Double-cartridge blasting method and accurate positioning device as well as positioning method for charging

A technology of precise positioning and charge roll, which is applied in the direction of blasting, etc., can solve the problems of affecting the seam forming effect and broken situation, and the trouble of fixing the position of the charge roll, so as to achieve good blasting seam forming effect, good seam forming effect and avoid asymmetry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

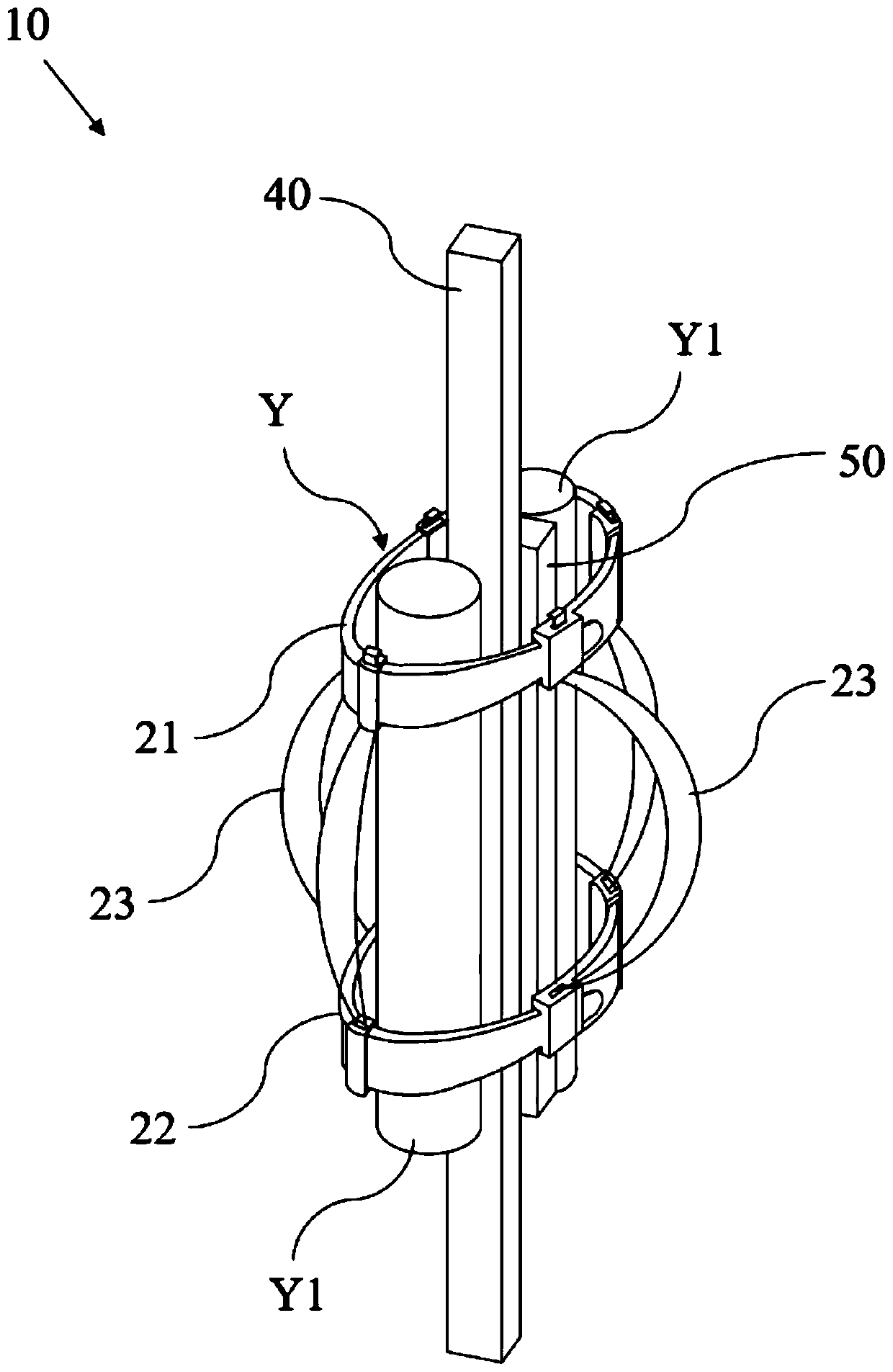

[0058] Step 1: Select a charge device with a blast hole diameter of 100mm, and a cartridge diameter of 25mm.

