Production process of low-viscosity iron oxide yellow

A technology of iron oxide yellow, production process, applied in dyeing low molecular organic compound treatment, chemical instruments and methods, dyeing organosilicon compound treatment, etc. It can reduce the viscosity of the slurry and improve the uniformity of the slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

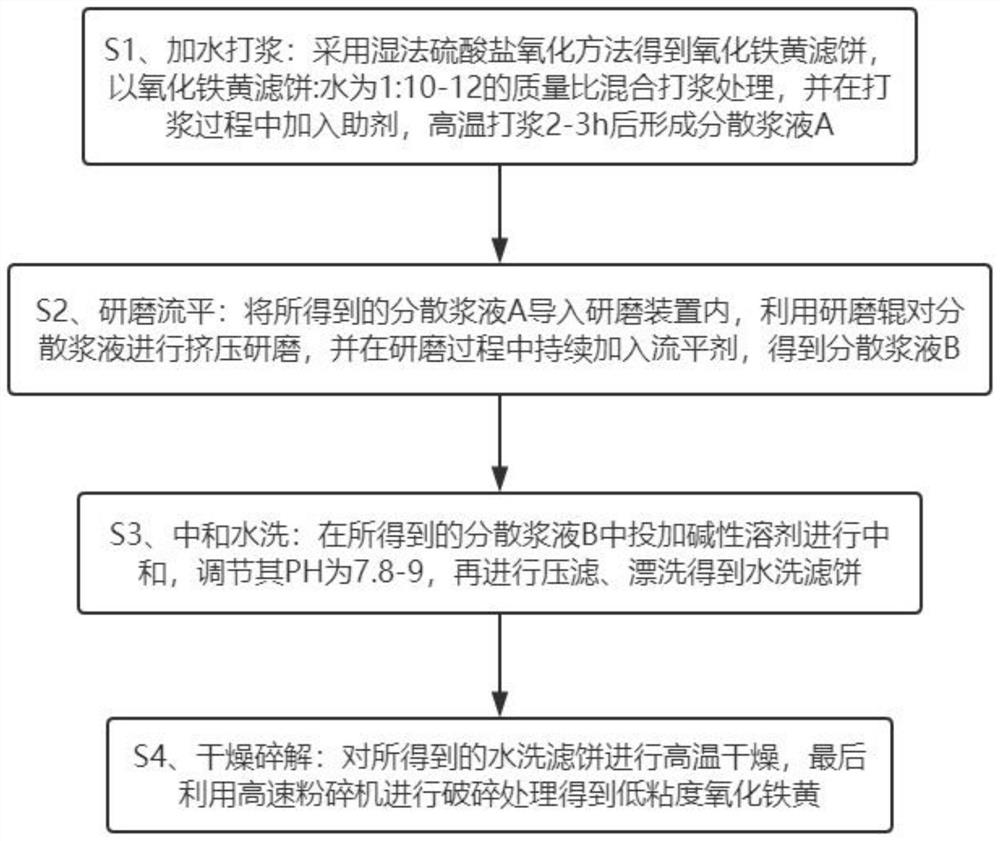

[0043] see figure 1 , a low-viscosity iron oxide yellow production process, comprising the following process steps:

[0044] S1, adding water and beating: adopt the wet sulfate oxidation method to obtain iron oxide yellow filter cake, mix and make beating with iron oxide yellow filter cake: water as a mass ratio of 1:10-12, and add additives in the beating process, high temperature Form dispersion slurry A after beating for 2-3 hours;

