A kind of pipeline preparation method

A pipeline and pipe body technology, applied in the field of pipeline preparation, can solve problems such as insufficient pipeline technology, failure to make full use of pipelines, and inability to strengthen pipeline construction, and achieve the effects of wide application range, simple method and processing cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

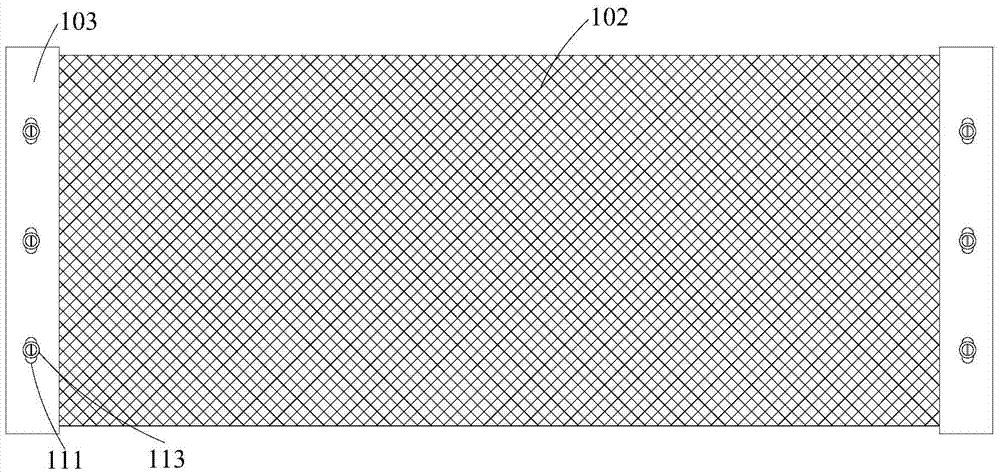

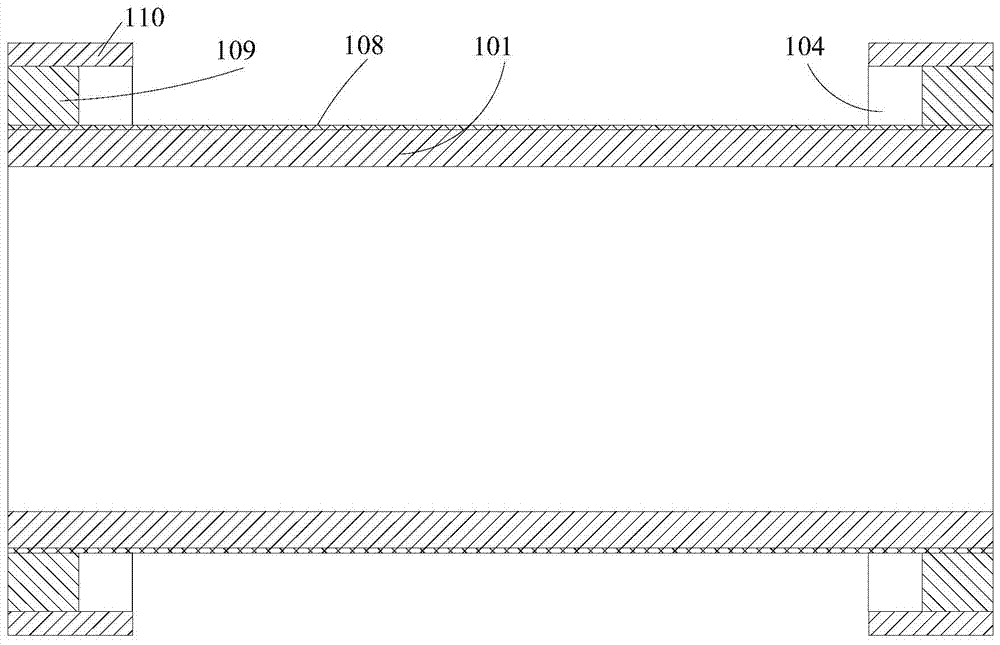

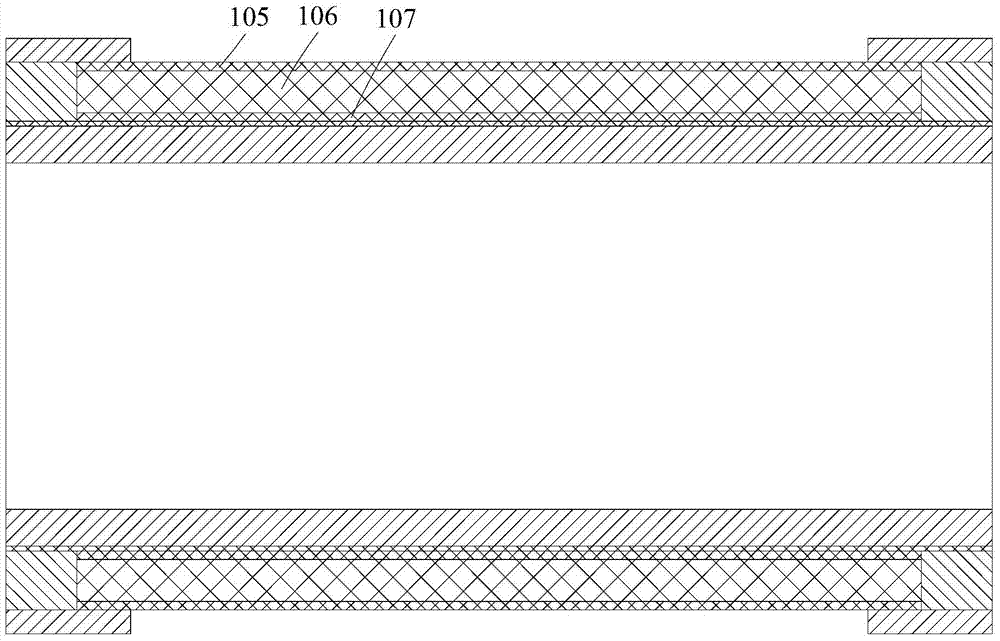

[0073] A pipeline, comprising a pipe body 101, the outer wall of the pipe body 101 is sequentially provided with a waterproof film layer 108 and a fabric layer 102 from the inside to the outside, and the fabric layer 102 is respectively composed of a mesh fabric layer 105 and a fiber silk layer from the outside to the inside 106 and compact fabric cloth layer 107; the thickness of fabric layer 102 is 10mm, and the grammage of fabric layer 102 is 1050 grams / square meter.

[0074] Two press-fit parts 103 are arranged symmetrically at both ends of the outer side of the pipe body 101; And forming accommodating spaces 104 , the two ends of the fabric layer 102 are respectively located in the two accommodating spaces 104 . The pressing piece 103 includes a connecting fixing piece 109 and a pressing piece 110 , both of which are ring-shaped, the fixing piece 109 is connected to the pipe body 101 , and the pressing piece 110 is connected to the outside of the fixing piece 109 . The w...

Embodiment 2

[0076] A pipeline preparation method, comprising prefabricating concrete blankets and laying concrete blankets outside the pipe body 101;

[0077] The prefabricated concrete blanket includes the steps of: preparing the fabric layer 102, the fabric layer 102 includes a mesh fabric layer 105, a fiber filament layer 106, and a dense fabric layer 107 connected in sequence; mixing and mixing sulphoaluminate cement and anhydrite to prepare cement Base composite material, the weight ratio of sulfoaluminate cement and anhydrite is 8:2; The cement base composite material is poured into the fabric layer 102 from the band mesh fabric cloth layer 105; The fabric layer 102 that has added the cement base composite material place on a vibrating table to vibrate; seal the mesh fabric cloth layer 105 of the fabric layer 102 with colloid;

[0078] Laying the concrete blanket outside the pipe body 101 includes steps:

[0079] A waterproof film layer 108 is arranged on the outer wall of the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com