A high heat resistant fiber reinforced hdpe plastic outdoor table and its manufacturing method

A fiber-reinforced, high-heat-resistant technology, applied to tables, legs of general furniture, furniture parts, etc., can solve problems such as poor aging resistance, poor environmental crack resistance, and performance degradation, and achieve enhanced compression and impact resistance , maintain structural stability, and improve environmental crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

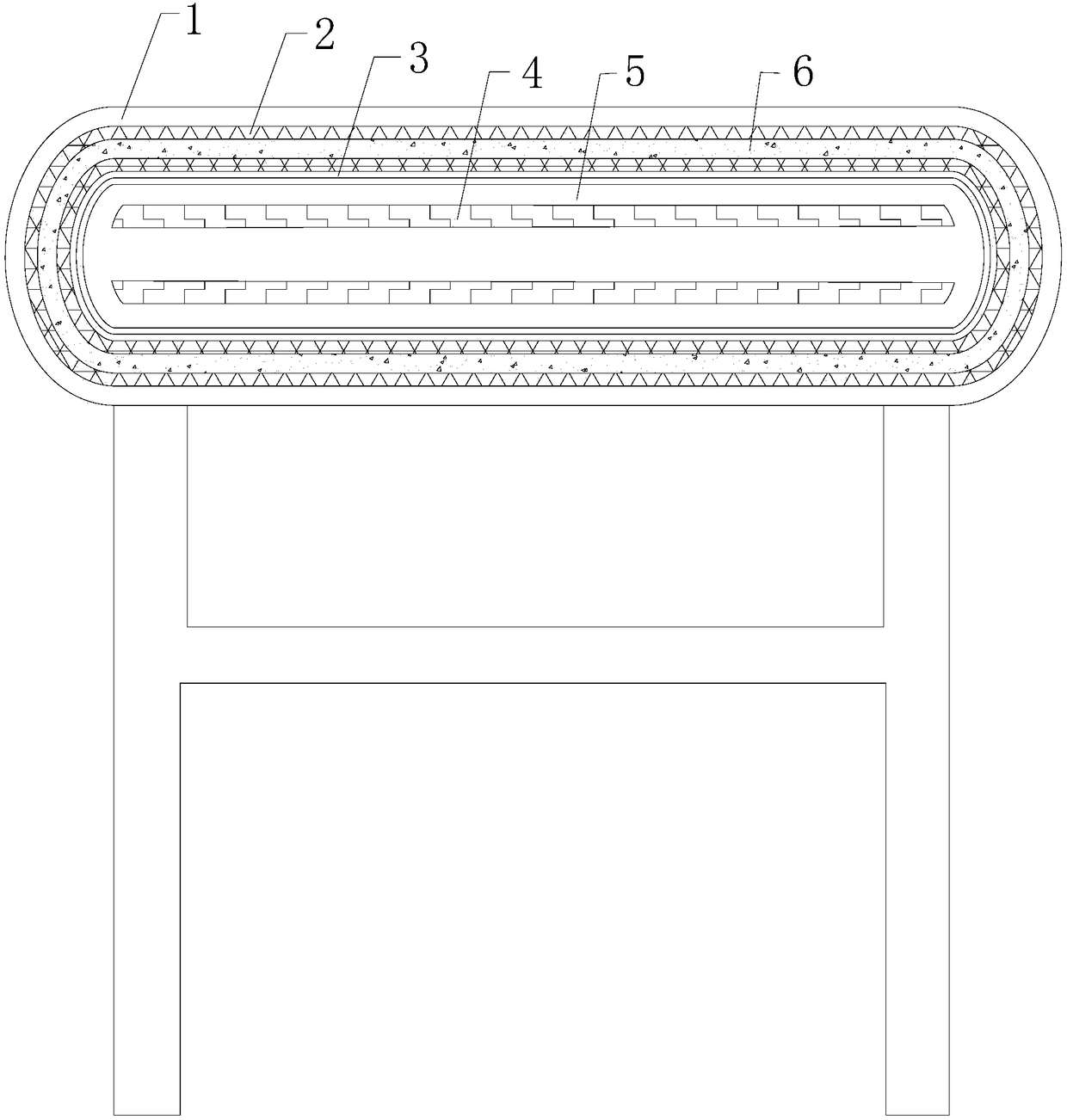

[0020] refer to figure 1 , a high heat resistant fiber reinforced HDPE plastic outdoor table of the present invention, comprising HDPE base material of the following components: HDPE 90-100; copolymerized PP 8-15; glass fiber 12-18; talcum powder 9-12; anti-ultraviolet agent 0.2 -0.5; other additives 0.1-0.3; including breathable and waterproof layer 1, high temperature resistant polypropylene non-woven fabric layer 2, anti-aging sealing plastic layer 3, fiber reinforced layer 4, HDPE desktop board 5, the breathable and waterproof layer 1 is wrapped and set Outside the high-temperature-resistant polypropylene non-woven fabric layer 2, the high-temperature-resistant polypropylene non-woven fabric layer 2 is wrapped and arranged on the anti-aging sealing plastic layer 3, and the anti-aging sealing plastic layer 3 is sealed and wrapped on the HDPE desktop board 5, and the HDPE desktop board 5 is provided with several fiber reinforced layers 4 inside, and the breathable and waterp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com