Green environment-friendly flocculant and method for preparing same

A green and environmentally friendly flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor flocculation effect and achieve the effects of fast settling speed, low cost and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

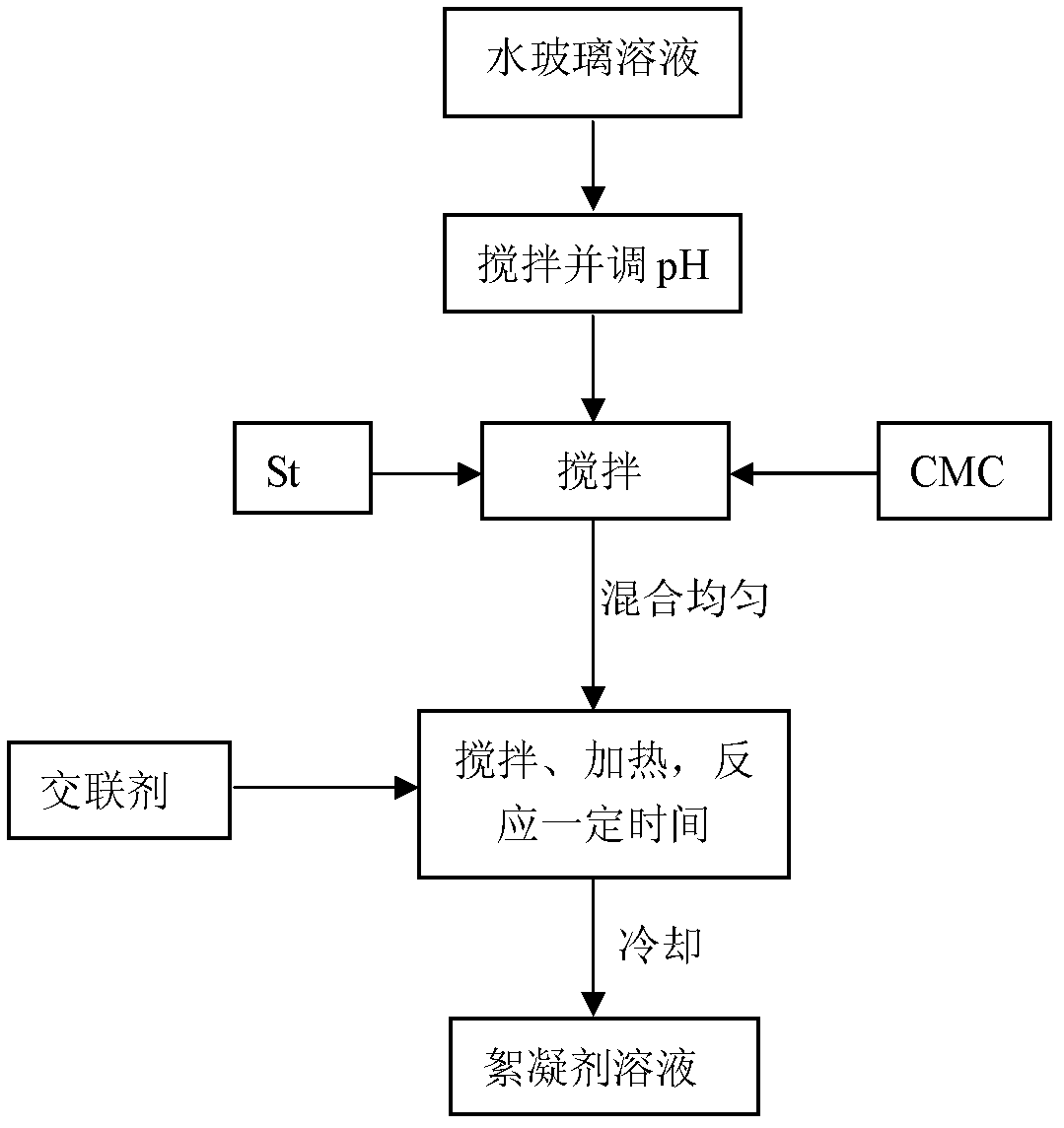

Embodiment 1

[0041] Weigh 1 g of water glass (nano silica) into a 100 mL beaker, add 50 mL of water, slowly adjust the pH to 3 with 0.1 mol / L hydrochloric acid, stir for 1 h to form a water glass solution (nano silica colloid), continue stirring or ultrasonically set aside. Take 50mL of the above-prepared water glass solution in a three-necked flask, and place it in a constant temperature water bath, add 2g St, 1g CMC, stir to dissolve, add 0.003g potassium persulfate when the temperature of the water bath reaches 70°C, and react in a constant temperature water bath for 5h, That is, the SSCMC flocculant solution is obtained.

