Silver-based electrical contact material curing-granulation powder and preparation method thereof

An electrical contact material, granulated powder technology, applied in nanotechnology, metal processing equipment, nanotechnology and other directions for materials and surface science, can solve the problems of easy hardening and difficult degumming, and achieve uniform particle distribution and production cycle. Short, the effect of achieving a uniform response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

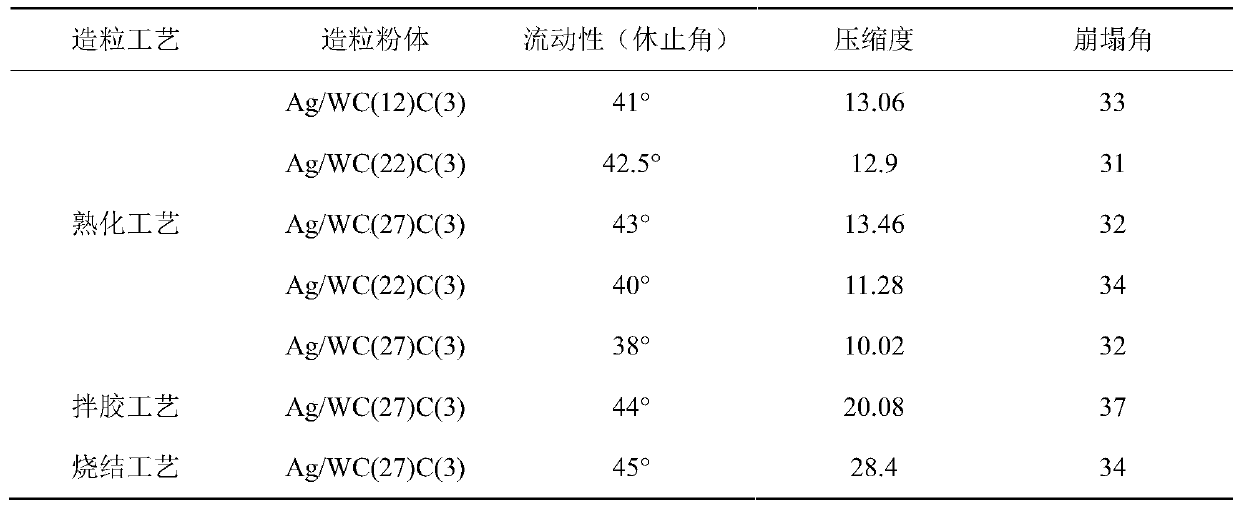

Examples

preparation example Construction

[0026] (1) Preparation of silver solution

[0027] Configure 0.65~0.79mol / L AgNO 3 In the aqueous solution, a certain mass percent (1-5wt.%) surfactant is added, and after fully dissolving, a reducing agent in an equal molar ratio to Ag+ is added to form a silver solution. Wherein, the reducing agent type is glucose, ethylene glycol, ascorbic acid and the like.

[0028] The silver solution prepared in this step is the basic condition for synthesizing high-quality silver nanoparticles. The silver solution system is composed of an oxidation solution, a reduction solution and a surface modifier according to a certain stoichiometric ratio. Then add WC powder and C powder to the silver solution, and use the principle of heterogeneous nucleation to realize uniform coating of Ag particles on the surface of WC powder and C powder.

[0029] (2) Preparation of precursor solution

[0030] Using silver solution, WC, and C powder as raw materials, calculate according to the target gran...

Embodiment 1

[0033] (1) Preparation of silver solution

[0034] Weigh silver nitrate (AgNO 3 ) mass 13.38g, configuration 0.79mol / L, 100ml of AgNO 3 Aqueous solution, add the polyvinylpyrrolidone K30 that accounts for the mass percent of silver nitrate total amount and be 5wt.%, add after fully dissolving and Ag+ same molar ratio (n(Ag + )=0.079mol) of the reducing agent to form a silver solution. Among them, the reducing agent is glucose.

[0035] (2) Preparation of precursor solution

[0036] Using silver solution, WC, and C powder as raw materials, calculate the stoichiometric ratio according to the target granulated powder Ag / WC(12)C(3) and weigh the corresponding raw material ratio content. Weigh 1.2g of tungsten carbide WC powder and 0.3g of graphite C powder, then add the corresponding ratio of WC powder and C powder to the above silver solution, and stir well to form a precursor solution.

[0037] (3) Put the precursor solution into a stirred hydrothermal reaction kettle, add ...

Embodiment 2

[0039] (1) Preparation of silver solution

[0040] Weigh silver nitrate (AgNO 3 ) mass 11.81g, configuration 0.70mol / L, 100ml of AgNO 3 In the aqueous solution, polyvinylpyrrolidone K30 with a mass percentage of 1wt.% of the total amount of silver nitrate is added, and after fully dissolving, a reducing agent with the same molar ratio as Ag+ is added to form a silver solution. Wherein, the reducing agent is ethylene glycol.

[0041] (2) Preparation of precursor solution

[0042] Using silver solution, WC, and C powder as raw materials, calculate the stoichiometric ratio according to the target granulated powder Ag / WC(22)C(3) and weigh the corresponding raw material ratio content. Weigh 2.2g of tungsten carbide WC powder and 0.3g of graphite C powder, then add the corresponding ratio of WC powder and C powder into the silver solution, and stir well to form a precursor solution.

[0043] (3) Put the precursor solution into a stirred hydrothermal reaction kettle, add polyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com