A high-efficiency and environment-friendly cylindrical sieve washing machine

A screening washing machine, environmental protection technology, applied in the direction of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of shortening the service life of equipment, easy damage of transmission parts, and affecting production efficiency, so as to save equipment investment and extend Long service life and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

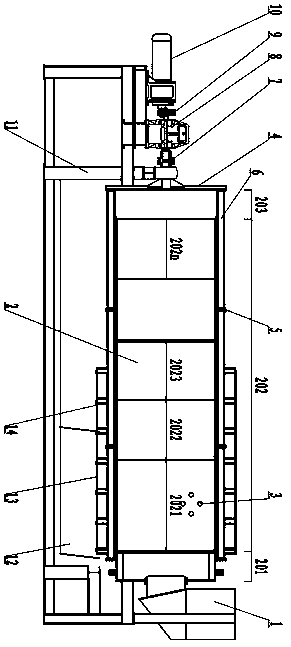

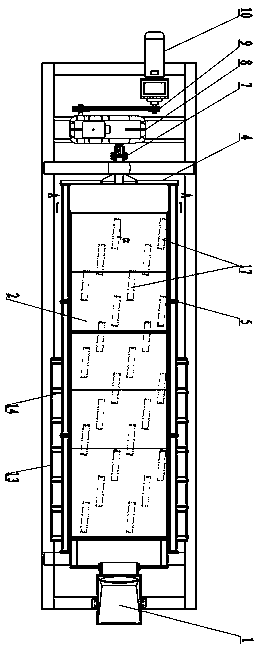

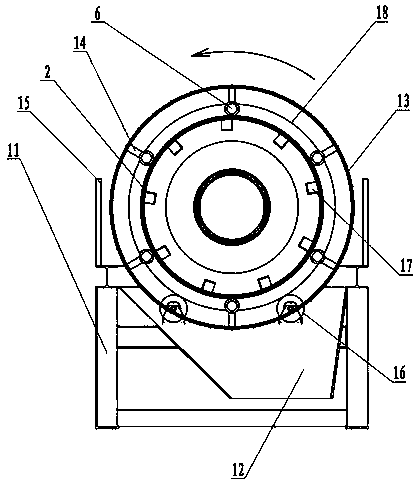

[0023] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

[0024] like Figure 1-Figure 3 Shown is the high-efficiency and environment-friendly cylindrical screen washing machine of the present invention, which includes a drum provided with a feed hopper 1, a collecting hopper 12 located at the bottom of the drum, and a driving device arranged on a bracket 11, and the driving device includes a rolling ring 18 1. The two supporting wheels 16 arranged on both sides of the bottom of the rolling ring 18 and the coupling 7, the reducer 8, the pulley 9 and the motor 10 connected to the inner cylinder panel 4 in sequence, and the rolling ring 18 is arranged on the inner cylinder body 2 On one end close to the feed hopper 1, the coupling 7 is a roller chain coupling. The drum includes an inner cylinder body 2 and inner cylinder panels 4 at both ends, the feed hopper 1 is arranged at one end of the inner cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com