A method for the recovery of nickel and energy substances from nickel hyperaccumulator plants

A super-enrichment plant and nickel-rich technology, applied in the field of solid waste recycling, can solve problems such as high operating costs, recovery of pyrolysis oil and pyrolysis gas, waste of resources, etc., and achieve high-value recovery and high recovery efficiency , to avoid the effect of wasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 A kind of method that utilizes vacuum pyrolysis staged condensation device to reclaim energy substance from nickel hyperaccumulation plant Brassica japonica (Alysumsbertooonii)

[0054] 1. Vacuum pyrolysis segmental condensation device

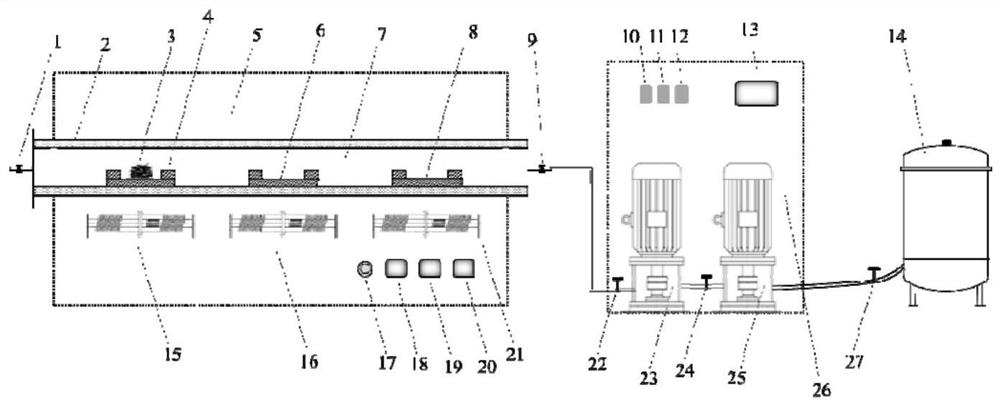

[0055] The structure of the vacuum pyrolysis segmental condensation device is as follows: figure 1 As shown, it includes three parts: vacuum pyrolysis condensation system 5 , vacuum pumping system 26 and pyrolysis gas collection system 14 . Vacuum pyrolysis condensation system 5 is divided into inlet valve 1 and outlet valve 9, and a corundum tube 7 is placed in the vacuum pyrolysis condensation assembly 2. The first temperature zone in the tube is the pyrolysis zone, and a corundum crucible-4 is placed to hold Put the super-enrichment plant harvest 3, and control the temperature of the first temperature zone by controlling the silicon molybdenum rod thermocouple heating element 15 through the temperature regulator 18; the...

Embodiment 2

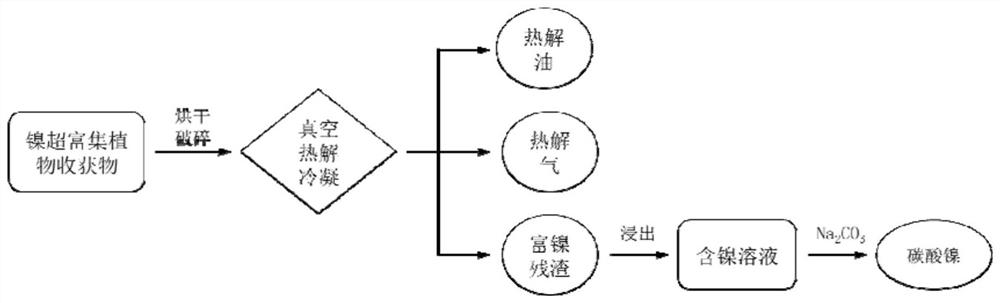

[0062] Example 2 Recovery of nickel and energy substances from nickel hyperaccumulator plant Brassica japonica (Alysums bertooonii)

[0063] (1) Drying 40 g of the harvested plant of the nickel hyperaccumulator Brassettina sativa, and crushing the dried plant in a shear crusher to obtain a uniform nickel hyperaccumulator harvested powder.

[0064] (2) The above-mentioned nickel hyperaccumulated plant powder is subjected to pyrolysis and condensation treatment using a vacuum pyrolysis staged condensation device. Set the vacuum degree of the first pyrolysis zone to 10Pa, the final pyrolysis temperature to 600°C, the heating rate to 30°C / min, and the retention time to 30min. Set the condensation temperature of the second condensation zone to 160°C, and set the condensation temperature of the third condensation zone to 60°C.

[0065] (3) Collect the pyrolysis products of the above-mentioned nickel hyperaccumulation plant harvests to obtain 27.67 g of mixed hydrocarbon pyrolysis o...

Embodiment 3

[0070] Embodiment 3 A kind of method that reclaims nickel and energy source material from nickel hyperaccumulator plant

[0071] (1) Drying 40 g of the harvested plant of the nickel hyperaccumulator Brassettina sativa, and crushing the dried plant in a shear crusher to obtain a uniform nickel hyperaccumulator harvested powder.

[0072] (2) The above-mentioned nickel hyperaccumulated plant powder is subjected to pyrolysis and condensation treatment using a vacuum pyrolysis staged condensation device. Set the vacuum degree of the first pyrolysis zone to 100Pa, the final pyrolysis temperature to 500°C, the heating rate to 20°C / min, and the retention time to 40min. Set the condensation temperature of the second condensation zone to 180°C, and set the condensation temperature of the third condensation zone to 80°C.

[0073] (3) Collect the pyrolysis products of the above-mentioned nickel hyperaccumulation plant harvests to obtain 24.14 g of mixed hydrocarbon pyrolysis oil and pyro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com