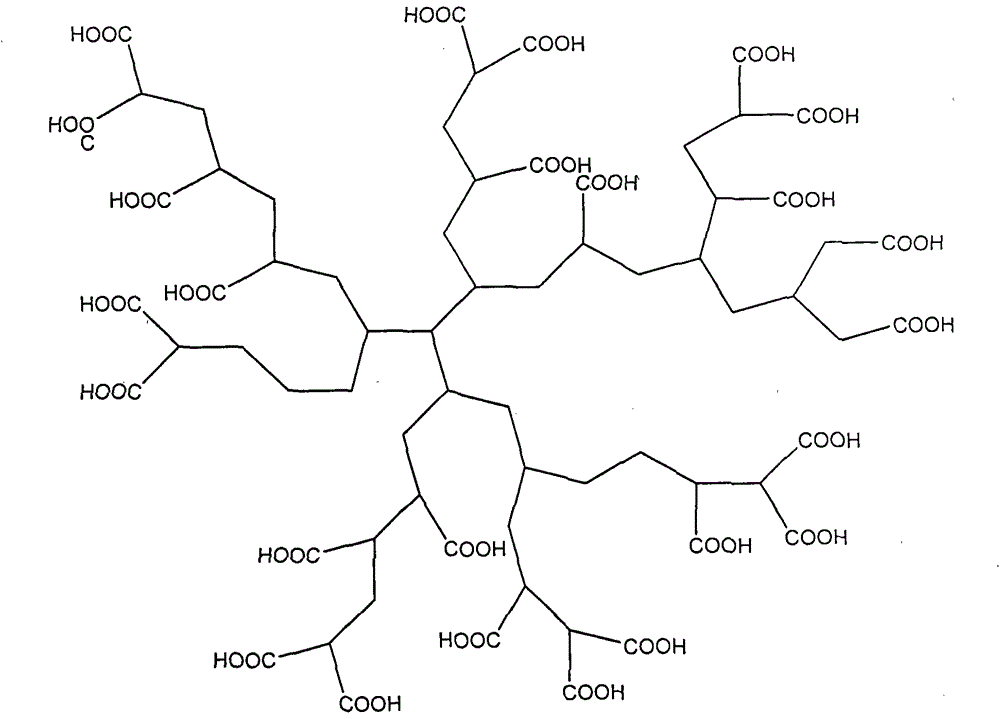

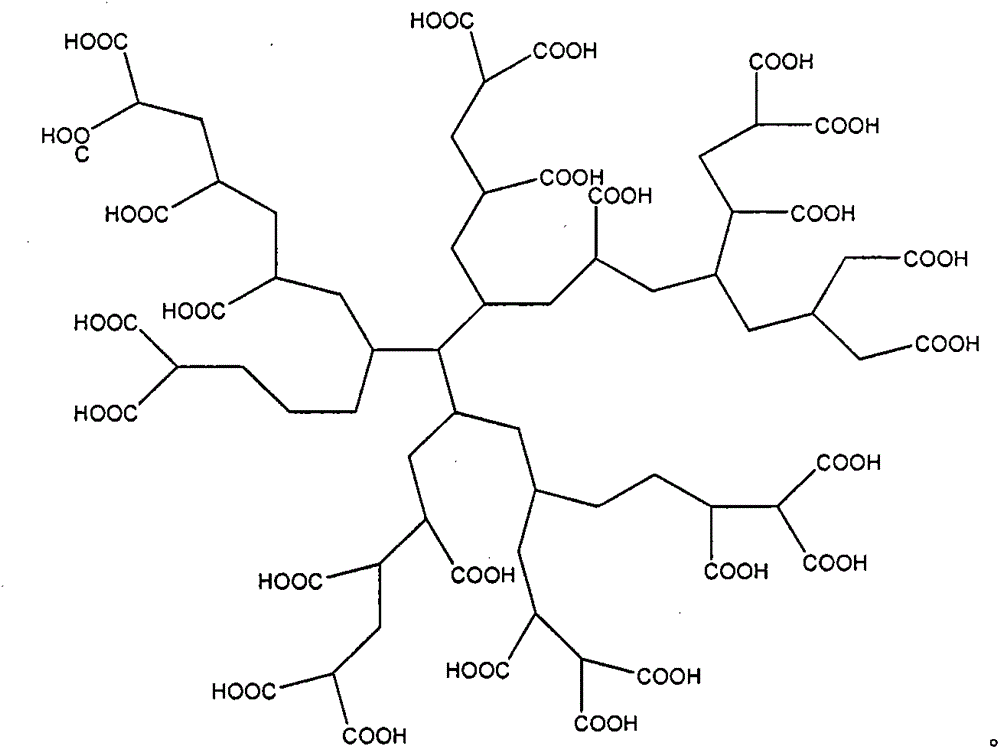

Carboxyl-terminated hyperbranched polymer scale inhibiting and preventing agent and synthesizing method

A technology of hyperbranched polymer and synthesis method, which is applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. , single scale inhibition mechanism and other problems, to achieve the effect of good scale prevention effect, small environmental impact, and the effect of solving the scaling problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: in the four-neck flask that thermometer, sampling port are housed, glycerol and maleic anhydride are mixed by the molar ratio of 1: 1, then add and account for glycerol and maleic anhydride gross mass percentage is 0.5% The p-toluenesulfonic acid was reacted at 120°C for 4h, and vacuumized to obtain a hyperbranched polyester with terminal hydroxyl groups; After the modification reaction for 2 hours, deionized water with 50% polymer mass was added to obtain a carboxyl-terminated hyperbranched polymer scale inhibitor and scale inhibitor solution.

Embodiment 2

[0032] Example 2: In a four-necked flask equipped with a thermometer and a sampling port, trimethylolpropane and phthalic anhydride are mixed in a molar ratio of 1:1, and then trimethylolpropane and phthalic anhydride are added. The total mass percentage of formic anhydride is 1% p-toluenesulfonic acid, react at 120 ℃ for 5h, and vacuumize to obtain the hyperbranched polyester with terminal hydroxyl; To anhydride, carry out modification reaction at 90° C. for 3 hours, add deionized water with 40% polymer mass, to obtain carboxyl-terminated hyperbranched polymer scale inhibitor and scale inhibitor solution.

Embodiment 3

[0033]Example 3: In a four-neck flask equipped with a thermometer and a sampling port, mix diethanolamine and maleic anhydride in a molar ratio of 1:1, react at 60°C for 0.5h, and then add diolamine and maleic anhydride The total mass percent is 0.2% p-toluenesulfonic acid, react at 120°C for 6h, and vacuumize to obtain the hyperbranched poly(amide-ester) with terminal hydroxyl; then add the hyperbranched poly(amide-ester) with terminal hydroxyl mole Succinic anhydride with a ratio of 1:1.2 was modified at 100° C. for 4 hours, and deionized water with 50% polymer mass was added to obtain a carboxyl-terminated hyperbranched polymer scale inhibitor and scale inhibitor solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com