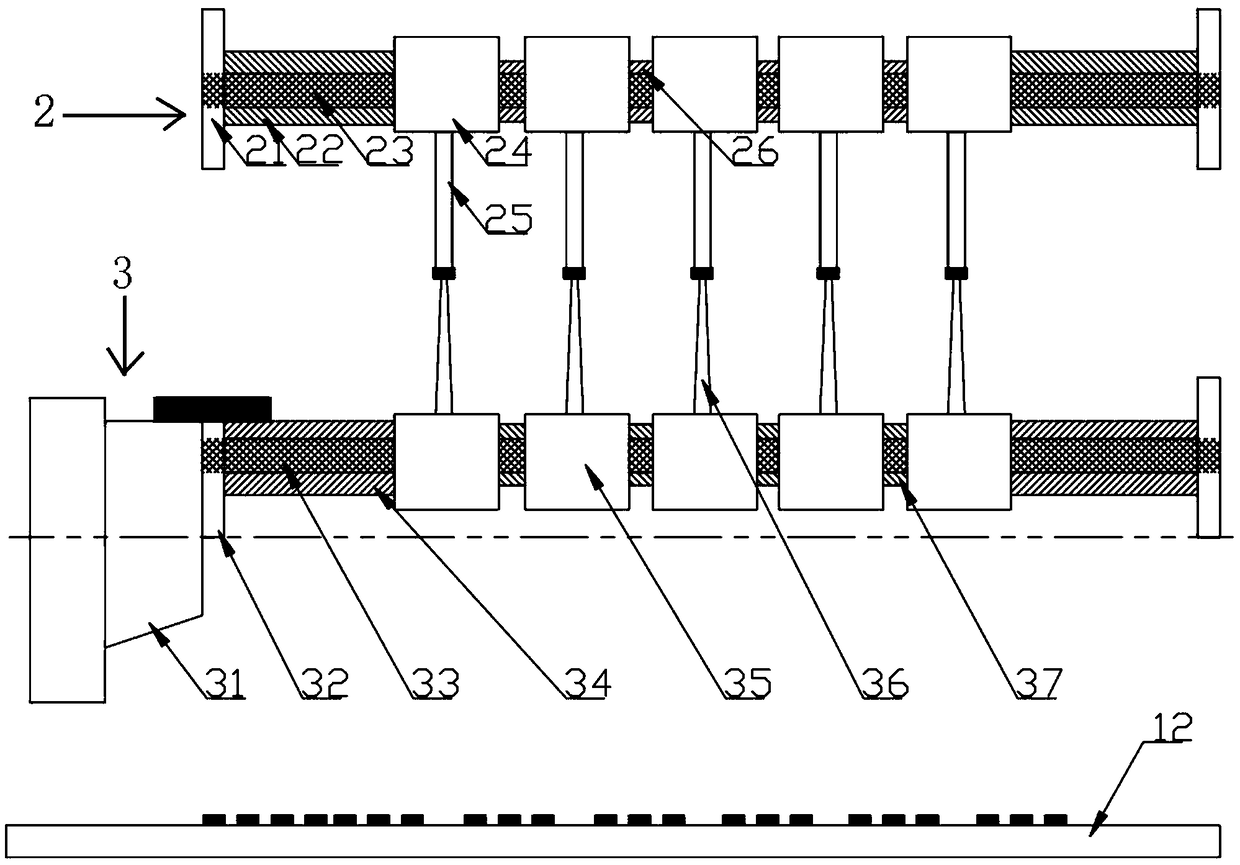

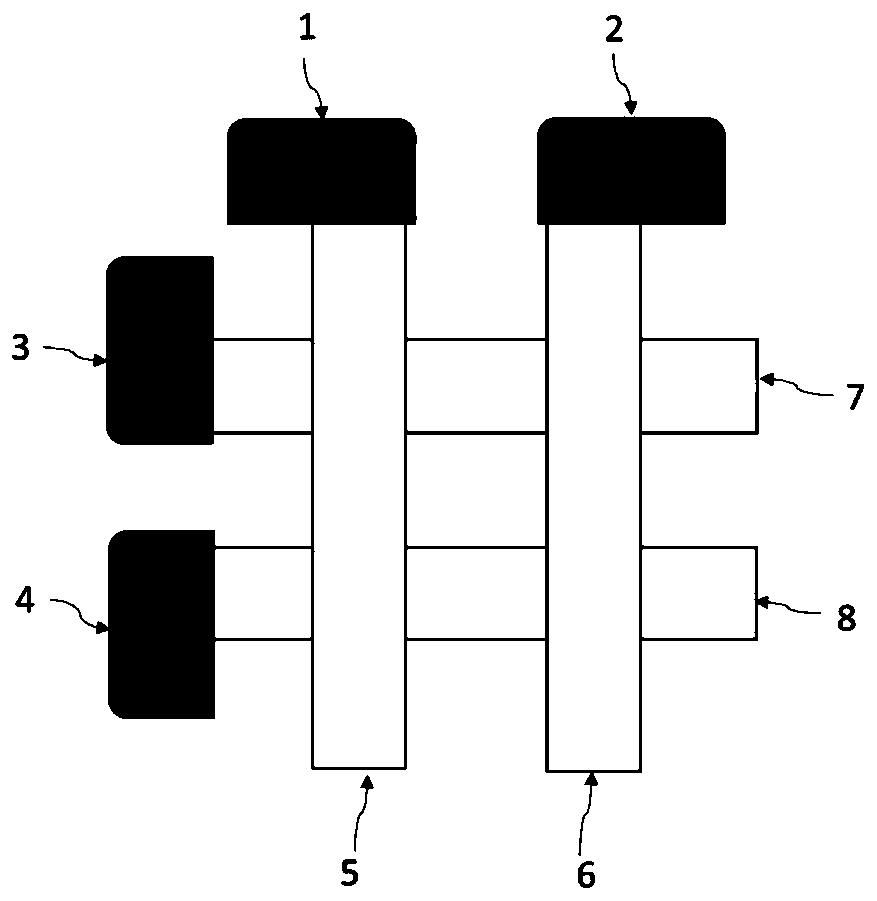

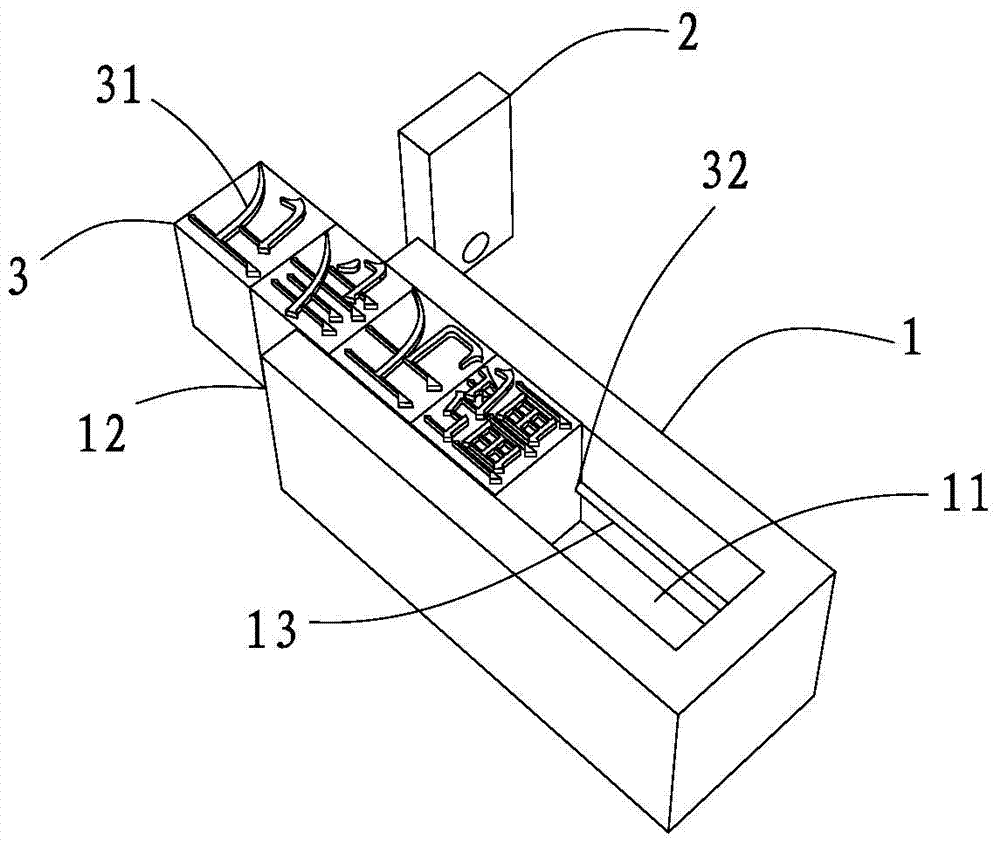

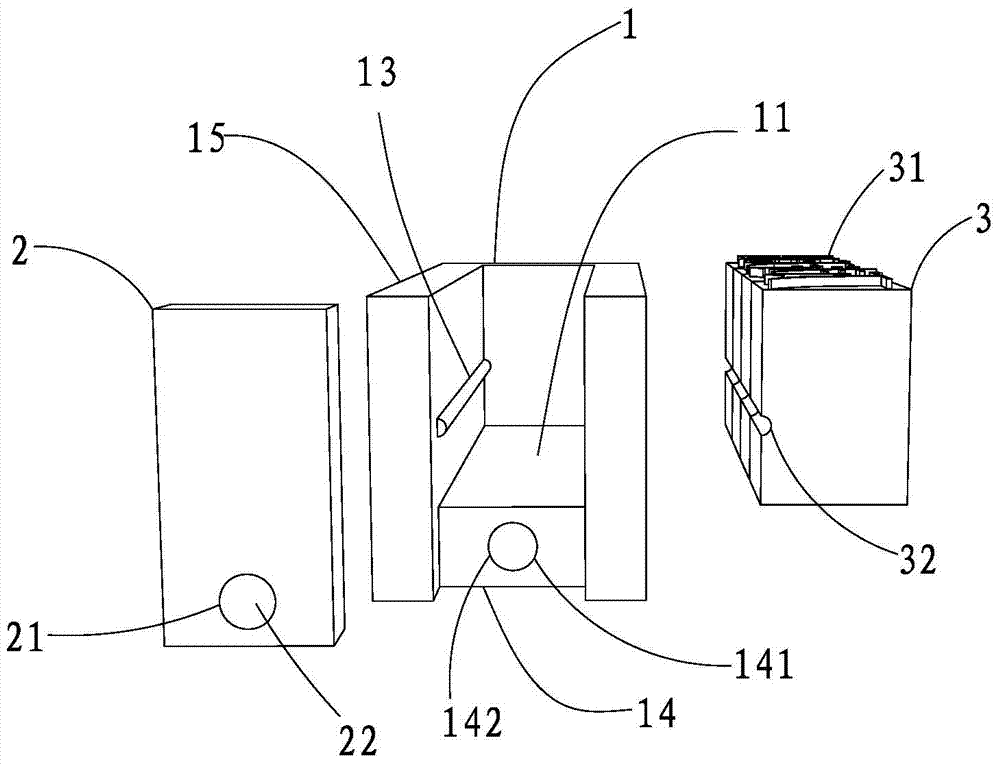

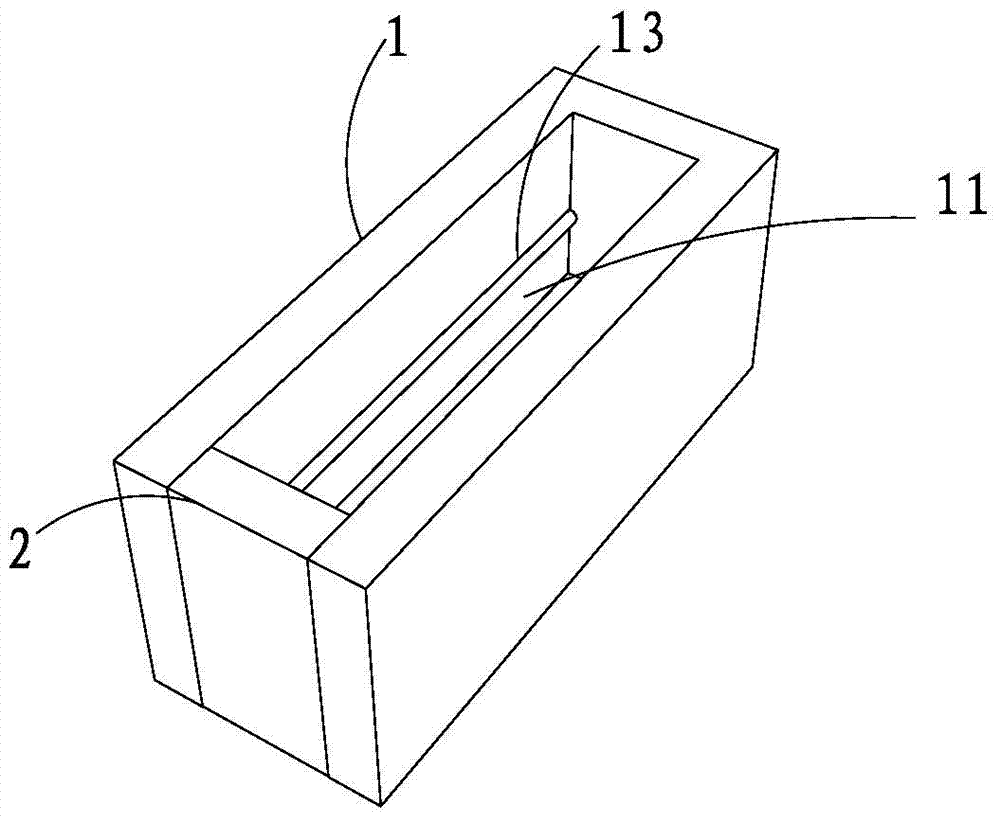

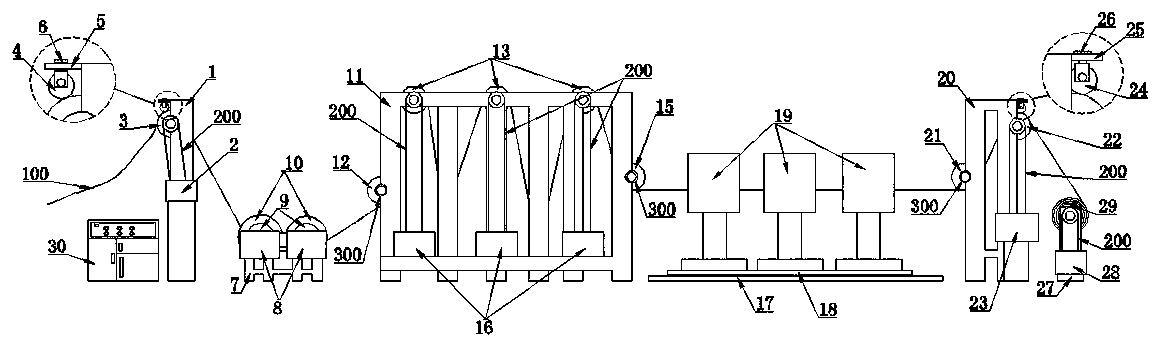

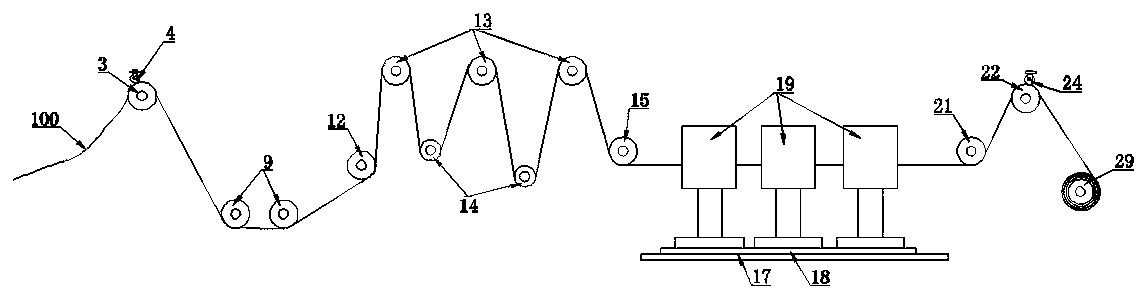

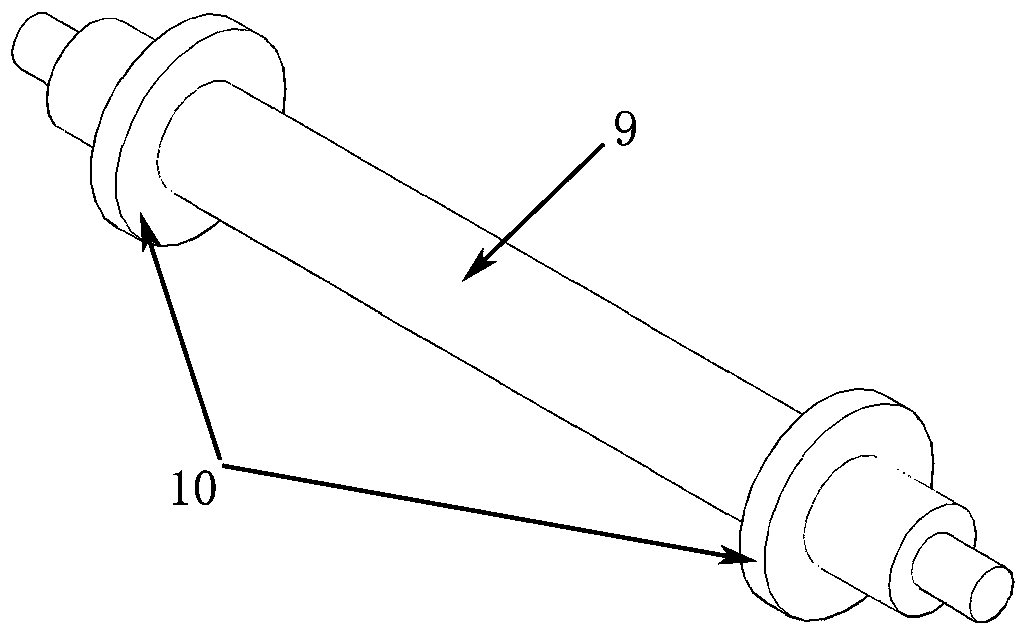

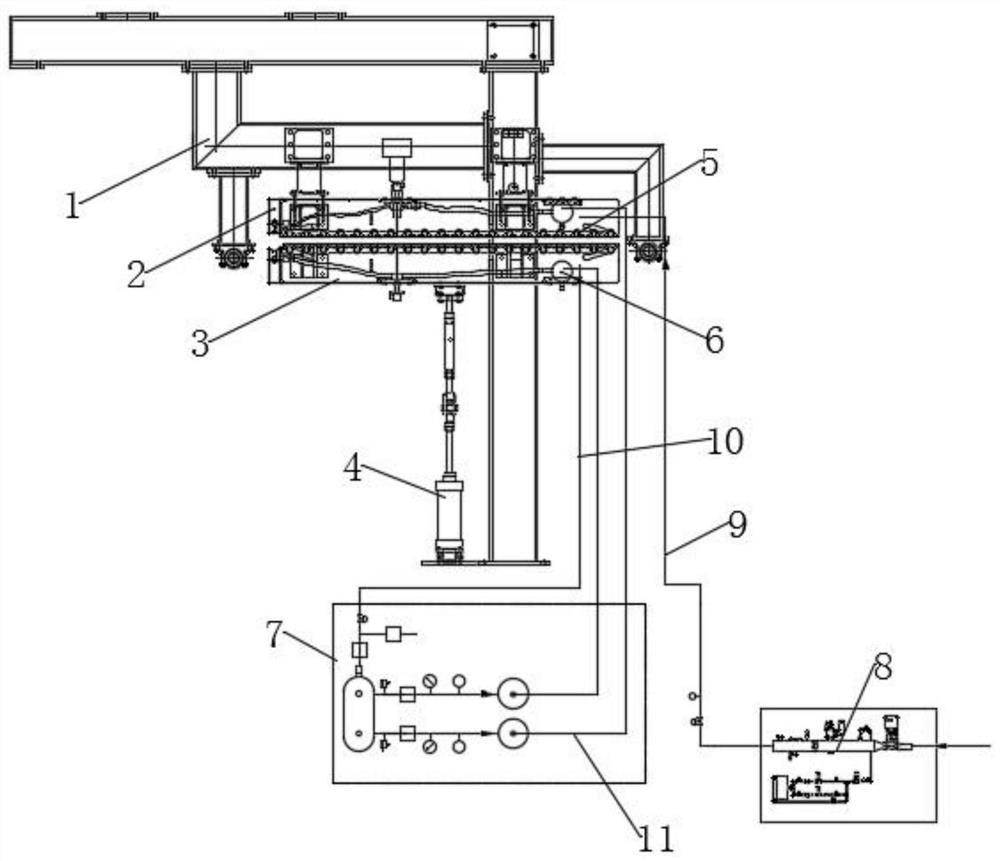

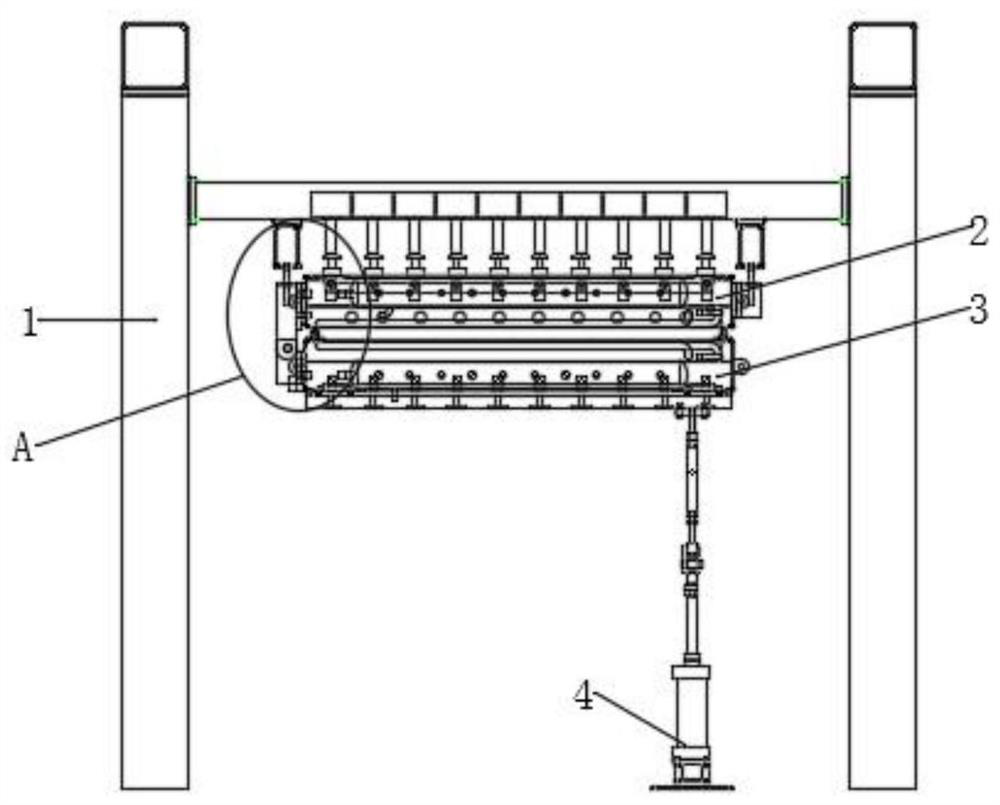

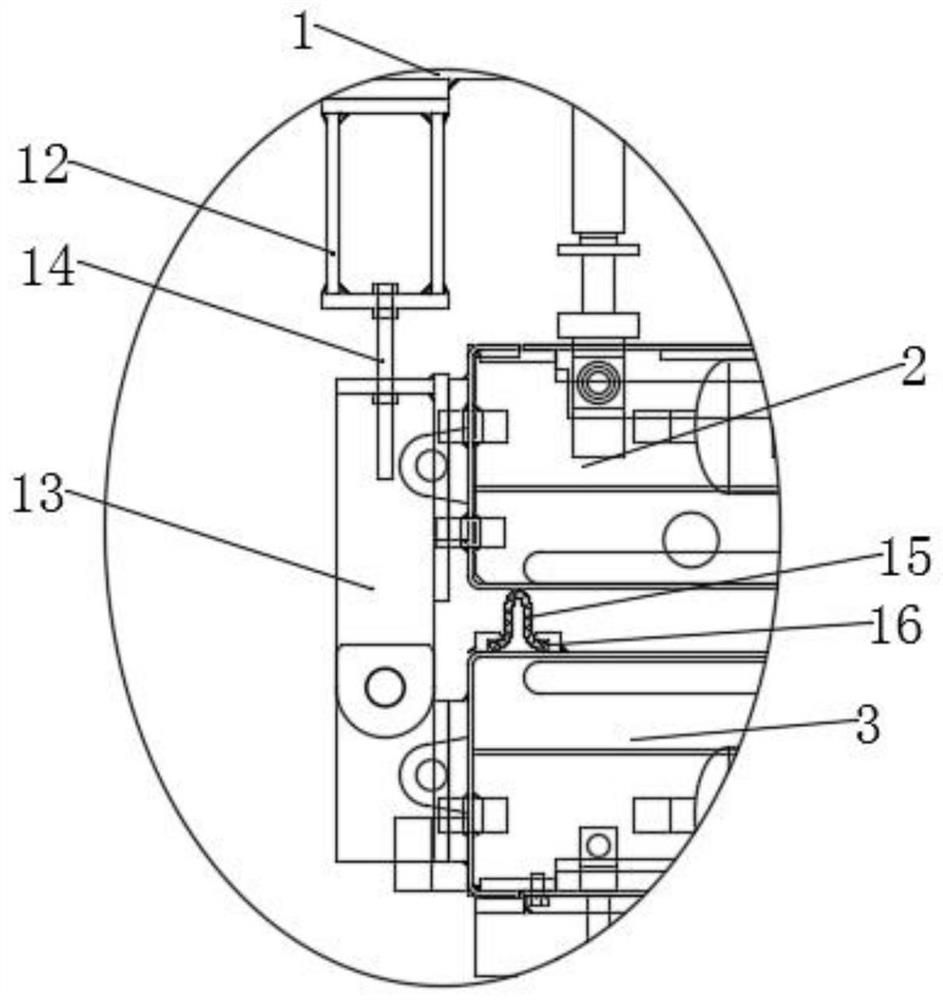

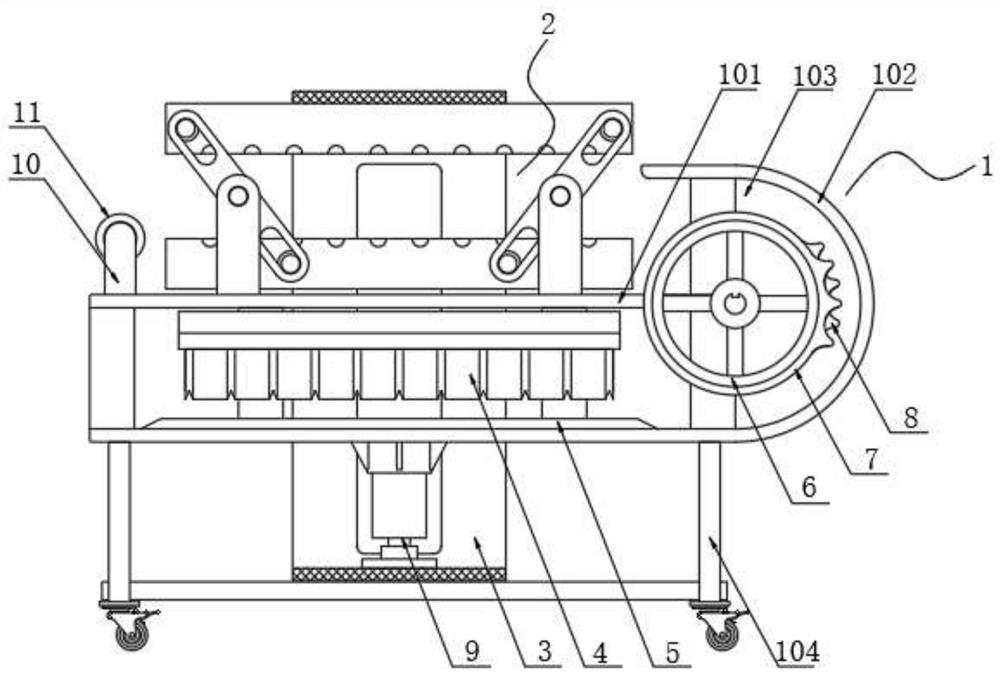

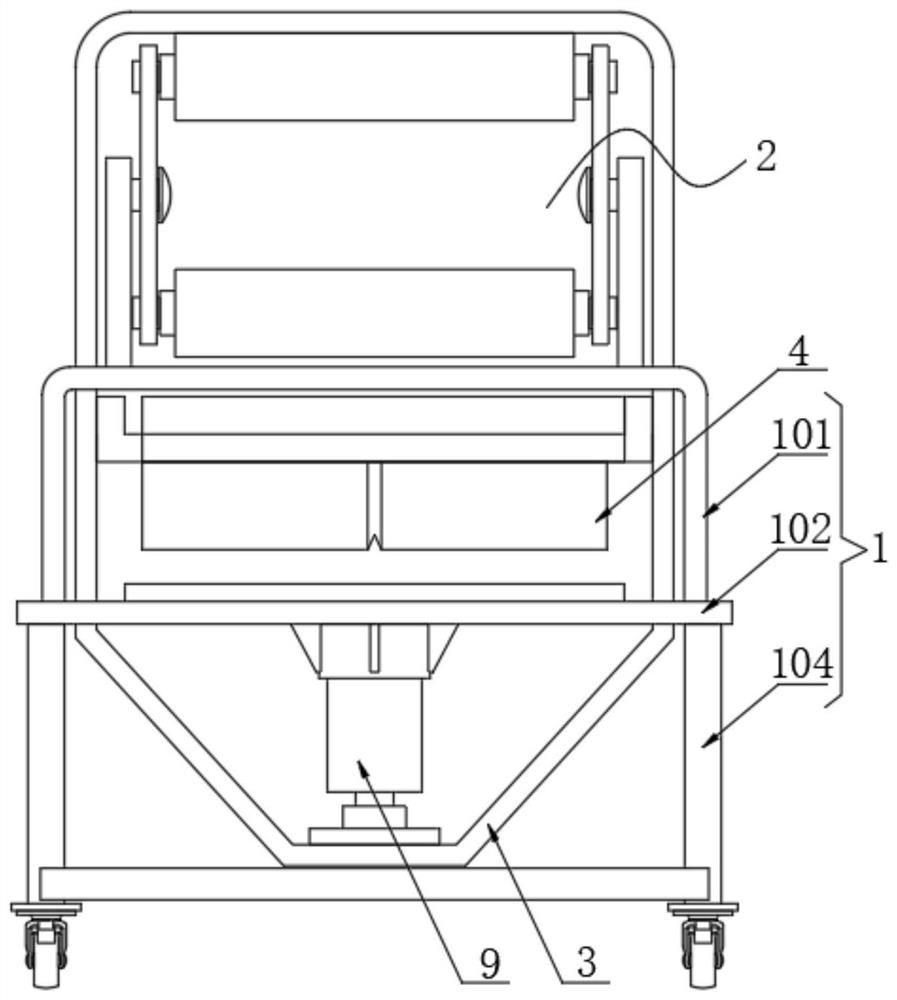

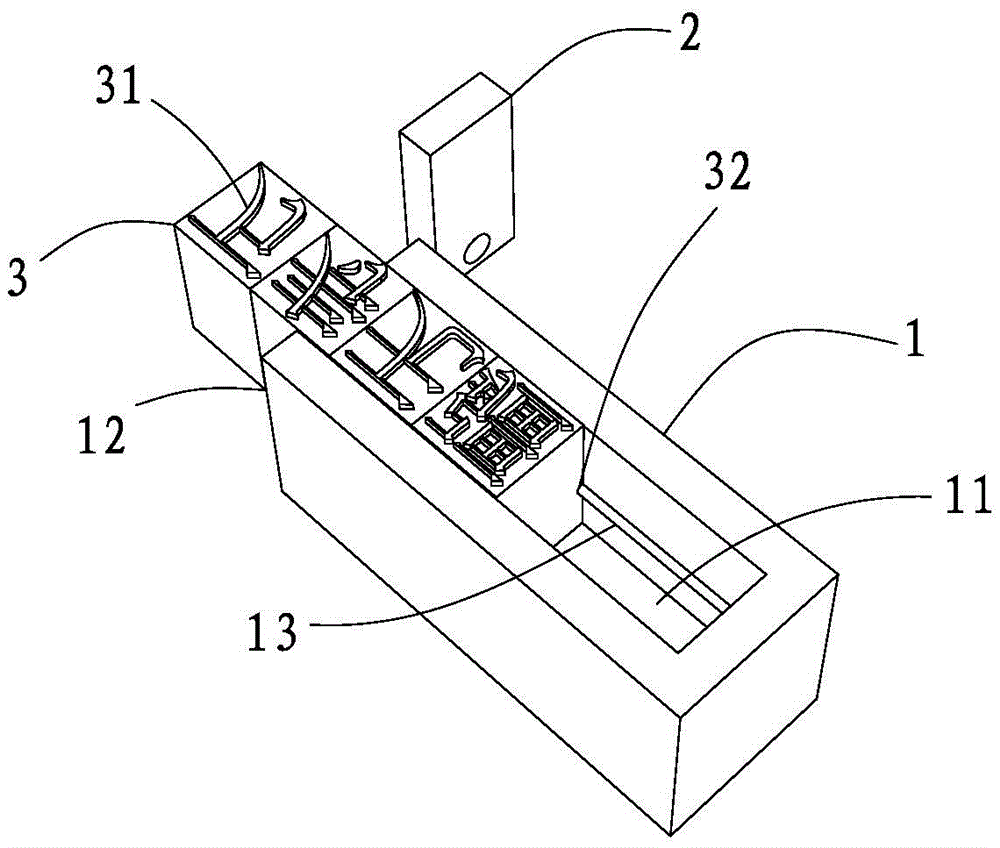

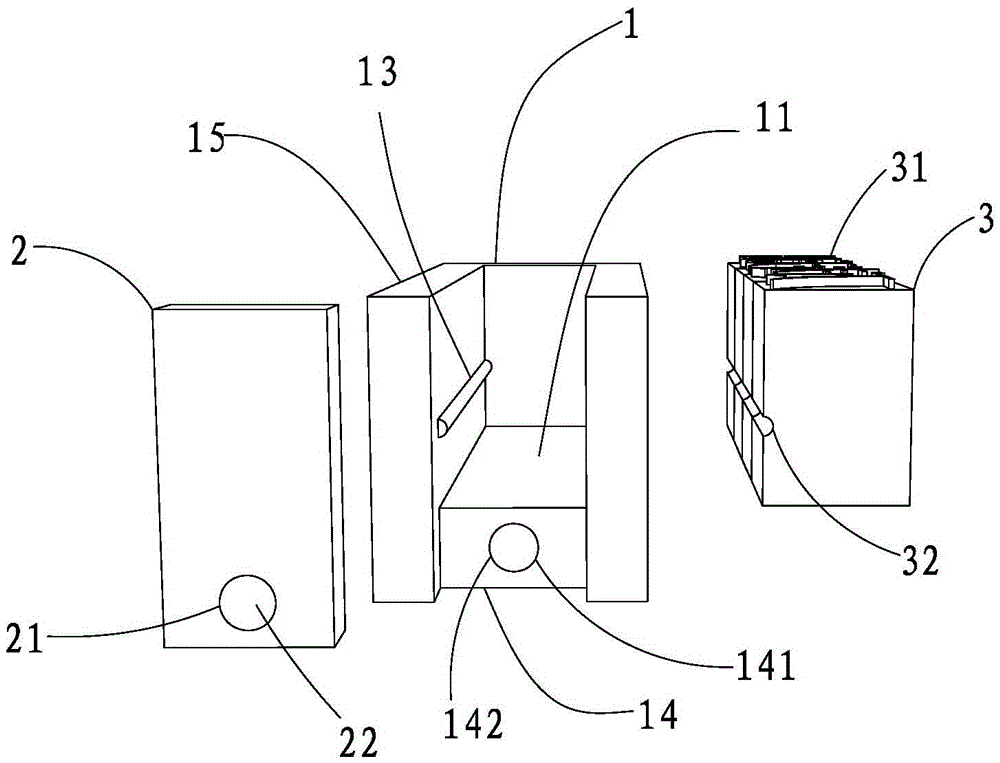

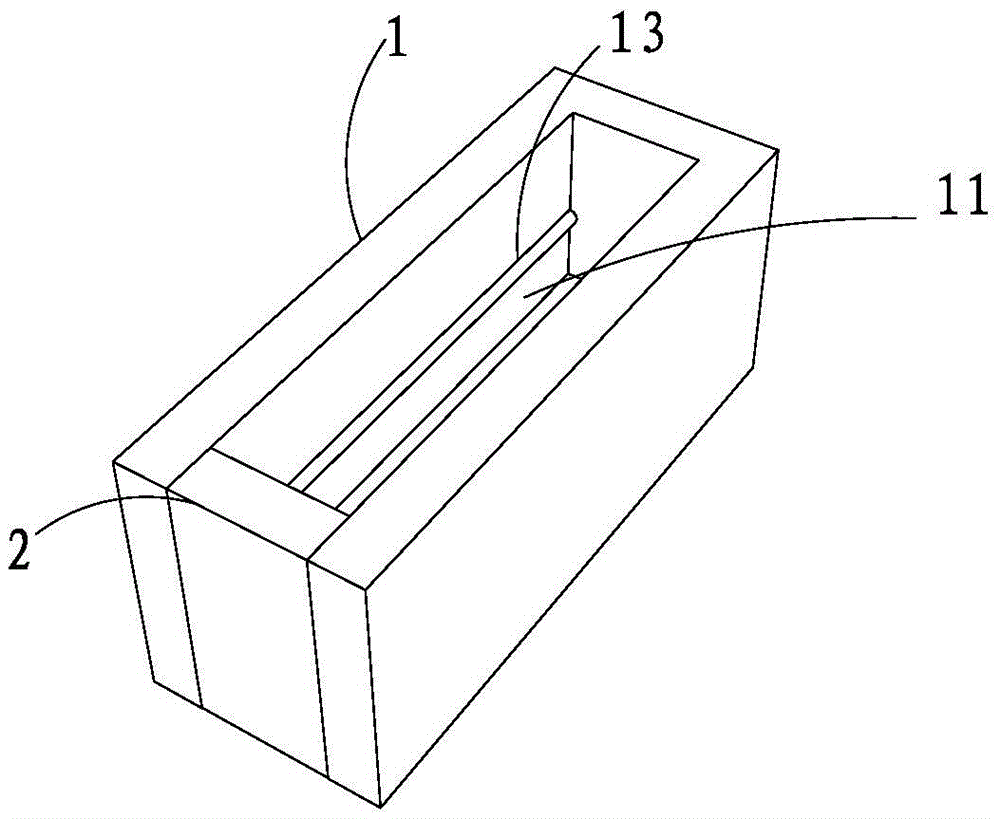

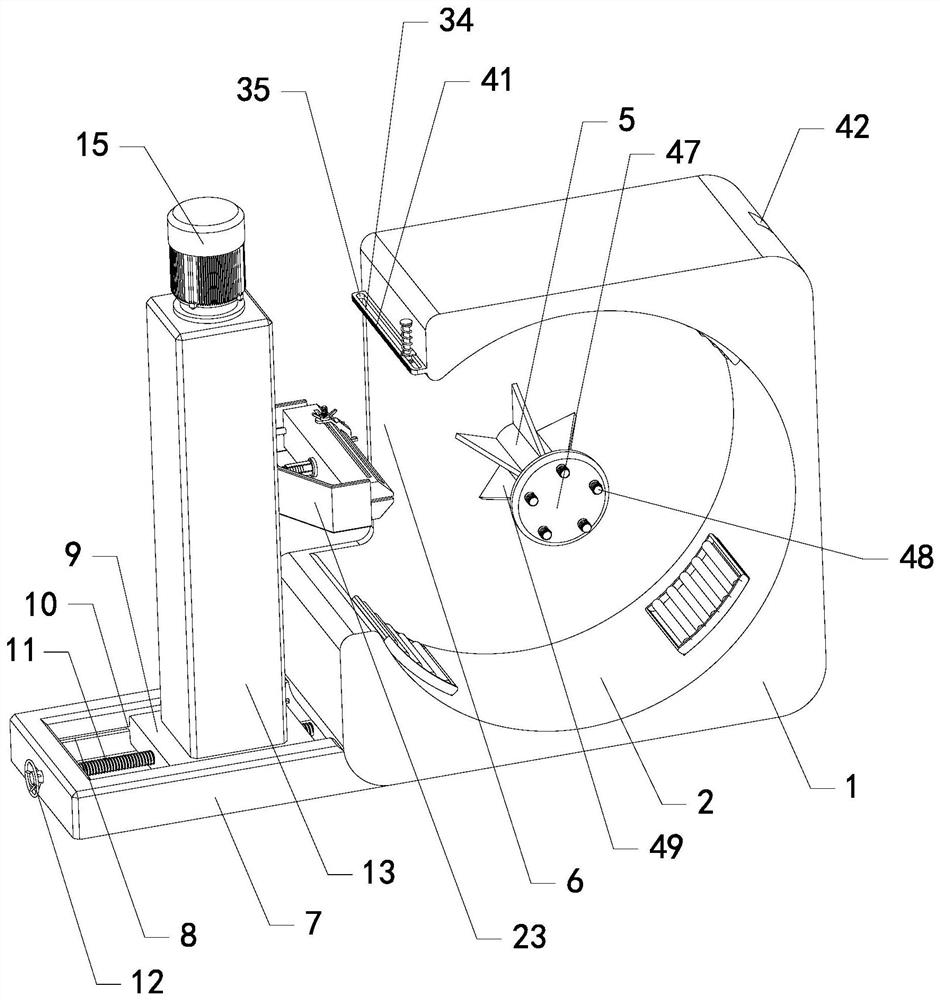

Mass transfer method and device for electronic elements

ActiveCN109449100ASpacing controllableImprove efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesElectric machineryEngineering

The invention relates to a mass transfer device for electronic elements. The device comprises a die bonding welding arm, a flip chip welding arm, external physical field devices and an operation table. The die bonding welding arm and the flip chip welding arm are electrically connected to the operation table, respectively; the external physical field devices are arranged on the two sides of the die bonding welding arm and the flip chip welding arm respectively; a flip chip rotating motor is arranged on one side of a flip-chip two-end clamping device; the flip-chip two-end clamping device is arranged on two sides of a flip-chip ejector rod; a flip-chip guide rail is arranged on the flip-chip ejector rod, a flip-chip bracket is movably arranged on the flip-chip guide rail; a flip-chip transfer head is arranged on the flip-chip bracket; and an flip-chip elastic material is arranged between the adjacent flip-chip brackets. The invention aims to provide a mass transfer method and device forelectronic elements. The device in the invention is simple, the efficiency is improved by a2c times, the distance between the electronic elements is completely controllable and a mass of the electronic elements are transferred to the target substrate. The method and the device have a great application value in the field of semiconductor manufacturing.

