Tea enzyme deactivation machine

A greening machine and tea technology, which are applied in the direction of tea processing before extraction, can solve the problems that the tea leaves cannot be heated uniformly, are inconvenient for tea feeding and unloading, and are hardened, so as to achieve automatic control, facilitate all-round greening, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

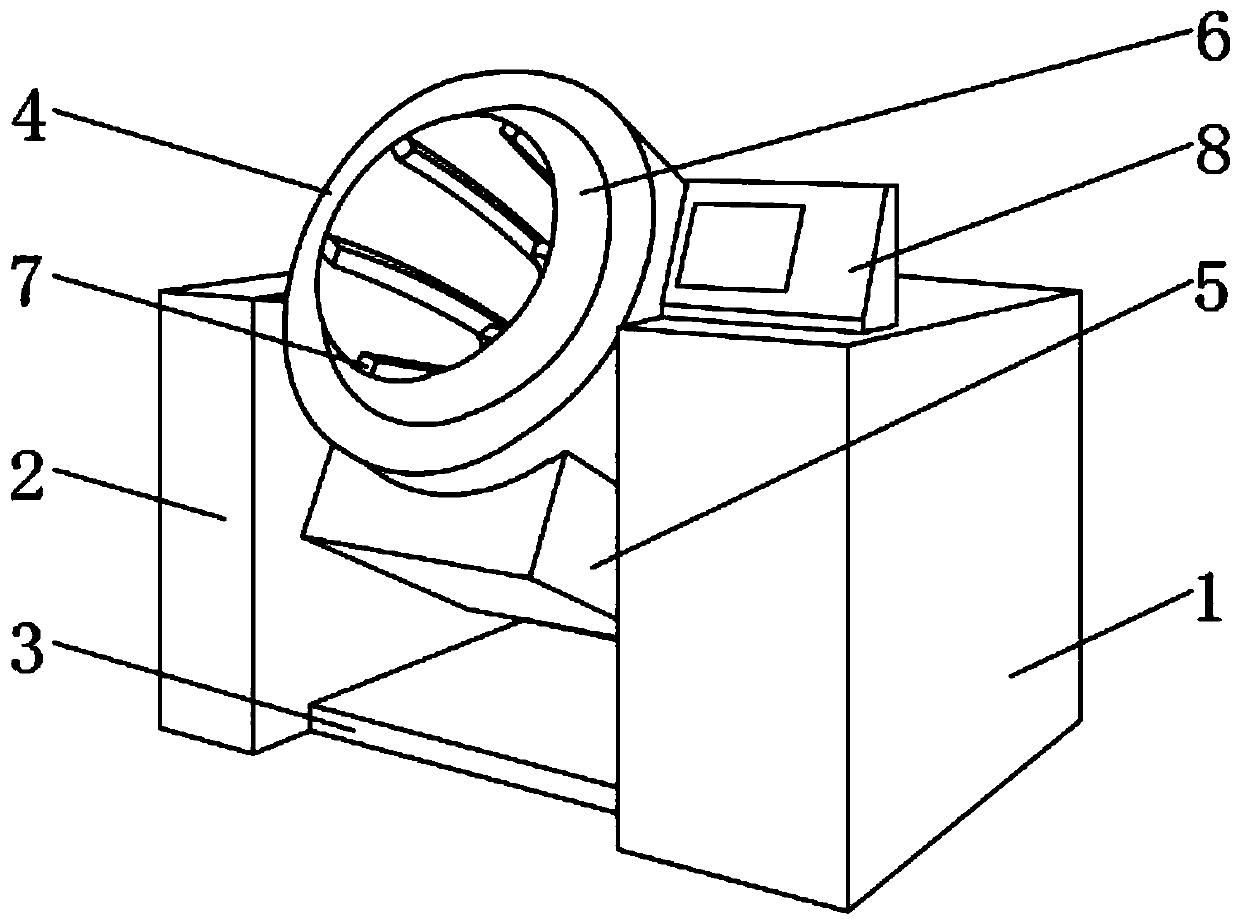

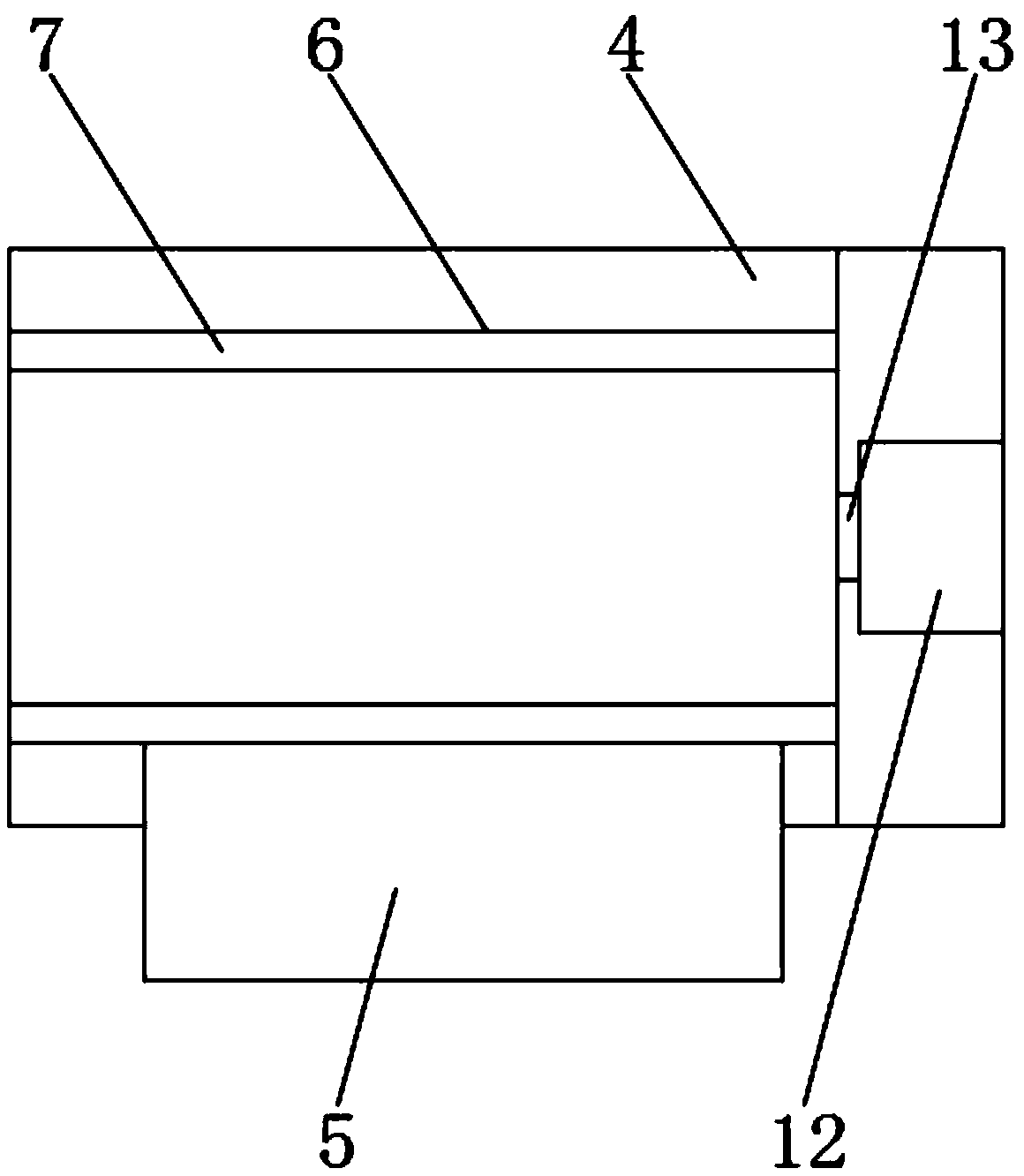

[0027] Such as Figure 1-6 As shown, a tea greening machine includes an electric control box 1, a connecting plate 3 is fixedly installed on one side of the bottom of the electric control box 1, a base box 2 is fixedly installed on one side of the connecting plate 3, the electric control box 1, the base The box 2 and the connecting plate 3 form a supporting base, and a casing 4 is arranged between the electric control box 1 and the base box 2, and two sets of rotating rods 9 are fixedly installed on the outer surface of the casing 4, and the two groups of rotating rods 9 are symmetrically distributed with respect to the casing 4 Two groups of rotating rods 9 penetrate through the upper end of the electric control box 1 and the base box 2 respectively, gears are fixedly installed on the outer peripheral surface of the rotating rod 9 inside the base box 2, and a transmission belt 17 is installed on the outer peripheral surface of the gears. , the inside of the bottom end of the ...

