Guniting corn bran preparation method and production system

A technology for spraying corn husks and production systems, which is applied in the fields of feed, food science, application, etc., can solve the problems of long time fermentation, low product utilization rate, cumbersome and other problems, and achieves good digestion and absorption, better effect, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

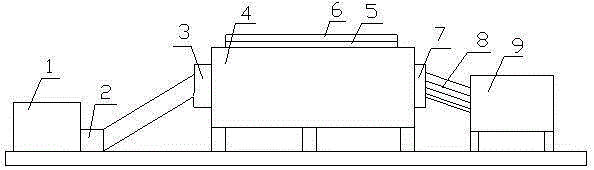

[0022] (2) The mixed wet corn husks are transported to the feeding device 3 through the feeding device 2, and the wet corn husks are transported into the rotary drum 4 by the feeding device 3;

[0023] (3) The wet corn husks are turned in the rotary drum, and the wet corn husks are fully contacted with the hot air in the rotary drum 4 through the air induction device 5 and the heating system 6, so as to achieve the drying purpose of heat transfer and mass transfer;

[0024] (4) The dried corn husks are discharged from the discharge device 8 at the end of the rotary drum 4 through the discharge device 7, and then cooled by the cooling system 9 to obtain the sprayed corn husk finished product.

[0025] Example 2

[0026] The preparation method of sprayed corn bran comprises the following steps:

Embodiment 2

[0028] (2) The mixed wet corn husks are transported to the feeding device 3 through the feeding device 2, and the wet corn husks are transported into the rotary drum 4 by the feeding device 3;

[0029] (3) The wet corn husks are turned in the rotary drum, and the wet corn husks are fully contacted with the hot air in the rotary drum 4 through the air induction device 5 and the heating system 6, so as to achieve the drying purpose of heat transfer and mass transfer;

[0030] (4) The dried corn husks are discharged from the discharge device 8 at the end of the rotary drum 4 through the discharge device 7, and then cooled by the cooling system 9 to obtain the sprayed corn husk finished product.

[0031] Example 3

[0032] The preparation method of sprayed corn bran comprises the following steps:

Embodiment 3

[0034] (2) The mixed wet corn husks are transported to the feeding device 3 through the feeding device 2, and the wet corn husks are transported into the rotary drum 4 by the feeding device 3;

[0035] (3) The wet corn husks are turned in the rotary drum, and the wet corn husks are fully contacted with the hot air in the rotary drum 4 through the air induction device 5 and the heating system 6, so as to achieve the drying purpose of heat transfer and mass transfer;

[0036] (4) The dried corn husks are discharged from the discharge device 8 at the end of the rotary drum 4 through the discharge device 7, and then cooled by the cooling system 9 to obtain the sprayed corn husk finished product.

[0037] Example 4

[0038] The preparation method of sprayed corn bran comprises the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com