Use method of super-gravity three-phase mass transferring and separating rotary bed

A supergravity, rotating bed technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of troublesome production and installation, complex distributor structure, weakened liquid atomization effect, etc., to simplify the inlet structure, Easy to seal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

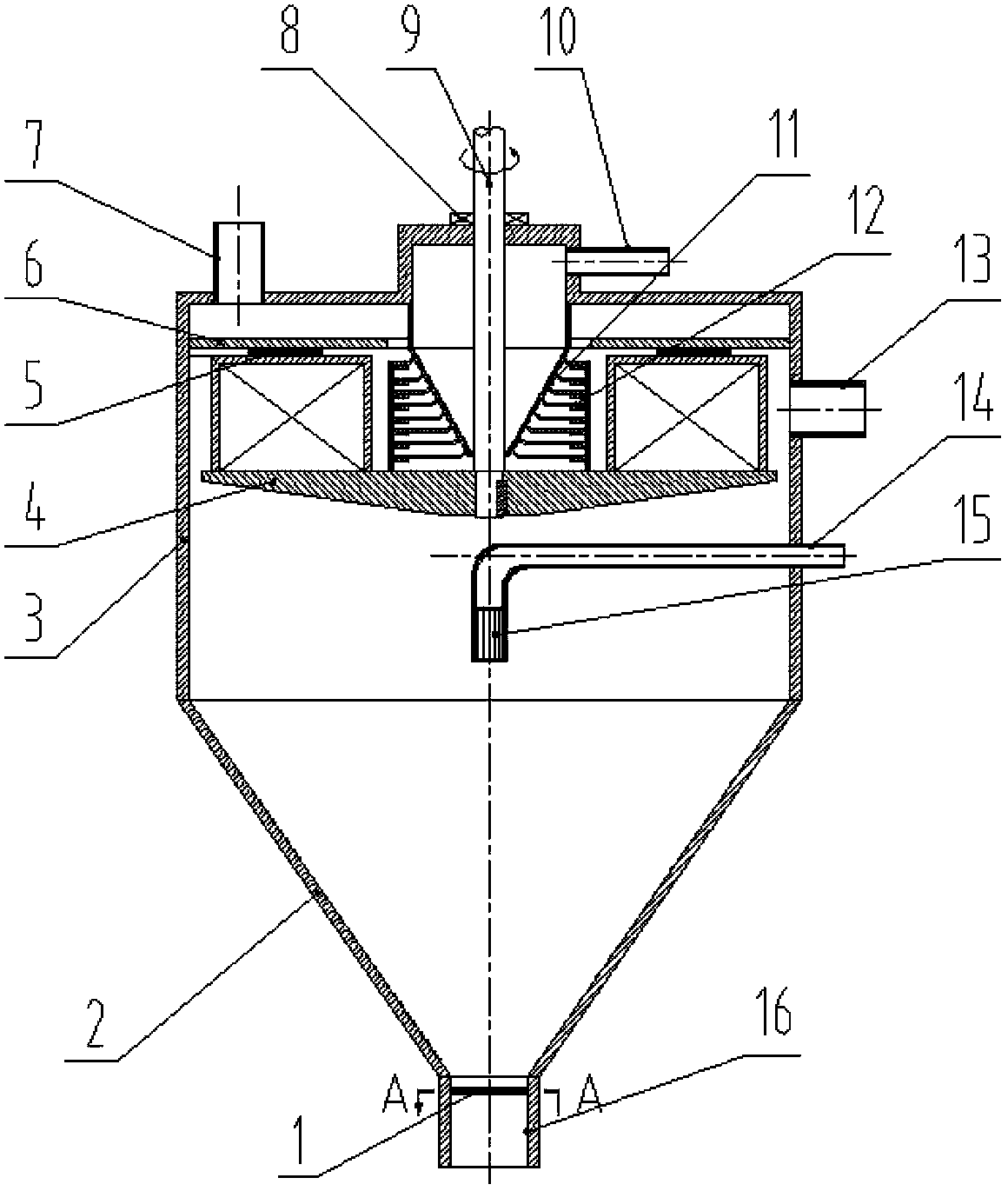

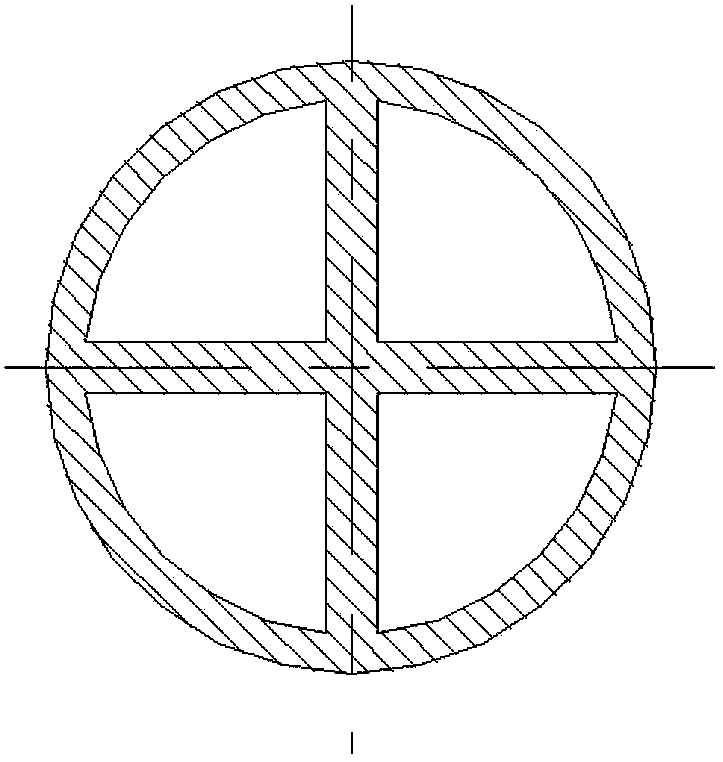

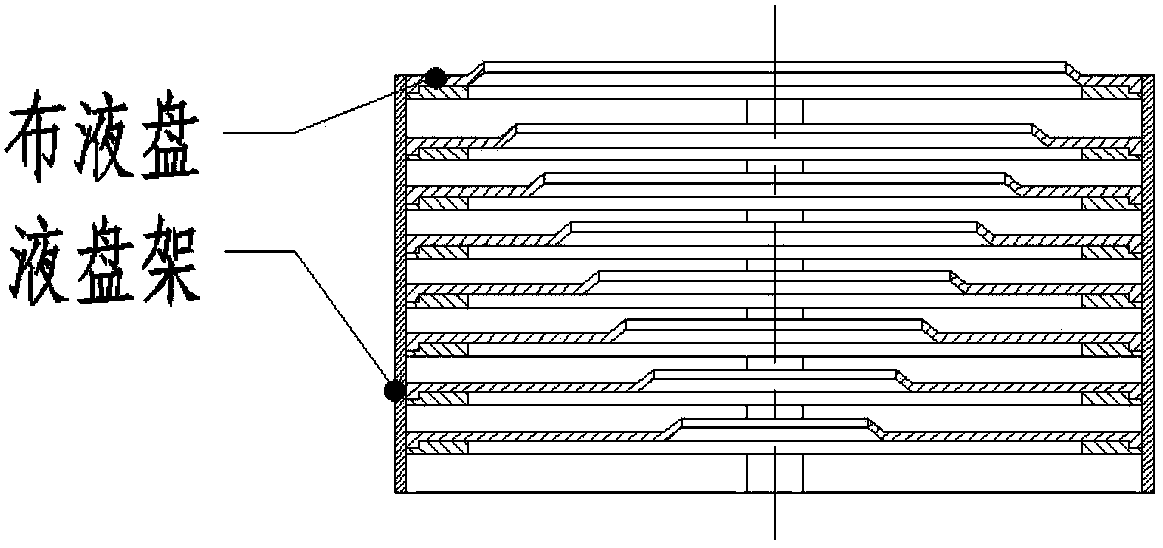

[0039] figure 1A schematic diagram of a supergravity three-phase mass transfer separation rotating bed is schematically shown, which is divided into a supergravity three-phase contact mass transfer section 3 and a lower cyclone solid-liquid separation section 2. The supergravity three-phase mass transfer separation rotary bed It includes: a rotating shaft 9, a mechanical seal 8 is arranged between the rotating shaft 9 and the shell of the supergravity three-phase mass transfer separation rotating bed; a rotor 4, the rotor 4 is arranged on the rotating shaft 9 and is located in the supergravity Within the gravity three-phase contact mass transfer section 3, a labyrinth seal 5 is set between the rotor 4 and the static baffle 6 located inside the shell of the supergravity three-phase mass transfer separation rotating bed; The solid-liquid mixture feed pipe 10 and the gas phase outlet 7 above the shell of the rotating bed for phase transfer and mass transfer separation; the conica...

Embodiment 2