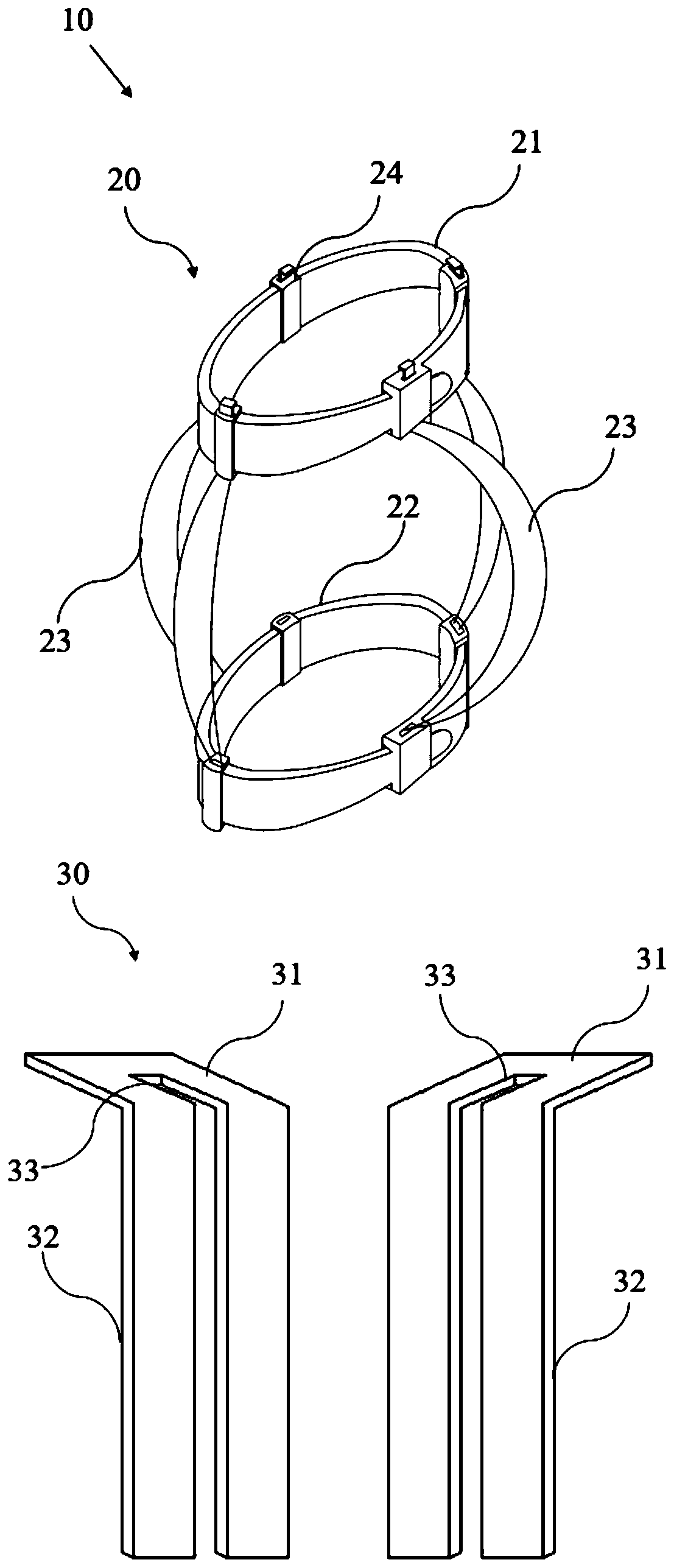

[0059] Step 2: Place two L-shaped guide plates 30 in the blasthole along the line A connecting the blastholes.

[0060] Step 3: Bind the bottom 4 medicine rolls on the bamboo strips with an interval of 300mm. Repeat the binding of the 4 medicine rolls, and the bottom 2m of the medicine is the same.

