A kind of preparation method of high-purity lanthanum stannate nano powder

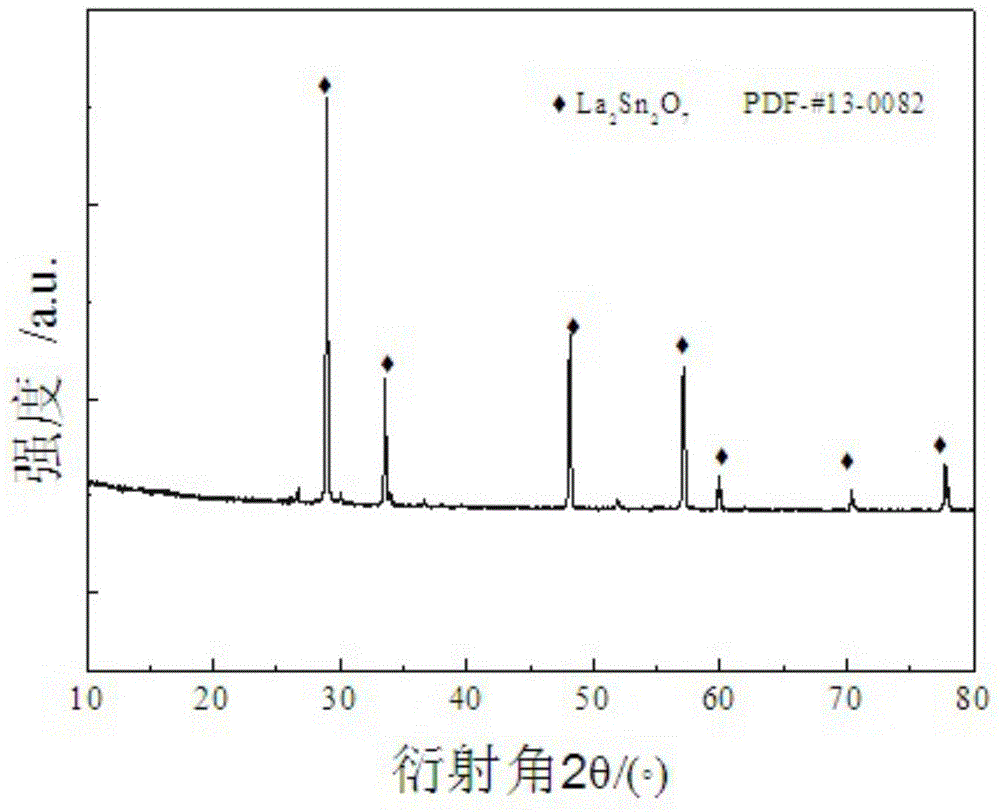

A technology of nano-powder and lanthanum stannate, which is applied in the field of preparation of pure-phase lanthanum stannate nano-powder, which can solve the problem of relatively stringent sintering temperature and sintering time, difficulty in significantly improving synthesis yield, and reaction cycle of synthesis yield. Short and other problems, to achieve the effect of shortened sintering time, fine particles, high degree of particle dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of precursor solution A

[0024] The solute is oxalic acid dihydrate, and the solvent is deionized water; a certain amount of solute is added to the solvent and magnetically stirred until it is completely dissolved, then pipetted into a volumetric flask with a glass rod to constant volume, and prepared into a non-alcoholic solution with a concentration of 0.03mol / L. The color transparent solution is denoted as A solution.

[0025] (2) Preparation of precursor solution B

[0026] The solute is lanthanum nitrate, tin tetrachloride pentahydrate, and the solvent is deionized water; weigh a certain amount of lanthanum nitrate and tin tetrachloride pentahydrate at a molar ratio of 1:1, and introduce them into deionized water with magnetic stirring until completely Dissolve, and then use a glass rod to transfer to a volumetric flask to constant volume, and prepare a colorless and transparent solution with a concentration of 1.5 mol / L, which is recorded as solu...

Embodiment 2

[0033] (1) Preparation of precursor solution A

[0034] The solute is oxalic acid dihydrate, and the solvent is deionized water; a certain amount of solute is added to the solvent and magnetically stirred until it is completely dissolved, then pipetted into a volumetric flask with a glass rod to constant volume, and prepared into a non-alcoholic solution with a concentration of 0.1mol / L. The color transparent solution is denoted as A solution.

[0035] (2) Preparation of precursor solution B

[0036] The solute is lanthanum nitrate, tin tetrachloride pentahydrate, and the solvent is deionized water; weigh a certain amount of lanthanum nitrate and tin tetrachloride pentahydrate at a molar ratio of 1:1, and introduce them into deionized water with magnetic stirring until completely Dissolve, and then use a glass rod to transfer to a volumetric flask to constant volume, and prepare a colorless and transparent solution with a concentration of 0.5 mol / L, which is recorded as B sol...

Embodiment 3

[0043] (1) Preparation of precursor solution A

[0044] The solute is oxalic acid dihydrate, and the solvent is deionized water; a certain amount of solute is added to the solvent and magnetically stirred until it is completely dissolved, then pipetted into a volumetric flask with a glass rod to constant volume, and prepared into a non-alcoholic solution with a concentration of 0.6mol / L. The color transparent solution is denoted as A solution.

[0045] (2) Preparation of precursor solution B

[0046] The solute is lanthanum nitrate, tin tetrachloride pentahydrate, and the solvent is deionized water; weigh a certain amount of lanthanum nitrate and tin tetrachloride pentahydrate at a molar ratio of 1:1, and introduce them into deionized water with magnetic stirring until completely Dissolve, and then use a glass rod to transfer to a volumetric flask to constant volume, and prepare a colorless and transparent solution with a concentration of 0.2 mol / L, which is recorded as solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com