Mass transfer method and device for electronic elements

A technology of electronic components and transfer methods, applied in the direction of electrical components, circuits, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

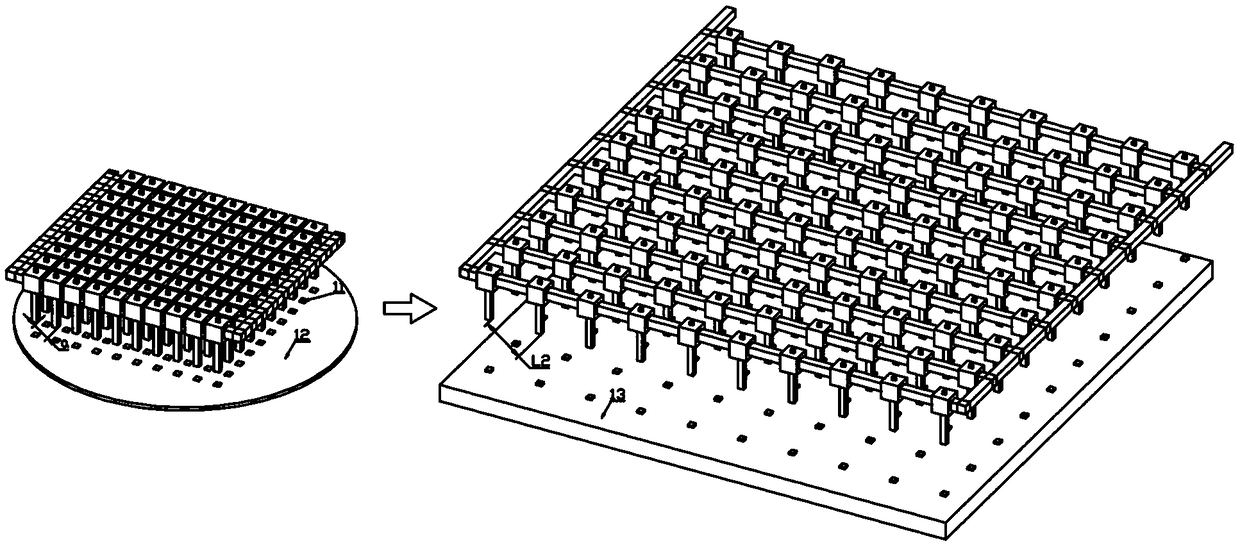

[0039] A mass transfer method for electronic components, comprising the following steps:

