Column plate downcomer for evenly distributing liquid stream

A uniform distribution and downcomer technology, applied in the field of downcomer, can solve the problems of long liquid residence time, flooding of downcomer, increase of liquid outlet resistance at the bottom of downcomer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

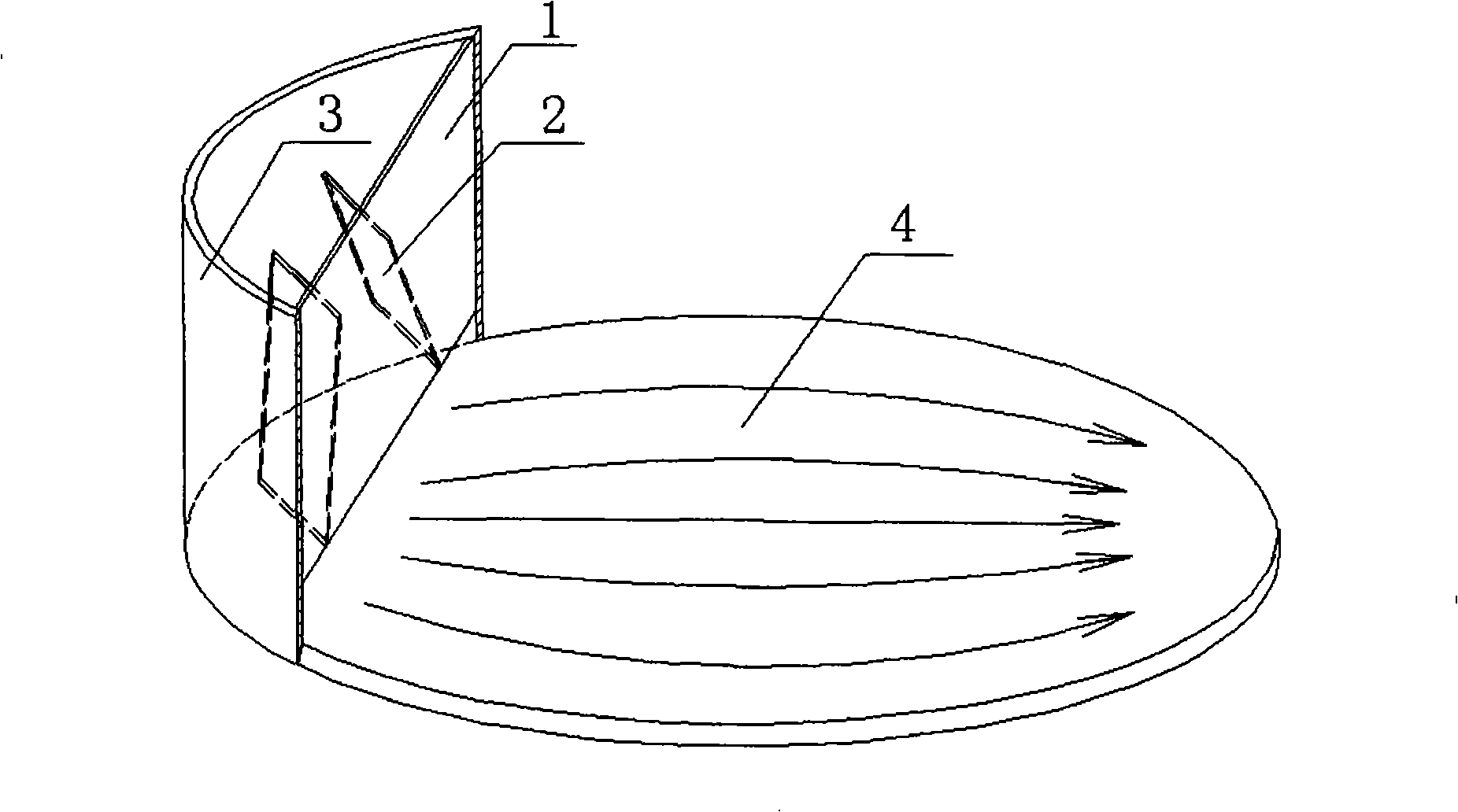

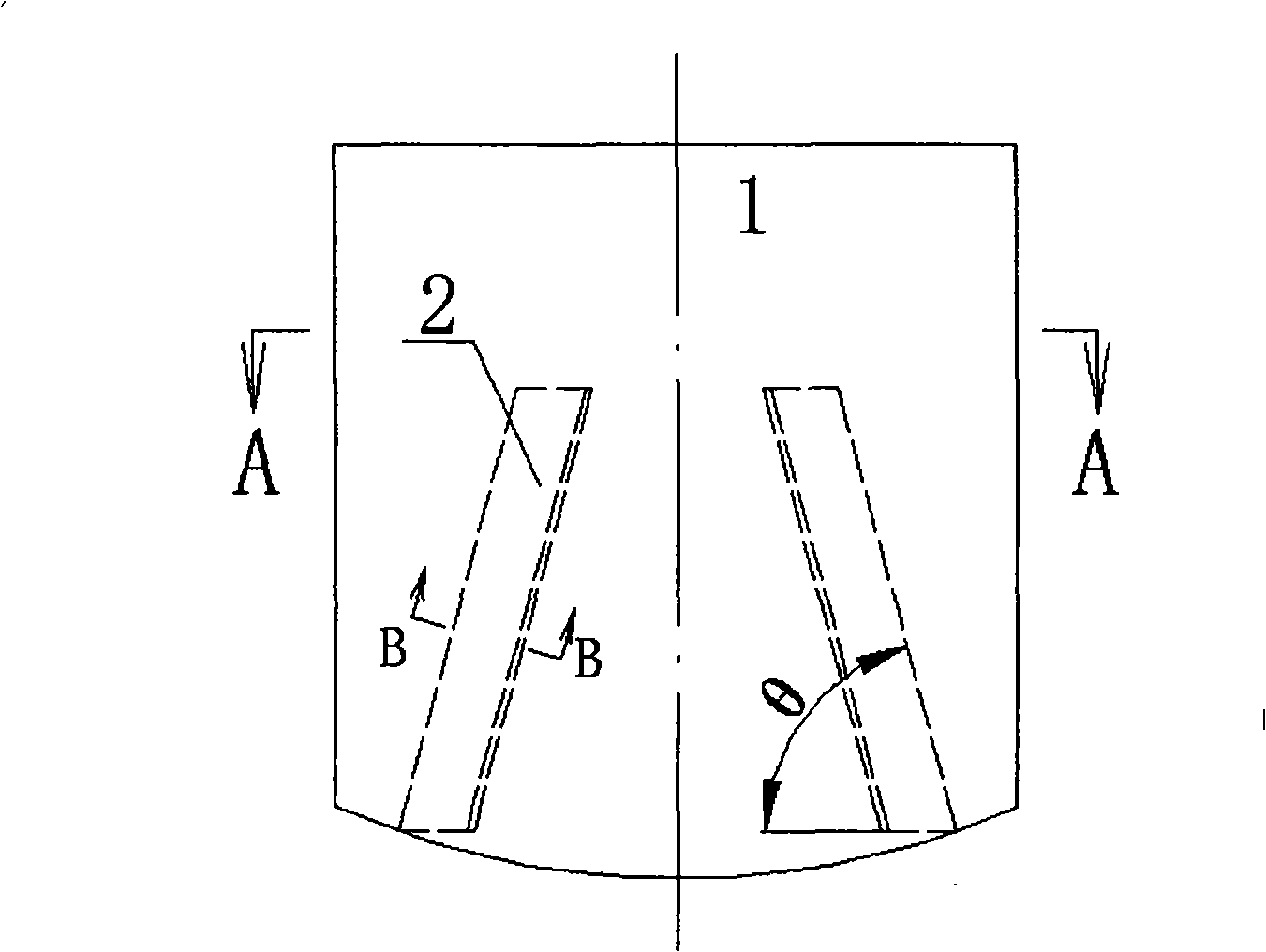

[0035] For a tray with an inner diameter of 600mm, the downcomer is as follows figure 2 So, its downcomer plate 1 is wide 800mm, long 1100mm, thick 3mm. Splitter 2 has a thickness of 2 mm, a width of 80 mm, and a length of 270 mm. The angle θ between it and the tray 4 is 75°, and the angle α between it and the downcomer plate 1 is 60°. The narrowest part of the splitter 2 from the tower wall 3 is 6mm, and the widest part is 26mm. The bottom of the downcomer plate 1 is in a zigzag arc shape, and the length is 440mm.

Embodiment 2