Owner:GUANGDONG UNIV OF TECH

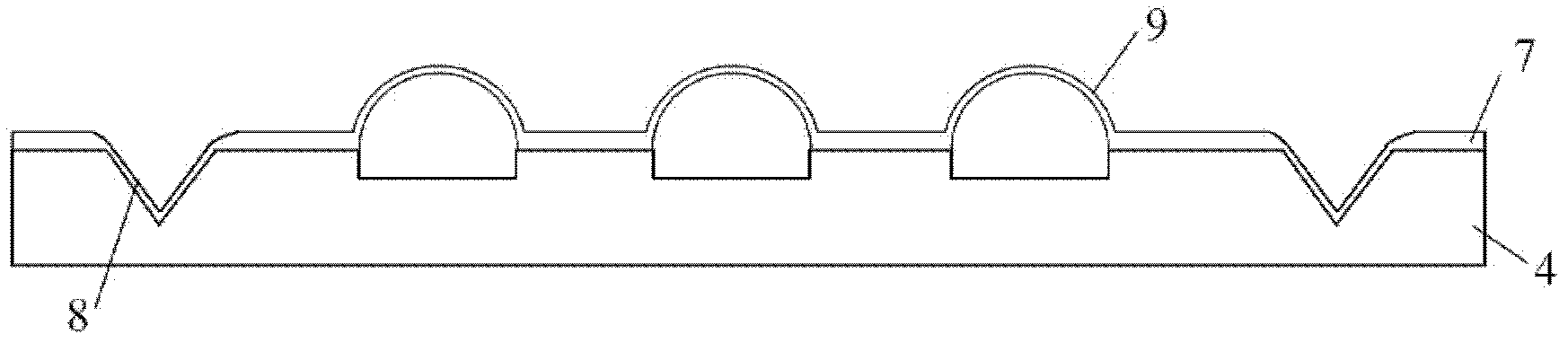

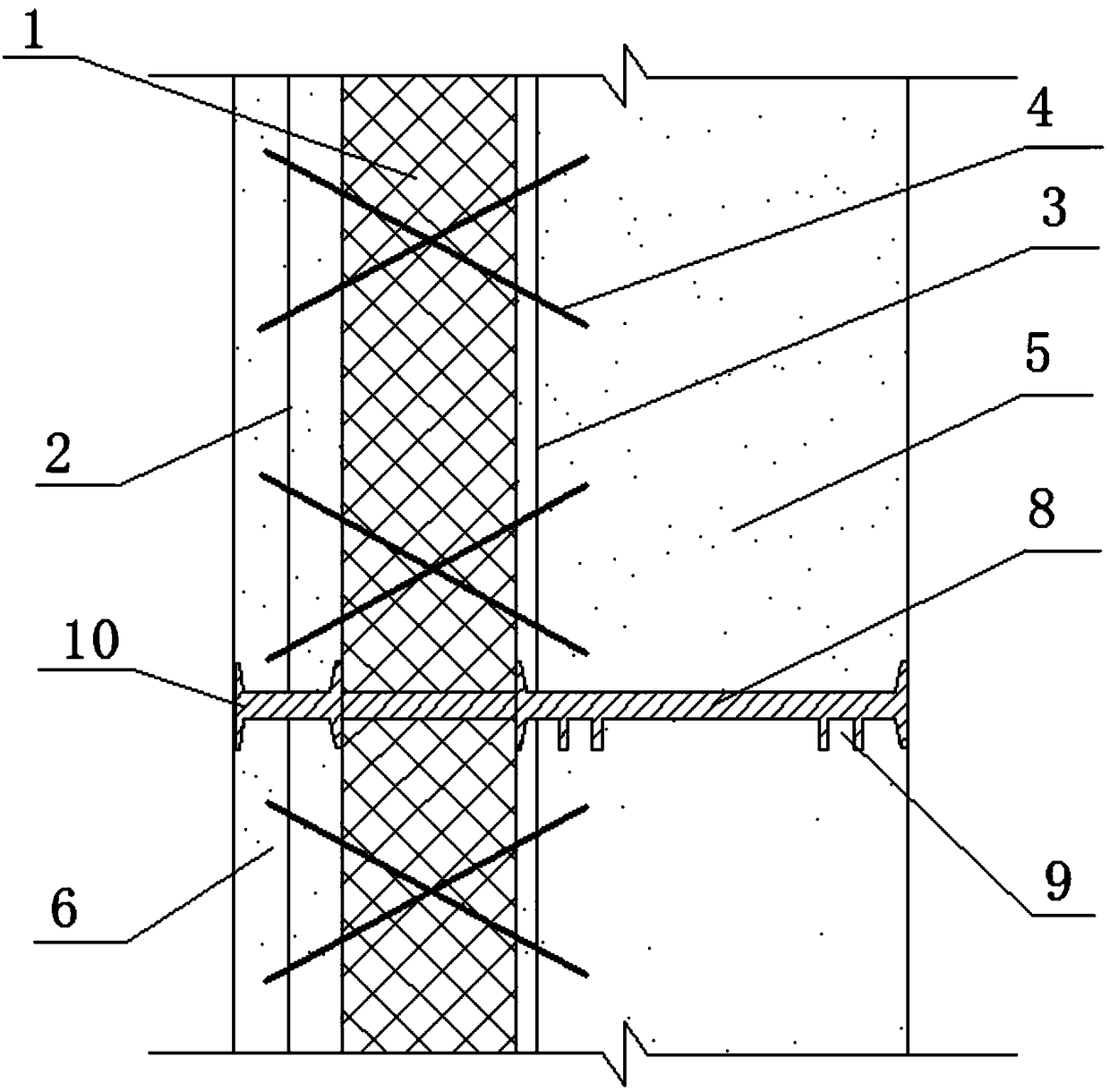

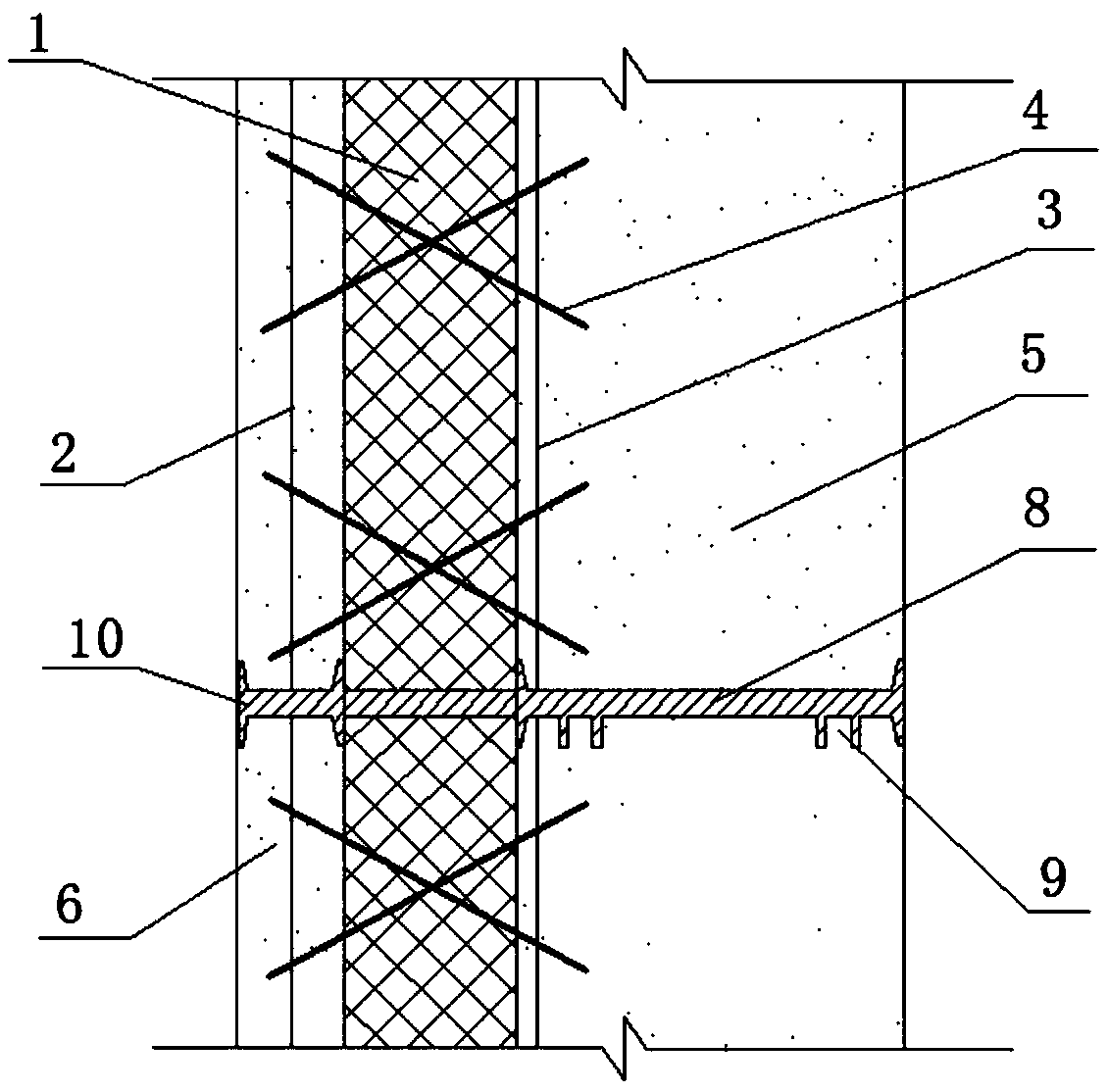

Double-sided steel wire net frame heat-insulation plate and composite wall body

The invention discloses a double-sided steel wire net frame heat-insulation plate which structurally comprises an outer steel wire net piece, web wires, a heat-insulation plate body, and an inner steel wire net piece. The heat-insulation plate body is located between the outer steel wire net piece and the inner steel wire net piece; the web wires penetrate through the heat-insulation plate body and are connected with the outer steel wire net piece and the inner steel wire net piece correspondingly to constitute a steel wire net frame to extend outwards; and the web wires in the extending partconstitute anchorage connection after concrete casting. Compared with a heat-insulating composite plate in the prior art, the double-sided steel wire net frame heat-insulation plate is simple in structure, easy to mount, and convenient in construction technology, a foundation structure of a heat-insulation wall body is formed by constructing a heat-insulation layer and the steel wire net frame, asurface protection layer does not need to be smeared any longer, during concrete cast-in-place, the composite wall body is constituted directly through cast-in-place, strength is greatly improved, thecombination degree is greatly increased, the spaces of all structural layers are easy to control, and the heat-insulation plate is positioned accurately.

Owner:济南城通保温工程有限公司

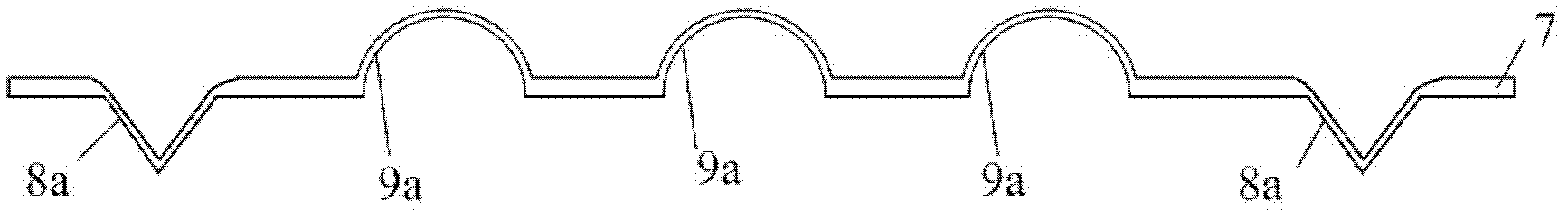

Method for constructing organic micron linear array with form board assisting in volatilization induced self-assemble

ActiveCN103413760AEasy to operateImprove bindingSemiconductor/solid-state device manufacturingMicro nanoOxygen plasma

The invention discloses a method for constructing an organic micron linear array with a form board assisting in volatilization induced self-assemble. The method comprises the following steps that (1) a substrate is washed through cleaning fluid in an ultrasonic mode, then the substrate is immersed in the piranha solution and processed by an oxygen plasma, and the surface of the substrate is made to have strong wettability; (2) the form board is constructed on the substrate; (3) the micron linear array is grown on the form board, the pre-processed form board is inserted in the organic solution for growth, and through volatilization induced self-assemble, the large-area highly-aligned organic micron linear array is obtained. The method is of great significance to manufacturing of large-area high-performance photoelectron micro-nano devices based on organic optoelectronic materials and further achieving of micro-nano device integration.

Owner:SUZHOU UNIV

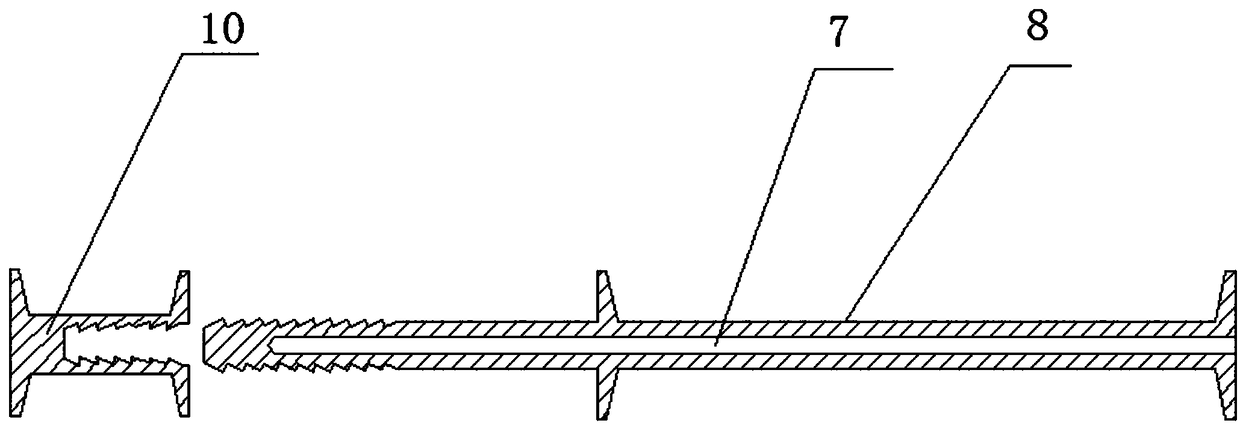

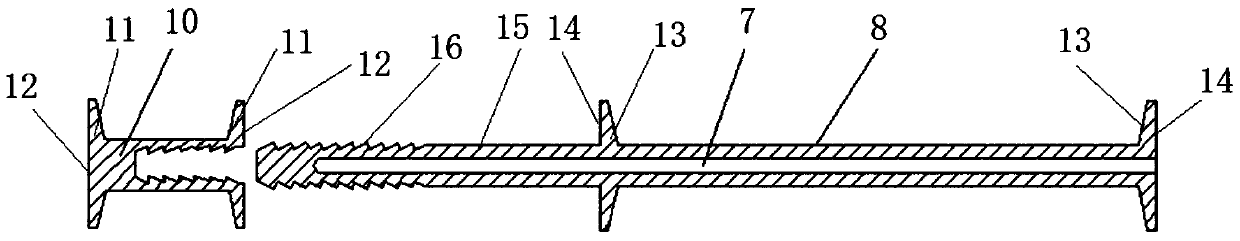

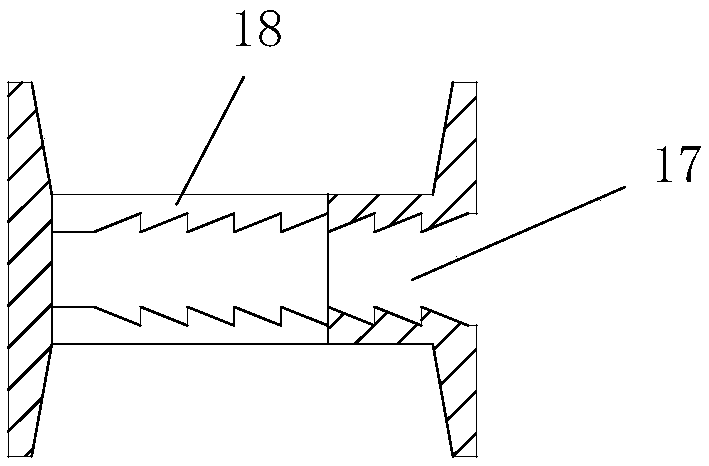

Connecting supporting positioning part, use method, steel wire mesh frame heat retaining plate and composite wall

The invention discloses a connecting supporting positioning part, a use method, a steel wire mesh frame heat retaining plate and a composite wall. The connecting supporting positioning part comprise afirst supporting part, a second supporting part and a connector, first limit clamping parts are arranged on two ends of the first supporting part, second limit clamping parts are arranged on two endsof the second supporting part, two ends of the connector are connected with the first supporting part and the second supporting part, a first left limit plane and a first right limit plane are used for limiting the distance between a middle construction layer and a left construction layer, and a second left limit plane and a second right limit plane are used for limiting the distance between themiddle construction layer and a right construction layer. Compared with a heat retaining composite plate in the prior art, the plate is simple in structure, easy to mount and convenient in construction process, the heat retaining layer and a steel wire mesh frame are constructed, a foundation structure of a heat retaining wall is formed, coating of surface protection is omitted, the composite wallis directly formed by cast-in-place concrete, strength and bonding degree of the composite wall are greatly improved, the distance between construction layers is easily controlled, and the heat retaining plate is accurately positioned.

Owner:济南城通保温工程有限公司

Low-pressure cold spraying copper-based self-lubrication coating and preparation method thereof

ActiveCN108486565AImprove the lubrication effectImprove wear resistancePressure inorganic powder coatingGraphiteCopper

The invention discloses a low-pressure cold spraying copper-based self-lubrication coating which comprises the following raw materials by weight percentage: 10-30% of copper-coated graphite, 8-12% ofaluminum oxide and the balance of copper. The invention further discloses preparation of the coating on the surface of stainless steel 304 by a low-pressure cold spraying technology. The coating is uniform in texture, is well combined with a substrate and has excellent mechanical properties and lubrication and antiwear performance. In addition, a preparation technology of the coating is green, environmentally friendly, convenient to operate and good in controllability; and the coating as a lubrication component in an oil-less or oil-lack environment has wide application prospects and an important practical value.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

