Special-shaped cigarette conveying device of tobacco packaging machine

A technology of conveying device and pushing device, which is applied in the directions of packaging, transportation packaging, transportation and packaging, etc., which can solve the problem of difficult positioning of cartons, and achieve the effect of good assembly compactness, high precision, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

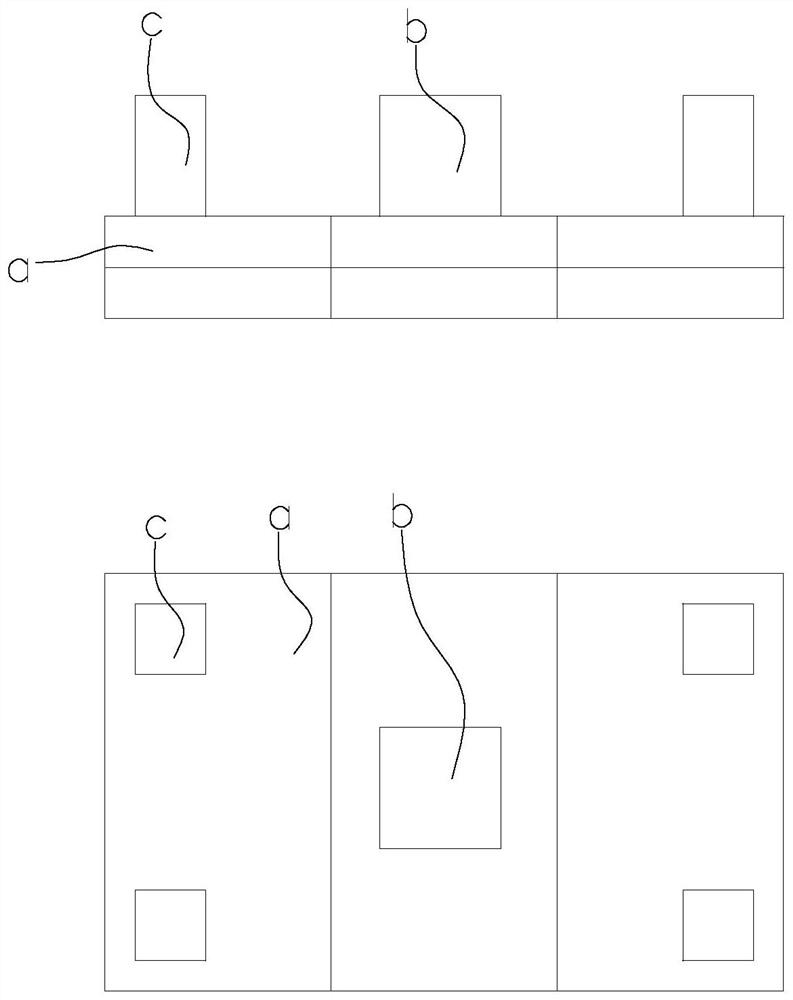

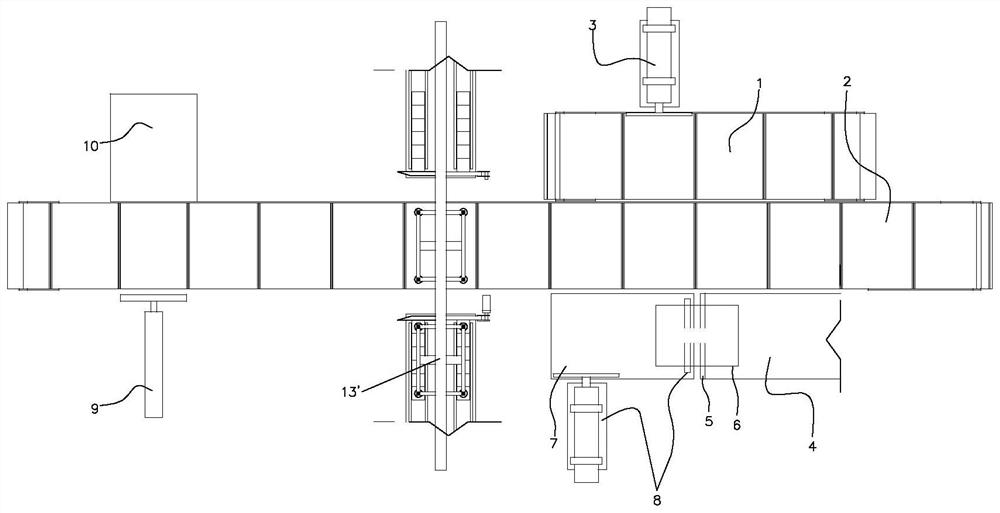

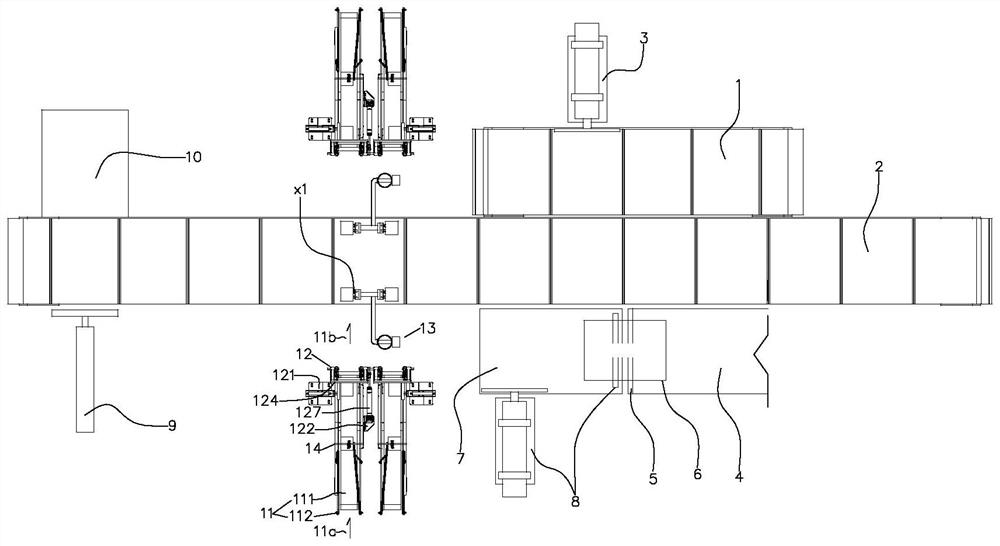

[0037] refer to Figures 1 to 13 This embodiment provides a special-shaped cigarette conveying device for a tobacco packaging machine, including a first conveying belt 1 for conventional smoke input, a transfer conveying belt 2 arranged in parallel with the first conveying belt 1, and a first conveying belt 1 for transferring the first conveying belt 1. The conventional cigarettes are transferred to the first pusher 3 on the transfer conveyor belt 2, the second conveyor belt 4 for the input of special-shaped cigarettes, the baffle plate 5 located on one side of the second conveyor belt 4, the parallel robot 6, the lifting and lowering The platform 7, the second pusher 8 for transferring the special-shaped smoke on the supporting platform to the transfer conveyor belt 2, the output station 10, and the mixed smoke for transferring the mixed smoke on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com