Barium-strontium scale inhibitor

A technology of scale inhibitors and strontium scale inhibitors, which is applied in the field of barium strontium scale inhibitors, can solve the problems of cumbersome preparation methods, use restrictions, environmental pollution, etc., achieve excellent scale inhibition effects, completely clarify water bodies, and save use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] (1) Preparation of terpolymer

[0022] ①Add 0.5mol maleic anhydride and 1.0-4.5mol distilled water into a four-necked flask equipped with an electric stirrer, two dropping funnels and a reflux condenser, stir to dissolve and heat to 60-75°C.

[0023] ②Put 0.1~0.3mol of acrylic acid or methacrylic acid and 0.25~0.5mol of acrylate mixture, 0.01~0.03mol of potassium persulfate solution into two dropping funnels, and drop these two solutions into the flask at the same time under stirring , and the dropwise addition was completed within 0.5 to 1.5 hours.

[0024] ③Continue heating the mixed reactant in ② to 80-95°C, then react at constant temperature for 3-6 hours, cool to room temperature to obtain a light yellow transparent liquid, and adjust the pH=7 with 50% sodium hydroxide solution to obtain the required ternary copolymer.

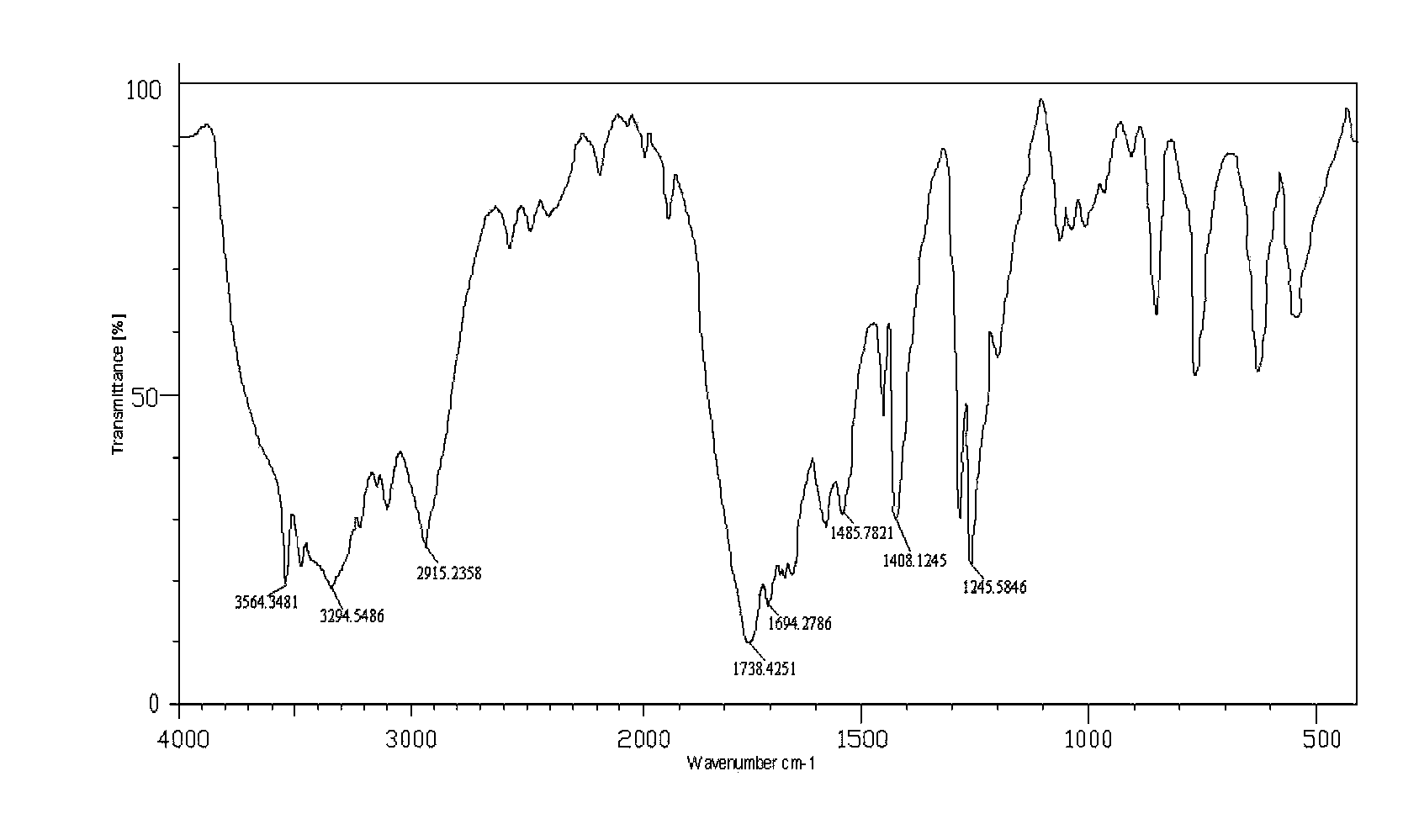

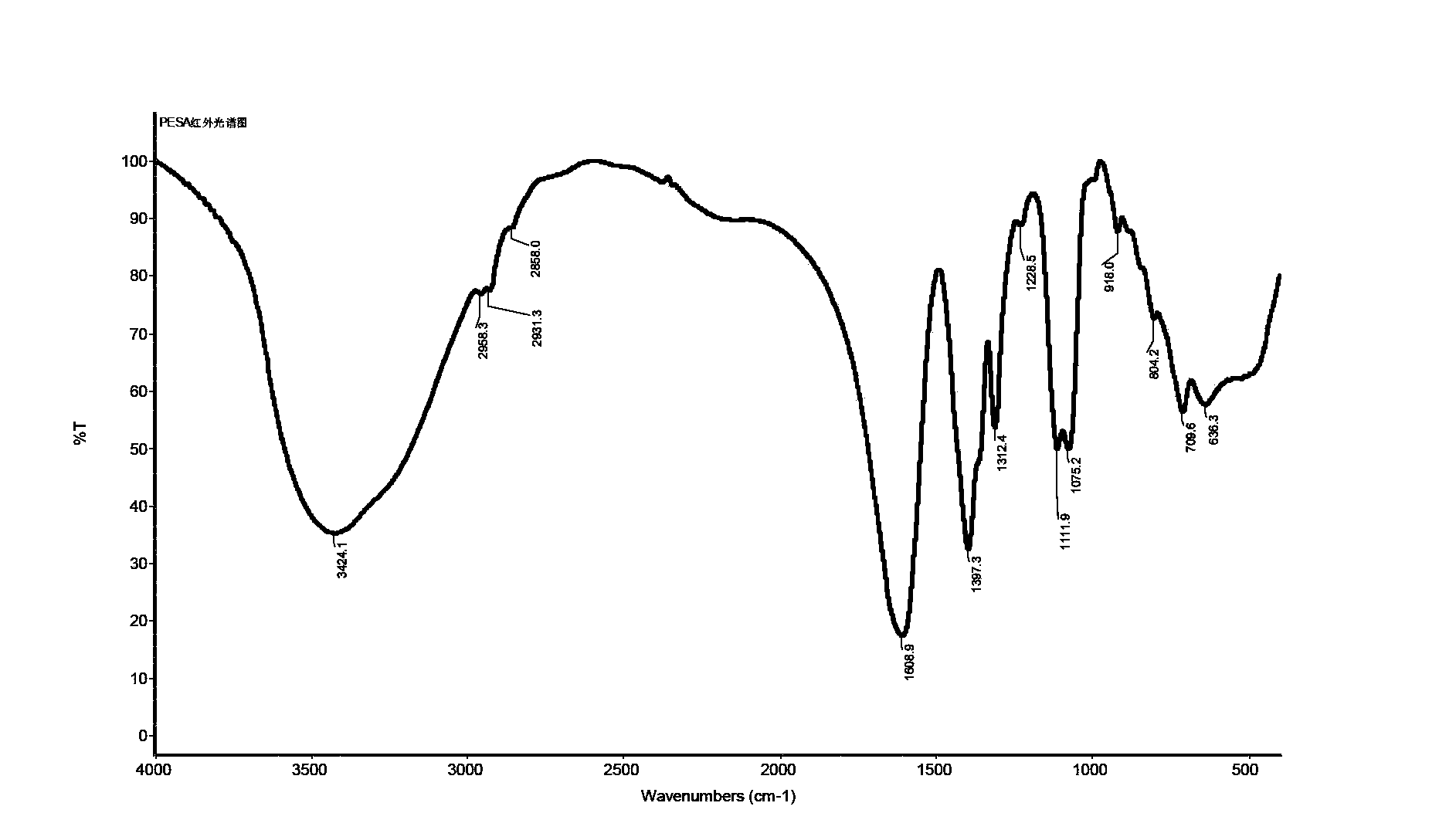

[0025] (2) Structural characterization of the terpolymer

[0026] Adopt KBr tablet method to carry out infrared spectrum analysis to the terpol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com