Knotting equipment for cloth or nets

A kind of equipment and technology of stepping motor, applied in the direction of sewing clothes tools, etc., to achieve the effect of avoiding being crooked, quality assurance, and high buckle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

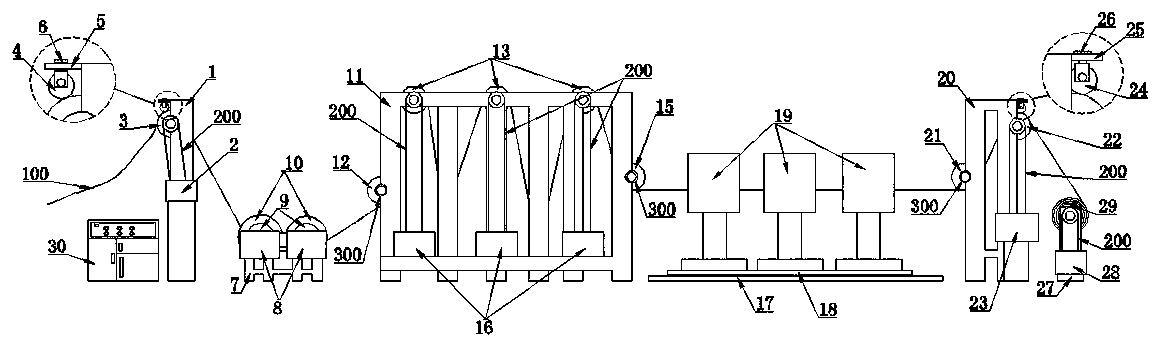

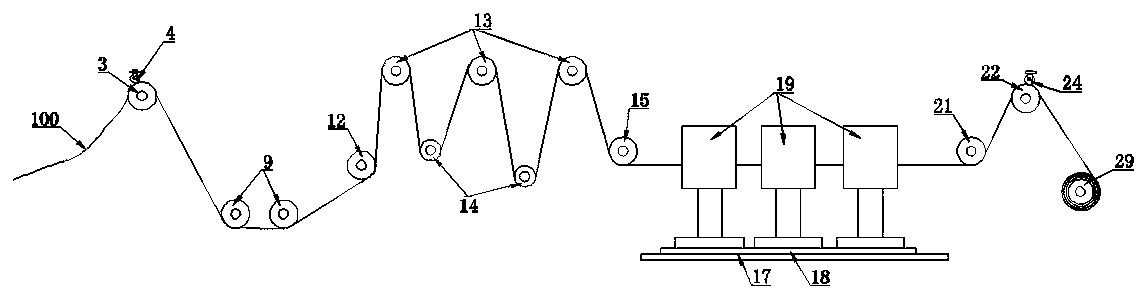

[0054] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a cloth or net buckling equipment includes an input device, a buckle platform and an output device arranged sequentially from front to back; the input device includes a conveyor I, a conveyor II and a tensioning device; the buckle platform is slidably connected with a buckle machine 19; the output device includes an output frame 20, and the output frame 20 is connected to output rollers through bearings 300, and the output rollers include front output rollers 21 and The rear output roller 22; the top of the rear output roller 22 is provided with an output pinch roller 24.

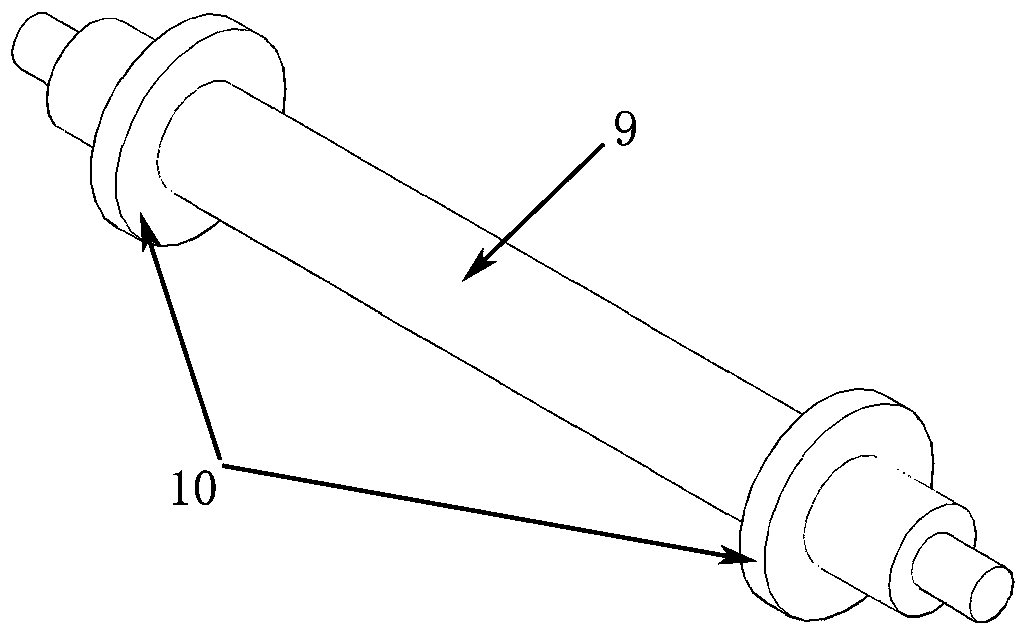

[0055] The conveyor I includes a transmission frame I1, the end of the transmission frame I1 is fixedly provided with a transmission stepper motor I2, and the output end of the transmission stepper motor I2 is connected to a transmission roller I3 through a tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com