Complex copper waste liquid and micro-etching waste liquid composite treatment method

A composite treatment and complex copper technology, applied in filtration treatment, precipitation treatment, water/sewage treatment and other directions, can solve the problems of affecting the extraction effect, consumption of large acids and oxidants, high cost, and achieve cost reduction, purity and high quality. , high-value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

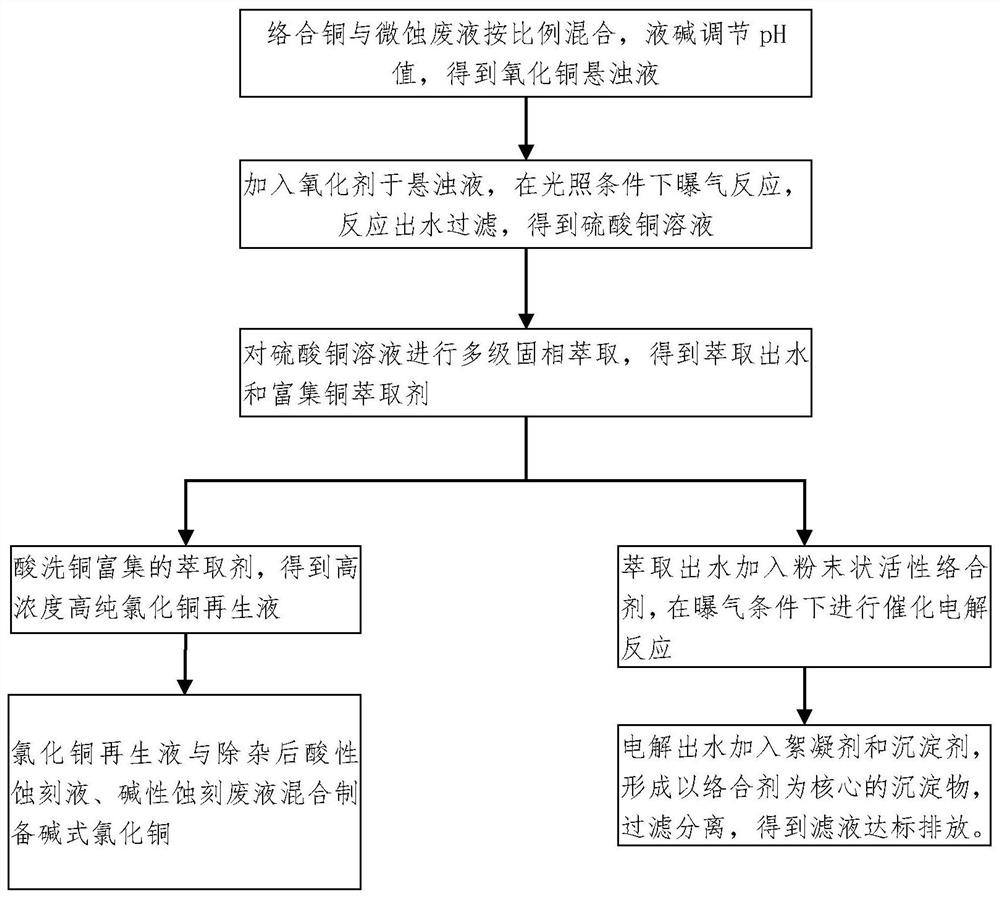

Method used

Image

Examples

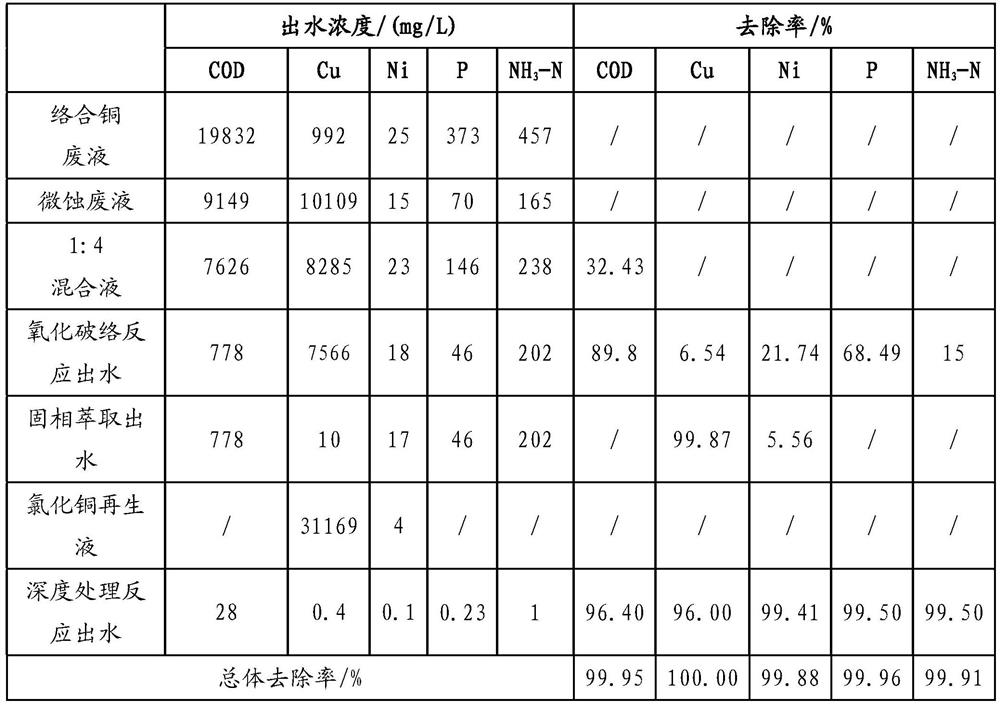

Embodiment 1

[0071] laboratory apparatus

[0072] Oxidative decomplexation reactor, 200mm×200mm×250mm, built-in 2 aeration heads and 2 UV lamps, externally connected to a water pump for internal circulation; solid phase extraction column, outer diameter (inner diameter) × height = 50(44) × 500mm Chromatographic column; deep flat electrolytic cell, 200mm×200mm×250mm, built-in aeration head and 8 flat electrode plates, externally connected to a water pump for internal circulation.

[0073] Step 1: Take 1L of electroless copper plating waste liquid from the circuit board factory into the reaction vessel, add 4L of micro-etching waste liquid, and turn on the aeration to fully mix. Add 50% liquid caustic soda to adjust the pH value of the mixed solution to 2.5 to generate a mixed suspension containing black copper oxide. Turn on the ultraviolet light source, slowly add 275ml of oxidizing agent at a volume ratio of 5.5%, and react for 2h.

