Multi-head embroidery machine shuttle box assembly with thread buckling mechanism, and embroidery machine

An embroidery machine and shuttle box technology, applied in the field of embroidery equipment, can solve problems such as small driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

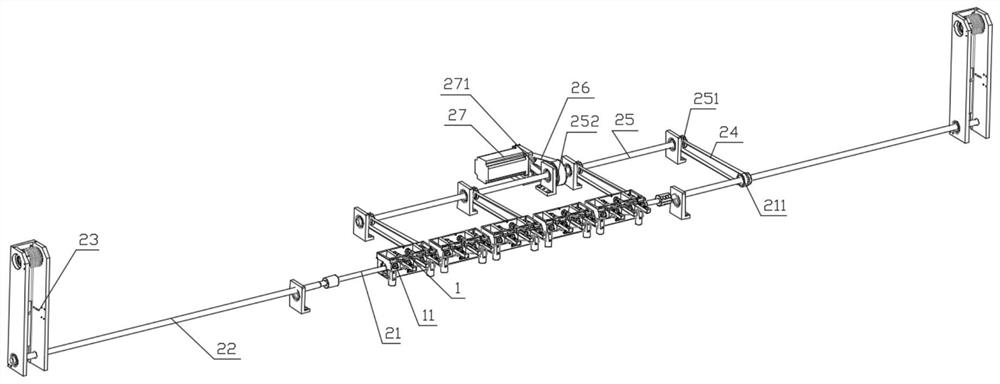

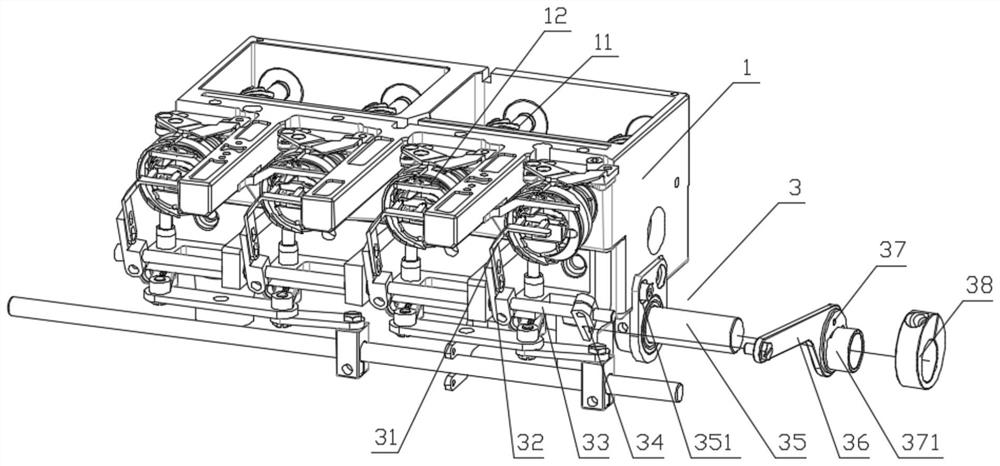

[0029] Such as figure 1 with figure 2 As shown, a multi-head embroidery machine shuttle box assembly with a hook thread mechanism includes a plurality of shuttle boxes 1 arranged side by side, the shuttle box is provided with a rotary hook shaft 11 and a rotary hook 12 connected to the rotary hook shaft 11, It also includes a multi-head rotary hook lower shaft drive mechanism 2 and a wire thread mechanism 3.

[0030] Such as figure 1 The shown multi-head rotary hook lower shaft drive mechanism 2 includes a lower shaft that passes through the plurality of shuttle boxes transversely, the lower shaft is connected to the rotary hook shaft in transmission, and the two ends of the lower shaft correspond to the two upper and lower shafts. The transmission box 23 is transmission connected. The drive mechanism for the lower shaft of the multi-head rotary hook also includes an auxiliary shaft 25 arranged parallel to the lower shaft. The auxiliary shaft 25 is driven by an auxiliary s...

Embodiment approach

[0031] As an implementation, the transmission assembly includes the lower shaft driving pulley 251 installed on the auxiliary shaft, the lower shaft driven pulley 211 installed on the lower shaft, and the lower shaft driving pulley and the lower shaft driven pulley. The first drive belt 24 .

[0032] Further, the motor shaft of the auxiliary shaft motor 27 is connected with the auxiliary shaft driving pulley 271, the auxiliary shaft driven pulley 252 is installed on the auxiliary shaft 25, the auxiliary shaft driving pulley 271 and the auxiliary shaft driven The second transmission belt 26 is connected between the pulleys 252 .

[0033] Preferably, the transmission belt 24 is a timing belt, and the lower shaft driving pulley 251 , the lower shaft driven pulley 211 , the auxiliary shaft driving pulley 271 and the auxiliary shaft driven pulley 252 are all timing pulleys. The lower shaft driving pulley and the lower shaft driven pulley have the same diameter, and the auxiliary s...

Embodiment 2

[0040] An embroidery machine includes the above-mentioned multi-head embroidery machine shuttle box assembly with a thread clamping mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com