Grouting material for connection of prefabricated concrete member sleeves for prefabricated construction and preparation method thereof

A prefabricated concrete and sleeve connection technology, applied in the field of cement-based grouting materials, can solve the problems of convenient construction, limited space for connecting sleeves, and tight construction time, so as to improve the compression and impact resistance and reduce production and preparation costs. Low, the effect of improving the antifreeze performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

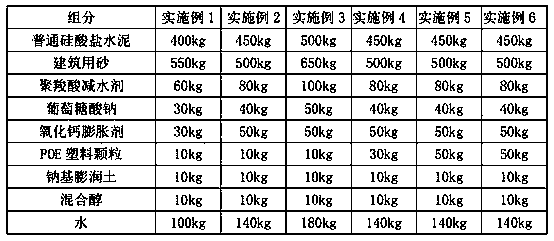

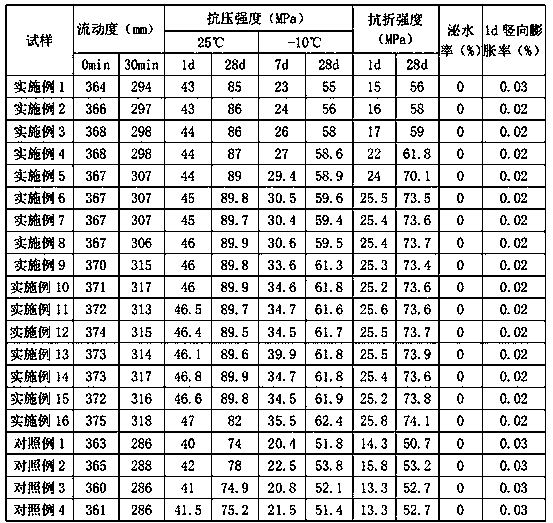

[0060] Embodiments 1-6 all relate to a kind of grouting material for sleeve connection of prefabricated concrete elements in prefabricated buildings. The raw material composition of each embodiment is as shown in Table 1.

[0061] Table 1.

[0062]

[0063] Wherein, all components except water are commercially available raw materials. The construction sand used is mixed from 20-40 mesh fine sand, 10-20 mesh medium sand and 6-10 mesh coarse sand. The specific mix is shown in Table 2:

[0064] Table 2.

[0065]

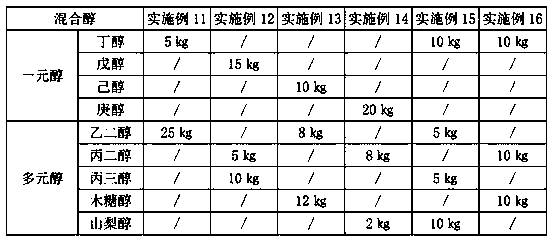

[0066] The mixed alcohol used contains at least one C4-C7 alcohol and at least one polyhydric alcohol. The mixed alcohols in Examples 1-6 are mixed with n-butanol and propylene glycol according to the mass ratio of 1:1; the particle diameters of the POE plastics used in Examples 1-6 are all ≤1.5mm, and the The POE plastic particles used in Example 6 were impregnated with nano titanium dioxide aqueous dispersion. The specific treatment process is as follows: ...

Embodiment 7

[0076] Embodiment 7-8 is all based on embodiment 6, and the difference with embodiment 6 is only: the dosage of sodium-based bentonite in the formula is different, the dosage of sodium-based bentonite in embodiment 7 is 20 kg, in embodiment 8 The dosage of sodium bentonite is 30kg.

Embodiment 9

[0078] Embodiment 9-10 is all based on embodiment 8, and the difference with embodiment 8 is only: the dosage of mixed alcohol in the formula is different, the dosage of mixed alcohol in embodiment 9 is 20 kg, the mixed alcohol in embodiment 10 The dosage is 30kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com