Rigid rapier loom 1 multiple 4 multi-shuttle box mechanism

A technology of rapier looms and shuttle boxes, which is applied in looms, fabrics, textiles, etc., and can solve the problems of low weft yarn discontinuity precision and the inability to weave small diameter tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

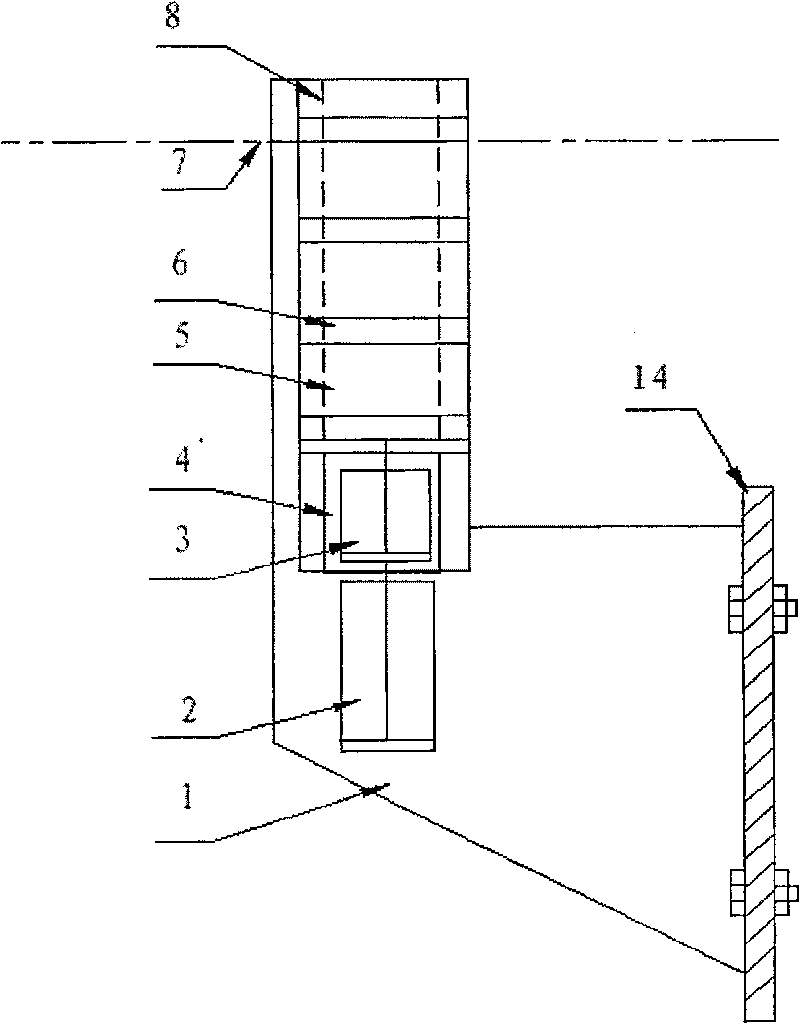

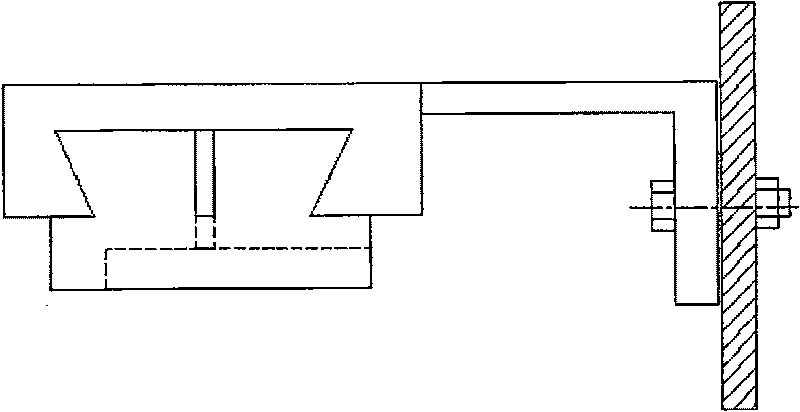

[0020] Embodiment 1: the bracket 1 is fixed on the left baffle plate of the loom, and the material is angle steel; the orientation chute 8 is fixed on the bracket 1 by screws, and the material is aluminum alloy ZALSI12, and the back of the shuttle box 5 is a T-shaped protrusion, which is connected to the The directional chute 8 is a sliding fit; the cylinder 3 is fixed on the movable slide 4, and the movable slide 4 and the directional chute 8 are also in a sliding fit. The front of the shuttle storage box 5 has a T-shaped slot for the shuttle to enter and exit, and the material is hard. plastic.

Embodiment 2

[0021] Embodiment 2: the bracket 1 is fixed on the left baffle plate of the loom, and the material is angle steel; the directional chute 8 is fixed on the bracket by screws, and the material is aluminum-silicon alloy ZALSI12, and the back of the shuttle box 5 is a dovetail-shaped protrusion, which is connected to the The directional chute 8 is a sliding fit; the cylinder 3 is fixed on the movable slide 4, and the movable slide 4 and the directional chute 8 are in a sliding fit. The material is aluminum alloy ZL102, and the front of the shuttle storage box 5 has a dovetail groove for the shuttle to enter and exit. , the material is aluminum alloy ZL102.

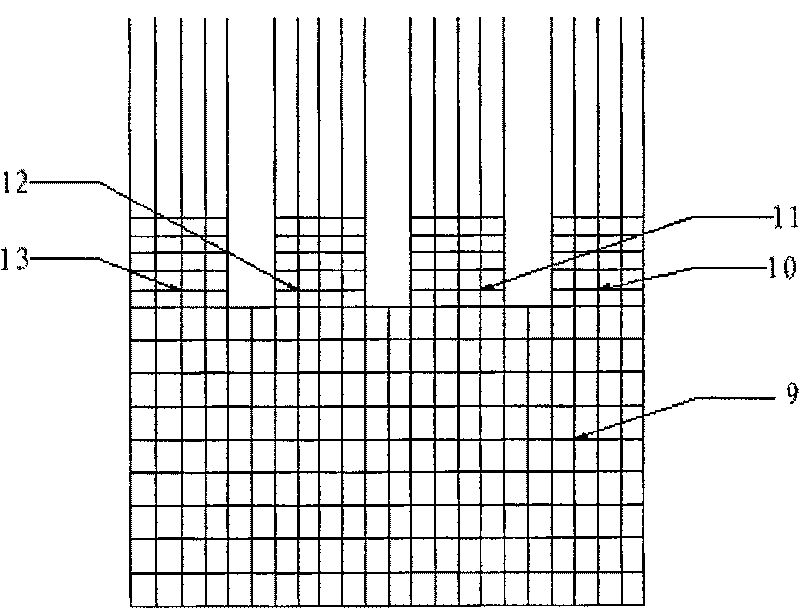

[0022] Taking the four-cross single-layer tubular fabric as an example, the features of the present invention and the kinematic coordination relationship between the various parts are as follows:

[0023] like Figure 4 , shown in 5, the initial state: the pistons of the first cylinder 2 and the second cylinder 3 do not stret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com