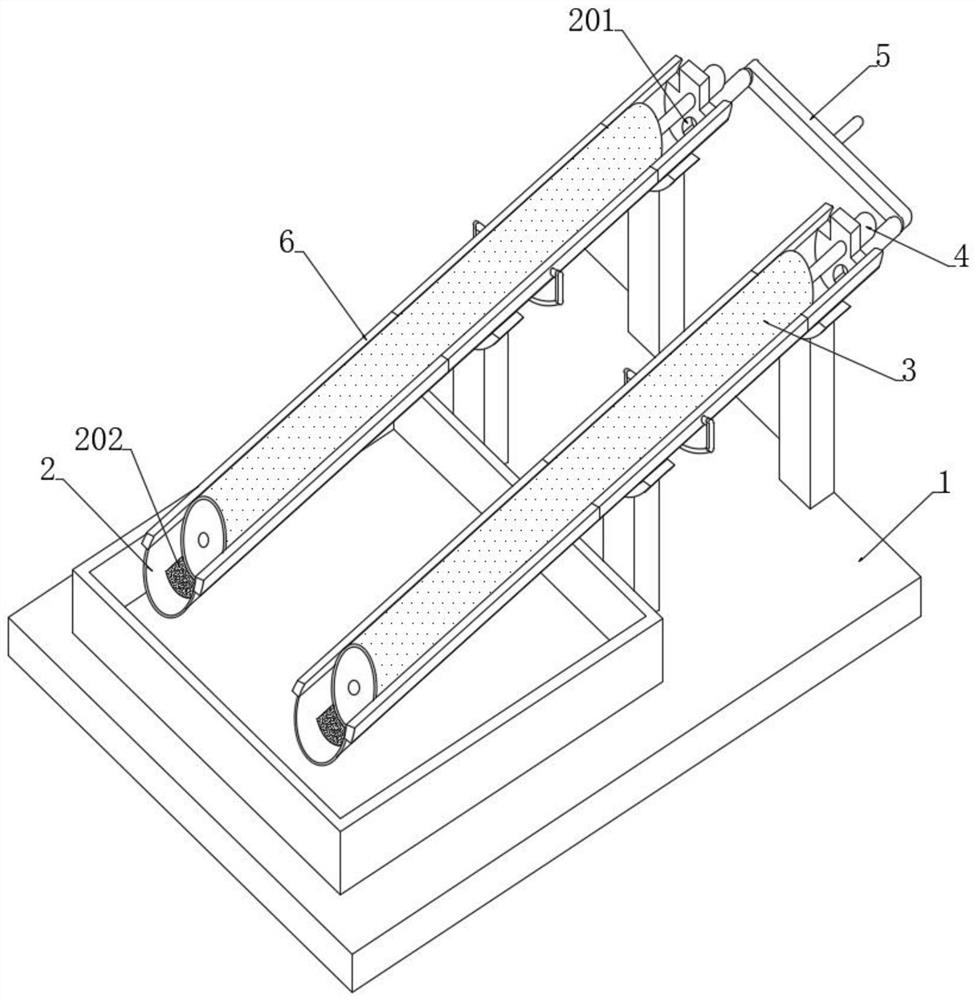

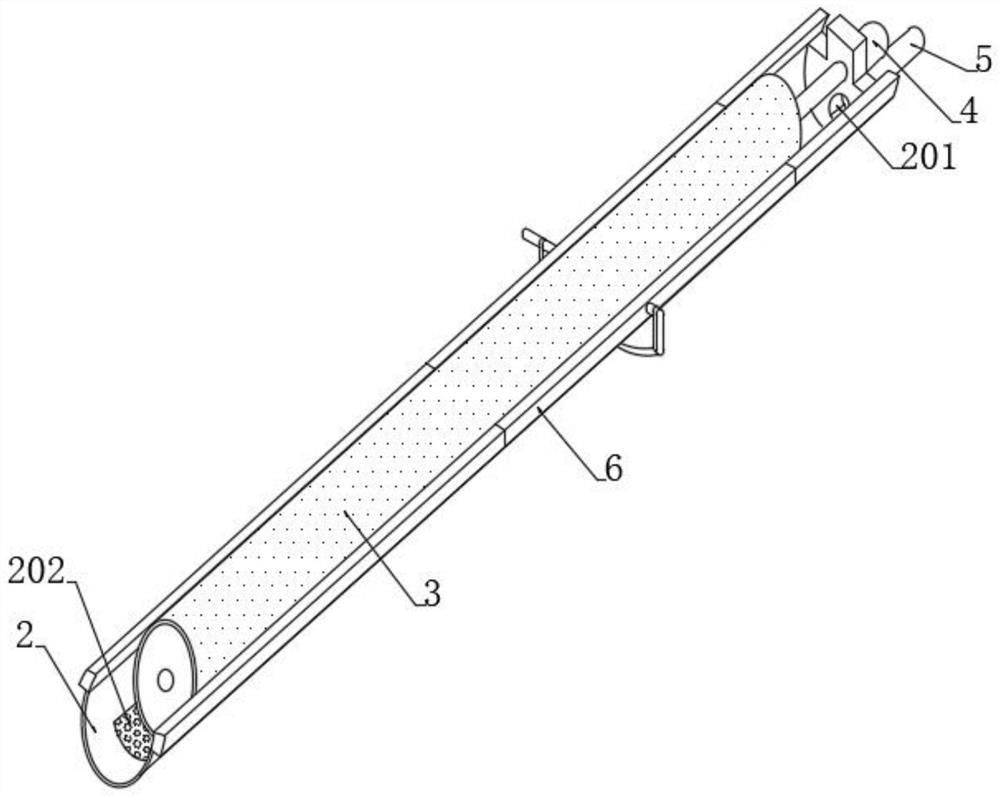

[0045] S2. Grinding and leveling: introduce the dispersed slurry A obtained in S1 into the grinding device, squeeze and grind the dispersed slurry with a grinding roller, and continuously add a leveling agent during the grinding process to obtain the dispersed slurry B;

[0046] S3, neutralization and water washing: add an alkaline solvent to the dispersion slurry B obtained in S2 for neutralization, adjust its pH to 7.8-9, and then perform pressure filtration and rinsing to obtain a water-washed filter cake;

[0047] S4. Drying and disintegr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com