A kind of oxidation-reduction lead electrocatalytic material and preparation method thereof and application in electrocatalytic reduction of sulfur dioxide

An electrocatalytic material, sulfur dioxide technology, applied in the direction of metal material coating process, electrodes, electrolytic components, etc., can solve the problems of large specific surface area of petal-shaped structure, poor selectivity of reducing to elemental sulfur, and more active site exposure, etc., to achieve Improve the selectivity of electrochemical catalysis, the selectivity advantage is obvious, and the effect of both environmental and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

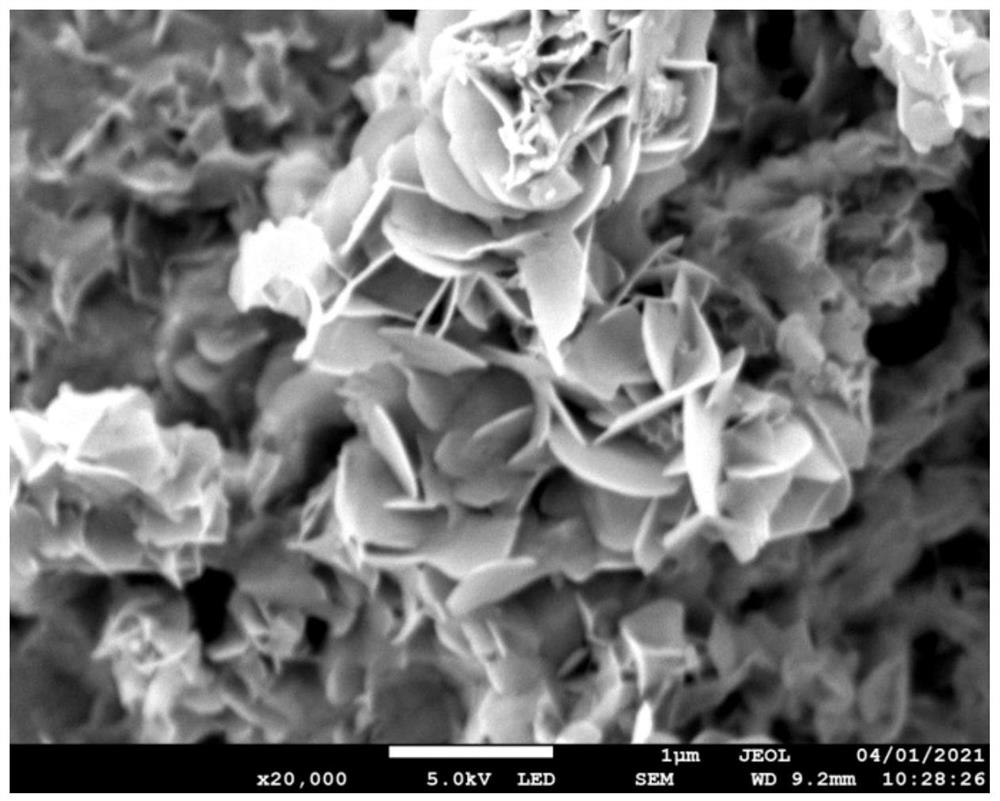

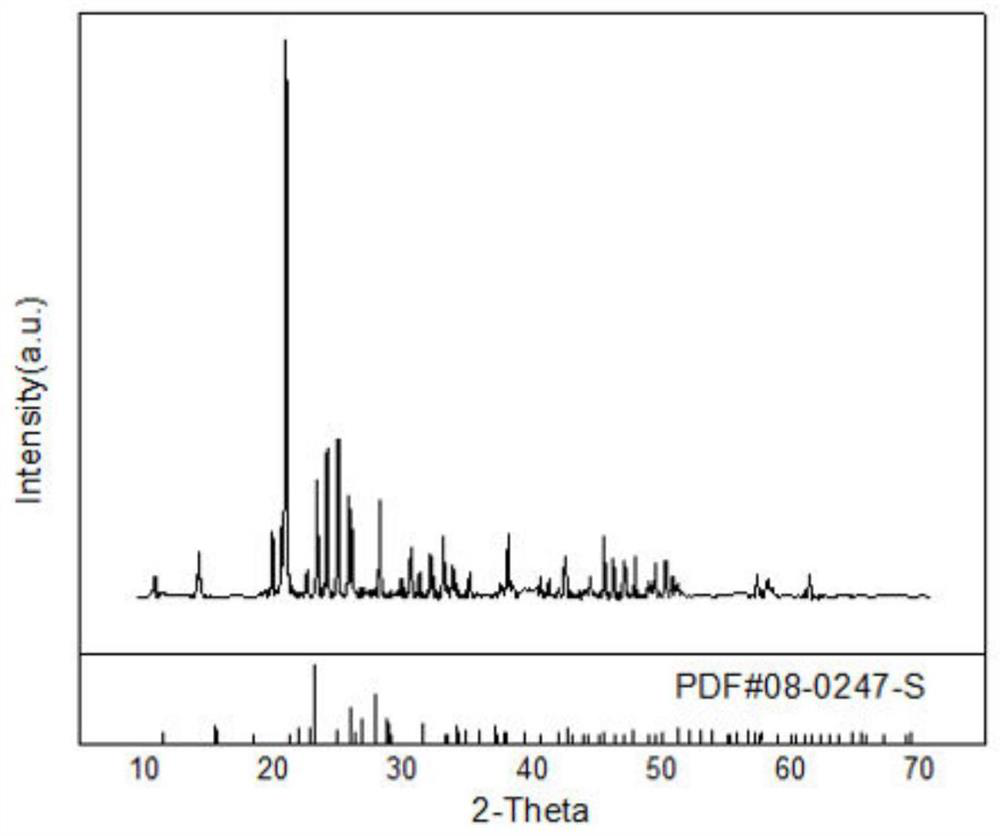

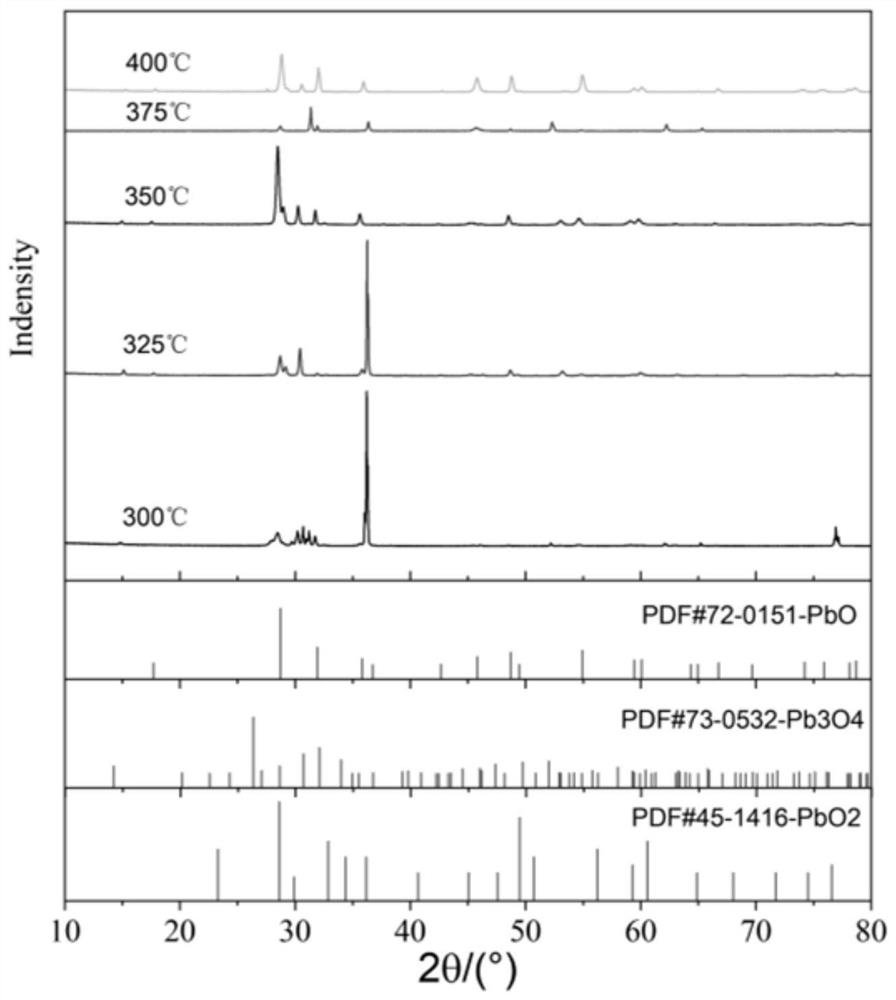

[0035] (1) Oxidation-reduction lead material preparation:

[0036] Take a high-purity lead sheet with a size of 15×10×0.3mm, clean it ultrasonically with acetone and ethanol solution, and immerse it in 10mL 2.66M NaOH and 10mL 0.13M (NH 4 ) 2 S 2 o 8 In the mixed solution, fully react for 10 minutes for pre-oxidation treatment. Subsequently, the material is placed at a high temperature (300° C. to 400° C.) and calcined for 50 minutes in an air atmosphere for oxidation treatment. The oxidized material is cleaned and dried to obtain a working electrode. An H-type electrolytic cell is used, and the cathode chamber and the anode chamber are separated by a DuPont N117 proton membrane. 0.08MNa 2 SO 4 As the electrolyte in the cathode and anode chambers, Pt as the counter electrode, and a saturated calomel electrode (SCE) as the reference electrode. The electrochemical reduction is carried out in 0~-1.5V cycle cv mode, the oxygen content is controlled to be about 5%, and the ox...

Embodiment 2

[0040] 50mL SO 2 The absorption liquid (sodium sulfite 0.08mol / L) is taken into the cathode chamber as the catholyte, 50mL of anhydrous sodium sulfate aqueous solution is used as the anolyte, and sulfuric acid is used to adjust the pH of the anode and cathode electrolytes (0.1, 0.3, 0.5, 0.7). The pure lead sheet or the OD-Pb material obtained at the calcination temperature of 350°C in Example 1 is used as the working electrode, Pt is used as the counter electrode, SCE is used as the reference electrode, the reduction voltage is -0.8V, the normal temperature water is circulated and cooled, and the electrolysis is stopped after 10min. Elemental sulfur is produced. Electrolysis to obtain a milky white or milky yellow suspension. The content of elemental sulfur in the solution was determined by a suspended solids analyzer. combine Figure 5 The results show that after the oxidation-reduction treatment, the faradaic efficiency of elemental sulfur is increased by nearly 20%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com