[0074] Step 2: Suction filtration of the reaction eff...

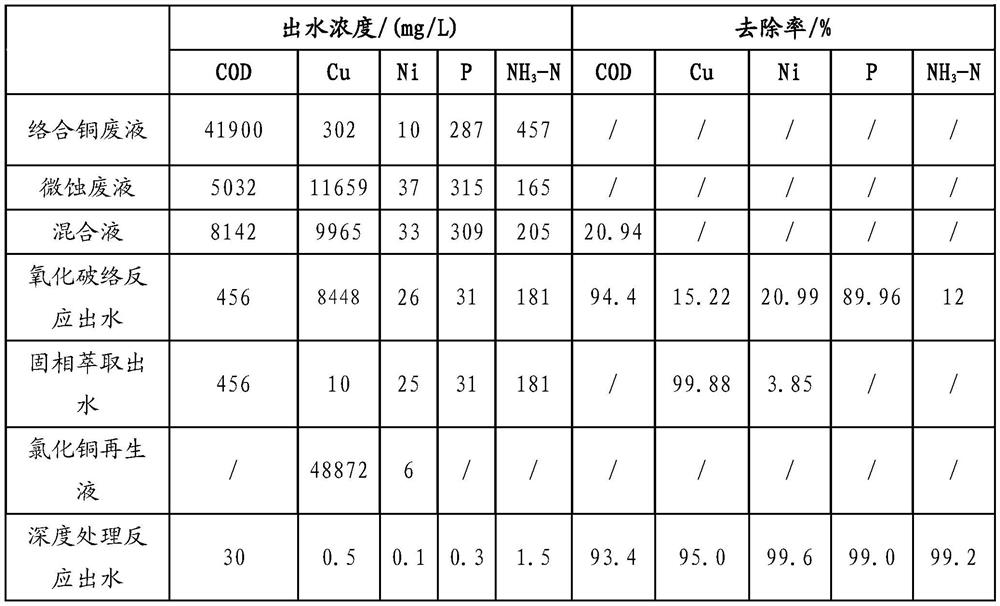

Embodiment 2

[0081] laboratory apparatus

[0082] Oxidative decomplexation reactor, 200mm×200mm×250mm, built-in 2 aeration heads and 2 UV lamps, externally connected to a water pump for internal circulation; solid phase extraction column, outer diameter (inner diameter) × height = 50(44) × 500mm Chromatographic column; deep flat electrolytic cell, 200mm×200mm×250mm, built-in aeration head and 8 flat electrode plates, externally connected to a water pump for internal circulation.

[0083] Step 1: Take 1L of electroless copper plating waste liquid from the circuit board factory into the reaction vessel, add 6L of micro-etching waste liquid, and turn on the aeration to fully mix. Add 50% liquid caustic soda to adjust the pH value of the mixed solution to 2 to generate a mixed suspension containing black copper oxide. Turn on the ultraviolet light source, slowly add 560ml of oxidizing agent according to the volume ratio of 8%, and react for 2h.

[0084] Step 2: Suction filtration of the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com