Motor with two-end output

A technology of output shaft and motor body, which is applied in the direction of electrical components, electromechanical devices, electric components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

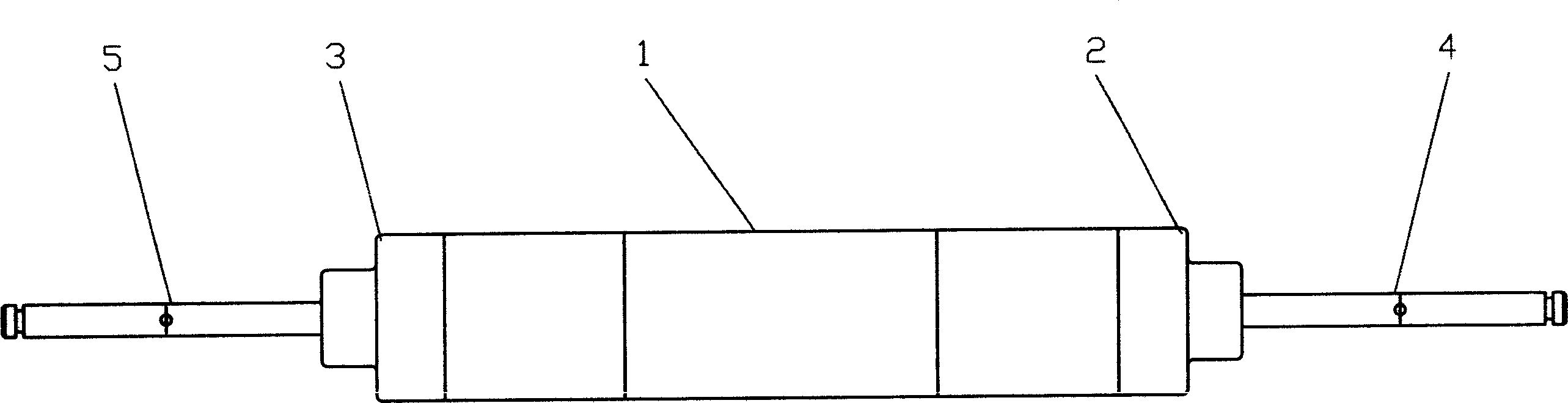

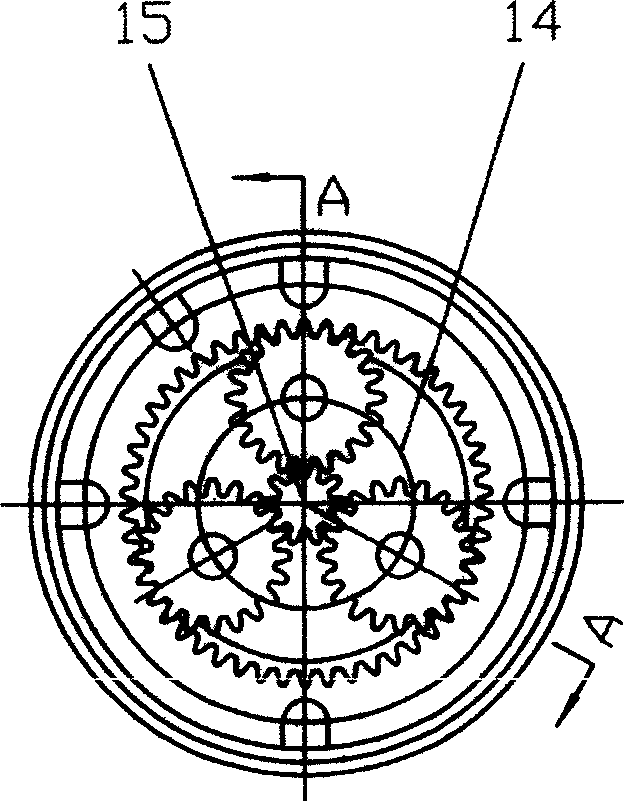

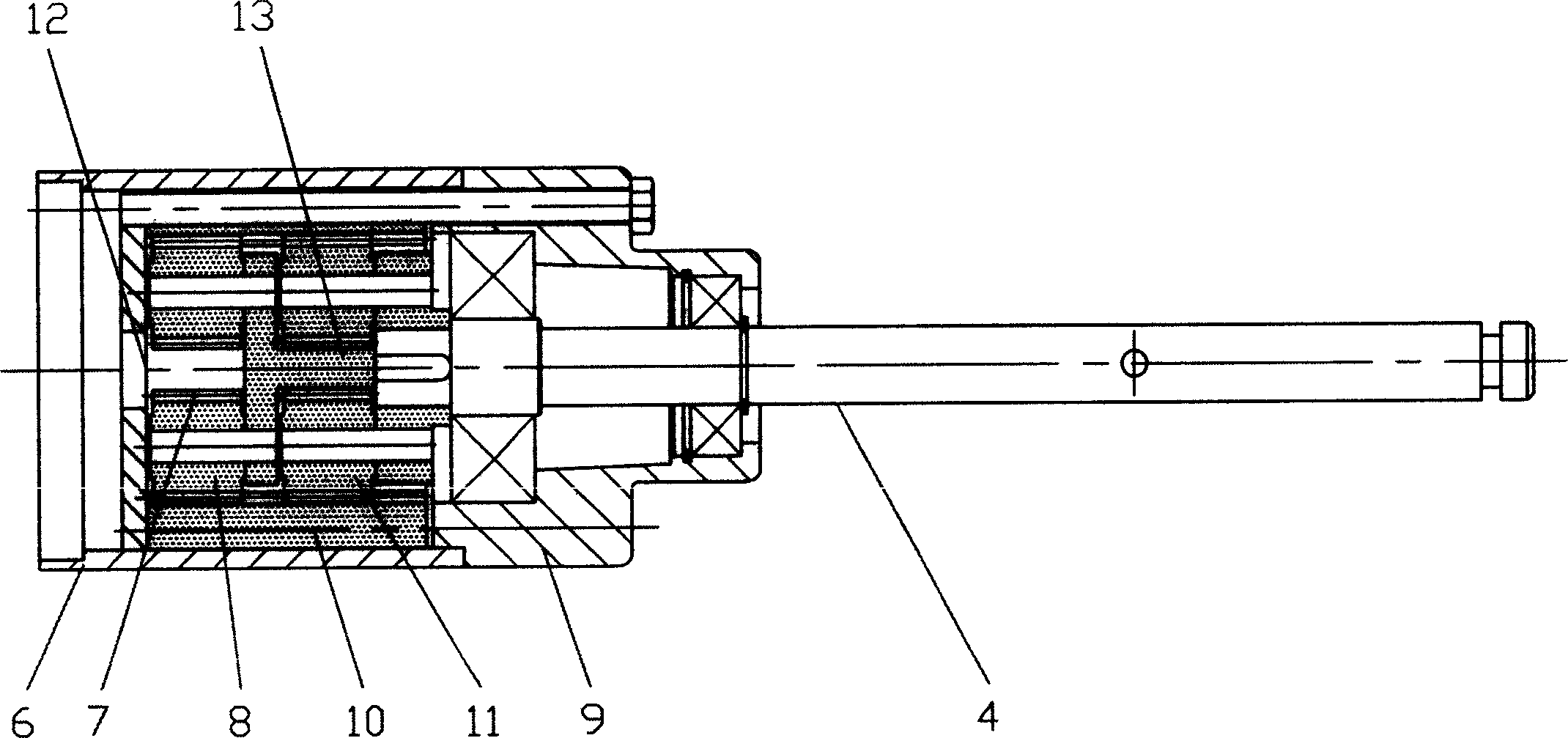

[0011] refer to figure 1 , The motor output at both ends, the motor body 1 adopts a standard permanent magnet DC motor with a power of 150W, and both ends of the motor body 1 are provided with a transmission shaft and gear reduction boxes 2 and 3. refer to figure 2 , 3 , the figure shows the structure of the gear box 2 at the right end. The gear reduction box 2 includes a box body 6, a box cover 9, a reduction gear set and an output shaft 4. The reduction gear set includes a first gear 7, a second gear 8, a third gear 10, and a fourth gear that mesh with each other in sequence. 11 and the output gear 13, the first gear 7 is sleeved on the transmission shaft 12 of the motor body, the output gear 13 is connected with the output shaft 12; the first gear 7 is connected with the second gear 8, the fourth gear 11 External meshing is used with the output gear 13 , and internal meshing is used between the second gear 8 and the third gear 10 and the third gear 10 and the fourth gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com