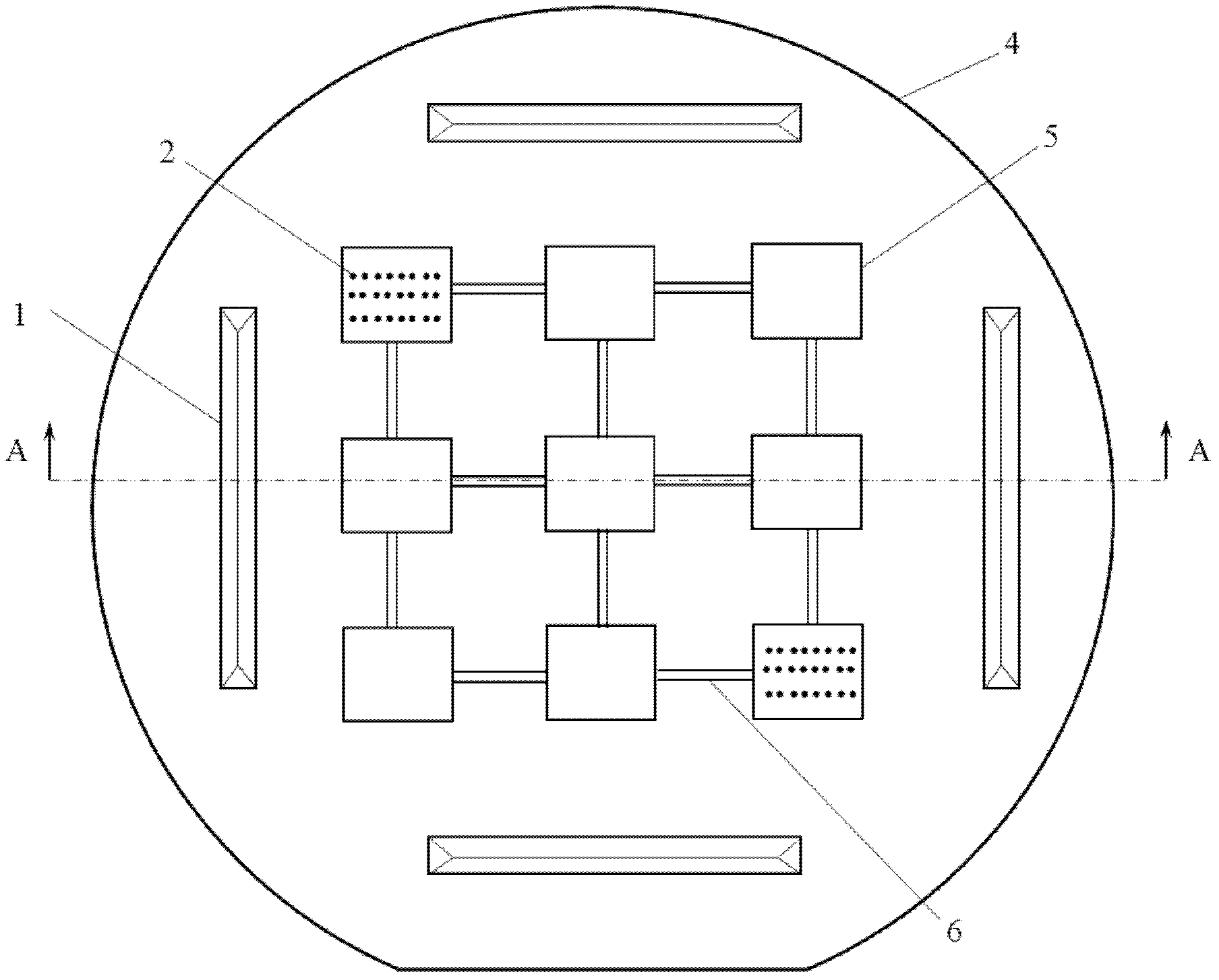

Preparation method of wafer-grade spherical micro-lens array

A microlens array and wafer-level technology, which is applied in the field of preparation of new microlens arrays, can solve the problems of high manufacturing cost of metal molds and high requirements for dimensional control, and achieve the effect of improving mechanical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

