High-performance polymeric aluminium and preparation method thereof

A polyaluminum chloride, high-performance technology, applied in chemical instruments and methods, water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of low Al content, low total Al concentration, and easy pollution, etc. problems, to achieve the effects of fast settlement, low dosage, and protection of the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

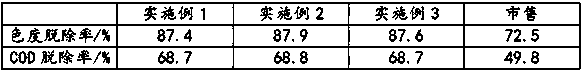

Examples

preparation example Construction

[0038] The preparation method of described high-performance polyaluminum chloride comprises the steps:

[0039] Step 1, adding zinc chloride to 36% industrial hydrochloric acid, stirring in a constant temperature water bath at 45-55°C for 30-40min, to obtain a zinc chloride solution;

[0040] Step 2. Add sodium silicate to ammonia-free distilled water, then add sulfuric acid with a mass fraction of 37% to adjust the pH to 3-4, and stir in a constant temperature water bath at 60°C at 30r / min for 60-70min to obtain polysilicon acid solution;

[0041] Step 3. Slowly add the above-prepared zinc chloride solution and polysilicate solution to the modified polyaluminum chloride, add NaHCO 3 Solution, stirred at 30r / min to dissolve and polymerized at 55°C for 60-70min, then placed in a drying oven at 108°C for 30h to obtain a viscous liquid;

[0042]Step 4, diluting, filtering and spray-drying the viscous liquid to obtain a powder;

[0043] Step 5, uniformly mixing the powder, sodi...

Embodiment 1

[0045] A high-performance polyaluminum chloride, made of the following main raw materials in parts by weight: 40 parts of modified polyaluminum chloride, 15 parts of sodium chlorate, 10 parts of industrial salt, 6 parts of zinc chloride, 20 parts of 36% industrial hydrochloric acid parts, 10 parts of sodium silicate, 80 parts of ammonia-free distilled water, NaHCO 3 18 parts of solution;

[0046] Described high-performance polyaluminum chloride is made by following steps:

[0047] Step 1, adding zinc chloride to 36% industrial hydrochloric acid, stirring in a constant temperature water bath at 45°C for 40 minutes, to obtain a zinc chloride solution;

[0048] Step 2. Add sodium silicate to ammonia-free distilled water, then add sulfuric acid with a mass fraction of 37% to adjust the pH to 3, and stir magnetically at 30 r / min in a constant temperature water bath at 60°C for 60 minutes to prepare a polysilicate solution;

[0049] Step 3. Slowly add the above-prepared zinc chlor...

Embodiment 2

[0053] A high-performance polyaluminum chloride, made of the following main raw materials in parts by weight: 45 parts of modified polyaluminum chloride, 18 parts of sodium chlorate, 13 parts of industrial salt, 7.5 parts of zinc chloride, 25 parts of 36% industrial hydrochloric acid Parts, 13 parts of sodium silicate, 90 parts of ammonia-free distilled water, NaHCO 3 21 parts of solution;

[0054] Described high-performance polyaluminum chloride is made by following steps:

[0055] Step 1, adding zinc chloride to 36% industrial hydrochloric acid, stirring in a constant temperature water bath at 50°C for 35 minutes, to obtain a zinc chloride solution;

[0056] Step 2. Add sodium silicate to ammonia-free distilled water, then add sulfuric acid with a mass fraction of 37% to adjust the pH to 3.5, and stir magnetically at 30 r / min in a constant temperature water bath at 60°C for 65 minutes to obtain a polysilicic acid solution;

[0057] Step 3. Slowly add the above-prepared zin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com