Intelligent papermaking machine partitioned steam humidifying device

A humidification device, paper machine technology, applied in the paper machine, wetting device, papermaking and other directions, can solve the problems of inconvenient operation, low positioning accuracy, difficulty in quickly putting paper between the steam boxes, etc., to achieve uniform steam spray humidification, Install controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

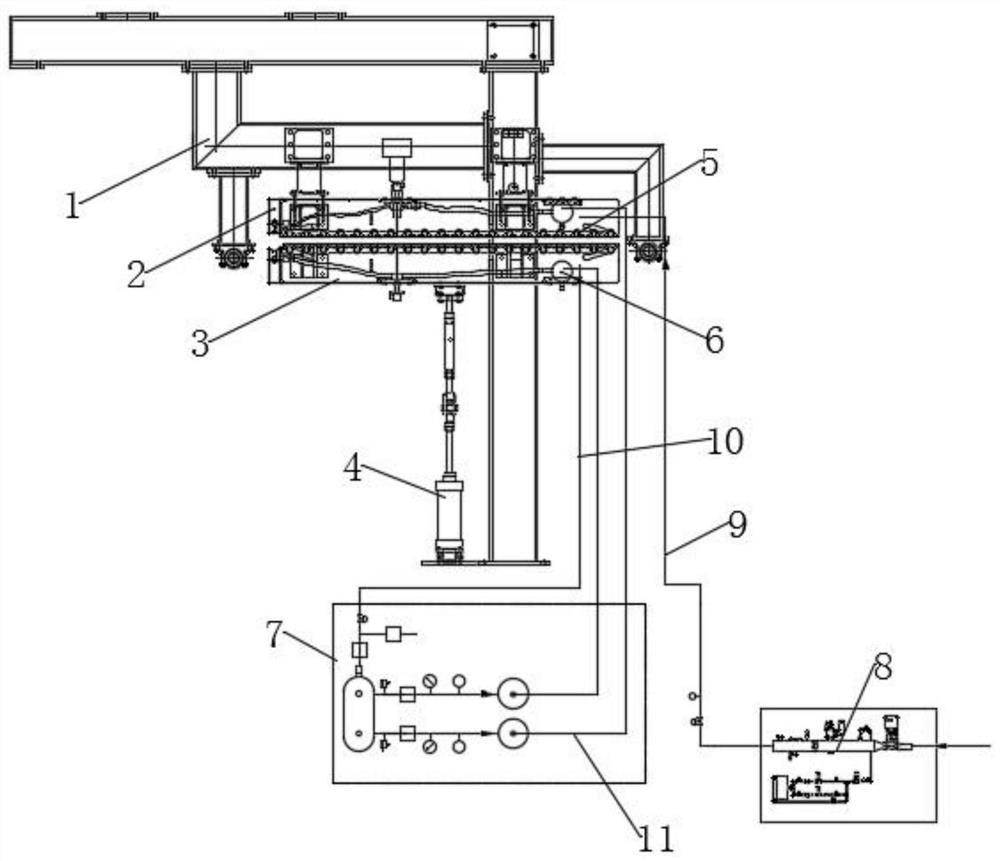

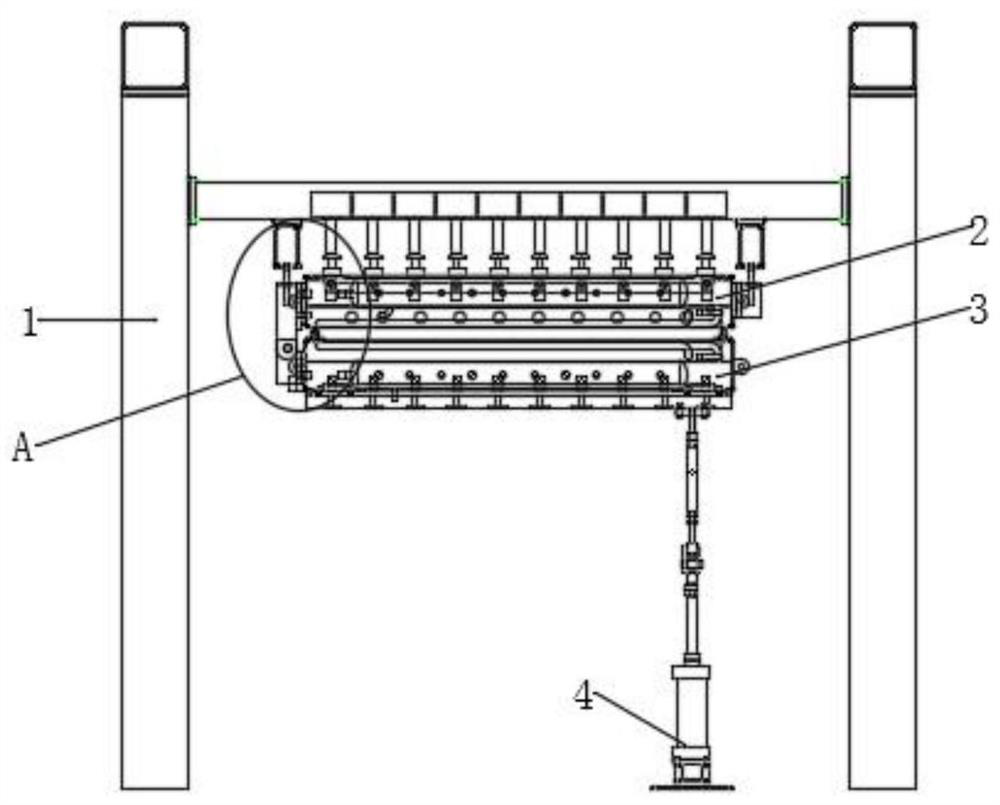

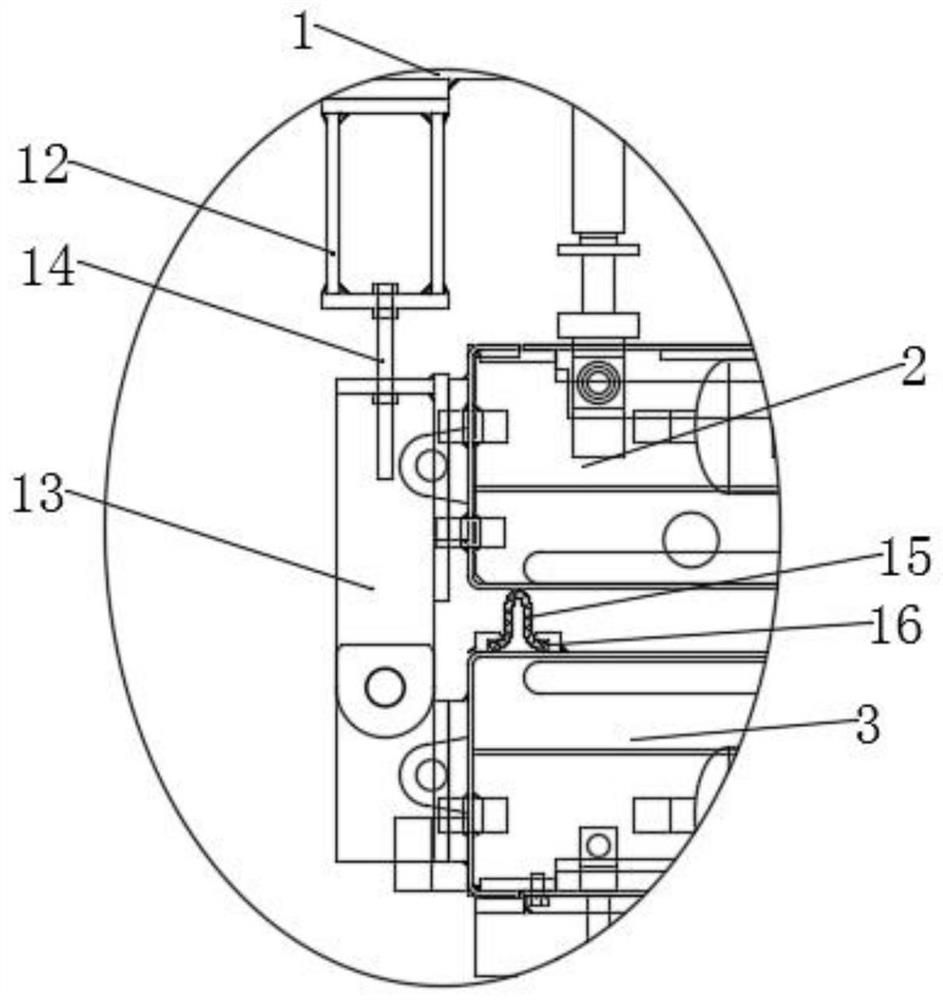

[0030] Example: such as Figure 1 to Figure 9 As shown, the present invention provides a kind of steam humidification device of intelligent paper machine division, comprises frame 1, and upper steam box 2 is fixedly installed on frame 1, and one side of frame 1 is hinged with the side of lower steam box 3, and lower steam The bottom of the other side of the box 3 is hinged to the push rod of the cylinder 4, and the cylinder 4 is hinged to the bottom of the frame 1. The upper steam box 2 and the lower steam box 3 are equipped with a coil pipe 5 and a steam injection assembly 6. There is a steam cabinet 7 on the outside, the input end of the steam cabinet 7 is connected to one end of the coil 5 through the preheated steam outlet pipe 10, and the other end of the coil 5 is connected to the decompression device 8 through the preheated steam inlet pipe 9, and the steam cabinet 7 The output end is connected to the steam injection assembly 6 through the dry steam inlet pipe 11 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com