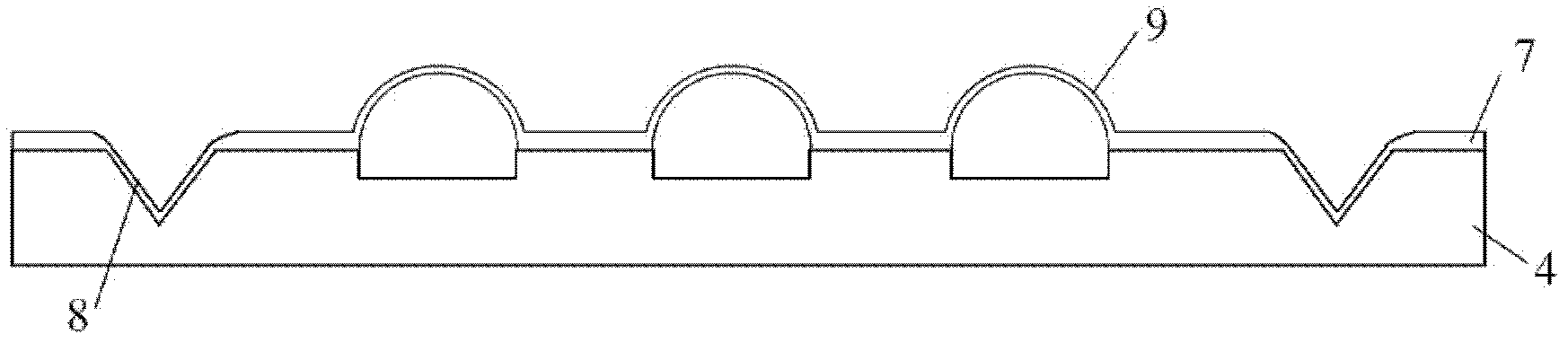

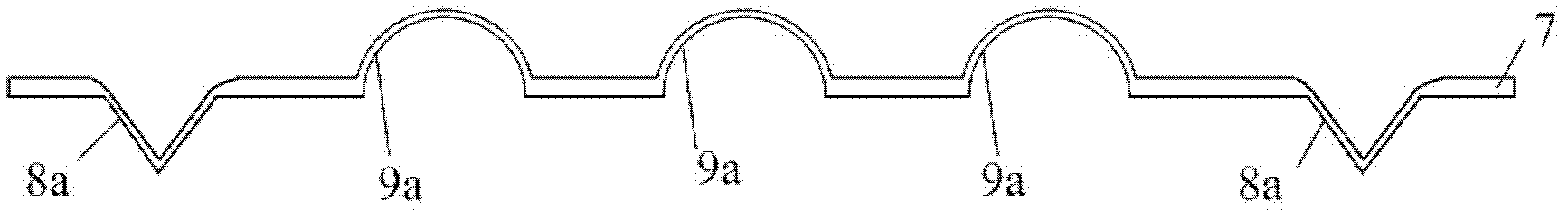

[0025]A method for preparing a wafer-level spherical microlens array, comprising the following steps: in the first step, respectively etching a lens mold microgroove array and a self-aligned silicon mold microgroove on a silicon wafer (such as a 4-inch wafer) to obtain The silicon wafer mold and the microgroove array of the lens mold are etched and connected by microchannels. The process for preparing the pattern structure on the silicon wafer is one or a combination of wet etching process, reactive ion etching (RIE) process or deep reactive ion etching (DRIE); in the second step, in the A certain amount of thermal air release agent powder is placed in the lens mold micro-groove array of the silicon wafer. The thermal air release agent is a powder that can release gas after heating, calcium carbonate powder or titanium hydride powder, and the powder particle size is 300 mesh or 800 mesh. Or 1000 mesh. The added mass is calculated according to the size of the required molding ...

Embodiment 2

[0028] A method for preparing a wafer-level spherical microlens array, comprising the following steps:

[0029] The first step: using 25% TMAH solution wet etching method to etch the shape on a 4-inch silicon wafer to form a microcavity array of a specific size.

[0030] The second step: coating a thermal air release agent in part of the microcavity array. The heat release agent is a powder that can release gas after heating, such as calcium carbonate powder or titanium hydride powder, and the particle size of the powder is 300 mesh, 800 mesh or 1000 mesh. The added mass is calculated according to the size of the required molding cavity, for example, if calcium carbonate is used, the mass can be 0.1mg, 0.5mg, 1mg, 1.5mg, 2mg.

[0031] Step 3: bonding the borosilicate glass wafer to the silicon wafer mold, so that the microcavity array of the silicon wafer mold is sealed. In the present invention, the glass is Pyrex7740 glass, the bonding is anodic bonding, and the typical pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com