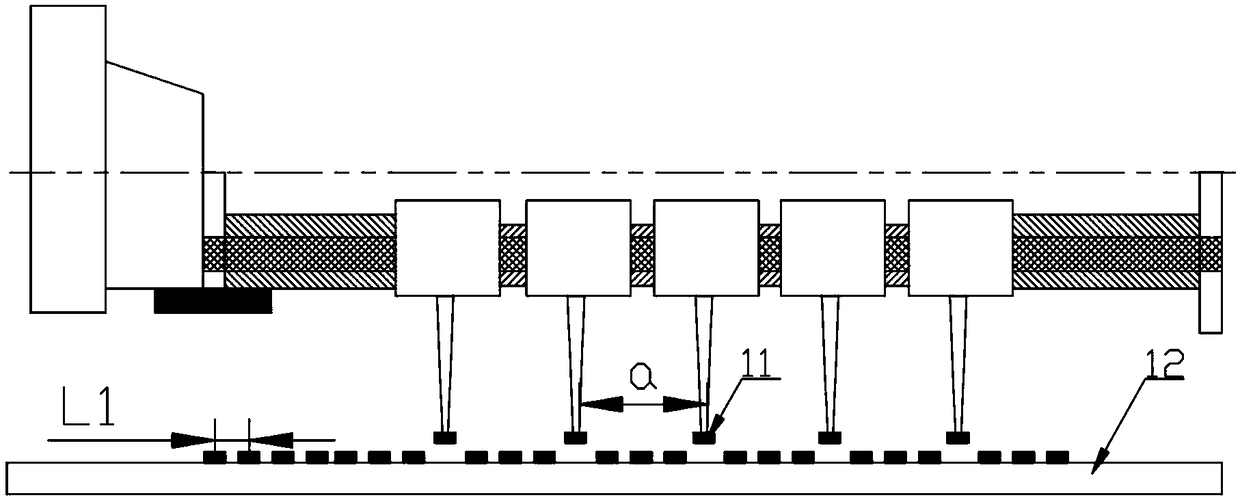

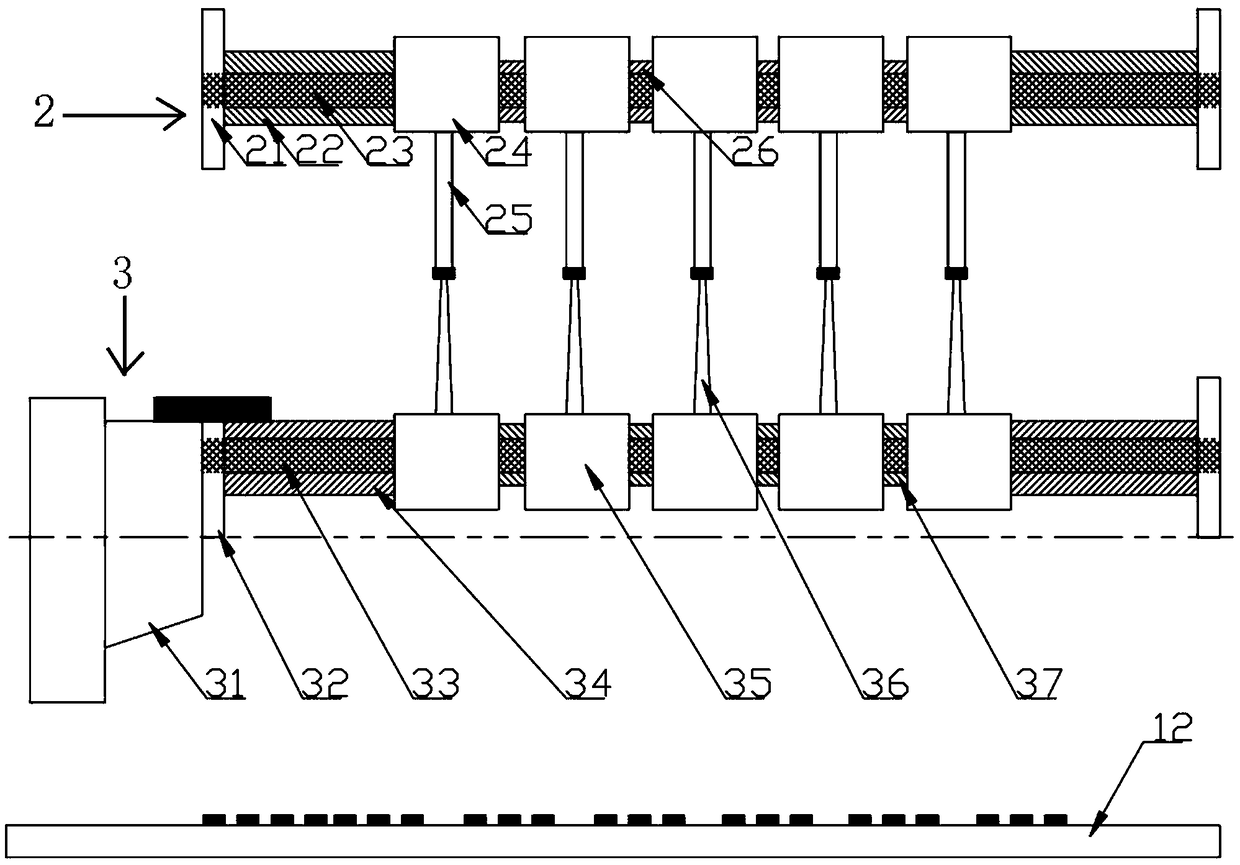

[0040] Step 1, drive the XY axis of the motion platform for machine vision alignment, and the Z axis to keep the flip-chip transfer head at a certain distance from the Micro-LED, and apply external force through the clamping devices at both ends according to the distance between the Micro-LED on the substrate to be grasped The elastic material is longitudinally deformed, the flip-chip transfer head is precisely aligned with the substrate Micro-LED, and the substrate Micro-LED is grasped when a positive voltage is applied to the flip-chip transfer head;

[0041] Step 2: Turn over the flip-chip transfer head, and at the same time, the die-bonding transfer head clamps the substrate Micro-LED up and down, grasp the LED when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com