Embodiment 2

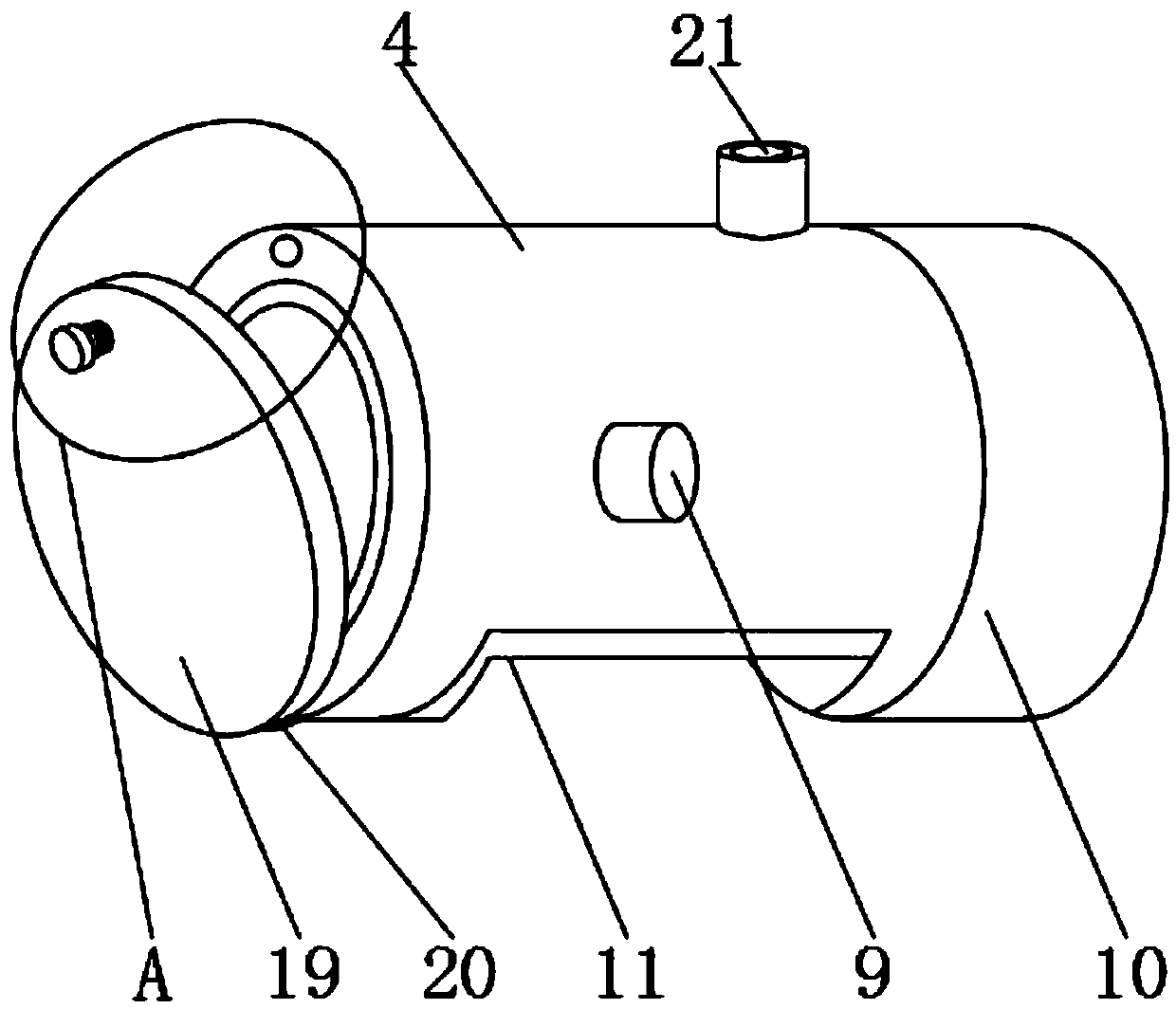

[0030] Such as Figure 1-6 As shown, the outer bottom of the shell 4 is provided with a through hole 11, the inside of the through hole 11 is fixedly installed with a heating box 5, the inside of the shell 4 is sleeved with an inner cylinder 6, and one end of the shell 4 is fixedly installed with a motor box 10. The other end of 4 is provided with a cylinder door 19, one side of the shell 4 is provided with a smoke vent 21, the inner wall of the inner cylinder 6 is fixedly installed with six sets of stirring ribs 7, and the inside of the heating box 5 is provided with several sets of heating wires 18, The bottom of the smoke vent 21 is located between the shell 4 and the inner tube 6, and the bottom inner wall of the smoke vent 21 is fixedly equipped with a filter screen, the inside of the heating box 5 is provided with a temperature controller, the rotating motor 12, the motor 14, The input ends of the temperature controller and the heating wire 18 are electrically connected ...

Embodiment 3

[0032] Such as Figure 1-6As shown, it includes the electric control box 1, the connection plate 3 is fixedly installed on the bottom side of the electric control box 1, the base box 2 is fixedly installed on one side of the connection plate 3, the electric control box 1, the base box 2 and the connection plate 3 A support base is formed, a casing 4 is arranged between the electric control box 1 and the base box 2, and two sets of rotating rods 9 are fixedly installed on the outer surface of the casing 4, and the two groups of rotating rods 9 are symmetrically distributed with respect to the casing 4, and the two groups of rotating rods 9 Respectively run through the upper end of the electric control box 1 and the base box 2, the outer circumferential surface of the rotating rod 9 inside the base box 2 is fixedly equipped with gears, the outer circumferential surface of the gears is provided with a transmission belt 17, and the bottom end of the transmission belt 17 A transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com