Repairing and resourceful treatment method of contaminated soil

A technology of polluted soil and disposal method, applied in the field of polluted soil remediation and resource disposal, can solve the problems of increased cost of ceramsite products, high production cost and high roasting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

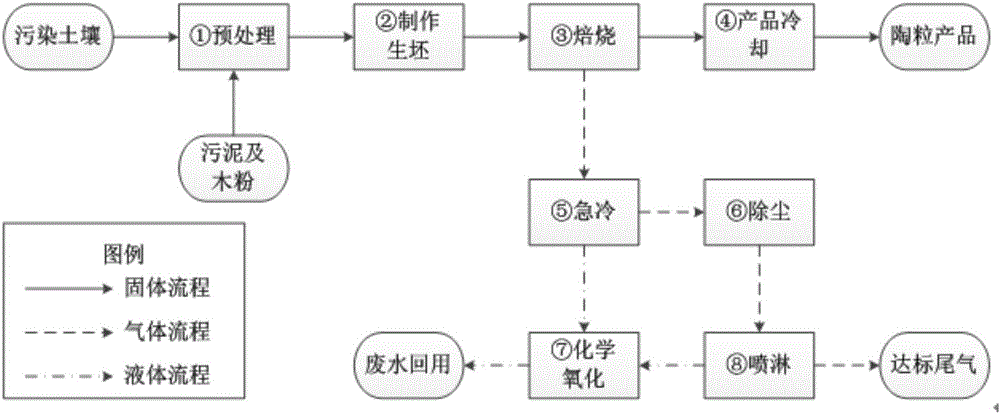

Method used

Image

Examples

Embodiment 1

[0025] The method of preparing light ceramsite from polycyclic aromatic hydrocarbon powder clay in a certain site is as follows:

[0026] (1) ball mill the contaminated soil of the site to 80 meshes with a ball mill, and screen the soil particle size through a vibrating screen;

[0027] (2) Add 3% of sludge, 5% of wood flour, and 5% of water, and mix well.

[0028] (3) The mixed raw materials are sent to a granulator for granulation to obtain a green body.

[0029] (4) drying the green body in step (3) and sending it to a rotary kiln for roasting at high temperature. The firing temperature was 1150°C, and the firing time was 15 min.

[0030] (5) After the fired ceramsite is naturally cooled, the ceramsite prepared from the polycyclic aromatic hydrocarbon-contaminated soil is obtained. After testing, the content of volatile and non-volatile organic compounds in ceramsite products is lower than the detection limit (GB 5085), and the ceramsite products belong to class 800 (GB / ...

Embodiment 2

[0033] The method for preparing light ceramsite for total petroleum hydrocarbon sand in a site is as follows:

[0034] (1) ball mill the contaminated soil of the site to 80 meshes with a ball mill, and screen the soil particle size through a vibrating screen;

[0035] (2) Add 20% sludge, 3% wood flour, 0% water, and mix well.

[0036] (3) The mixed raw materials are sent to a granulator for granulation to obtain a green body.

[0037] (4) drying the green body in step (3) and sending it to a rotary kiln for roasting at high temperature. The firing temperature was 1100°C, and the firing time was 10 min.

[0038] (5) After the fired ceramsite is naturally cooled, the ceramsite prepared with total petroleum hydrocarbon polluted soil is obtained. After testing, the content of organic pollutants in ceramsite products is lower than the detection limit (GB 5085), and the ceramsite products belong to class 600 (GB / T 17431).

[0039] (6) The exhaust gas produced in step (4) is subj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com