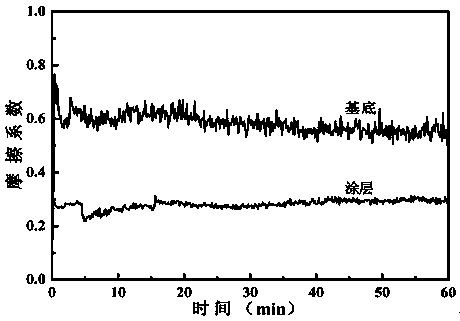

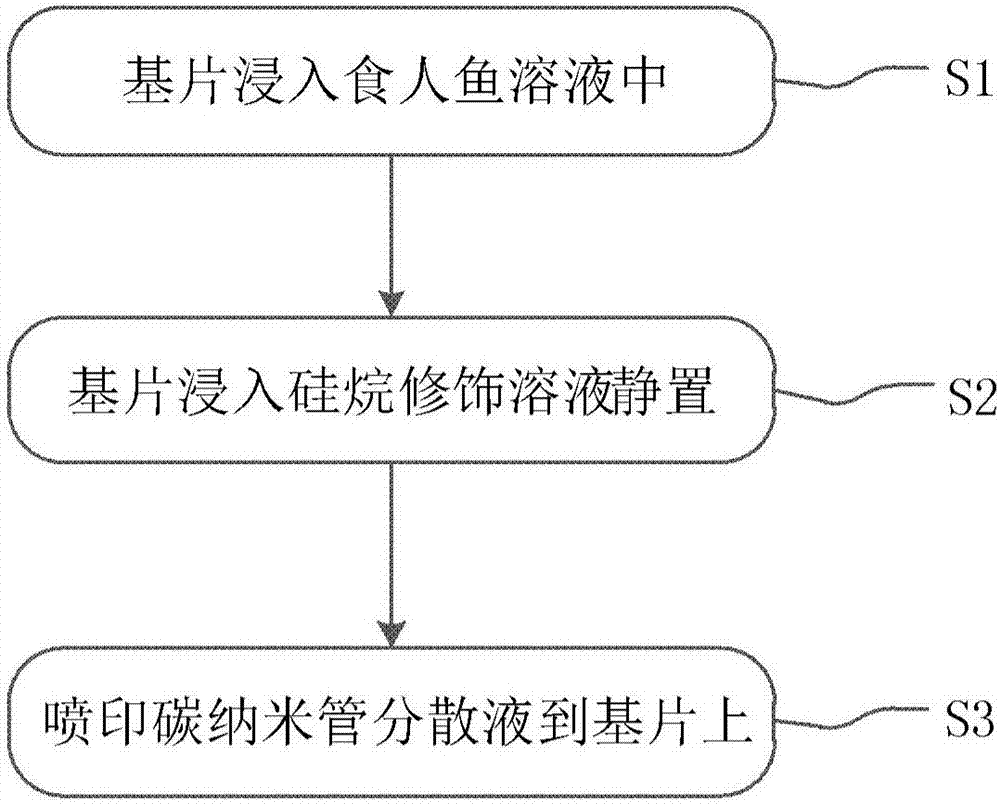

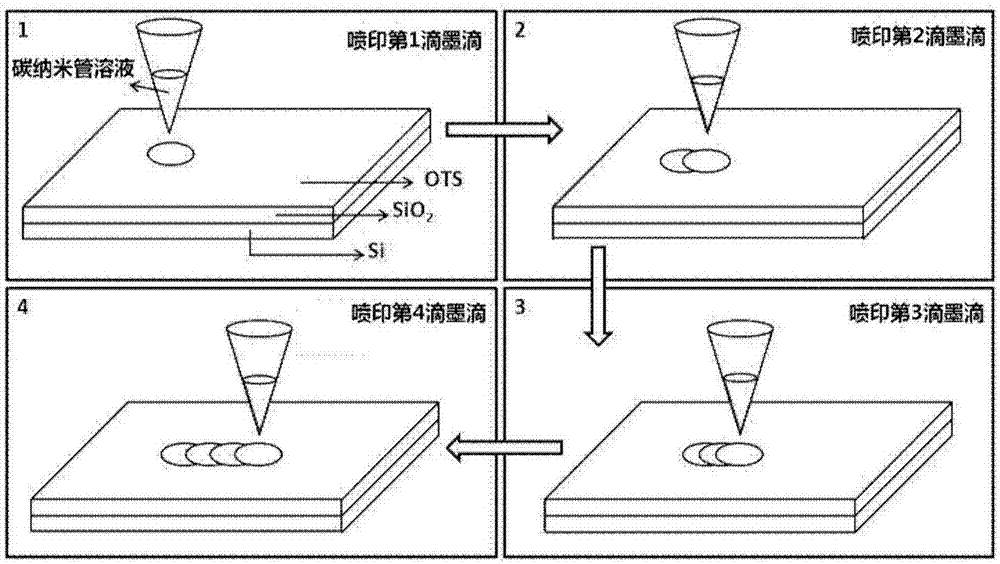

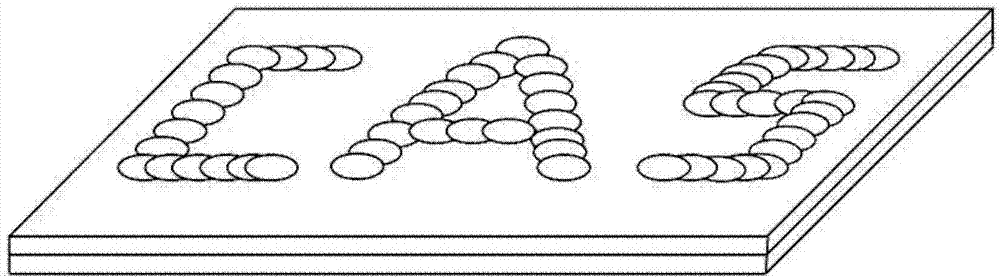

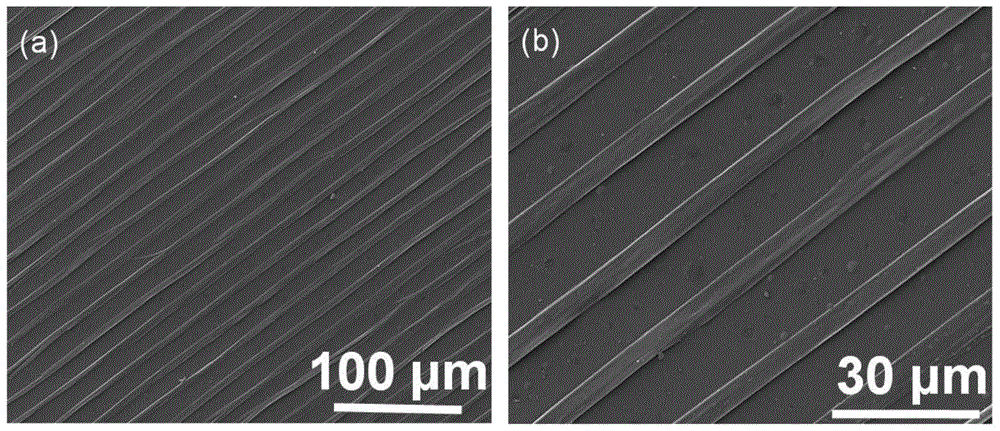

Single aligned carbon nano tube jet-printing arrangement method

ActiveCN107963610ASimple processAchieve patterningMaterial nanotechnologyNanostructure manipulationOctadecyltrichlorosilaneNano-device

The invention provides a single aligned carbon nano tube jet-printing arrangement method. The method comprises the steps that a substrate is modified with octadecyltrichlorosilane (OTS), so that the surface of the substrate has a hydrophobic property; precise control over the thin film position, the aligned density and patterning of aligned carbon nano tubes is achieved on the functional hydrophobic substrate through ink-jet printing, and a carbon nano tube thin film which is uniform in density and consistent in orientation and has different patterns is arranged. By means of the method, the carbon nano tube arrangement area of the size from several micrometers to the wafer level can be effectively controlled; the problems can be solved that in all existing arrangement methods, the arrangement position, the arrangement orientation, the arrangement density and the thin film array patterning of one-dimensional nano materials on the substrate cannot be efficiently and precisely controlled;the method can be widely used for preparing various high-performance photoelectric devices, logic circuits and functional thin films based on the carbon nano tubes, and the method also has a wide application prospect in the field of flexible wearable nano devices.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

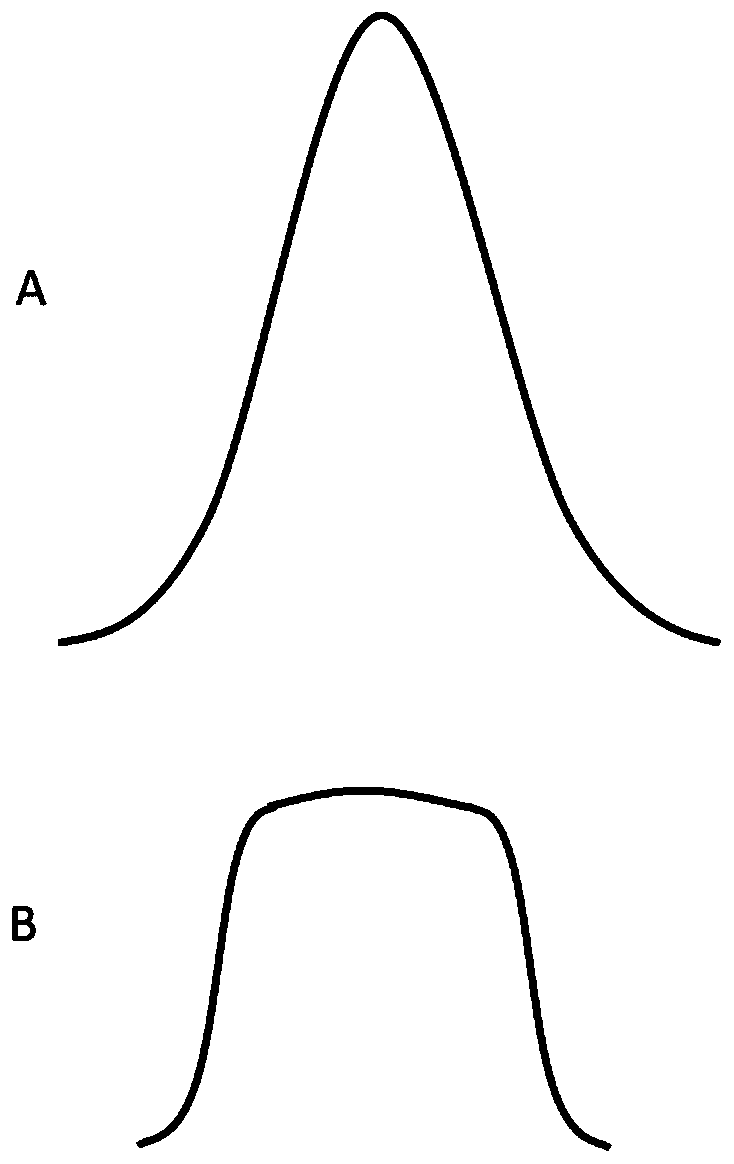

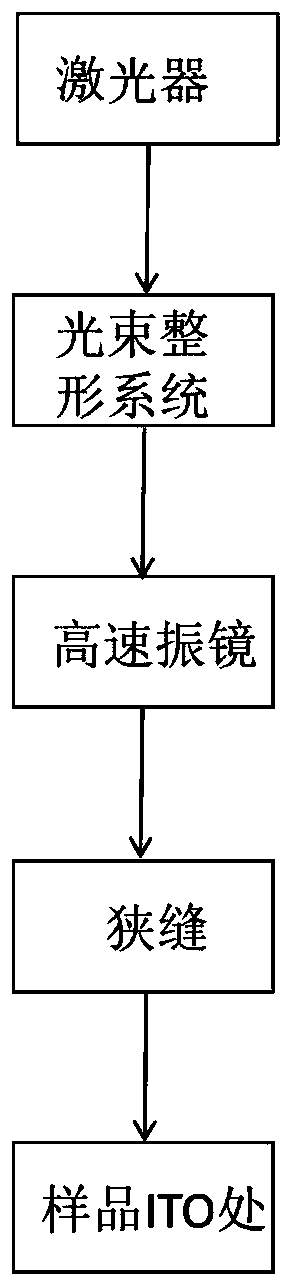

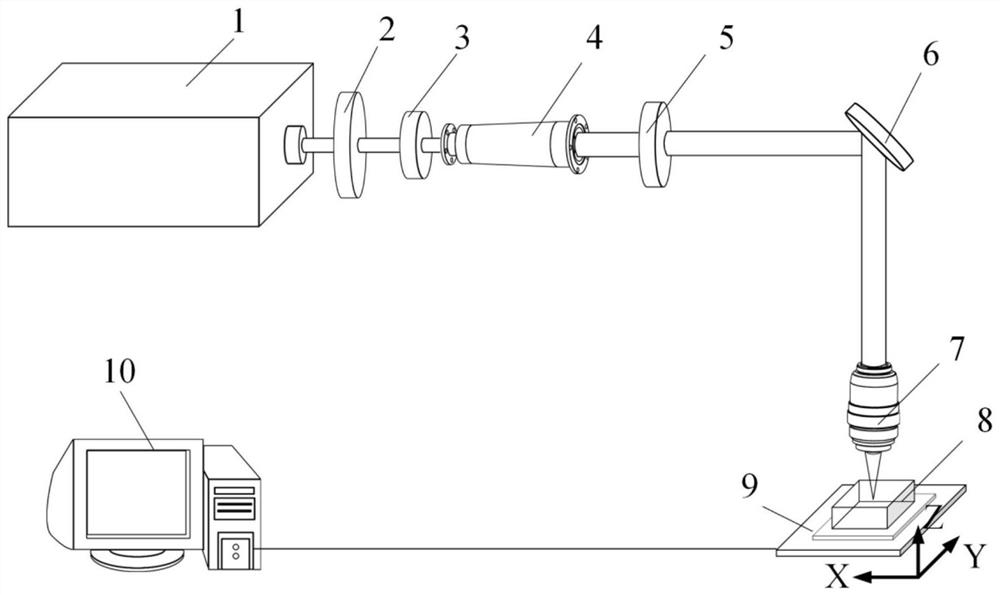

Method for repairing light leakage defects of display screen by using laser scribing scanning

InactiveCN110102960ARepair light leak defectsLight Leakage Defect RealizationLaser beam welding apparatusLaser scanningLaser scribing

The invention discloses a method for repairing light leakage defects of a display screen by using laser scribing scanning. The method comprises the following steps of 1, fixing a display screen to berepaired on a processing platform after the surface of the display screen to be repaired is cleaned, adjusting laser transmission direction of a laser or the angle of the processing platform to make laser beam be perpendicular to the surface of the display screen to be repaired; 2, adjusting laser parameters according to the required repairing pixel size, ITO blackening degree and depth, and irradiating ITO perpendicular to the surface of the display screen to be repaired by using a plurality of pulse lasers to blacken the surface of the ITO; 3, setting a laser scanning path according to the size of the area required to be blackened, wherein the path is a plurality of parallel line segments to cover the ITO area required to be blackened; and 4, adjusting the laser pulse frequency f to be between 100 Hz and 1,000 Hz, setting the laser machining initial point, and blackening the ITO on the surface of the display screen to be repaired by using the processing parameters in step 1, 2, and 3through a scribing scanning mode or pulse dotting so as to repair the light leakage defects. According to the method, the repairing effect is good.

Owner:BEIJING C&W TECH DEV

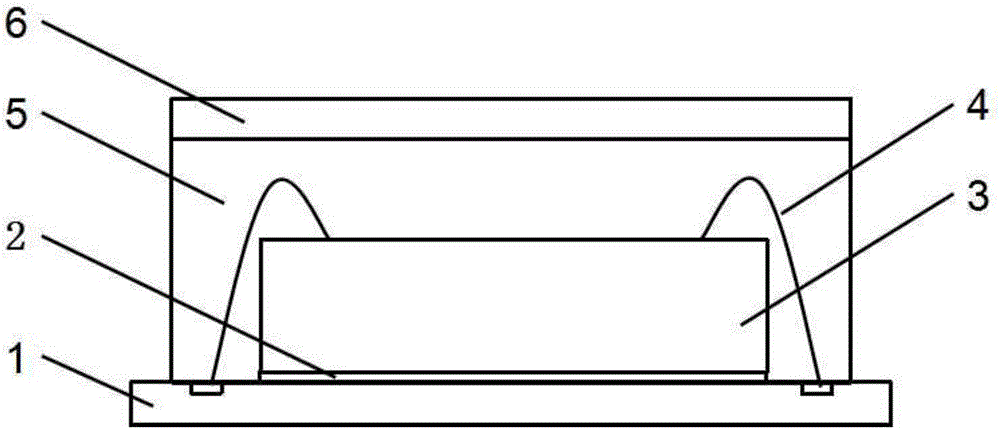

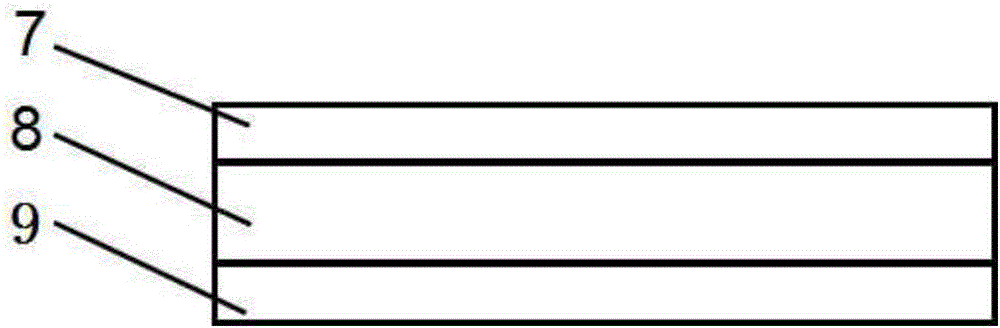

Packaging structure of DAF film-wrapped fingerprint sensor chip and manufacturing method of packaging structure

InactiveCN106158780AThe overall thickness is thinSpacing controllableSemiconductor/solid-state device detailsSolid-state devicesEngineering

The invention discloses a packaging structure of a DAF film-wrapped fingerprint sensor chip and a manufacturing method of the packaging structure. The packaging structure comprises a substrate, a fingerprint sensor chip and a protective cover plate, wherein the fingerprint sensor chip and the substrate are connected with each other by a bonding wire, and the upper surface of the substrate and the lower surfaces of the fingerprint sensor chip, the bonding wire and the protective cover plate are wrapped by DAF films. According to the packaging structure, the protective cover plate is directly pasted by adopting the DAF films, so that a plastic packaging procedure is omitted, and the process flow is simplified; additionally, the protective cover plate is directly pasted by adopting the DAF films, so that the spacing between the protective cover plate and the surface of the fingerprint sensor chip is easy to control, and the packaging structure is thin.

Owner:HUATIAN TECH XIAN

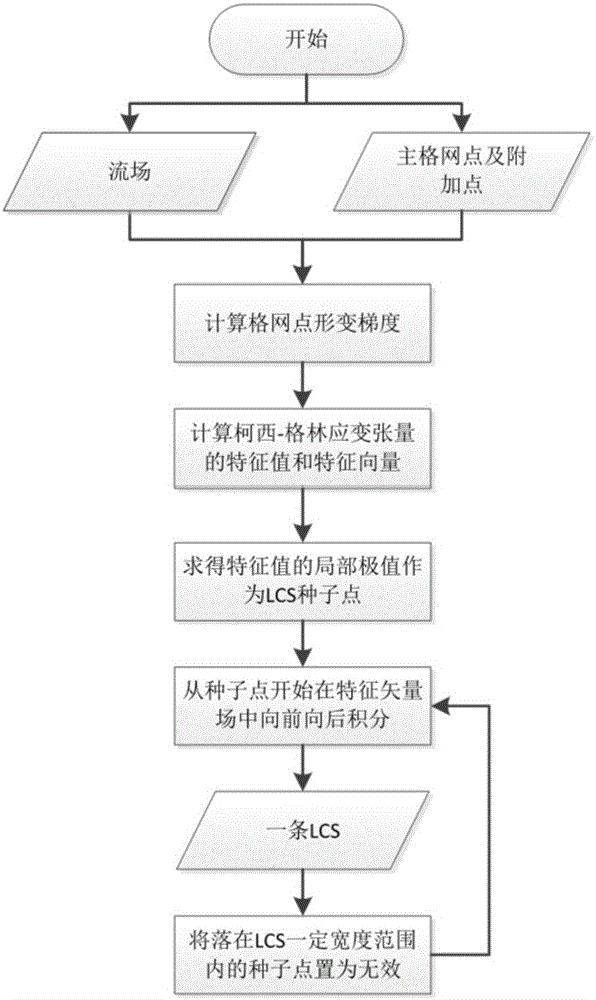

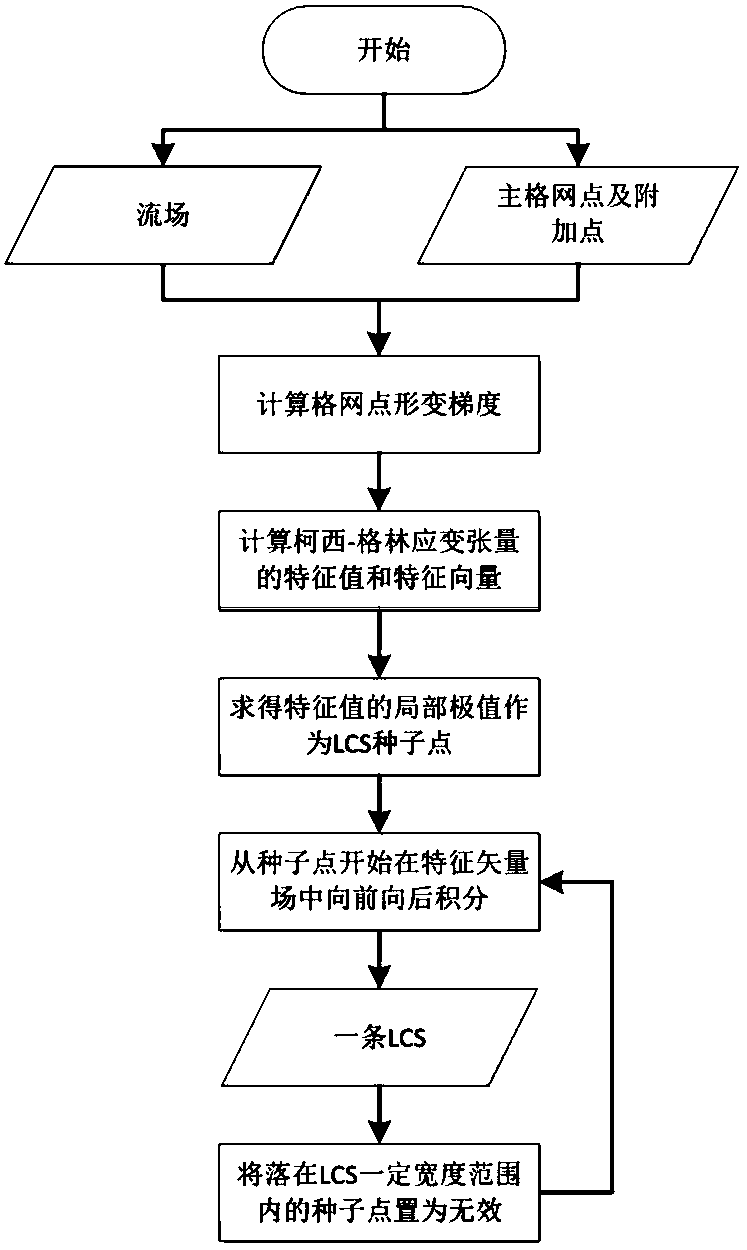

Two-dimensional ocean current Lagrangian coherent structure analytical algorithm

ActiveCN105975437AClear locationSpacing controllableComplex mathematical operationsComputational physicsFluid field

The invention relates to a two-dimensional ocean current Lagrangian coherent structure analytical algorithm. The algorithm is based on a Cauchy-Green right strain tensor, wherein the tensor is obtained in a way that a gradient obtained after particles move for a period of time in a flow field is calculated. Particle movement uses a Runge-Kutta 4 order integration method, and cubic interpolation is adopted for the flow field. In order to improve calculation accuracy, four neighbor points are added on each grid point to calculate the gradient by using a finite difference. The Cauchy-Green right strain tensor is provided with two real eigenvalues, wherein the local maximum value of the large eigenvalue and the local minimum value of the small eigenvalue are seed points of an LCS (Lagrangian Coherent Structure), and the Runge-Kutta 4 order integration is carried out in a non-corresponding characteristic vector field forwards and backwards to obtain a Lagrangian coherent structure. During integration, the direction discontinuity of a character vector is considered. The direction is always kept consistent with the direction of a previous point, and inversion is carried out if the direction differs more than 90 degrees. After one LCS is generated, the LCS seed points in a certain width range of the LCS are set to be ineffective, and an interval between the LCSs is controlled. The Lagrangian coherent structure is an important flow field topological structure, can be effectively applied to the range of ocean current, season-year changes and main flow and branch flow analysis.

