LABVIEW-based variable frequency water treatment control system

A control system and water treatment technology, applied in the field of ABVIEW, can solve problems such as difficult to meet the power requirements of water treatment equipment, small frequency range, single water treatment function, etc., and achieve the goal of expanding the scope of application and functions, improving the effect, and powerful functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: a kind of frequency conversion water treatment control system based on LABVIEW of the present invention is made up of software control part and frequency conversion water treatment control equipment; The software control part includes the LABVIEW program of upper computer and the application program of lower computer single-chip microcomputer and forms;

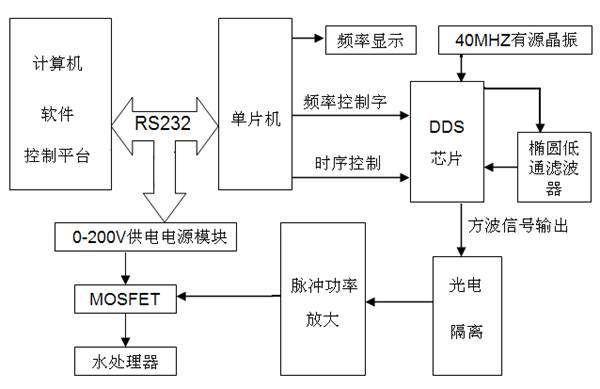

[0047] Frequency conversion water treatment control equipment see figure 1 , by computer software control platform, serial port interface module, single chip microcomputer, DDS

[0048] chip, photoelectric isolation module, pulse power amplifier module, 40MHZ active crystal oscillator, elliptic low-pass filter, 0-200V power supply module, MOSFET module and water processor; the computer software control platform communicates with the Single-chip connection, single-chip connection to DDS chip, 40MHZ active crystal oscillator is also connected to DDS chip, DDS chip is connected to elliptic low-pass filter an...

Embodiment 2

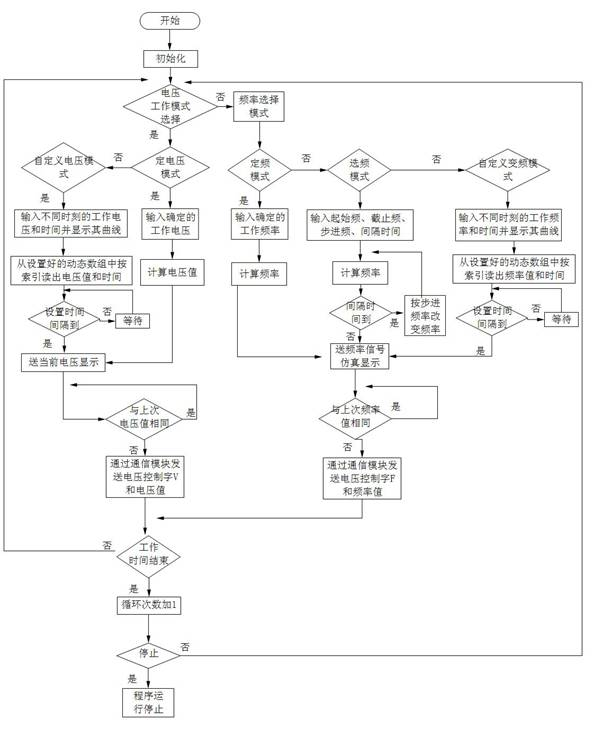

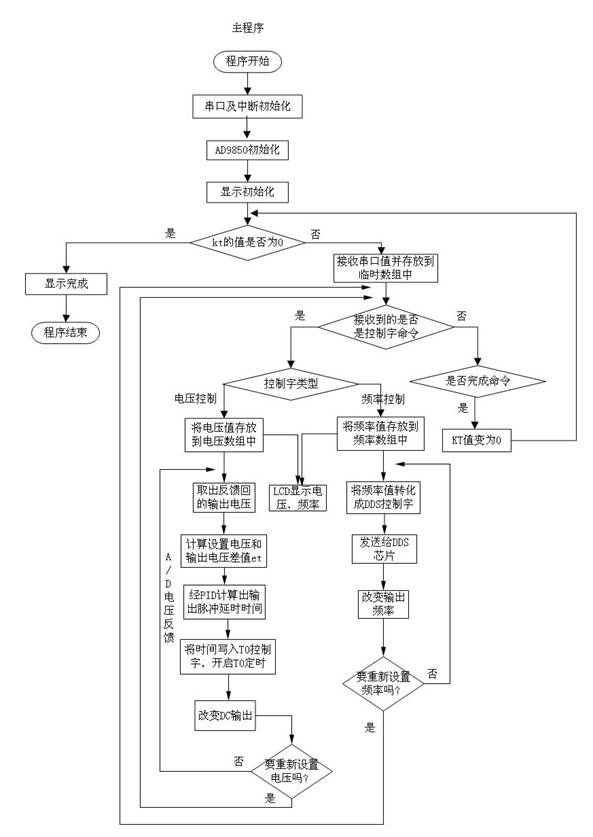

[0052] Embodiment 2: use the frequency conversion water treatment control system based on LABVIEW of the present invention of embodiment 1 for the water treatment process, the operation steps of the control system of the present invention are: 1. install the water processor on the equipment to be treated; The water processor control system of the present invention is connected to a 220V AC power supply, the upper computer is turned on, and the program flow chart of the upper computer and the lower computer is shown in figure 2 , 3 ;The operation interface of the computer appears, see Figure 4 ;③Set various parameters in the operation interface; first select the voltage working mode: if you first select the variable voltage mode, in Figure 5 On the custom voltage setting operation interface shown, set different voltages at different times, set a group and click "Add" to add the set parameters to the dynamic array, after setting all the voltage and time values, click "Save ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com