Graphene oxide preparation method with controllable inter-layer spacing

A graphene, interlayer spacing technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of long reaction time, small interlayer spacing, complex processing, etc., to achieve short experimental period, large interlayer spacing, experimental simple conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

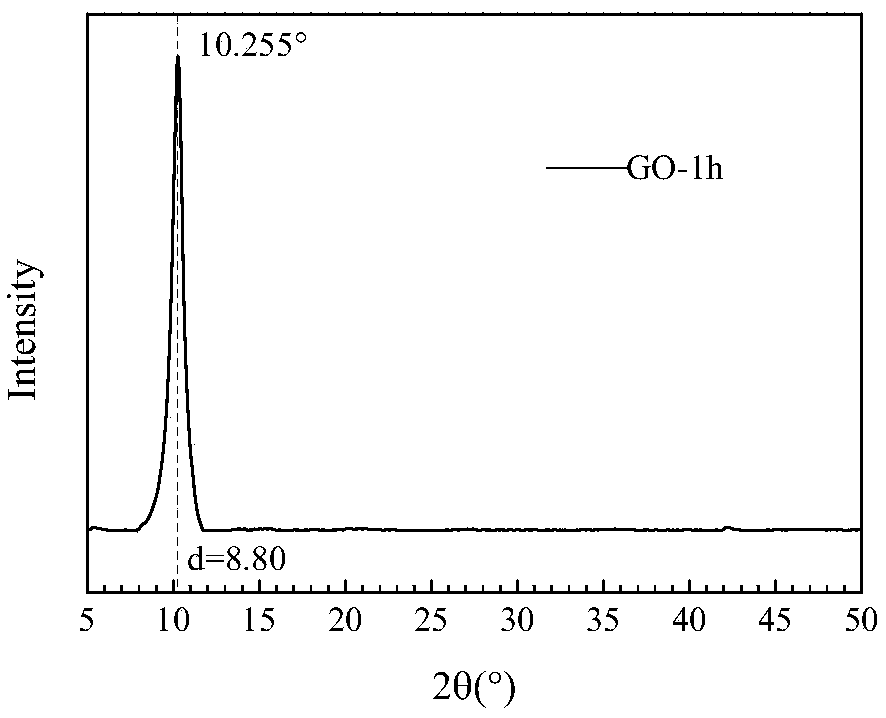

[0024] The specific steps of the preparation method of graphene oxide in the present embodiment are as follows:

[0025] (1) Add 1 mL of concentrated H 2 SO 4 , 0.2gK 2 S 2 o 8 and 1gNaNO 3 Add it to a 50mL flask, stir vigorously in an ice-water bath for 1h, add 2g of graphite powder, stir for 0.2h until the color of the mixture turns black, raise the temperature to 80°C and continue the reaction for 0.2h, stop stirring, cool to room temperature, and use Diluted with ionized water, filtered to obtain a solid, washed to neutral, and dried for later use;

[0026] (2) All the solids obtained in the previous step were added to a 250mL flask, and then 10mL of concentrated H 2 SO 4 , slowly add 1gKMnO 4 , keep at 20°C for 1h, raise the temperature to 30°C for 1h, slowly add 100mL deionized water to the mixture, raise the temperature to 95°C, continue stirring for 15 minutes; cool to room temperature, add 1mL 30wt% H 2 o 2 , stirred for a while to obtain a mixed solution; ...