Owner:OCEAN UNIV OF CHINA

High-precision and interval-controllable electrode and preparing method thereof

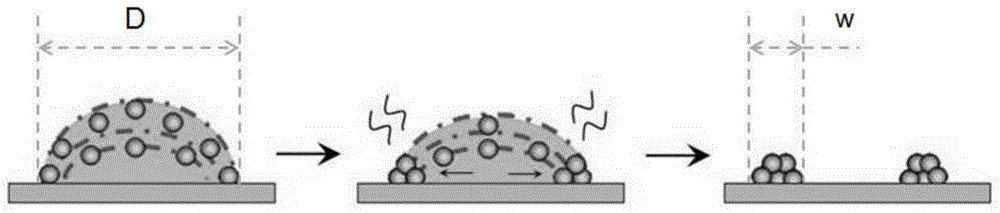

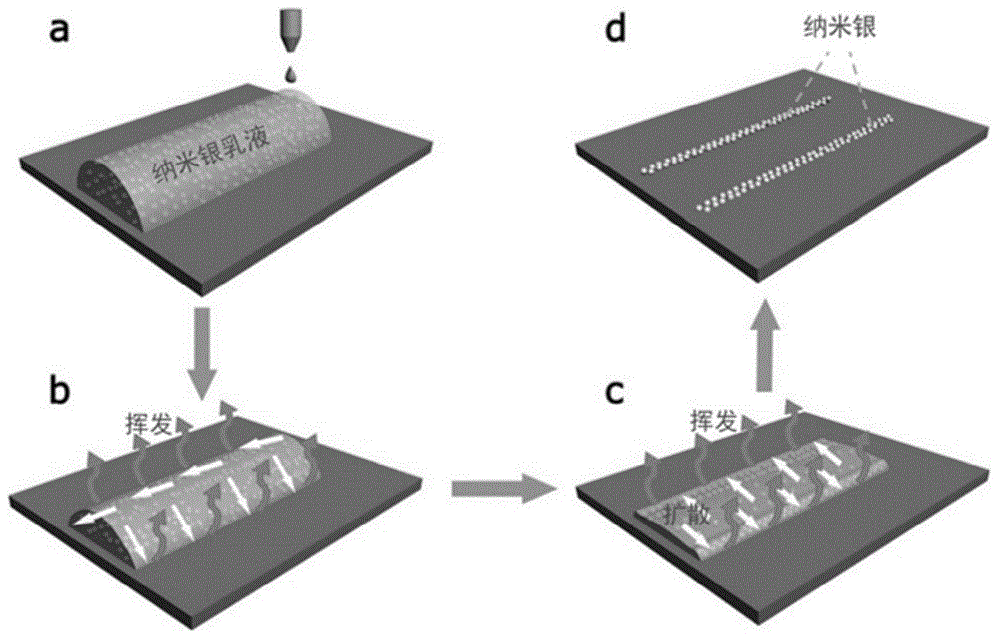

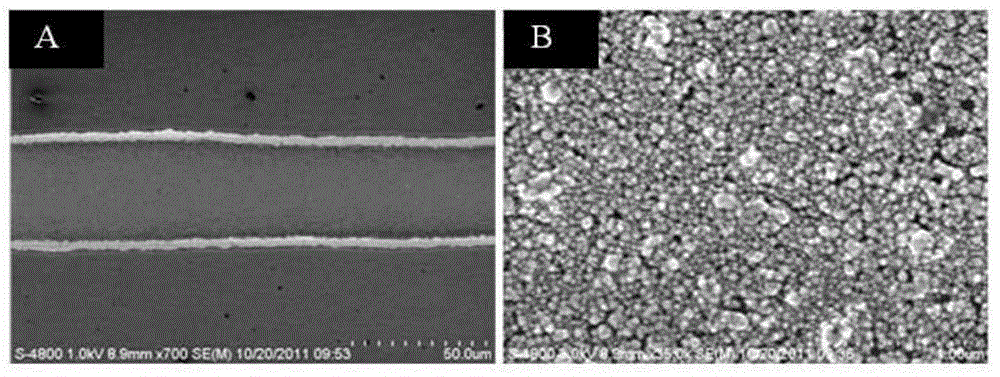

The invention provides a high-precision and interval-controllable electrode and a preparing method of high-precision and interval-controllable electrodes. The method comprises the steps that firstly, a substrate is designed and prepared, wherein high surface energy regions and lower surface energy regions are alternately arranged on the substrate; the high surface energy regions are fully paved with a solution or emulsion including conductive fillers; then, evaporation diffusion is conducted, along with the volatilization of the solvent, the freely-diffused conductive fillers are gathered and arranged on the boundary regions, adjacent to the low surface energy regions, of the high surface energy regions, the lower surface energy regions serve as dams and are used for controlling the further diffusion of liquid drops, the diffused and arranged conductive fillers are solidified through heating or photon sintering and then form interval-controllable high-precision electrodes, and the intervals of the electrodes are controlled by the width of the high surface energy regions. The high-precision and interval-controllable electrode prepared through the method has important application on the aspect of preparing high-precision electrodes of devices such as transparent conductive films, high-end sensors, transistors, storage devices and capacitors.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Anisotropic conducting film and manufacturing method for same

InactiveCN103811102AGood vertical conductivityImprove insulation performanceNon-insulated conductorsPlastic/resin/waxes insulatorsAnisotropic conductive filmScreen printing

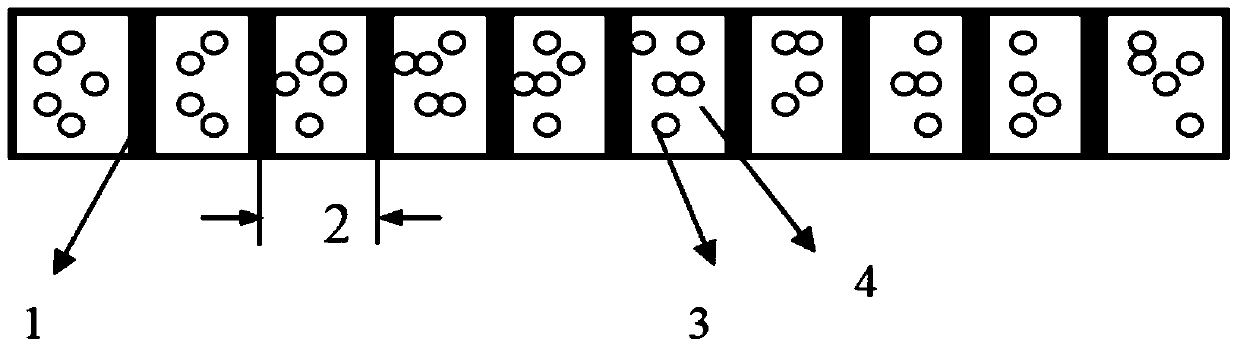

The invention provides an anisotropic conducting film and a manufacturing method for the same. The anisotropic conducting film comprises a plurality of strip-shaped insulating isolation layers extending along a film width direction and vertically to the surface of the anisotropic conducting film, and mutually parallel, a plurality of micro-cavities composed of an interval space between every two adjacent insulating isolation layers respectively, and conducting particles and resin adhesives filled in the plurality of micro-cavities, wherein the conducting particles are uniformly dispersed in the resin adhesives. The anisotropic conducting film provided by the invention is good in vertical conductivity and transversal insulativity, and beneficial to further narrow-distance realization. In addition, according to the manufacturing method for the anisotropic conducting film provided by the invention, the plurality of isolation layer structures are formed by a silk-screen printing method, the distances, heights and thicknesses of the isolation layers are easy to control, the process is simple, and the cost is low.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

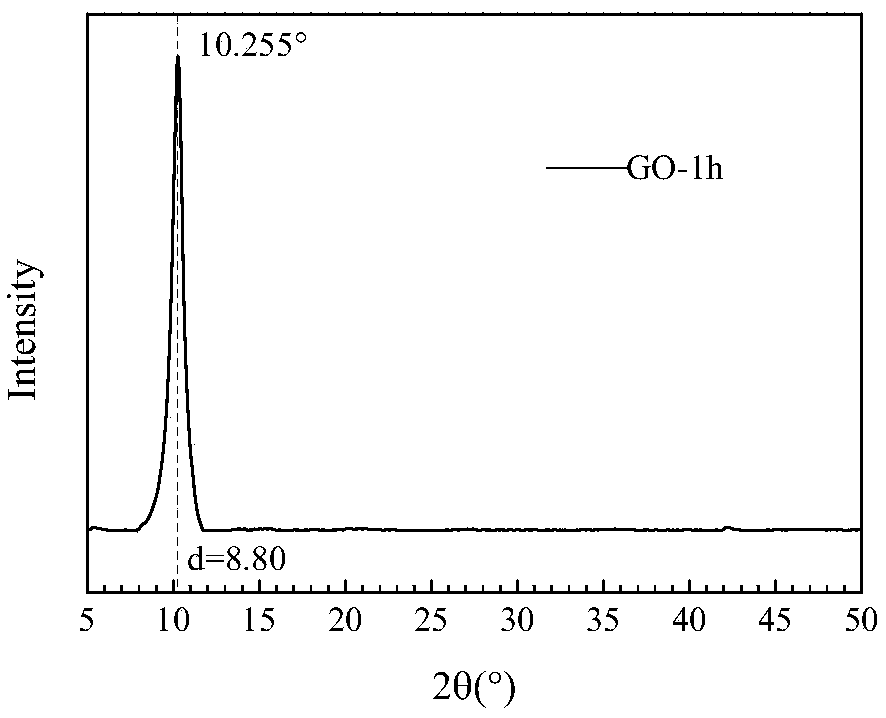

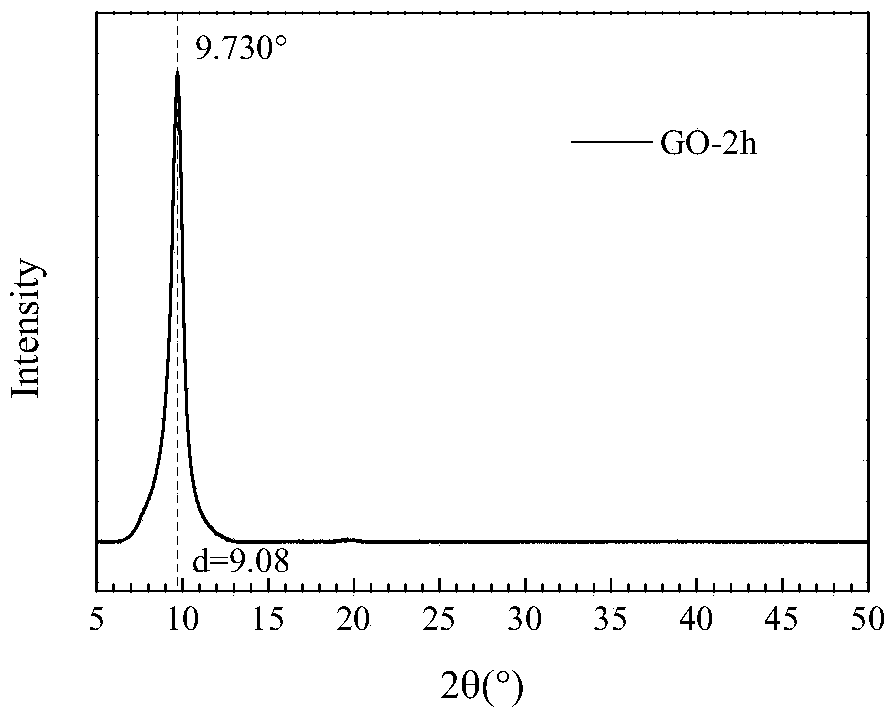

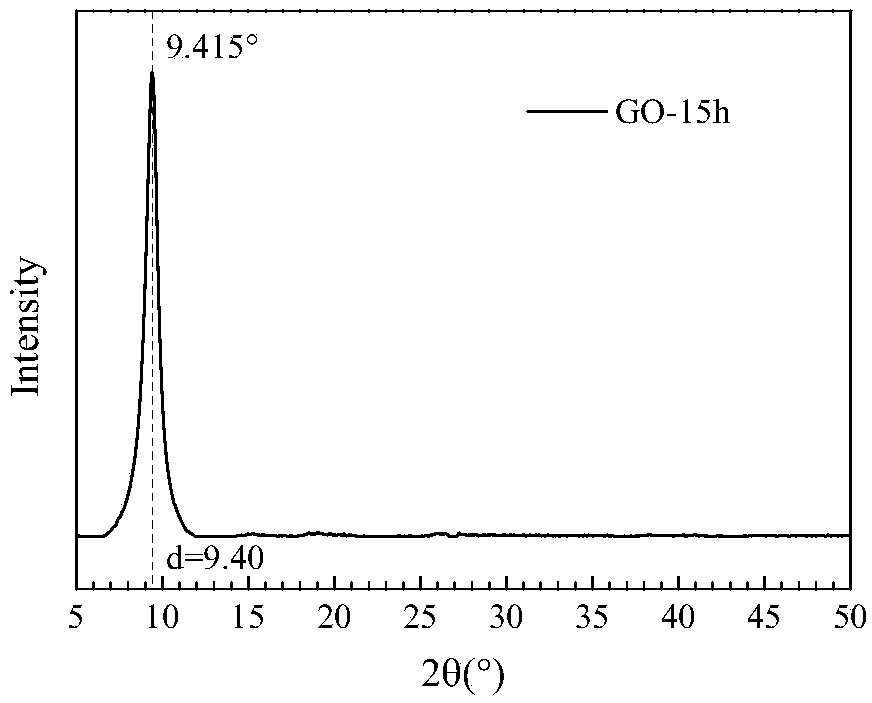

Graphene oxide preparation method with controllable inter-layer spacing

The invention relates to a graphene oxide preparation method with controllable inter-layer spacing. The preparation method includes the following steps that 1, graphene powder is pre-oxidized in a concentrate-sulfuric acid environment, and solids are washed to be neutral and aired for usage; 2, a pre-oxidation product is increased in temperature through multiple steps for secondary oxidation underthe effects of potassium permanganate and concentrated sulfuric acid strong oxidant; 3, centrifugal separation is conducted, and freeze drying is conducted to obtain graphene oxide. The method has the advantages that the inter-layer spacing of the prepared graphene oxide is large; by changing experimental conditions, graphene oxides with kinds of inter-layer spacing are prepared under control. Agood microenvironment is provided for preparation of an organic-inorganic intercalation compound, and the graphene oxide has broad application prospects in the fields of preparation of compound materials, ocean corrosion prevention, fouling prevention and others.

Owner:ZHEJIANG UNIV

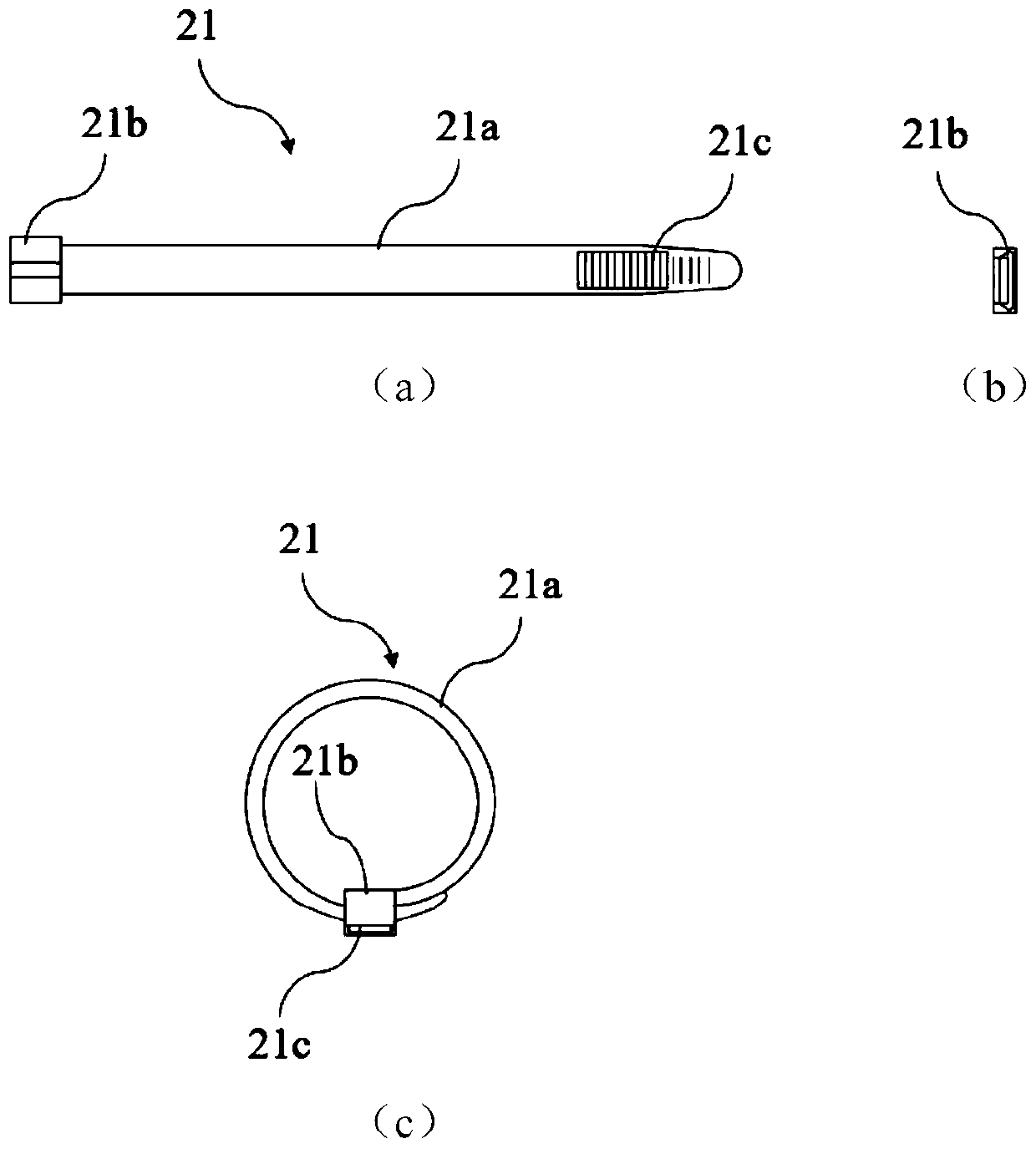

Letter press stamp

The invention discloses a letter press stamp which is characterized by comprising a stamp box and a plurality of press stamps, wherein the press stamps are fixed in the stamp box; movable types are engraved on one ends of the press stamps; the stamp box comprises a clamping plate and a box; an opening is arranged on one side of the box; the clamping plate is closed in the opening position of the box; the clamping plate and the box are encircled into an accommodating space; the plurality of press stamps can be contained in the accommodating space; a limiting part is arranged on an inner side wall of the box; clamping joint parts are arranged on the positions corresponding to the press stamps; the clamping joint parts are matched with the limiting part; an opening surface is arranged at the top of the box; the length of the press stamps is matched with the height of the box; and the movable type top surfaces on the press stamps are higher than the top surface of the box. The letter press stamp can realize the splicing fixing of the press stamps; at a stamping moment, the press stamps cannot drop out, and the printing effect is good; the press stamps can be flexibly exchanged; the printing demand of people can be met; the letter press stamp has wide market prospect.

Owner:深圳市字在文化传播有限公司

Unmanned aerial vehicle automatic planting method

InactiveCN108569401ASpacing controllableSave resourcesAircraft componentsClimate change adaptationPlanting seedUncrewed vehicle

The invention provides an unmanned aerial vehicle automatic planting method and relates to the field of unmanned aerial vehicle automatic seeding in forestry and agriculture. The unmanned aerial vehicle automatic planting method comprises the following steps: 1) setting a flight path, namely setting a flight path of an unmanned aerial vehicle over a seeding required area before the unmanned aerialvehicle takes off; 2) setting a seed launching frequency, namely setting the seed launching frequency according to inter-plant distances of plant seeds to be launched; 3) setting the flight speed ofthe unmanned aerial vehicle, namely setting the flight speed of the unmanned aerial vehicle to be equal to a product of the launching frequency and the inter-plant distance according to the inter-plant distances of the plant seeds to be launched and the launching frequency; and 4) enabling the unmanned aerial vehicle to take off and seed, namely enabling the unmanned aerial vehicle to fly along apreset path, and seeding in a seed cabin according to the preset launching frequency. According to the method disclosed by the invention, by setting a matching relationship between the flight speed ofthe unmanned aerial vehicle and the launching frequency of the seeds, the distance controllability between the seeds can be ensured, so that resources are saved, and the plantation effect is improved.

