Method for preparing methoxyethyl acrylate and methoxyethyl methacrylate

A technology of methoxyethyl methacrylate and methoxyethyl acrylate, which is applied in the field of chemical product preparation, can solve problems such as a large amount of waste water, troublesome post-treatment, poor product quality, etc., so as to improve use efficiency and reduce recycling Equipment, the effect of content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 5 liters of reactor, the rectification tower on the reactor is Φ50×2.5mm, and the height of the tower is 1000mm.

[0044] The catalyst is dibutyltin sulfide, and the polymerization inhibitor is poly{[6-[(1,1,3,3-tetramethylbutyl)amino]]-1,3,5-triazine-2,4-bis [(2,2,6,6,-tetramethyl-piperidinyl)imino]-1,6-hexanediamine[(2,2,6,6-tetramethyl-4-piperidinyl) Imino]}, the entrainer is n-hexane.

[0045] In the reactor, 2451 g of methyl acrylate and 1444 g of ethylene glycol-methyl ether were added according to the weight ratio of substances of 1.5:1, 78 g of catalyst and 7.8 g of polymerization inhibitor were added.

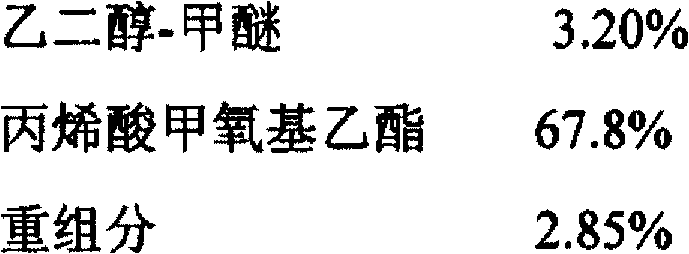

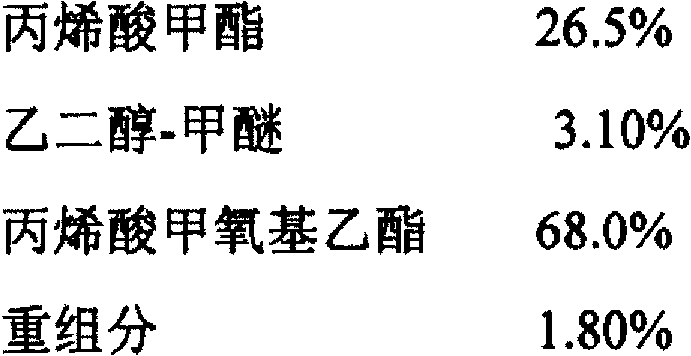

[0046] The reaction kettle is heated up, and when the bottom temperature of the rectification column on the reaction kettle rises to 50°C, the top reflux pump of the rectification tower is turned on, and the entrainer is refluxed according to a certain flow rate. The top temperature was 49°C. After 6 hours of reaction, the temperature of the reactor was 110°C....

Embodiment 2

[0051] 5 liters of reactor, the rectification tower on the reactor is Φ50×2.5mm, and the height of the tower is 1000mm.

[0052] The catalyst is dibutyltin sulfide, and the polymerization inhibitor is poly{[6-[(1,1,3,3-tetramethylbutyl)amino]]-1,3,5-triazine-2,4-bis [(2,2,6,6,-tetramethyl-piperidinyl)imino]-1,6-hexanediamine[(2,2,6,6-tetramethyl-4-piperidinyl) A compound of imino]} and polysuccinic acid (4-hydroxy-2,2,6,6-tetramethyl-1-piperidine ethanol) ester, the mass ratio of the two is 1:3, and the entrainer for cyclohexane.

[0053] In the reactor, 2451 g of methyl acrylate and 1444 g of ethylene glycol-methyl ether were added according to the weight ratio of substances of 1.5:1, 78 g of catalyst and 7.8 g of polymerization inhibitor were added.

[0054] The reaction kettle is heated up, and when the bottom temperature of the rectification column on the reaction kettle rises to 50°C, the top reflux pump of the rectification tower is turned on, and the entrainer is refl...

Embodiment 3

[0058] 5 liters of reactor, the rectification tower on the reactor is Φ50×2.5mm, and the height of the tower is 1000mm.

[0059] The catalyst is a compound of dibutyl tin oxide and tetrabutyl titanate, the mass ratio of the two is 3:1, and the polymerization inhibitor is poly{[6-[(1,1,3,3-tetramethylbutyl Base)amino]]-1,3,5-triazine-2,4-bis[(2,2,6,6,-tetramethyl-piperidinyl)imino]-1,6-hexanediamine [(2,2,6,6-tetramethyl-4-piperidinyl)imino]} and polysuccinic acid (4-hydroxy-2,2,6,6-tetramethyl-1-piperidine ethanol) ester compound, the mass ratio of the two is 1:3, and the entrainer is methylcyclohexane.

[0060] In the reactor, 2451 g of methyl acrylate and 1444 g of ethylene glycol-methyl ether were added according to the weight ratio of substances of 1.5:1, 78 g of catalyst and 7.8 g of polymerization inhibitor were added.

[0061] The reaction kettle is heated up, and when the bottom temperature of the rectification column on the reaction kettle rises to 50°C, the top ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com