Method for reclaiming and utilizing paper-making industrial waste water

A technology for paper industry wastewater and industrial water treatment, which is applied in processing wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. , the effect of beautifying the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

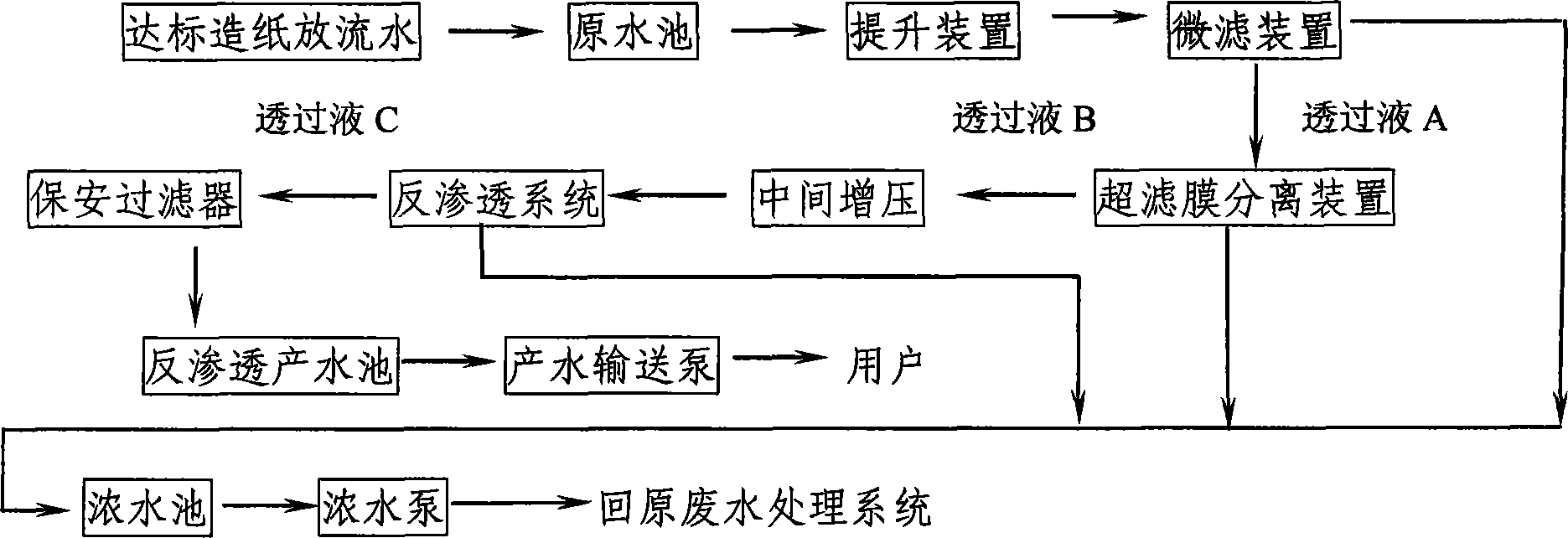

[0021] A kind of recycling method of papermaking industrial waste water of the present invention, it combines membrane technology and industrial water treatment technology together, comprises the following steps:

[0022] 1) Microfiltration process section: pre-treat the papermaking effluent after being treated by the biochemical system. The up-to-standard papermaking effluent first settles in the raw water pool, and then enters the self-cleaning filter in the microfiltration device through the lifting device to remove impurities in the raw water; The permeate A enters the next ultrafiltration process section, and the concentrated water containing impurities passes through the concentrated water tank and the concentrated water pump returns to the original chemical system for treatment.

[0023] The main purpose of the microfiltration process section is to remove suspended solids, colloids, chroma, turbidity, organic matter and other impurities in the raw water that hinder the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com