Gas mask filter element and machining device and machining method thereof

A gas mask and processing device technology, applied in the cleaning method of using tools, metal processing, breathing masks, etc., can solve the problems of limited ventilation volume, loss of toxicity of poisonous gas, and small amount of ventilation in pores, etc., to achieve increased gas exchange Gas volume, increased ventilation volume, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

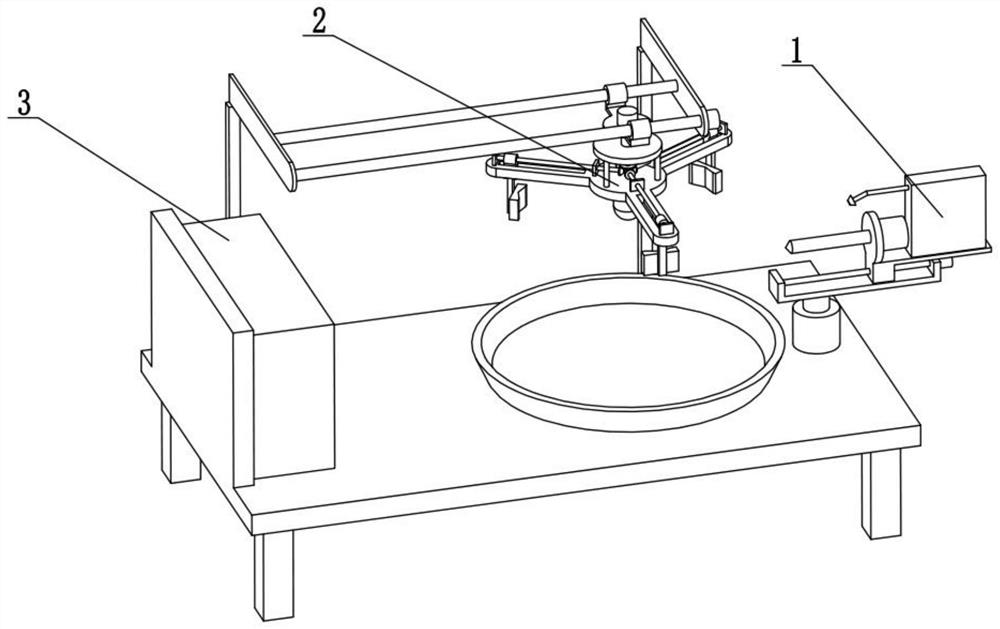

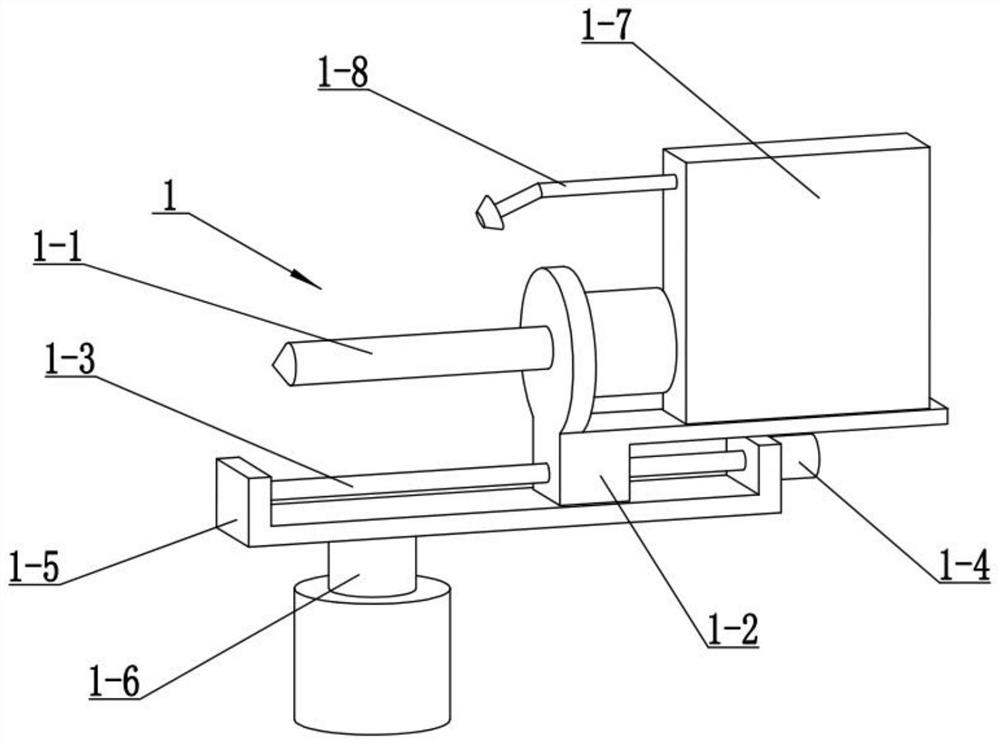

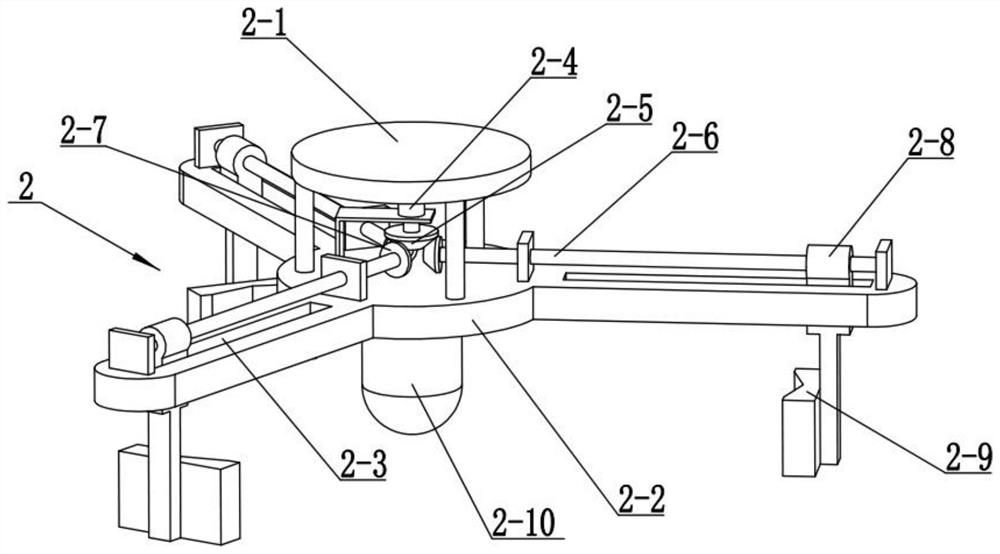

[0028] The present embodiment will be described below in conjunction with the drawings. A gas mask filter element processing device includes a matching drilling mechanism 1, a clamping and rotating mechanism 2, and a cleaning and finishing mechanism 3. The matching drilling mechanism 1 is connected to the right side of the cleaning and finishing mechanism 3. The tight rotating mechanism 2 is connected on the cleaning mechanism 3, and the described cooperating drilling mechanism 1 includes a drill bit punching machine 1-1, a telescopic base 1-2, a rotating screw mandrel 1-3, No. 1 motor 1-4 and telescopic Slideway 1-5, rotating screw mandrel 1-3 is connected on telescopic slideway 1-5, and the right end of rotating screw mandrel 1-3 is fixedly connected on the output shaft of No. 1 motor 1-4, No. 1 motor 1- 4. It is fixedly connected to the telescopic slideway 1-5, and the telescopic base 1-2 is threadedly connected to the rotating screw rod 1-3. The bottom surface of the telesc...

specific Embodiment approach 2