[0037] For a tray with an inner diameter of 600mm, the downcomer is as follows Figure 5 So, its downcomer plate 1 is wide 800mm, long 1100mm, thick 3mm. Divider plate 2 has a thickness of 2 mm, a width of 80 mm, and a length of 270 mm. The angle θ between it and the tray 4 is 75°, and the angle α between it and the downcomer plate 1 is 90°. The narrowest part of the splitter plate 2 from the tower wall 3 is 6 mm, and the widest part is 20 mm. The bottom of the downcomer plate 1 is smooth and arc-shaped, and the length is 440mm.

Embodiment 3

[0039] For a tray with an inner diameter of 600mm, the downcomer is as follows Figure 6 So, its downcomer plate 1 is wide 800mm, long 1100mm, thick 3mm. Divider plate 2 has a thickness of 2 mm, a width of 80 mm, and a length of 270 mm. The angle θ between it and the tray 4 is 75°, and the angle α between it and the downcomer plate 1 is 90°. The narrowest part of the splitter 2 from the tower wall 3 is 6mm, and the widest part is 20mm. The bottom of downcomer plate 1 is a zigzag trapezoid, with a top length of 200 mm and a height of 70 mm. Wherein the welding direction of the splitter plate 2 intersects with the waist of the trapezoid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com