Sluice valve with high sealing property

A high-sealing and high-performance technology, applied in shaft seals, sliding valves, valve details, etc., can solve the problem of reducing the transmission force of the valve stem, achieve the effect of reducing the transmission force of the polished rod, preventing the thread from being stuck, and improving the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

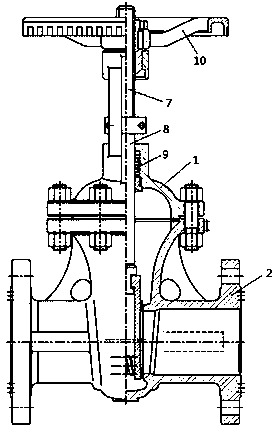

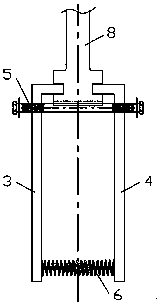

[0019] Example 1, such as Figure 1 to Figure 3 As shown in , the present invention is a gate valve with high sealing performance, including a valve stem, a valve cover 1, a valve seat 2 and a gate plate; the valve cover 1 encapsulates the fixedly connected valve stem and gate plate in the valve seat 2, The valve stem is the sealing actuator of the gate; the valve stem drives the gate to move up and down to open and close the valve seat 2; the gate is a double gate structure composed of a left gate 3 and a right gate 4; the left gate 3 And the upper part of the right flashboard 4 is fixed by the bolt 5, and the inner side of the lower part is elastically supported by the spring 6.

[0020] The integral gate in the prior art is usually supported by castings, and its compression is at most 3%, and the fluid medium on both sides does not produce rebound after compression, so the seal of the gate will be poor. The gate valve in the present invention has a structure of single gate...

Embodiment 2

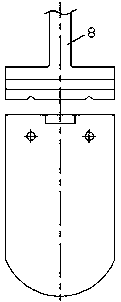

[0022] Example 2, such as figure 1 and Figure 4 As shown in , the valve rod is composed of a fixedly connected screw rod 7 and a polished rod 8; the screw rod 7 rises or falls relative to the threaded rotation of the valve cover 1, and the polished rod 8 rises or falls linearly relative to the valve cover 1; the lower end of the polished rod 8 is connected to the The top of the gate plate is snapped connected; the fixed connection between the screw rod 7 and the polished rod 8 is a clamp connection, a hook connection or a shrink-fit connection; a non-metallic sealing packing 9 is provided between the polished rod 5 and the valve cover 1, The non-metal sealing packing 9 is made of flexible graphite or polytetrafluoroethylene.

[0023] Three fixed connection methods of screw and polished rod: such as figure 1 As shown in , the connection mode between the screw rod 7 and the polished rod 8 is a clamp connection, that is, the screw rod 7 and the polished rod 8 are clamped and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com