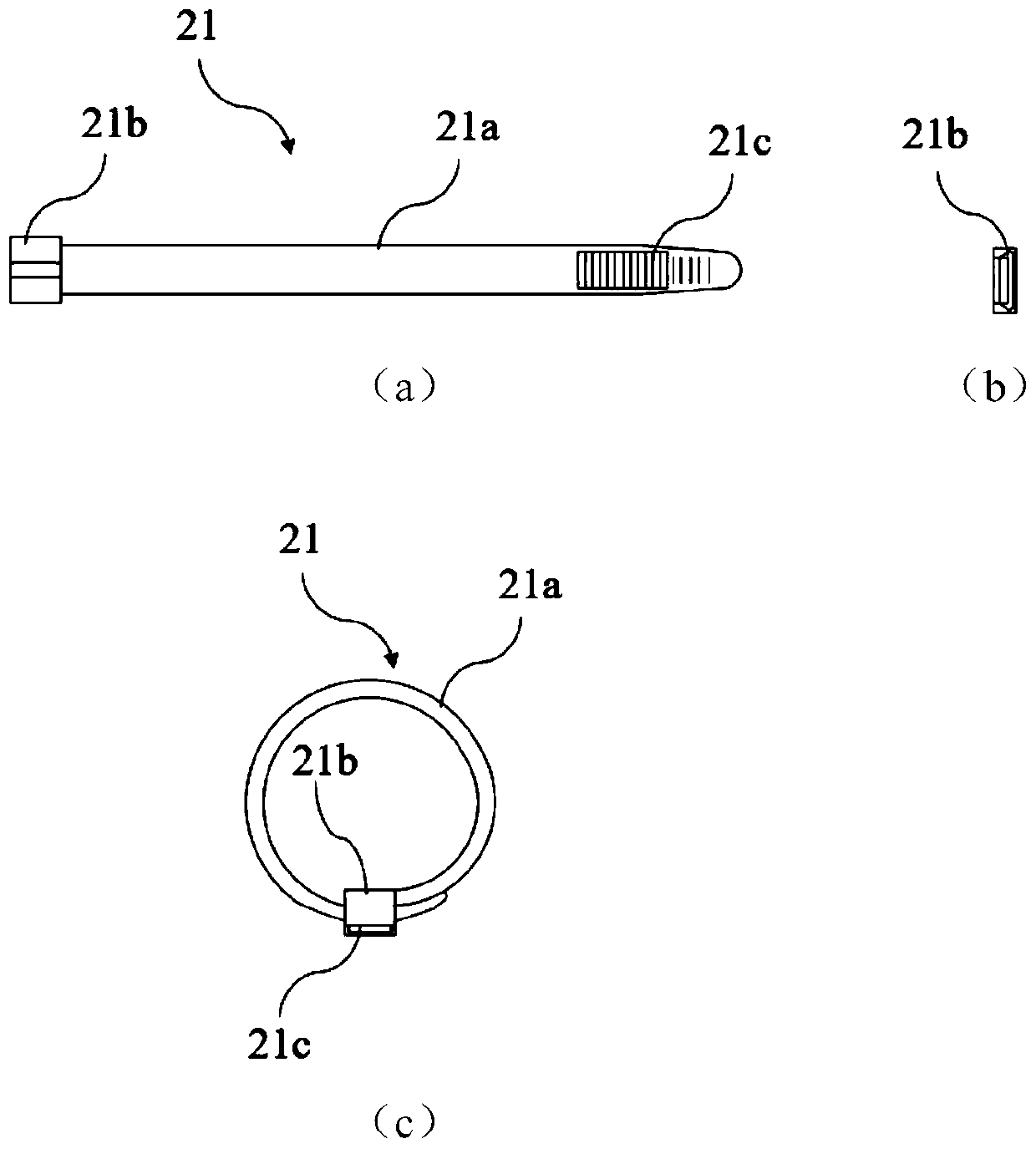

[0061] Step 4: The middle section is charged according to the line charging density of 600g / m, and double drug rolls are used for charging. According to the design requirements, the center distance of the drug rolls is 37mm. The bamboo strip is selected to be 3000mm×50mm×6mm to determine the position of the charge roll in the blast hole, and the wooden block with a size of 100mm×50mm×6mm is selected, and the detonation index is used to detonate. The blasting cord is tied together.

[0062] Step 4: Adjust the position of the snap ring 24 at the same time to ensure that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com