Methods for preparing and applying modified polyaspartic acid scale inhibitor

A polyaspartic acid and scale inhibitor technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. Low scale efficiency and other problems, to achieve the effect of increasing scale inhibition performance, not destroying the ecological environment, good biodegradability and water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] (1) Preparation of polysuccinimide (PSI)

[0021] ① While stirring, add 29.4g of maleic anhydride and 60mL of deionized water into a 250mL four-neck flask, raise the temperature to 85°C and add dropwise 45mL of ammonia water with a mass fraction of 25%. A colorless solution was obtained after the ammonia water was added dropwise. Stir at 75-85°C for 2 hours to completely dissolve the suspension and obtain a clear homogeneous solution.

[0022] ②The homogeneous solution in step ① was distilled under reduced pressure at 90°C to obtain a mixture of white crystals and a small amount of viscous liquid. Add about 45mL of deionized water and heat again until the crystals dissolve. The liquid was cooled in an ice bath, crystals were precipitated, and white flaky crystals of maleimide were obtained by suction filtration.

[0023] ③ Dissolve the white flaky crystal maleimide prepared in step ② with 20-30ml of deionized water, put it in a methyl silicone oil bath for condensati...

Embodiment 1

[0029] Based on 1 liter of water, 12mg / L of CSN-PASP, 12mg / L of self-made PASP, 12mg / L of CSN and 6mg / L of homemade PASP and 6mg / L of CSN were prepared in the volumetric flask according to the mass concentration ratio. Then pour it into a Erlenmeyer flask, cover it tightly with a rubber stopper with a glass tube, heat it in a constant temperature water bath at 80°C for 10 hours, and measure the scale inhibition rate of the agent. The results are shown in Table 1.

[0030] Table 1

[0031]

Embodiment 2

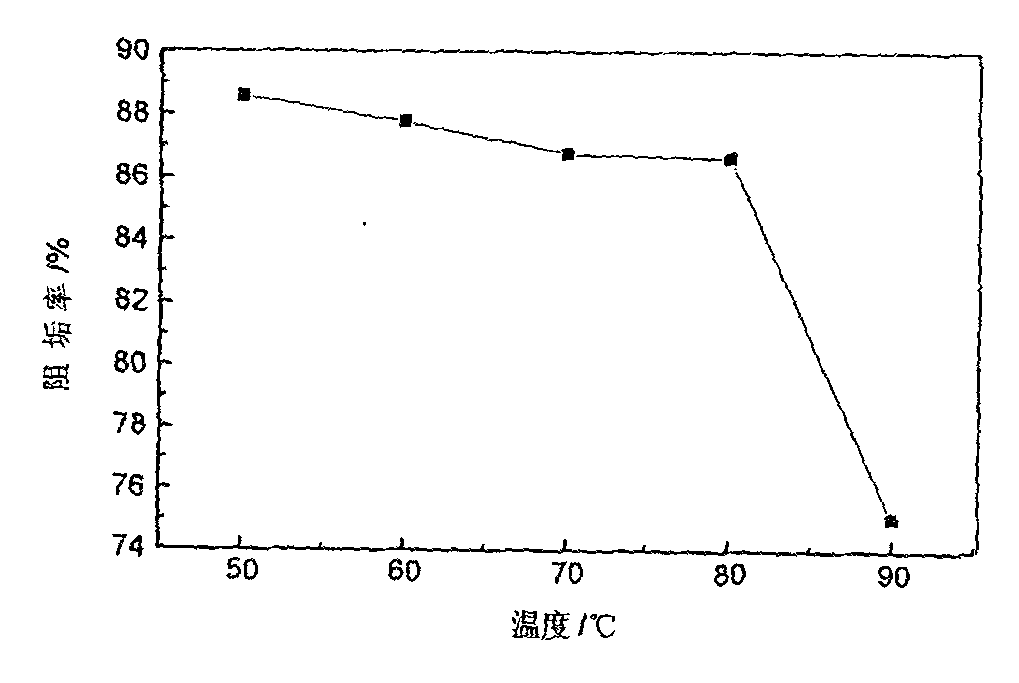

[0033] Based on 1 liter of water, prepare 12mg / L CSN-PASP antiscalant solution according to the mass concentration ratio, place them in constant temperature water baths at 60°C, 70°C, 80°C and 90°C for 10 hours, then measure the carbonation resistance of the agent Calcium scale inhibition rate. When the temperature is less than 80℃, the antiscalant has good adaptability. The result is as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com