Owner:河南方达空间信息技术有限公司

Double-cartridge blasting method and accurate positioning device as well as positioning method for charging

The invention provides a double-cartridge blasting method and an accurate positioning device as well as positioning method for charging. Through the double-cartridge blasting method and the accurate positioning device as well as positioning method, the asymmetric damage effect can be avoided, the damage to surrounding rock can be effectively reduced, and the construction efficiency can be improved. The double-cartridge blasting method comprises the following steps: step 1, blasting parameters are determined according to a single-cartridge blasting design method; step 2, the total charging quantity of each double-cartridge group is determined according to the double-cartridge charging quantity and corresponding double cartridges are selected; step 3, the cartridge center distance is determined, that is, the center distance between two cartridges in each double-cartridge group is set to be 1 to 2 times of the cartridge diameter; step 4, for each blasting hole, each double-cartridge groupis mounted by adopting the accurate positioning device for charging according to the diameter of the blasting hole and the cartridge center distance, the preset center distance between the two cartridges in each double-cartridge group is kept, and the two cartridges in each double-cartridge group are symmetrically arranged; and step 5, the mounting operation in step 4 is continuously performed according to the blasting parameters, the double cartridges are mounted in each blasting hole, and a trigger is arranged.

Owner:WUHAN UNIV OF TECH

Knotting equipment for cloth or nets

PendingCN108606387AAvoid crooked situationsPrecise Control of SpacingClothes making applicancesEngineeringOutput device

The invention discloses knotting equipment for cloth or nets, and belongs to the technical field of knotting machines. The knotting equipment comprises an input device, a knotting platform and an output device which are arranged sequentially from front to back; the input device comprises a transmission machine I, a transmission machine II and a tensioning device which are arranged sequentially from front to back; the knotting platform is slidably connected with a knotting machine; the output device comprises an output rack, the output rack is connected with an output roller through a bearing,the output roller comprises a front output roller and a back output roller, and the upper portion of the back output roller is provided with an output compression roller. The knotting equipment for the cloth or nets has the advantages that traditional knotting for the cloth or nets is abandoned, mechanical operation is utilized to replace manual operation to avoid that rivet buckles are tilted, thereby precisely controlling space among the rivet buckles and ensuring the product quality, the worker participation is basically excluded during knotting, the time and labor are reduced, the knottingefficiency is high, and it is avoided that the healthy growth of enterprises is affected.

Owner:BINZHOU JINHUI NET +1

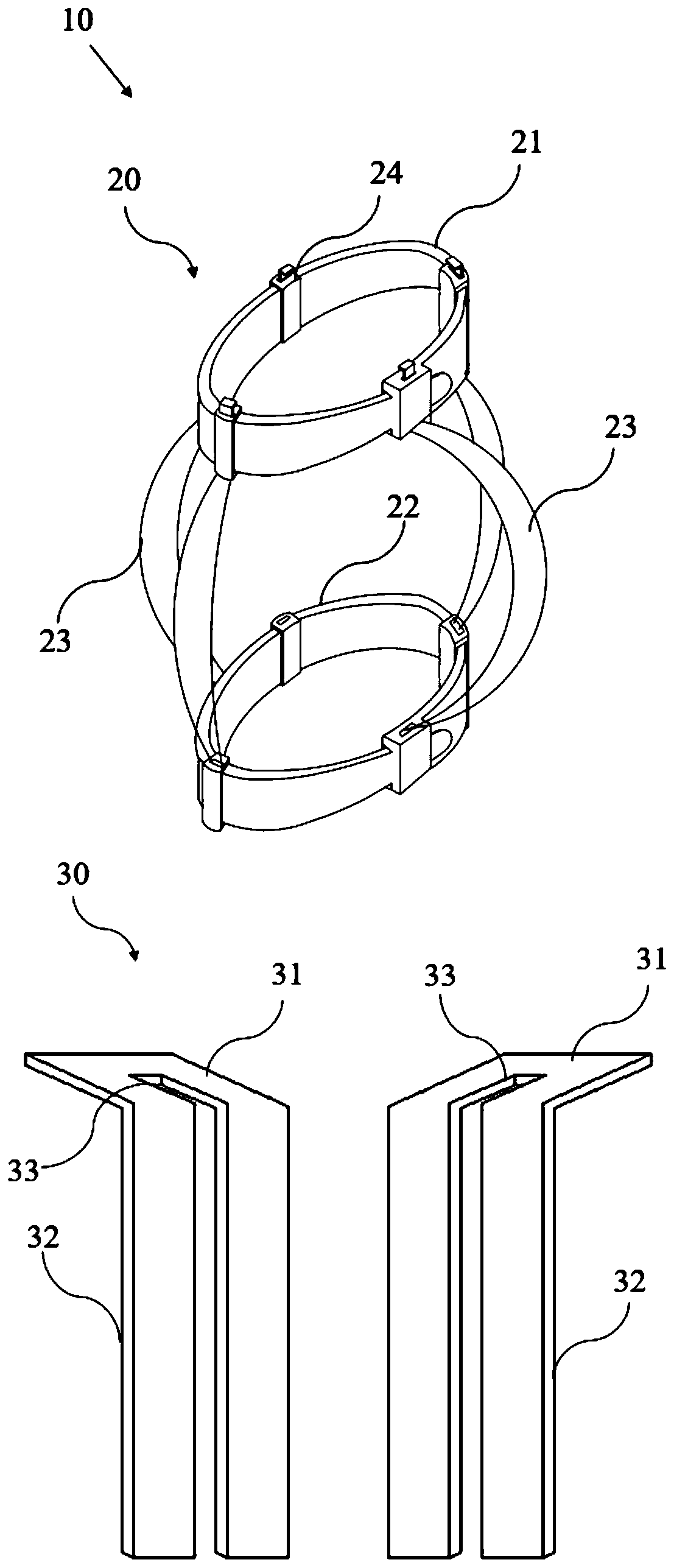

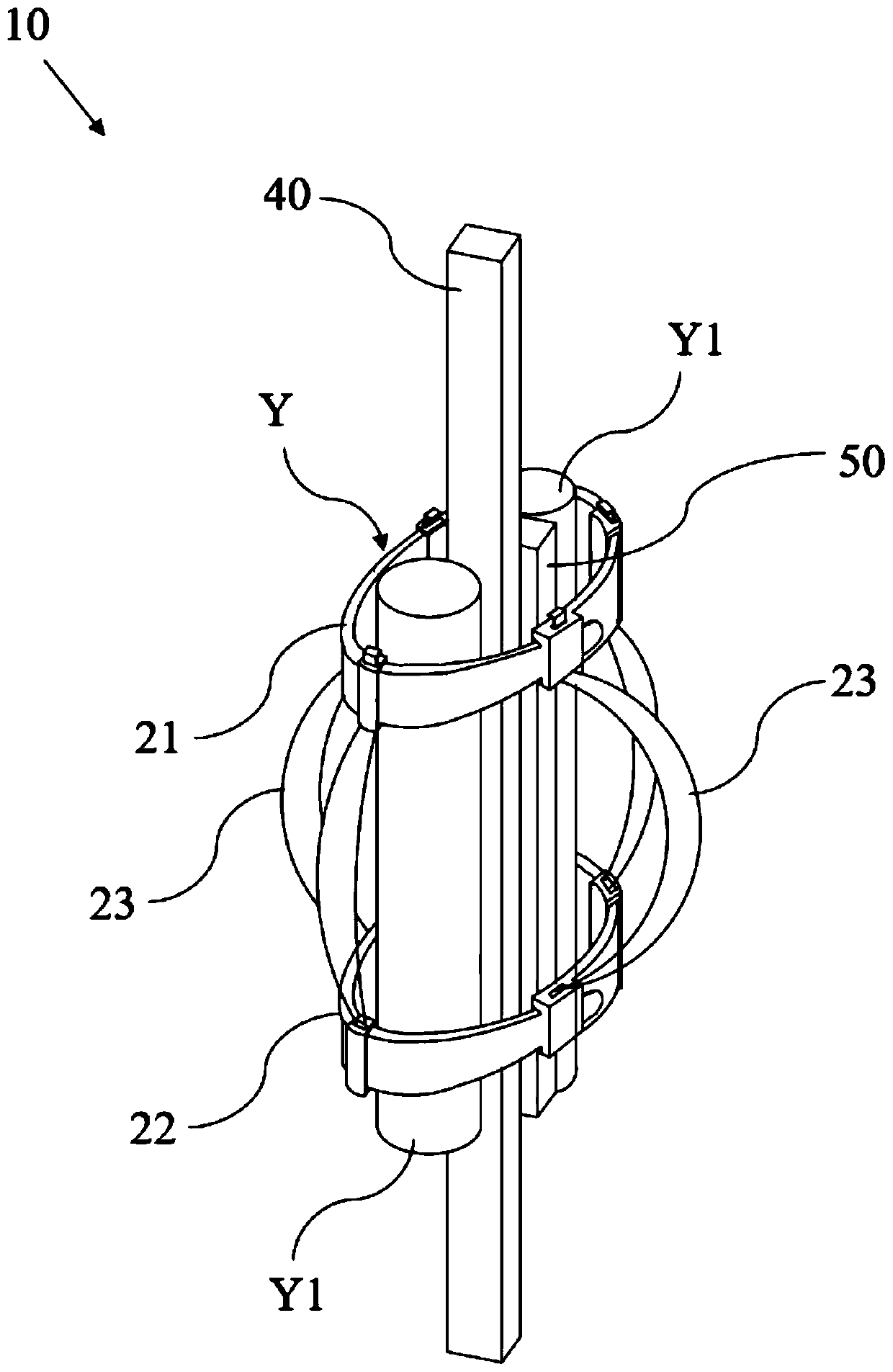

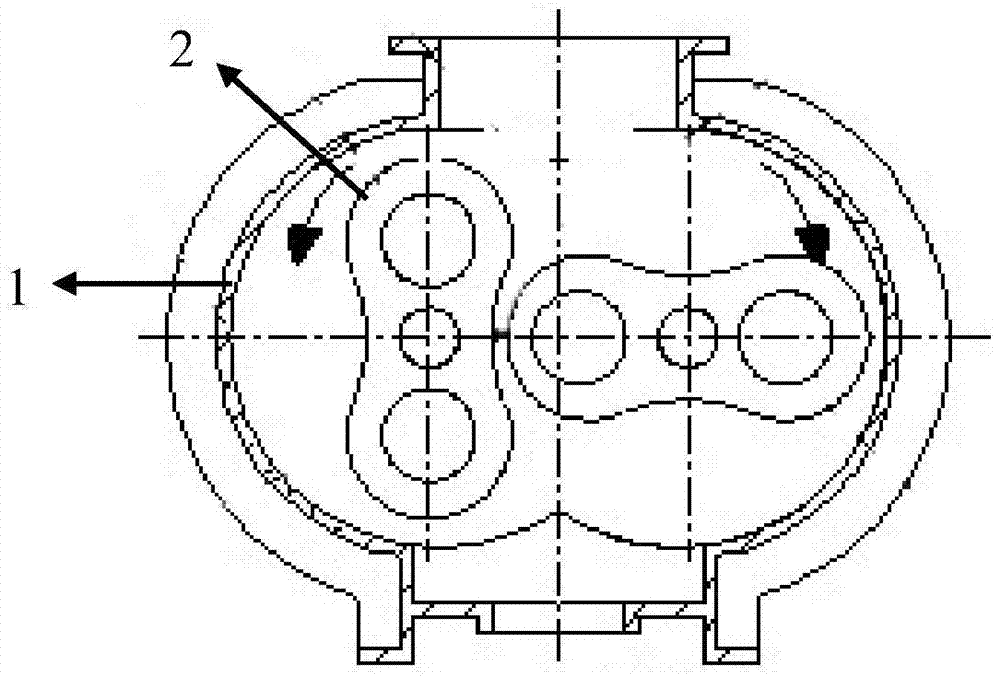

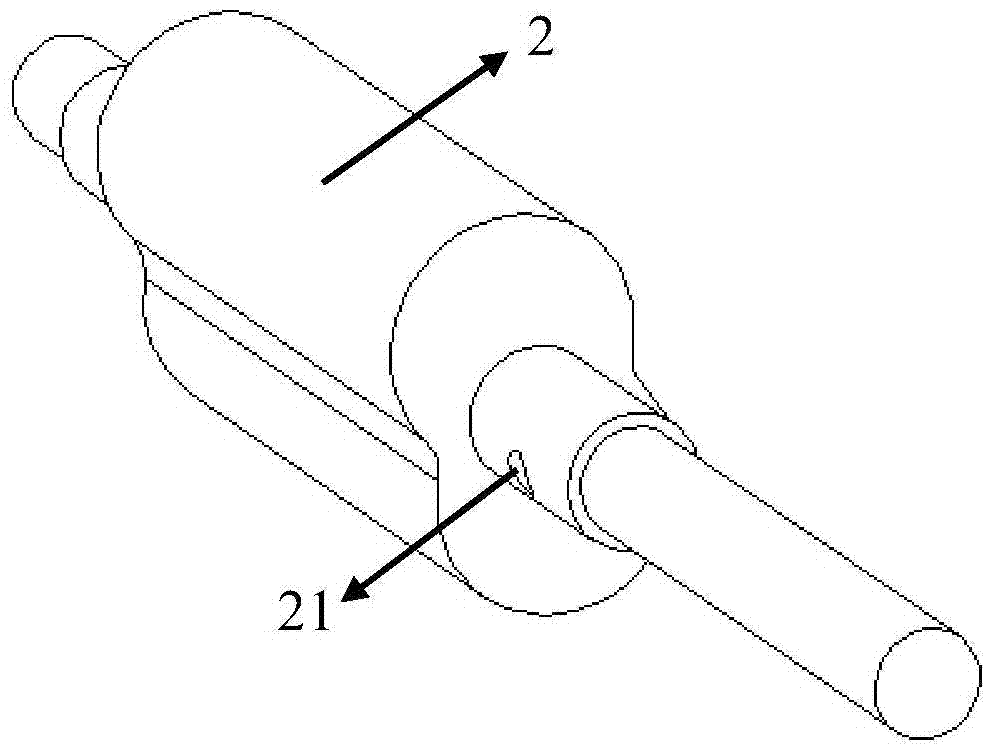

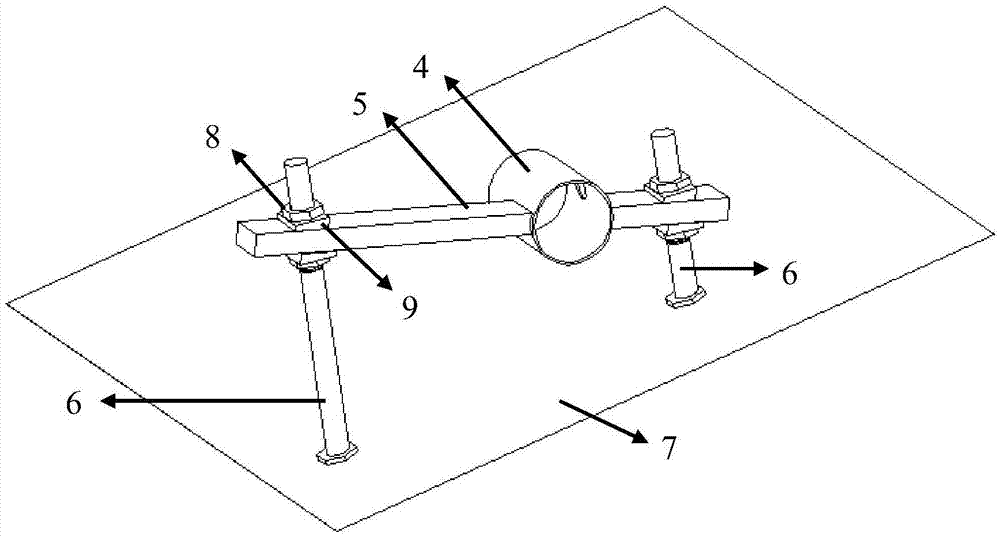

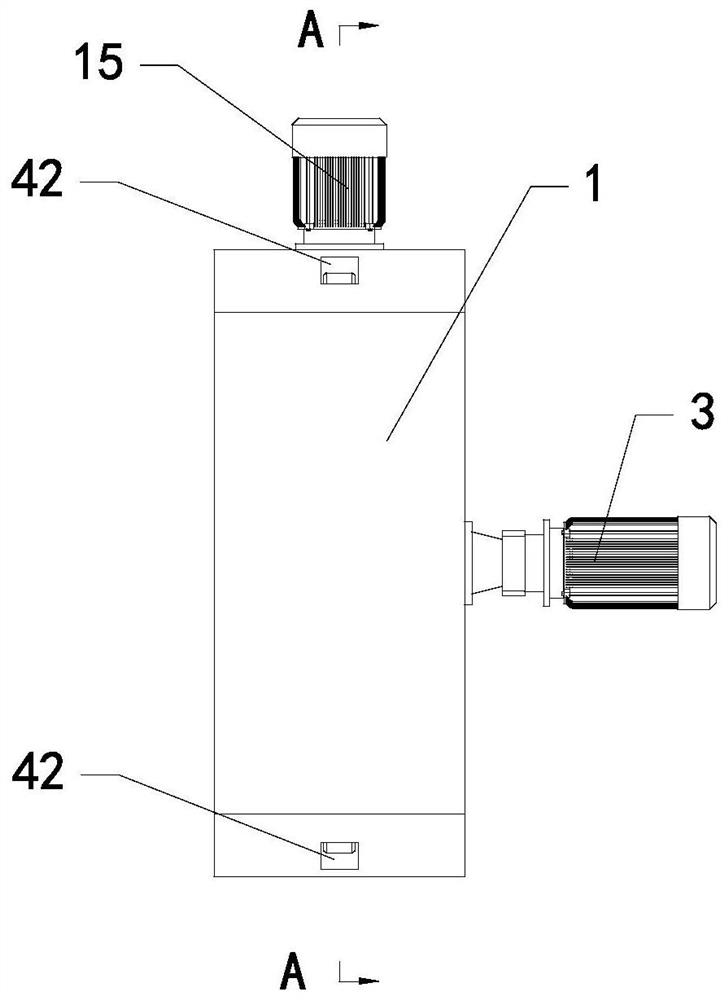

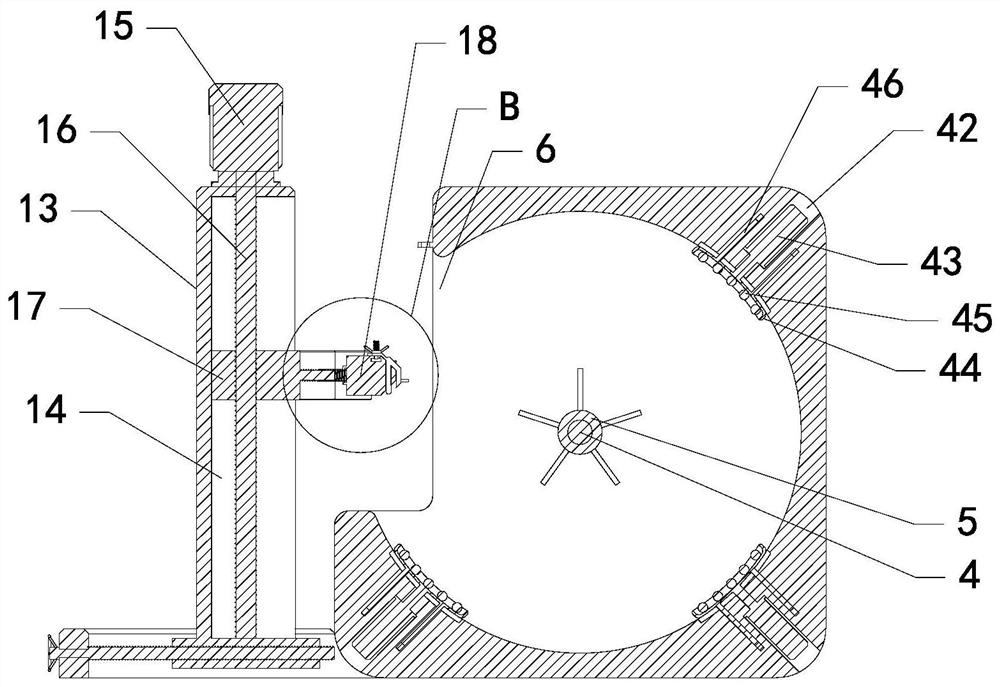

Roots pump mounting/fixing device

ActiveCN105437115ASpacing controllableImprove stabilityWork holdersEngineeringMechanical engineering

Owner:天津南玻节能玻璃有限公司

An Algorithm for Analyzing Lagrangian Quasi-order Structure of 2D Ocean Current

ActiveCN105975437BClear locationSpacing controllableComplex mathematical operationsStructure analysisComputational physics

The invention relates to a two-dimensional ocean current Lagrangian coherent structure analytical algorithm. The algorithm is based on a Cauchy-Green right strain tensor, wherein the tensor is obtained in a way that a gradient obtained after particles move for a period of time in a flow field is calculated. Particle movement uses a Runge-Kutta 4 order integration method, and cubic interpolation is adopted for the flow field. In order to improve calculation accuracy, four neighbor points are added on each grid point to calculate the gradient by using a finite difference. The Cauchy-Green right strain tensor is provided with two real eigenvalues, wherein the local maximum value of the large eigenvalue and the local minimum value of the small eigenvalue are seed points of an LCS (Lagrangian Coherent Structure), and the Runge-Kutta 4 order integration is carried out in a non-corresponding characteristic vector field forwards and backwards to obtain a Lagrangian coherent structure. During integration, the direction discontinuity of a character vector is considered. The direction is always kept consistent with the direction of a previous point, and inversion is carried out if the direction differs more than 90 degrees. After one LCS is generated, the LCS seed points in a certain width range of the LCS are set to be ineffective, and an interval between the LCSs is controlled. The Lagrangian coherent structure is an important flow field topological structure, can be effectively applied to the range of ocean current, season-year changes and main flow and branch flow analysis.

