Desulfurizing tower for gas desulfuration by using liquid phase catalytic oxidation

A liquid-phase catalysis and desulfurization tower technology, applied in the desulfurization field, can solve the problems of high rigidity and strength requirements of the support structure, unfavorable eccentric load and wind load, large span of the support beam, etc., to achieve easy fabrication and installation, reduce amplification effect, The effect of reducing stiffness and strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

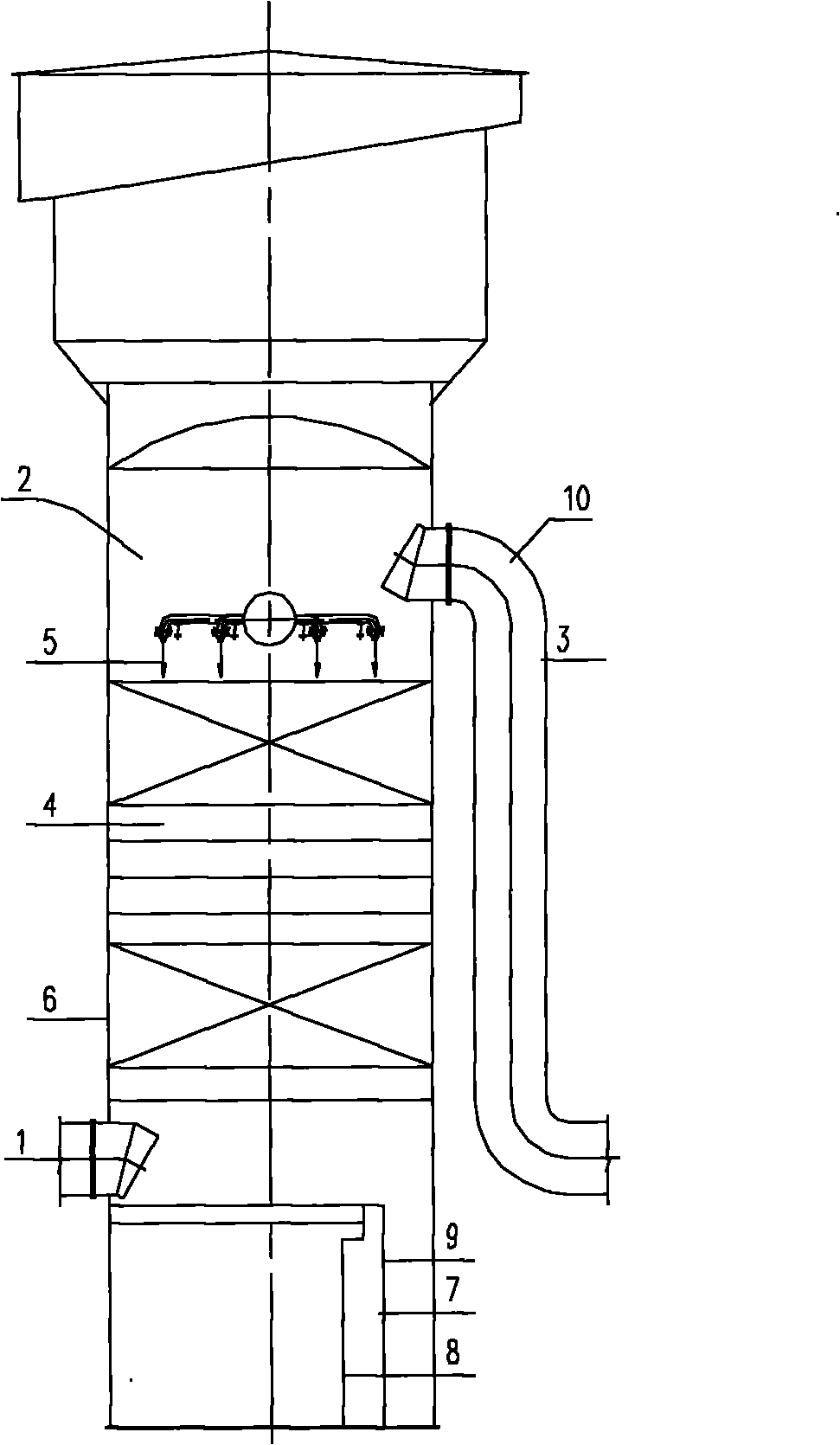

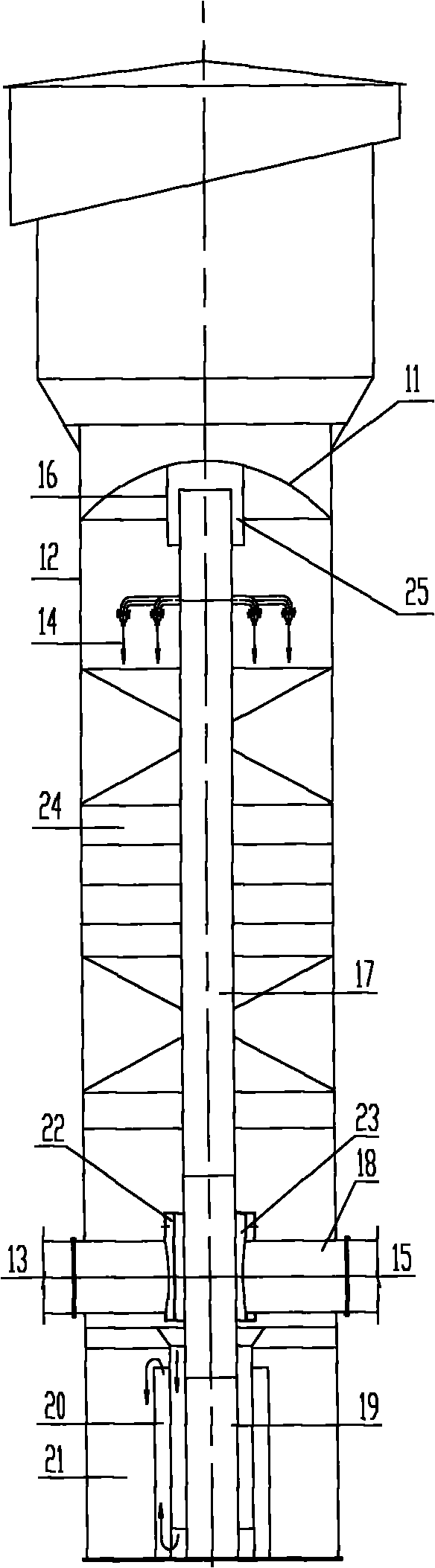

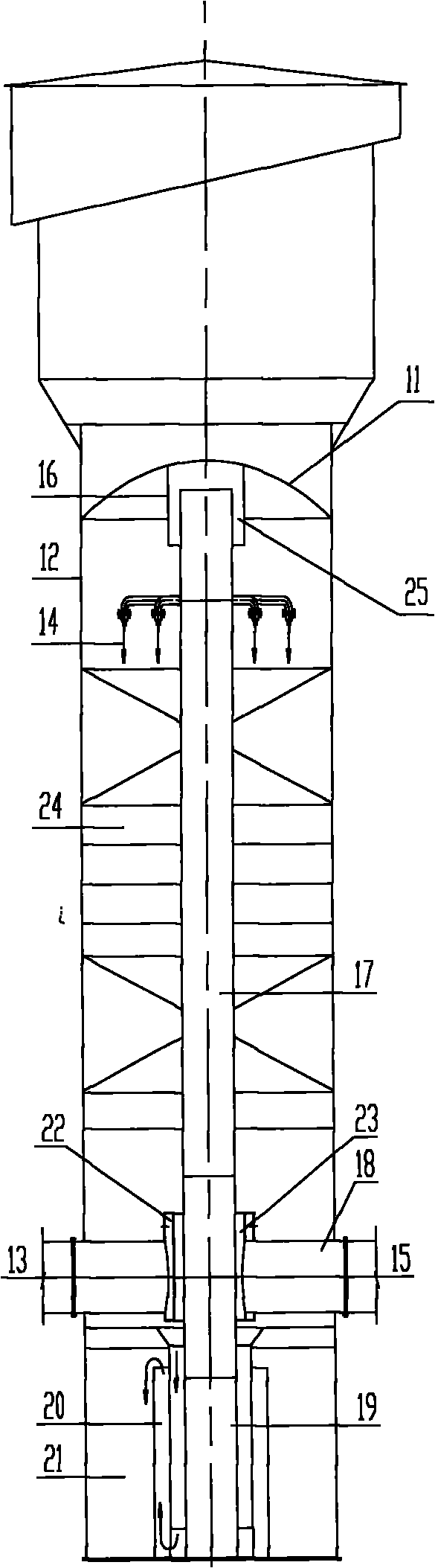

[0017] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] Such as figure 2 Shown: Take the desulfurization regeneration tower for desulfurization of gas containing sulfide such as hydrogen sulfide as an example. The lower part of section 12 is fed with desulfurized gas 13 containing sulfide such as hydrogen sulfide, and the upper part of washing section 12 is sprayed with desulfurization liquid 14 to absorb sulfide in gas 13 . The washed desulfurized gas 15 passes through the upper part of the washing section and is equipped with a mist trapping device 16 to remove the entrained liquid droplets, and then enters the descending pipe 17 arranged along the axis of the washing section of the desulfurization regeneration tower. The supporting part 19 with sealing function, the desulfurized gas 15 is exported to the scrubbing section 12 of the desulfurization regeneration tower throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com