Double-sided steel wire net frame heat-insulation plate and composite wall body

A steel wire grid and composite wall technology, applied in thermal insulation, building components, construction, etc., can solve problems such as insufficient strength and poor bonding of cast-in-place concrete, and achieve improved strength and bonding, simple structure, and easy spacing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

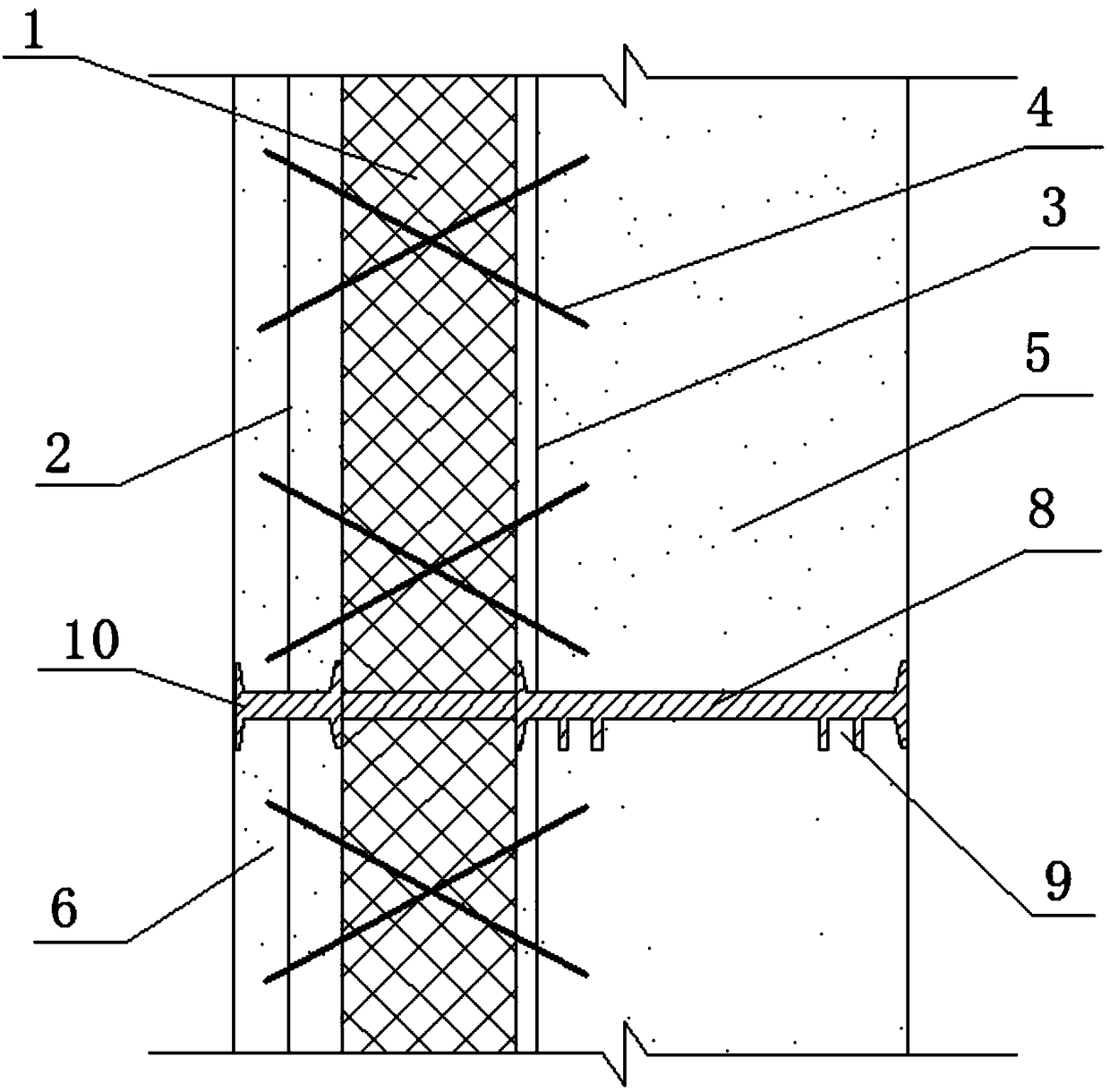

[0027] Such as figure 1 As shown, a double-sided steel wire grid insulation board, the structure of the double-sided steel wire grid insulation board includes: outer steel wire mesh sheet 2, abdominal wire 4, insulation board 1, inner steel wire mesh sheet 3, wherein insulation board 1 It is located between the outer steel mesh sheet 2 and the inner steel mesh sheet 3; the abdominal wire 4 passes through the insulation board 1 and connects with the outer steel mesh sheet 2 and the inner steel mesh sheet 3 respectively to form a steel mesh frame and extends outward. After the abdominal wire 4 is poured with concrete, it forms an anchor connection.

[0028] The structure of the double-sided steel wire grid insulation board also includes several connection support positioning parts for controlling the distance between the structural layers of the composite wall system. The connection support positioning parts run through the insulation board 1, and one end extends out of the oute...

Embodiment 2

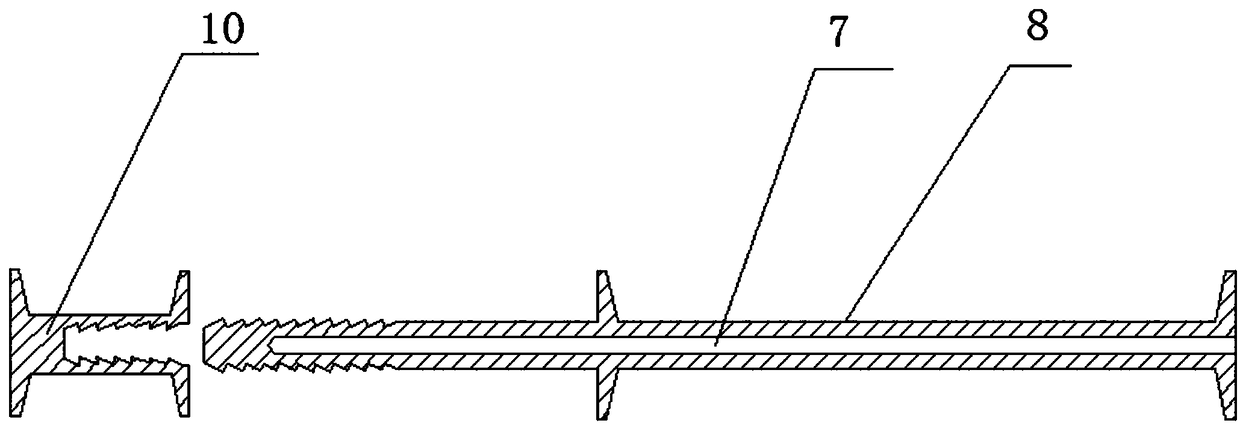

[0030] Such as figure 2 As shown, the structure for connecting the supporting positioning member includes a supporting rod 8 and a positioning member 10, and the supporting rod 8 and the positioning member 10 are connected by threaded insertion, wherein:

[0031] The support rod 8 is used to control the distance between the inner template and the insulation board 1;

[0032] The positioning piece 10 is used to control the distance between the outer formwork and the insulation board 1 .

[0033] The two ends of the support rod 8 are respectively provided with a limit card surface, which is used to support the inner formwork and the insulation board 1, and control the distance between the inner formwork and the insulation board 1, that is, to control the thickness of the cast-in-place concrete member 5, and the support rod 8. The distance between the limit card surfaces at both ends has different specifications (180mm, 200mm) according to the thickness of the concrete member 5...

Embodiment 3

[0040] A double-sided steel wire grid insulation board composite wall based on any of the above-mentioned embodiments, the structure of the composite wall includes: a double-sided steel wire grid insulation board, an outer cast-in-place concrete layer 6 and a cast-in-place concrete member 5, Wherein the outer cast-in-place concrete layer 6 and the cast-in-place concrete member 5 are formed by pouring concrete after supporting the inner and outer formworks on both sides of the double-sided steel wire grid insulation board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com