Device and method for preparing electrode of vertical graphene double electric layer capacitor at constant voltage

A technology of electric double-layer capacitors and graphene, which is applied in the manufacture of hybrid/electric double-layer capacitors, capacitors, capacitors, etc., can solve problems affecting the growth rate and growth area of graphene, hindering the preparation and application of high-quality nanomaterials, etc. Achieve the effects of increasing the effective energy storage area, low cost, and fast graphene growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

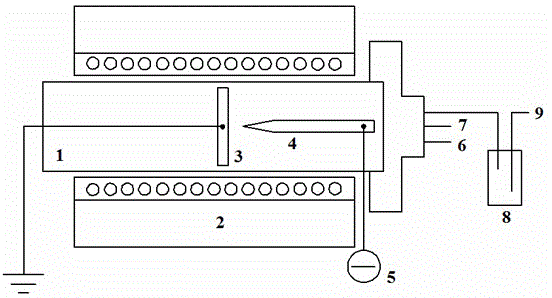

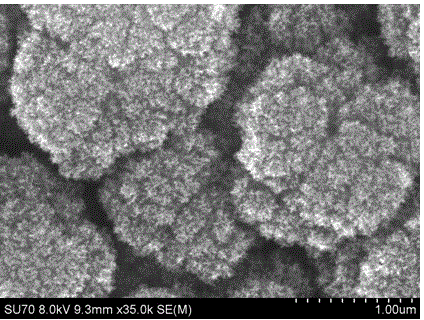

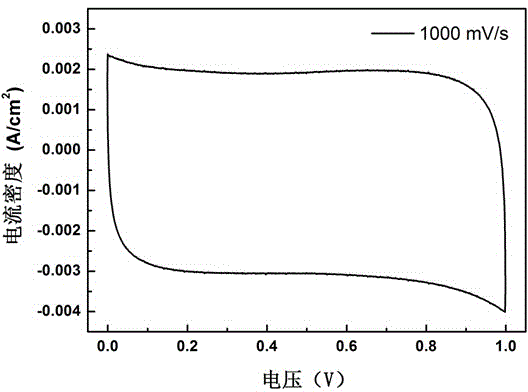

[0038] Example 1: Using methane as the carbon source gas to make a vertically oriented graphene electric double layer supercapacitor electrode.

[0039] The current collector is a stainless steel sheet with a thickness of 0.025 mm, the taper of the needle tip of the needle electrode is 1:5, the distance between the needle tip and the current collector is 10 mm, the inert gas is argon, and the carbon source gas is methane.

[0040] A mixed gas of hydrogen and argon is fed into the quartz tube at a flow rate of 2000 ml / min, the ratio of hydrogen and argon is 1:1, and normal pressure is maintained. Heat the current collector to 700°C. Maintain the normal pressure and current collector temperature in the quartz tube, and switch the gas inlet to a mixed gas of methane and argon after 10 minutes. The flow rate of the mixed gas is 1500 ml / min, the ratio of methane and argon is 1:10, the relative humidity of the mixed gas is 40%, and the normal pressure is maintained. Turn on the hi...

Embodiment 2

[0041] Example 2: Using acetylene as the carbon source gas to make vertically oriented graphene electric double layer supercapacitor electrodes.

[0042] The current collector is a copper sheet with a thickness of 0.02 mm, the taper of the needle tip of the needle electrode is 1:20, the distance between the needle tip and the current collector is 5 mm, the inert gas is argon, and the carbon source gas is acetylene.

[0043] A mixed gas of hydrogen and argon is fed into the quartz tube at a flow rate of 2000 ml / min, the ratio of hydrogen and argon is 1:1, and normal pressure is maintained. Heat the current collector to 900°C. Maintain the normal pressure and current collector temperature in the quartz tube, and switch the gas inlet to a mixed gas of acetylene and argon after 10 minutes. The flow rate of the mixed gas is 1500 ml / min, the ratio of acetylene and argon is 1:30, the relative humidity of the mixed gas is 55%, and the pressure is kept at normal pressure. Turn on the...

Embodiment 3

[0044] Example 3: Using methane as the carbon source gas to make a vertically oriented graphene electric double layer supercapacitor electrode.

[0045] The current collector is a nickel sheet with a thickness of 0.05 mm, the taper of the needle tip of the needle electrode is 1:10, the distance between the needle tip and the current collector is 1 mm, the inert gas is helium, and the carbon source gas is methane.

[0046] Pass the mixed gas of hydrogen and helium into the quartz tube, the flow rate is 2000 ml / min, the ratio of hydrogen and helium is 1:1, and the normal pressure is maintained. Heat the current collector to 700°C. Maintain the normal pressure and current collector temperature in the quartz tube, and switch the gas intake to a mixed gas of methane and helium after 10 minutes. The flow rate of the mixed gas is 1500 ml / min, the ratio of methane and helium is 1:5, the relative humidity of the mixed gas is 45%, and the normal pressure is maintained. Turn on the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com