[0046] Figure 5 Another supergravity three-phase mass transfer separation rotary bed is schematically shown, which is exactly the same as the supergravity three-phase mass transfer separation rotary bed in Example 1, the difference is that the light phase outlet 14 is arranged in the cyclone solid-liquid separation. Below the section 2, near the heavy phase outlet 16, so that the separated light and heavy phases flow to the bottom of the shell and flow out from the corresponding outlets respectively. The shell above the heavy phase outlet 16 is designed as a gradually expanding circular truncated structure, which can provide space for the pipeline of the light phase outlet 14 on the one hand, and further reduce the rotation speed of the heavy phase and reduce the pressure drop of the equipment on the other hand.

Embodiment 3

[0048] Image 6 Schematically shows another supergravity three-phase mass transfer separation rotating bed, which is exactly the same as the supergravity three-phase mass transfer separation rotating bed in Example 1, the difference is that the shape of the inner surface of the cyclone solid-liquid separation section It is different from the situation in Example 1. The cyclone solid-liquid separation section 2 is in the form of cone 1-cylinder-cone 2, which is suitable for gas, liquid and solid three-phase supergravity mass transfer separation devices with larger diameters. The existence of the cone 1-shaped line can improve the tangential velocity of the material liquid thrown out from the outer edge of the rotor 4, improve the solid-liquid separation efficiency, increase the liquid volume ratio of the cyclone solid-liquid separation section 2, and reduce the cyclone solid-liquid separation section 2. volume.

[0049] It should be noted that the light phase outlet 14 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com