[0031] The present embodiment will be described below in conjunction with the drawings. This embodiment will further illustrate the first embodiment. The described drilling mechanism 1 also includes a lifting cylinder 1-6, and the telescopic slideway 1-5 is fixedly connected to the cylinder of the lifting cylinder 1-6. on the rod; the lifting cylinder 1-6 can drive the telescopic slideway 1-5 to lift, so that the drill bit punching machine 1-1 can be adjusted up and down on the side of the gas mask filter element, and a plurality of evenly spaced holes can be punched in the vertical direction on the side of the gas mask filter element. hole.

specific Embodiment approach 3

[0033] The present embodiment will be described below in conjunction with the drawings. This embodiment will further illustrate the second embodiment. The described coordinating drilling mechanism 1 also includes a cooling water tank 1-7 and a water mist nozzle 1-8, and the water mist nozzle 1-8 is fixedly connected. On the left side of the cooling water tank 1-7, the cooling water tank 1-7 is fixedly connected to the right side of the telescopic base 1-2, and the water mist nozzle 1-8 communicates with the inside of the cooling water tank 1-7; When drilling, the water in the cooling water tank 1-7 can be sprayed on the drill bit of the drill bit punching machine 1-1 through the water mist nozzle 1-8 to cool down the drill bit and prevent the drill bit from overheating and scalding due to rotational friction The gas mask filter element also avoids the wear and tear of the drill bit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com