Embodiment 2

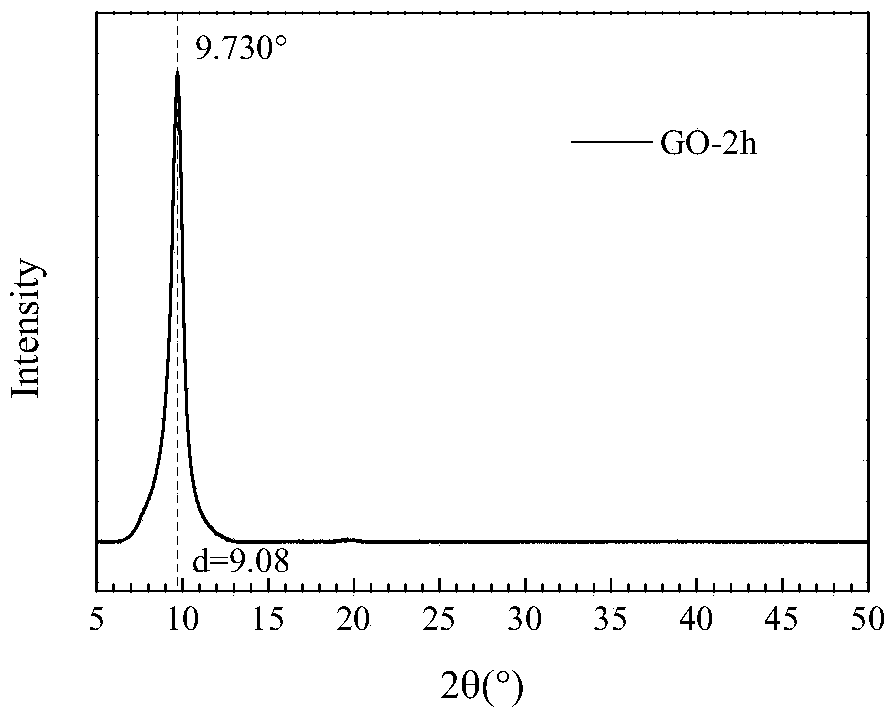

[0029] The specific steps of the chemical preparation method of graphene oxide in the present embodiment are as follows:

[0030] (1) Add 1 mL of concentrated H 2 SO 4 , 1gK 2 S 2 o 4 and 0.2g NaNO 3 Add it to a 50mL flask, stir vigorously in an ice-water bath for 0.2h, add 5g of graphite powder, and stir for 0.2h until the color of the mixture turns black, raise the temperature to 60°C and continue the reaction for 1h, stop stirring, cool to room temperature, and use Diluted with ionized water, filtered to obtain a solid, washed to neutral, and dried for later use;

[0031] (2) All the solids obtained in the previous step were added to a 250mL flask, and then 45mL of concentrated H 2 SO 4 , slowly add 6gKMnO 4 , keep at 10°C for 0.2h, raise the temperature to 40°C for 2h, slowly add 100mL of deionized water to the mixture, raise the temperature to 100°C, continue stirring for 5 minutes; cool to room temperature, add 6mL of 30wt% H 2 o 2 , stirred for a while to obta...

Embodiment 3

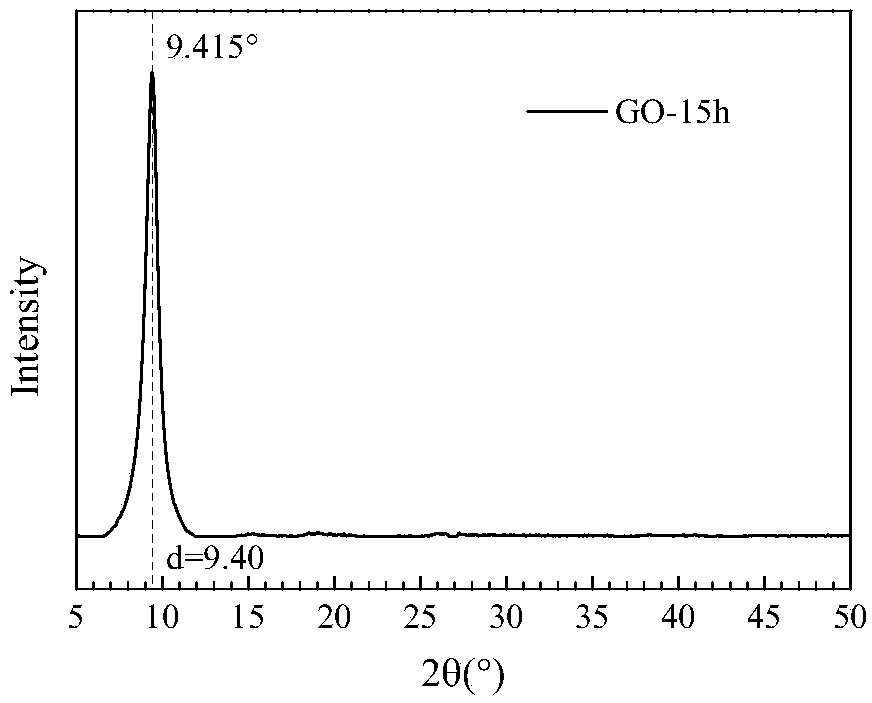

[0034] The specific steps of the chemical preparation method of graphene oxide in the present embodiment are as follows:

[0035] (1) Dissolve 5 mL of concentrated H 2 SO 4 , 1gK 2 S2 o 4 and 1gNaNO 3 Add it into a 50mL flask, stir vigorously in an ice-water bath for 1h, add 2g of graphite powder, and stir for 1h until the color of the mixture turns black, raise the temperature to 80°C and continue the reaction for 0.2h, stop stirring, cool to room temperature, and use a deionized Dilute with water, filter to obtain a solid, wash until neutral, and dry for later use;

[0036] (2) All the solids obtained in the previous step were added to a 250mL flask, and then 45mL of concentrated H 2 SO 4 , slowly add 6gKMnO 4 , keep at 10°C for 1h, raise the temperature to 30°C for 15h, slowly add 150mL of deionized water to the mixture, raise the temperature to 95°C, continue stirring for 15 minutes; cool to room temperature, add 6mL of 30wt% H 2 o 2 , stirred for a while to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com