Owner:OCEAN UNIV OF CHINA

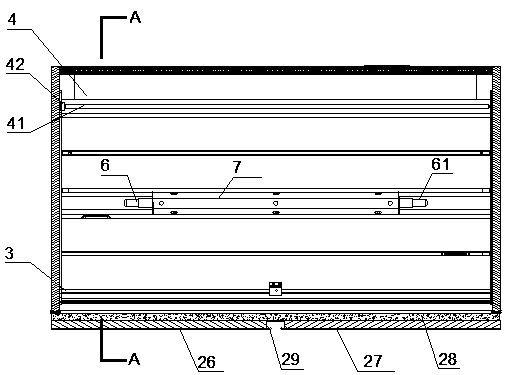

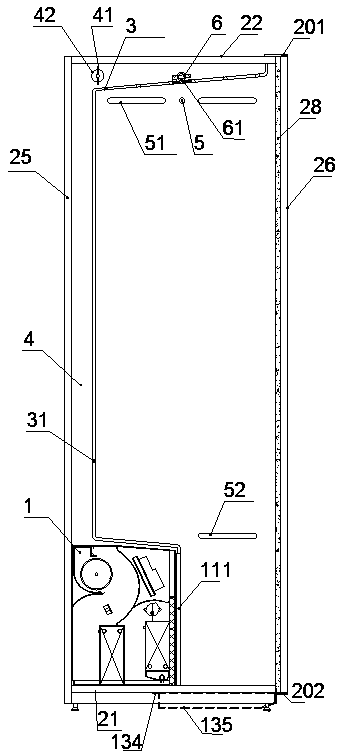

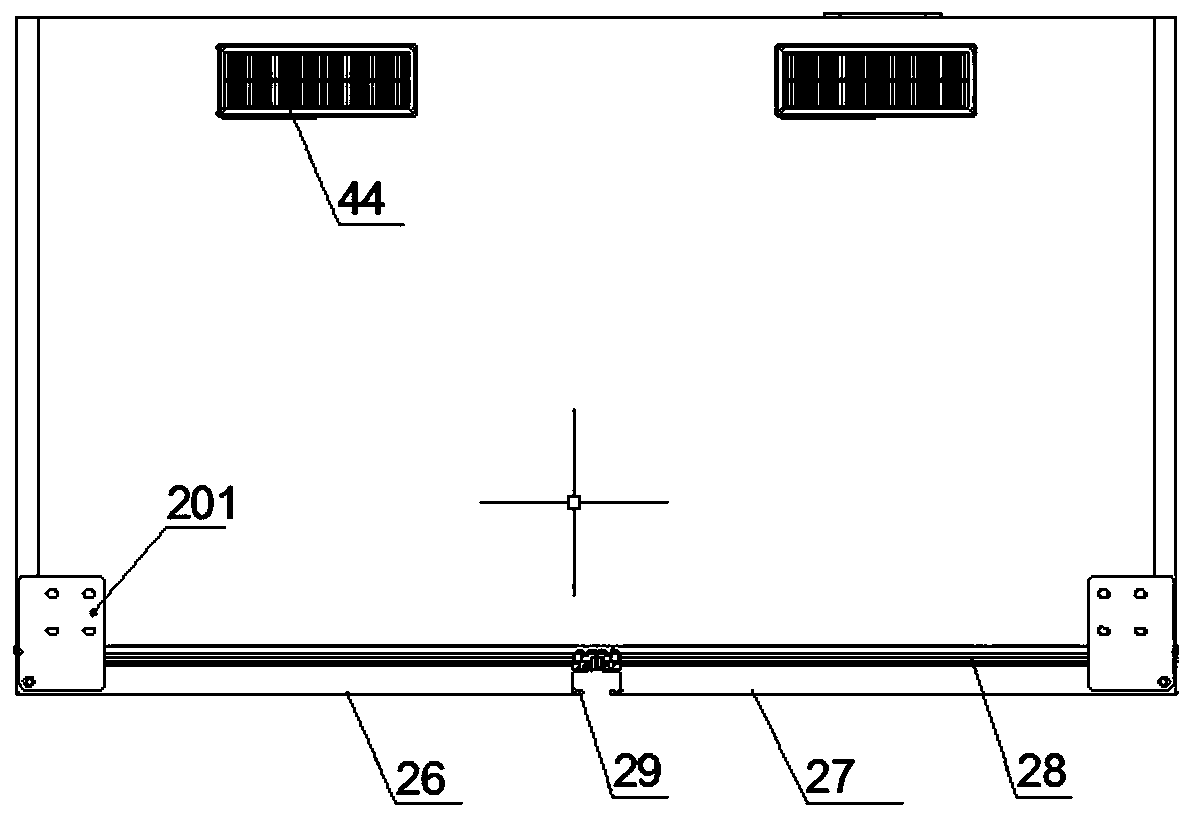

Multifunctional cabinet type heat pump clothes dryer

PendingCN111041797ASolve the problem of easy windingWinding will notDispersed particle separationLavatory sanitoryThermodynamicsEngineering

The invention discloses a multifunctional cabinet type heat pump clothes dryer. The multifunctional cabinet type heat pump clothes dryer comprises a cabinet body and a dehumidification main machine arranged in the cabinet body, wherein a combined air duct is arranged in the cabinet body through a partition plate; an air supply outlet is further formed in the top of the cabinet body; an air outletof the dehumidification main machine and the air supply outlet in the top of the cabinet body communicate with the combined air duct respectively; and a clothes airing rod is arranged below the air supply outlet. The multifunctional cabinet type heat pump clothes dryer can effectively solve a series of problems that an existing clothes dryer is limited in clothes drying capacity, clothes are proneto being wound, different types of clothes cannot be dried synchronously, clothes which are not resistant to abrasion cannot be dried, clothes which are not resistant to high temperature cannot be dried, and electric heating clothes drying energy consumption is too large.

Owner:成都佳阳智能家居有限公司

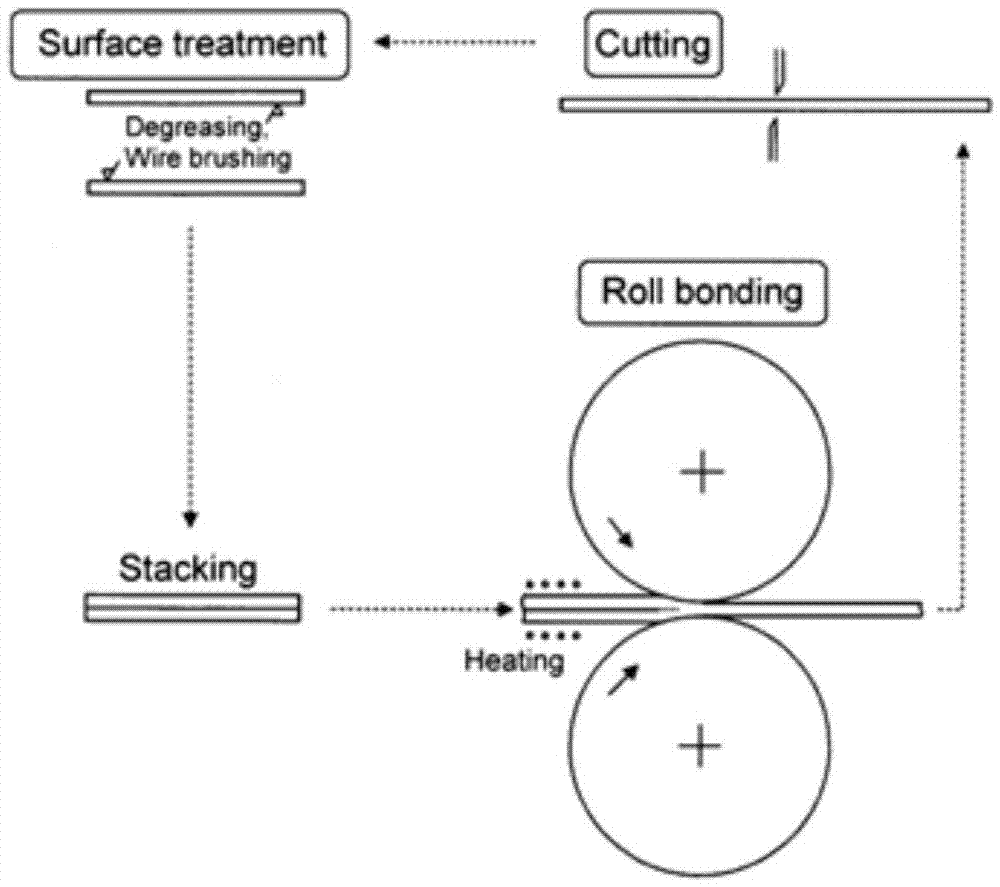

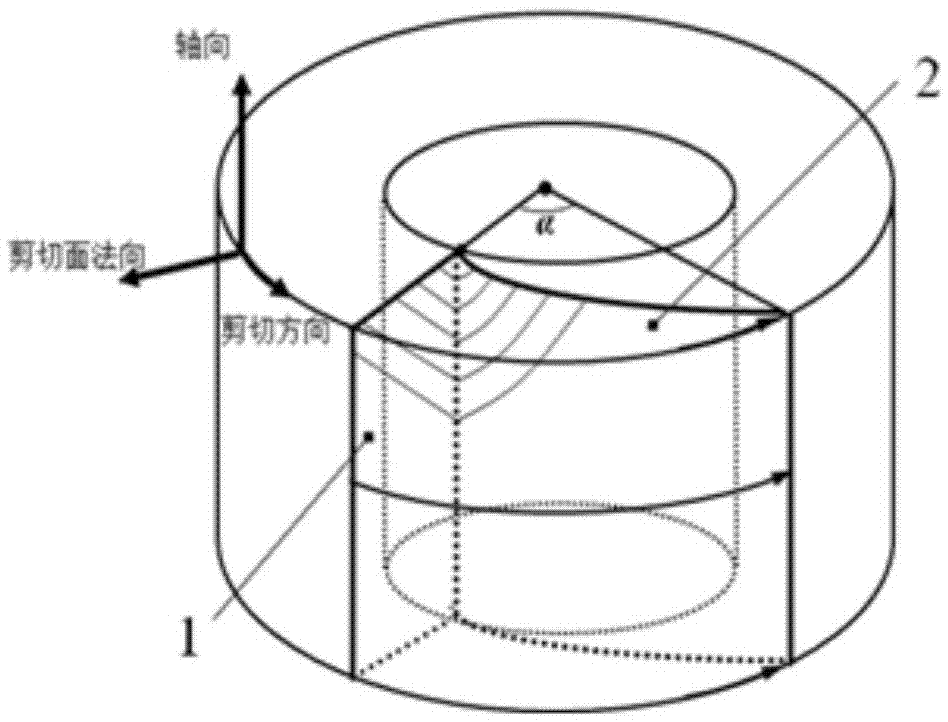

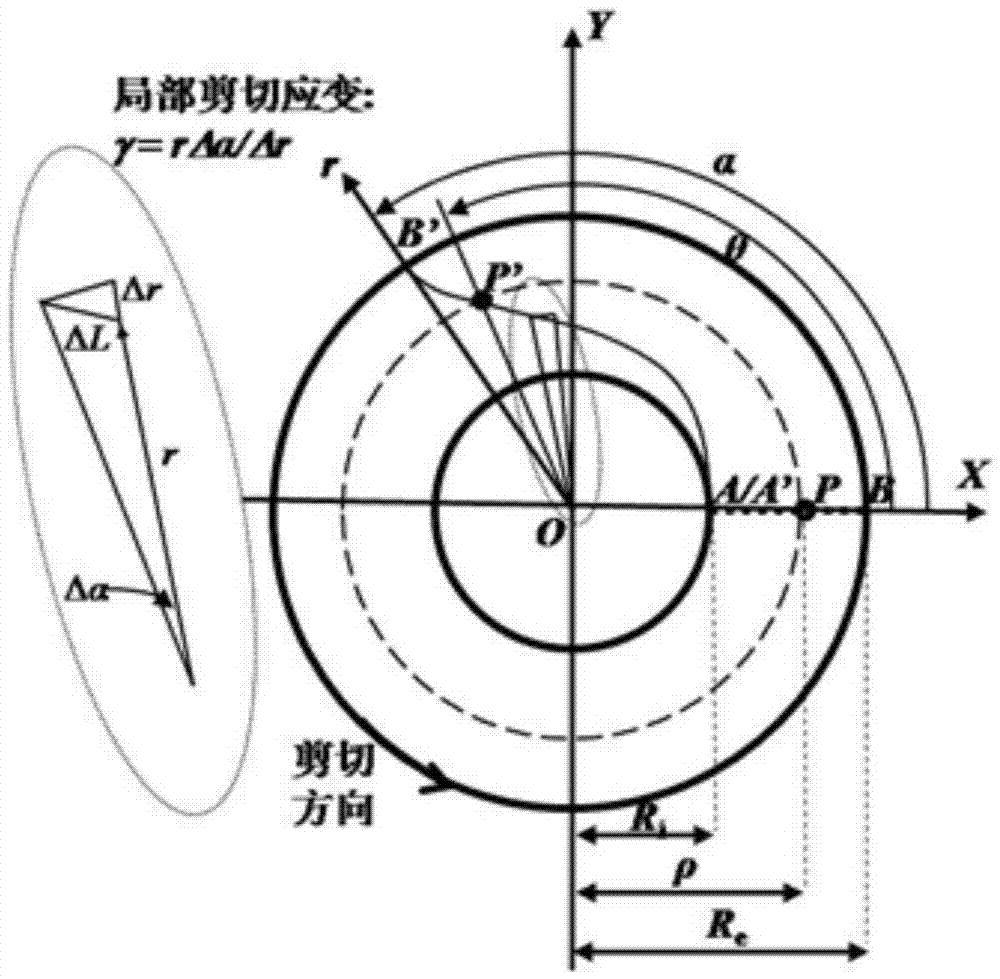

Single-process machining method of multilayer metal composite material

The invention discloses a single-process machining method of a multilayer metal composite material. The single-process machining method is characterized in that two or more solid metals or alloys are taken as raw materials, and circular arc workpieces of the different metals or the different alloys are placed closely and are spliced into a complete tube-shaped sample; the internal wall and the external wall of the tube-shaped sample are completely restrained by an internal restriction body and an external restriction body, pressure is applied to the annular end faces or the cylindrical surface of the tube-shaped sample, and the internal restriction body and the external restriction body rotate oppositely around a center axis shared by the internal restriction body, the external restriction body and the circular arc workpieces; the circular arc workpieces undergo tangential shearing deformation under a high hydrostatic pressure condition, constant growth of the contact surfaces of the different metals is realized, and interface multiplication is formed; and with the continuous increasing of a rotation angle, initial interfaces penetrating through the interior and the exterior of the tube-shaped sample, which are initially formed through close contact of the circular arc workpieces of the different metals gradually develop into spiral interfaces of which starting points and terminal points are formed at the internal wall and the external wall of the complete tube-shaped sample, and the spiral interfaces are wound by several circles in the tube wall, thereby forming a multilayer metal composite material structure. With the adoption of the single-process machining method, the disadvantages that the traditional metal layer composite material machining method is complicated, and low in efficiency, interfaces are prone to be polluted by the environment and the interface bonding quality is poor are overcome, and the multilayer metal composite material having required components, the required number of layers, the required layer thickness and the like can be prepared by a single process.

Owner:NANJING UNIV OF SCI & TECH

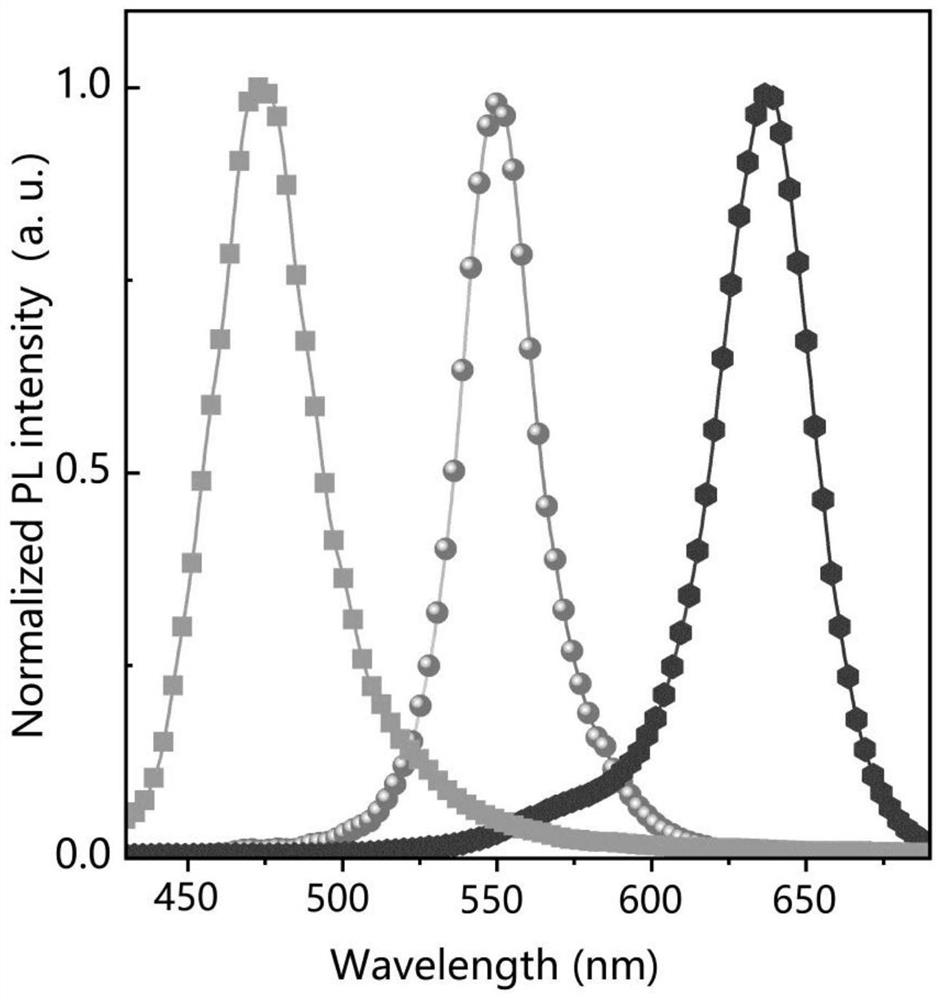

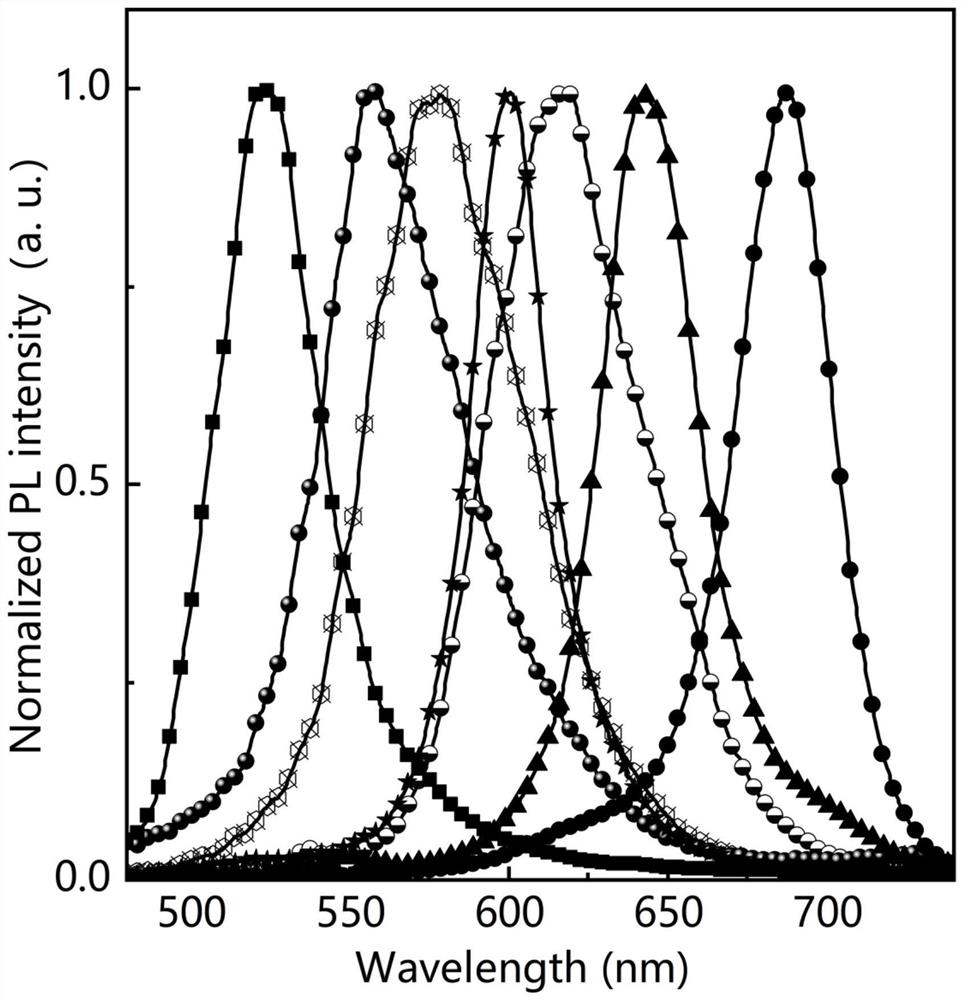

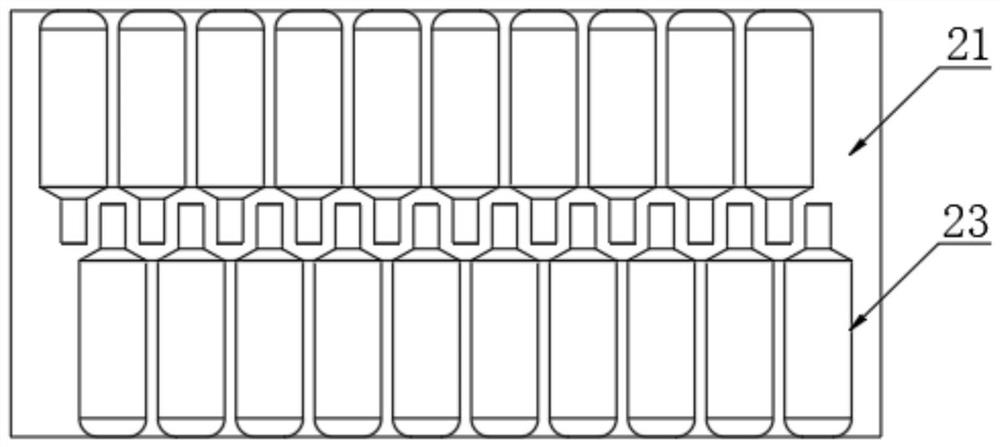

Full-color Micro-LED display device based on quantum dots in glass and preparation method of full-color Micro-LED display device

PendingCN113380775AGood size controlSpacing controllableSolid-state devicesSemiconductor devicesLED displayDisplay device

The invention discloses a full-color Micro-LED display device based on quantum dots in glass and a preparation method of the full-color Micro-LED display device. The device mainly comprises a glass machine body, a Micro-LED light-emitting device array and a Micro-LED driving chip from top to bottom, the Micro-LED light-emitting device array is mainly formed by arranging a plurality of Micro-LED light-emitting devices at intervals in an array mode, the Micro-LED light-emitting devices are all electrically connected and packaged on the Micro-LED driving chip, and quantum dot light-emitting units distributed in an array mode are arranged in the glass machine body. The quantum dot light-emitting units are generated by direct writing induction of ultrafast laser in the glass body, and the quantum dot light-emitting units in the glass body have different light-emitting wavelengths. The prepared full-color Micro-LED display device is smaller in size and lower in cost, and the problem that the stability of a perovskite material is poor is solved.