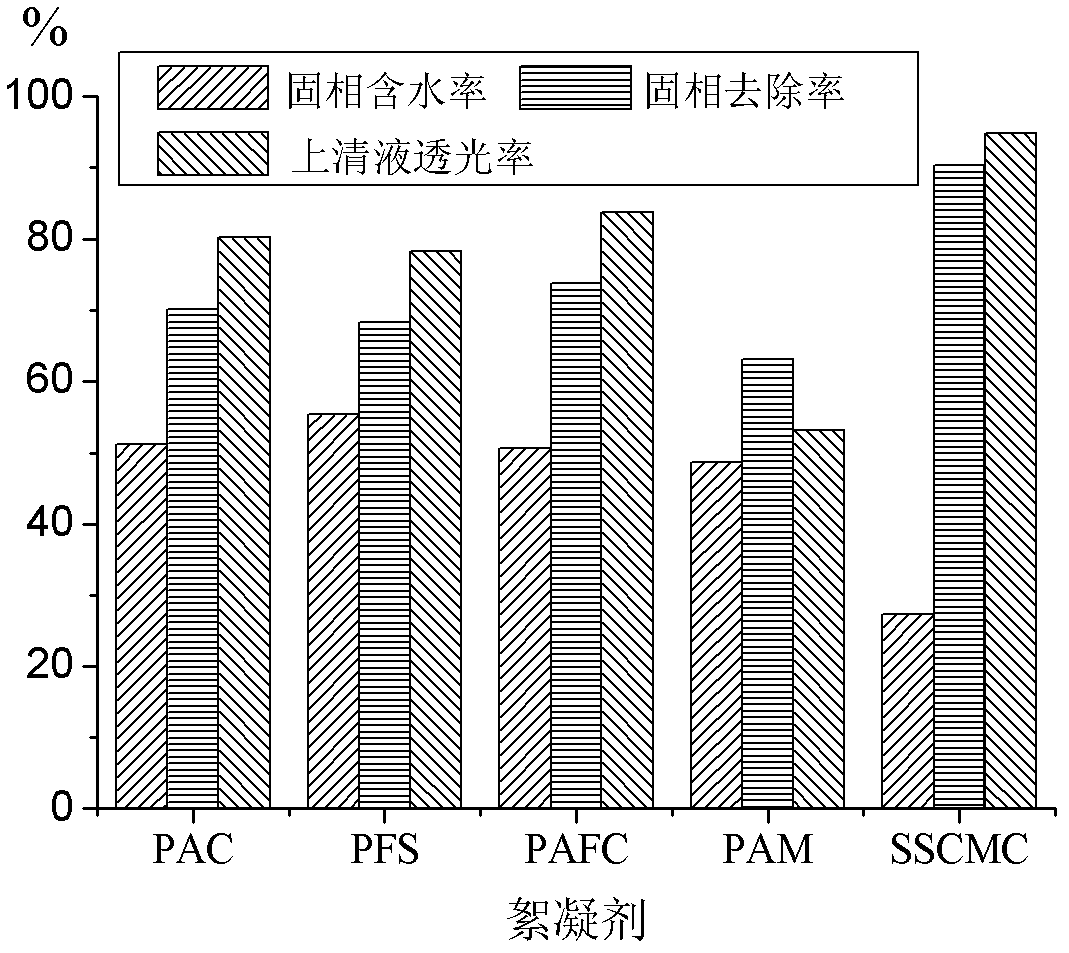

[0042]Weigh 100g of waste drilling fluid, add 0.5g of the above-prepared SSCMC solution, stir evenly and let it stand, centrifuge at a speed of 4000r / min for 10min in a centrifuge, pour out the upper layer liquid, and measure it at 650nm with an ultraviolet spectrophotometer. The light transmittance (T, %) of the clear liquid, and the mass of the solid filter cake in...

Embodiment 2

[0050] Weigh 5 g of water glass into a 100 mL flask, add 50 mL of water, slowly adjust the pH to 7 with 0.1 mol / L hydrochloric acid, stir for 2 hours to form a water glass solution, continue to stir or sonicate for later use. Take 50mL of the above-prepared water glass solution in a three-necked flask, and place it in a constant temperature water bath, add 7.5g St, 5g CMC, stir and dissolve, add 0.125g potassium persulfate and sodium sulfite (persulfate The mass ratio of potassium to sodium sulfite is 1:1), react in a constant temperature water bath for 4 hours, and obtain the SSCMC flocculant solution.

[0051] The determination of solid phase moisture content, solid phase removal rate, and supernatant liquid permeability is the same as in Example 1. Add 0.1 g of the above-mentioned SSCMC flocculant solution to 100 g of waste drilling fluid for treatment, and the flocculant has a positive effect on the two waste drilling fluids. The flocculation effect is as follows: the mois...

Embodiment 3

[0053] Weigh 0.5 g of water glass into a 100 mL flask, add 50 mL of water, slowly adjust the pH to 5 with 0.1 mol / L hydrochloric acid, stir for 1 hour to form a water glass solution, continue stirring or sonicate for later use. Take 50mL of the above-prepared water glass solution in a three-necked flask, and place it in a constant temperature water bath, add 0.5g St, 0.75g CMC, stir and dissolve, when the temperature of the water bath reaches 90°C, add 0.0065g potassium persulfate, and react in a constant temperature water bath After 5 hours, the SSCMC flocculant solution was obtained.

[0054] The determination of solid phase water content, solid phase removal rate and supernatant liquid permeability is the same as in Example 1. Add 1 g of the above-mentioned SSCMC flocculant solution to 100 g of waste drilling fluid for treatment. The flocculation effect is as follows: the moisture content of the solid phase is 31.52%, the removal rate of the solid phase is 81.56%, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com