A kind of comprehensive recovery method of lithium iron phosphate cathode material

A cathode material, lithium iron phosphate technology, which is applied in the field of lithium, iron and phosphorus recovery in lithium iron phosphate cathode material, can solve the problems of waste of phosphorus resources, complicated process and high processing cost, and achieves less residue and mild process conditions. , Process cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

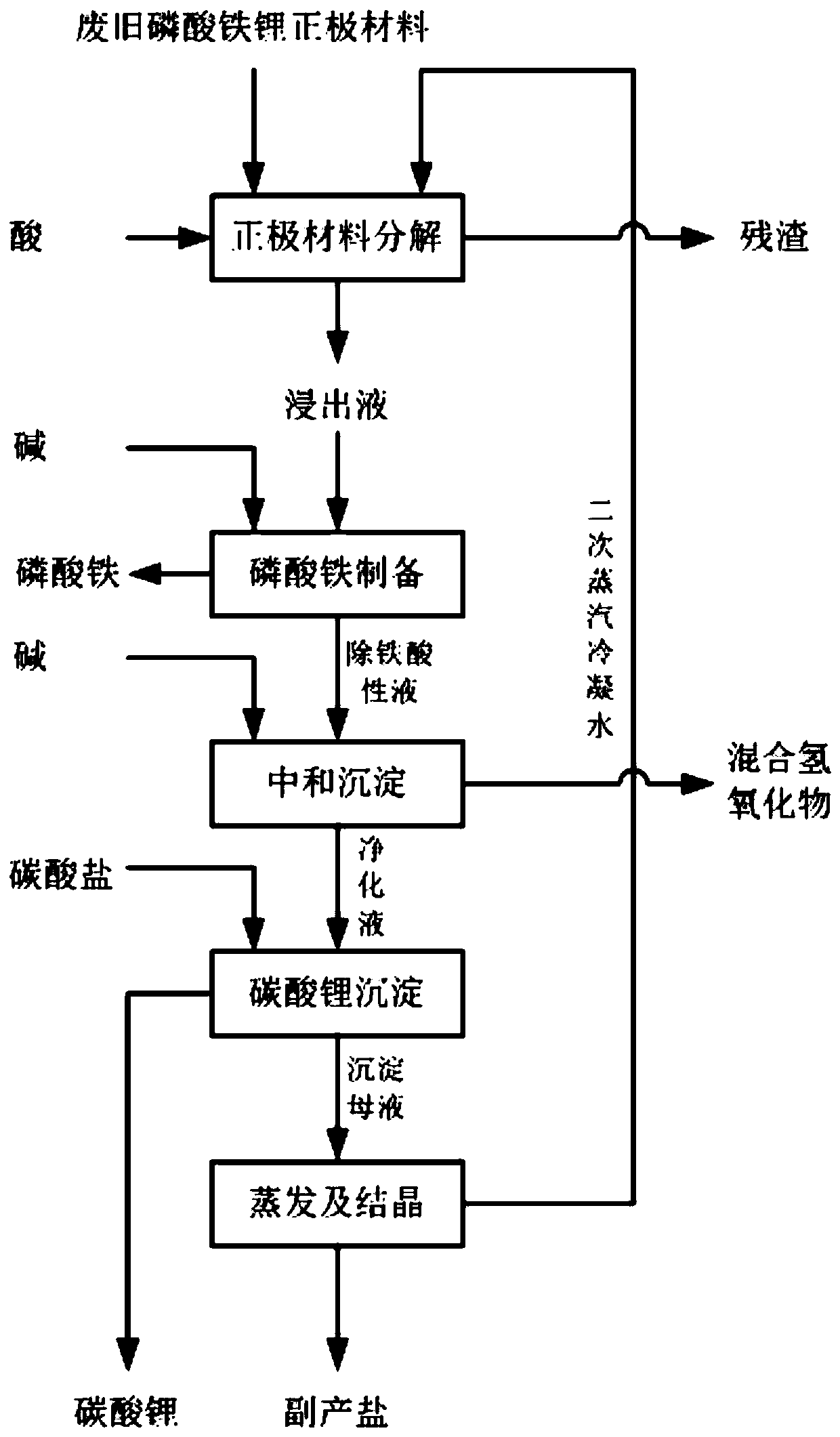

[0043] A comprehensive recovery method for waste and old lithium iron phosphate cathode materials, comprising the steps of:

[0044](1) Mix the waste lithium iron phosphate cathode material with condensed water to slurry, add sulfuric acid to it after the slurries are complete, the mass ratio of sulfuric acid (the content is calculated as 100wt%) to the cathode material is 0.3; In order to realize the decomposition of the positive electrode material under the condition of 150°C, the liquid-solid separation of the reacted material is carried out to obtain the leaching liquid and the residue respectively;

[0045] (2) adding ammonia water to the leaching solution to adjust the pH to 1.5, and precipitating ferric phosphate at normal temperature;

[0046] (3) adjusting pH to 5 with ammonia water in the pickling solution after precipitating ferric phosphate, precipitation of impurities such as aluminum and iron in the solution, and obtaining mixed hydroxide precipitation and purifi...

Embodiment 2

[0051] A comprehensive recovery method for waste and old lithium iron phosphate cathode materials, comprising the steps of:

[0052] (1) Mix the waste lithium iron phosphate positive electrode material with condensed water to slurry, add hydrochloric acid to it after the slurry is complete, the mass ratio of hydrochloric acid (content is calculated by 100wt%) to positive electrode material is 1; In order to realize the decomposition of the positive electrode material under the condition of 120°C, the liquid-solid separation of the reacted material is carried out to obtain the leaching liquid and the residue respectively;

[0053] (2) adding ammonium bicarbonate to the leaching solution to adjust the pH to 1.5, and precipitate ferric phosphate at 60°C;

[0054] (3) The pH of the pickling solution after the precipitation of ferric phosphate is adjusted to 8 with ammonium bicarbonate, the impurities such as aluminum and iron in the solution are precipitated, and the mixed hydroxi...

Embodiment 3

[0059] A comprehensive recovery method for waste and old lithium iron phosphate cathode materials, comprising the steps of:

[0060] (1) Mix the waste lithium iron phosphate positive electrode material with condensed water to slurry, add nitric acid to it after the slurry is complete, the mass ratio of nitric acid (content in 100wt%) to the positive electrode material is 2; In order to realize the decomposition of the positive electrode material under the condition of 90°C, the liquid-solid separation of the reacted material is carried out, and the leachate and residue are obtained respectively;

[0061] (2) adding sodium bicarbonate to the leaching solution to adjust the pH to 3, and precipitating ferric phosphate at 90°C;

[0062] (3) adjusting the pH to 8 with sodium bicarbonate in the pickling solution after the precipitation of iron phosphate, precipitation of impurities such as aluminum and iron in the solution, and obtaining mixed hydroxide precipitation and purificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com