Owner:ZHEJIANG UNIV

Intelligent papermaking machine partitioned steam humidifying device

ActiveCN113981730AStable spacingSpacing controllablePipeline systemsDamping devicesThermodynamicsPapermaking

The invention discloses an intelligent papermaking machine partitioned steam humidifying device, which belongs to the technical field of papermaking machines and comprises a rack, an upper steam box is mounted on the rack, one side of the rack is hinged to one side of a lower steam box, the bottom of the other side of the lower steam box is hinged to a push rod of a cylinder, and the cylinder is hinged to the bottom of the rack. Coil pipes and steam spraying assemblies are installed in the upper steam box and the lower steam box, a steam cabinet is arranged on the outer side of the rack, the input end of the steam cabinet is connected with one ends of the coil pipes through preheating steam outlet pipes, the other ends of the coil pipes are connected with a pressure reducing device through preheating steam inlet pipes, and the output end of the steam cabinet is connected with the steam spraying assemblies through dry steam inlet pipes. The coil pipes carry out preheating and heat preservation on the upper steam box and the lower steam box through steam, condensate water is prevented from dropping on paper, the preheated steam flows into the steam cabinet through the preheating steam outlet pipes, the steam cabinet carries out flow dividing and drying on the steam, dry steam is provided for the steam spraying assemblies in the upper steam box and the lower steam box, . the steam spraying assembly evenly sprays steam to the two faces of the paper for humidification.

Owner:ZHEJIANG HUAZHANG TECH

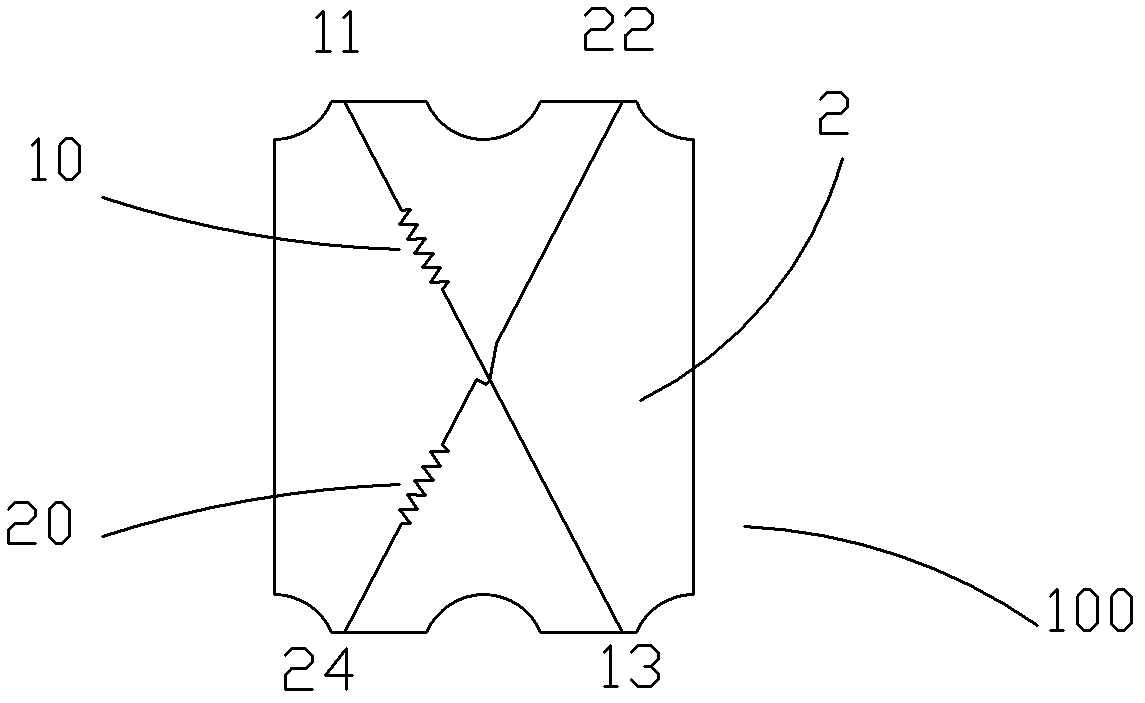

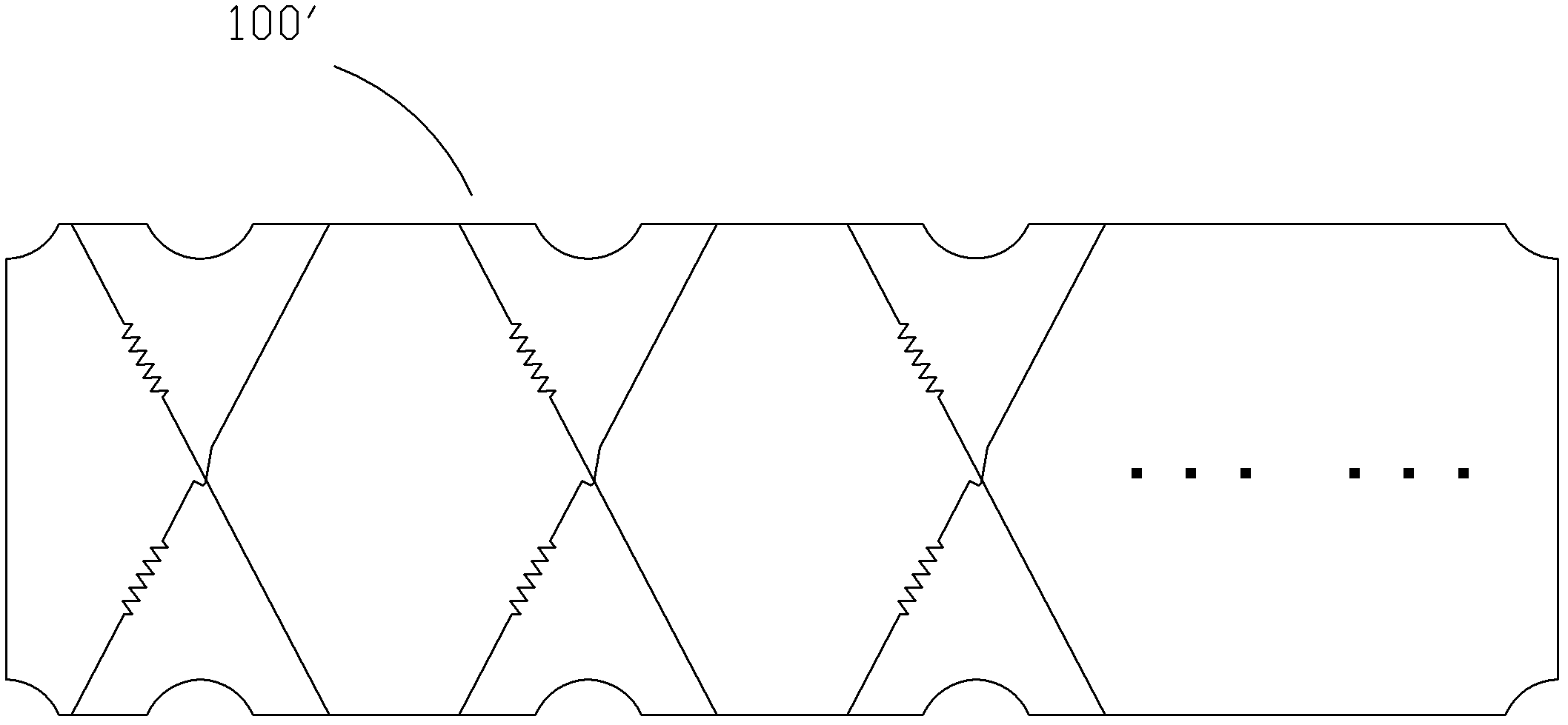

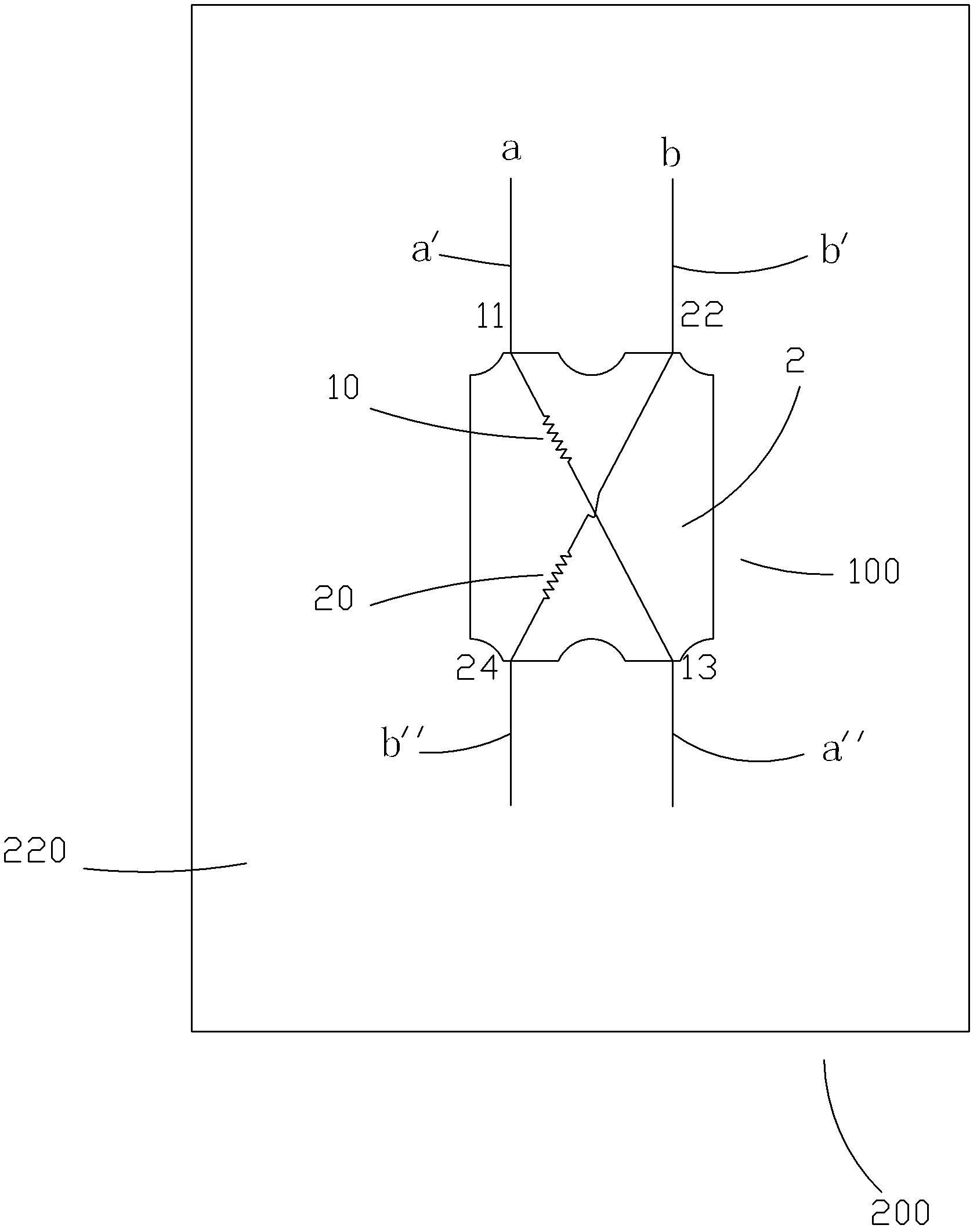

Array resistor and PCB board applied with the array resistor

InactiveCN102324292AImplementing a cross output transformQuality assuranceResistorsPrinted circuit non-printed electric components associationElectrical resistance and conductanceSignal quality

The invention provides an array resistor and a PCB board applied with the array resistor. The array resistor comprises a packaging body and resistors in pairs arranged in the packaging body. Resistors in each pair are symmetrically crossed and insulating with each other; two ends of each resistor are respectively provided with corresponding pins on the packaging body; and two ends of each resistor are electrically connected to packaging body pins respectively. The invention can realize crossing output transformation of signals, solve difficulty wiring and adjusting, and guarantee signal quality; meanwhile, crossing output transformation of differential signals is realize through the array resistor, so as to solve difficulty in wiring and adjusting and realize a function like a twisted pair on a board, and the array resistor is tighter than the twisted pair, has controllable spacing and amazing effect on interference inhibition.

Owner:深圳市卓怡恒通电脑科技有限公司

Template-assisted volatilization-induced self-assembly to construct organic microwire arrays

ActiveCN103413760BEasy to operateImprove bindingSemiconductor/solid-state device manufacturingMicro nanoOxygen plasma

Owner:SUZHOU UNIV

Forming device for processing medicine tube and method of using the same

ActiveCN112497341BCoherent and simultaneous loading and unloading operationsAutomated operation saves time and effortMetal working apparatusPunchingMolding machine

The invention discloses a forming device for processing medicine tubes and a method for using the same, comprising a frame and a forming mechanism installed on the frame, wherein the frame includes a support table and a punching platform arranged in sequence from top to bottom, and the support table The top of the punching platform is fixedly connected, and a push frame is fixedly connected to the top of the forming mechanism. The invention relates to the technical field of plastic product processing. The molding device for processing a medicine tube and a method of using the same can realize the synchronous movement of the molding mechanism and the punching knife by using the same set of driving mechanisms, and then simultaneously complete the steps of extrusion molding and removing residual materials, and at the same time, a runner and a rubber sleeve are arranged. The cooperation with the structure such as convex teeth and the semi-circular arc section of the right half of the punching platform can realize the operation of automatically transferring the semi-finished products after extrusion from the upper part to the lower punching platform, and realize the continuous and synchronous loading and unloading operation, which saves the cost of automatic operation. Time-saving and labor-saving, and the two equipments are integrated, which not only improves work efficiency, but also reduces equipment costs.

Owner:湖北吴都医药包装材料有限公司

Movable type seal

The invention discloses a letter press stamp which is characterized by comprising a stamp box and a plurality of press stamps, wherein the press stamps are fixed in the stamp box; movable types are engraved on one ends of the press stamps; the stamp box comprises a clamping plate and a box; an opening is arranged on one side of the box; the clamping plate is closed in the opening position of the box; the clamping plate and the box are encircled into an accommodating space; the plurality of press stamps can be contained in the accommodating space; a limiting part is arranged on an inner side wall of the box; clamping joint parts are arranged on the positions corresponding to the press stamps; the clamping joint parts are matched with the limiting part; an opening surface is arranged at the top of the box; the length of the press stamps is matched with the height of the box; and the movable type top surfaces on the press stamps are higher than the top surface of the box. The letter press stamp can realize the splicing fixing of the press stamps; at a stamping moment, the press stamps cannot drop out, and the printing effect is good; the press stamps can be flexibly exchanged; the printing demand of people can be met; the letter press stamp has wide market prospect.

Owner:深圳市字在文化传播有限公司

Tread pattern grooving device for tire retreading

PendingCN114043555AOperation saves time and effortFree laborOther workshop equipmentMetal working apparatusElectric machineryDrive motor

The invention relates to the technical field of tire machining, in particular to a tread pattern grooving device for tire retreading. The device includes a fixing base, the center of the front side wall of the fixing base is inwards provided with a wheel containing groove, a driving motor is arranged on the rear side of the fixing base, an output shaft of the driving motor vertically and movably penetrates through the center of the rear side wall of the fixing base to be connected with a rotating shaft arranged in the wheel containing groove, and a fixing piece is arranged at the front end of the rotating shaft. The rotating shaft in the wheel containing groove is movably sleeved with a sleeve abutting against the inner wall of the fixing base, a machining channel communicated with the wheel containing groove is formed in the left end of the fixing base, a supporting frame is arranged on the left side wall of the fixing base below the machining channel, and a machining mechanism is clamped in the supporting frame through a first-order adjusting mechanism arranged at the bottom of the machining mechanism. And a line drawing mechanism is arranged on the side wall of the fixing seat above the machining channel. The device is reasonable in structural design and convenient to operate, adopts semi-automatic mechanical work, effectively liberates manpower, and solves many problems existing in the machining process of a water chute in the prior art.

Owner:山东银宝轮胎集团有限公司

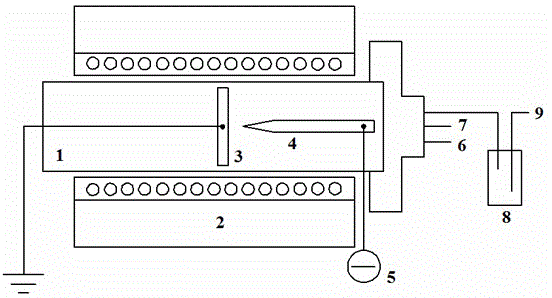

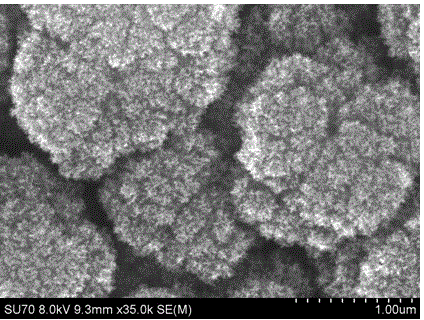

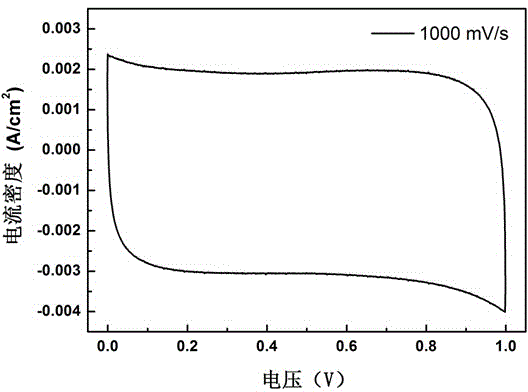

Device and method for preparing electrode of vertical graphene double electric layer capacitor at constant voltage

ActiveCN102610398BNo apparent agglomerationObvious reunion phenomenonCapacitor manufactureHybrid/EDL manufactureHigh pressureBottle

The invention discloses a device and a method which are used for preparing an electrode of a vertical graphene double electric layer capacitor at the constant voltage. The device comprises a quartz tube, a heating furnace, a flow collector, a needle-like electrode, a high voltage negative power supply, an inert gas inlet, a hydrogen inlet, a bubble bottle and a carbon source gas inlet. The flow collector and the needle-like electrode are placed inside the quartz tube, the needle-like electrode is externally connected with the high voltage negative power supply and the needle tip of the needle-like electrode is opposite to the flow collector. The flow collector is grounded. The quartz tube is placed in the heating furnace. One end of the quartz tube is opened while the other end of the quartz tube is provided with the inert gas inlet, the hydrogen inlet, and the carbon source gas inlet, wherein the carbon source gas inlet is connected with the quartz tube through the bubble bottle. With the adoption of constant voltage glow normal discharge plasma-enhanced chemical vapor deposition method, a vertical-oriented graphene nanopiece grows directly on the surface of the flow collector, so that the electrode of the double electric layer supercapacitor, which uses the vertical-oriented graphene as an active material, is directly obtained without a bonder.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com