High-early-strength-type alkali-free liquid accelerator and preparation method and application thereof

An early-strength, quick-setting agent technology, applied in the field of building material admixtures, can solve the problems of shortening the initial and final setting time of cement, reducing shotcrete, endangering construction safety, etc. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

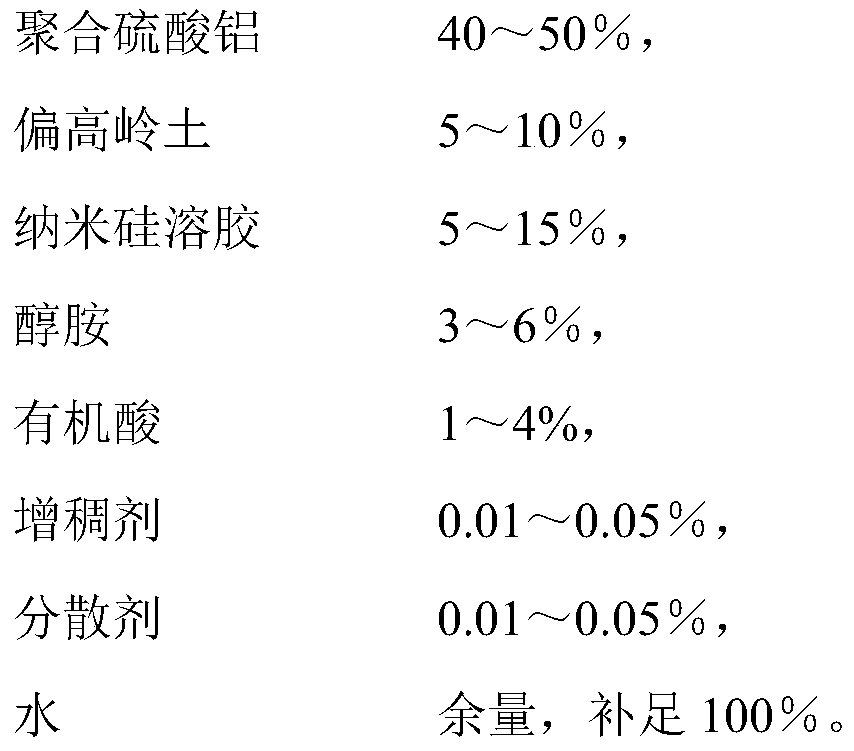

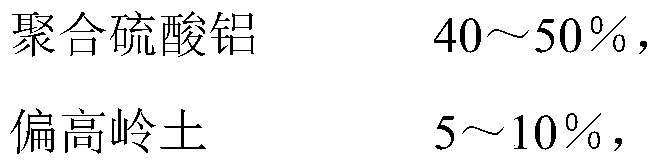

[0034] A high-early-strength non-alkali liquid quick-setting agent is composed of the following raw materials in weight percentage.

[0035] Polyaluminum sulfate: 40%,

[0036] Metakaolin: 10%,

[0037] Nano silica sol: 15%,

[0038] N,N-Dimethylethanolamine: 6%,

[0039] Organic acids: 4%,

[0040] Thickener: 0.05%,

[0041] Dispersant: 0.05%,

[0042] Water: 24.9%

[0043] The above-mentioned raw materials are prepared according to the above-mentioned preparation method to obtain a high-early-strength type alkali-free liquid accelerator.

Embodiment 2

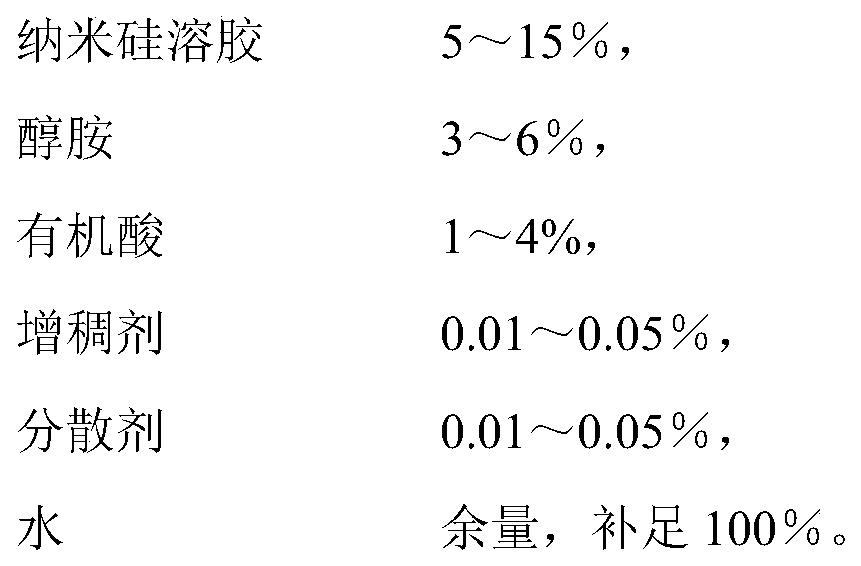

[0045] A high-early-strength non-alkali liquid quick-setting agent is composed of the following raw materials in weight percentage.

[0046] Polyaluminum Sulfate: 55%,

[0047] Metakaolin: 5%,

[0048] Nano silica sol: 5%,

[0049] Diethylene glycol amine: 4%,

[0050] Organic acids: 3%,

[0051] Thickener: 0.01%,

[0052] Dispersant: 0.01%,

[0053] Water: 27.98%.

[0054] The above-mentioned raw materials are prepared according to the above-mentioned preparation method to obtain a high-early-strength type alkali-free liquid accelerator.

Embodiment 3

[0056] A high-early-strength non-alkali liquid quick-setting agent is composed of the following raw materials in weight percentage. Polyaluminum sulfate: 50%,

[0057] Metakaolin: 8%,

[0058] Nano silica sol: 10%,

[0059] N-Methyldiethanolamine: 3%,

[0060] Organic acid: 1%,

[0061] Thickener: 0.03%,

[0062] Dispersant: 0.02%,

[0063] Water: 27.95%.

[0064] The above-mentioned raw materials are prepared according to the above-mentioned preparation method to obtain a high-early-strength type alkali-free liquid accelerator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com