Patents

Literature

37results about How to "Conducive to the realization of large-scale industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-early-strength-type alkali-free liquid accelerator and preparation method and application thereof

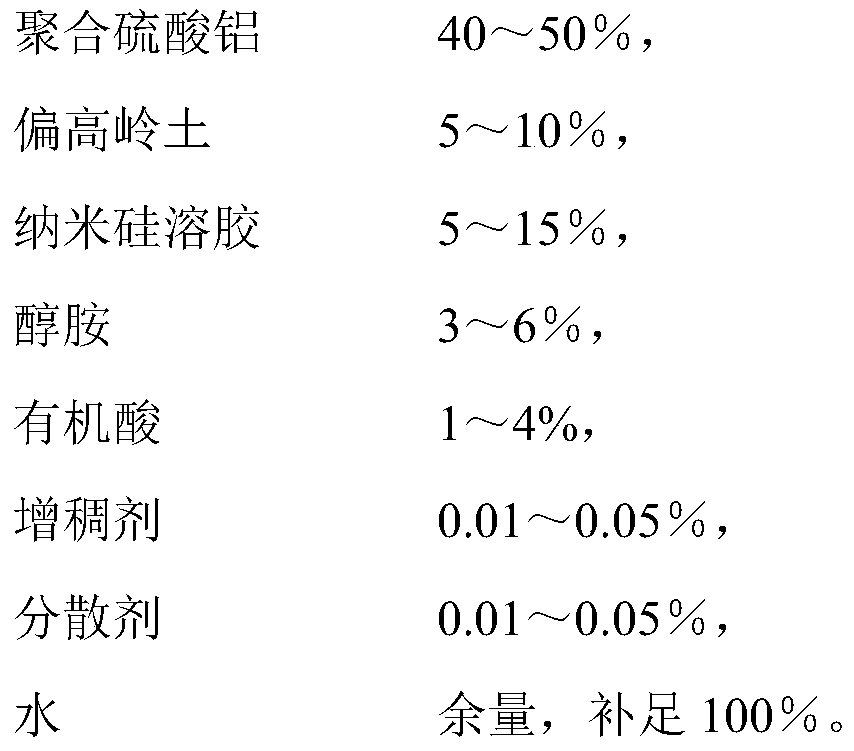

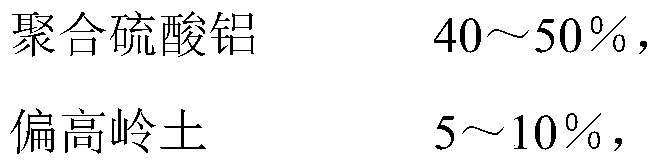

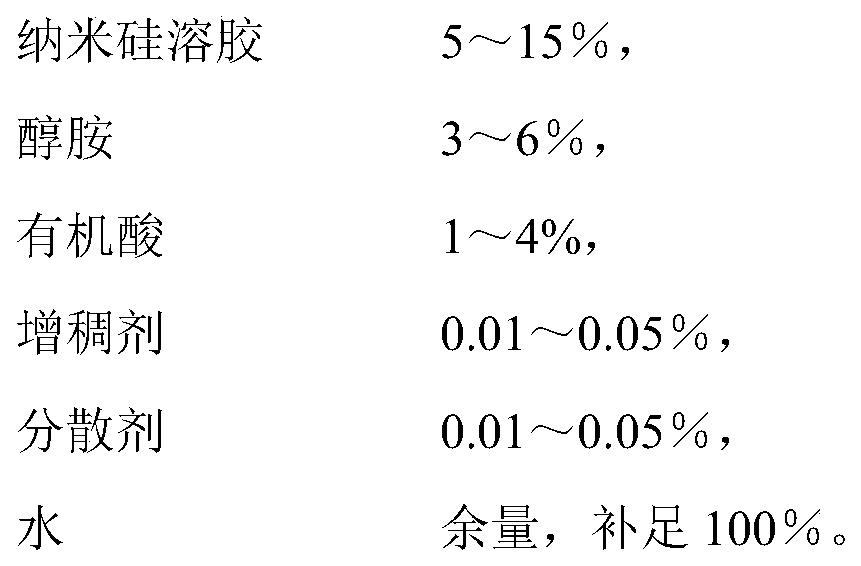

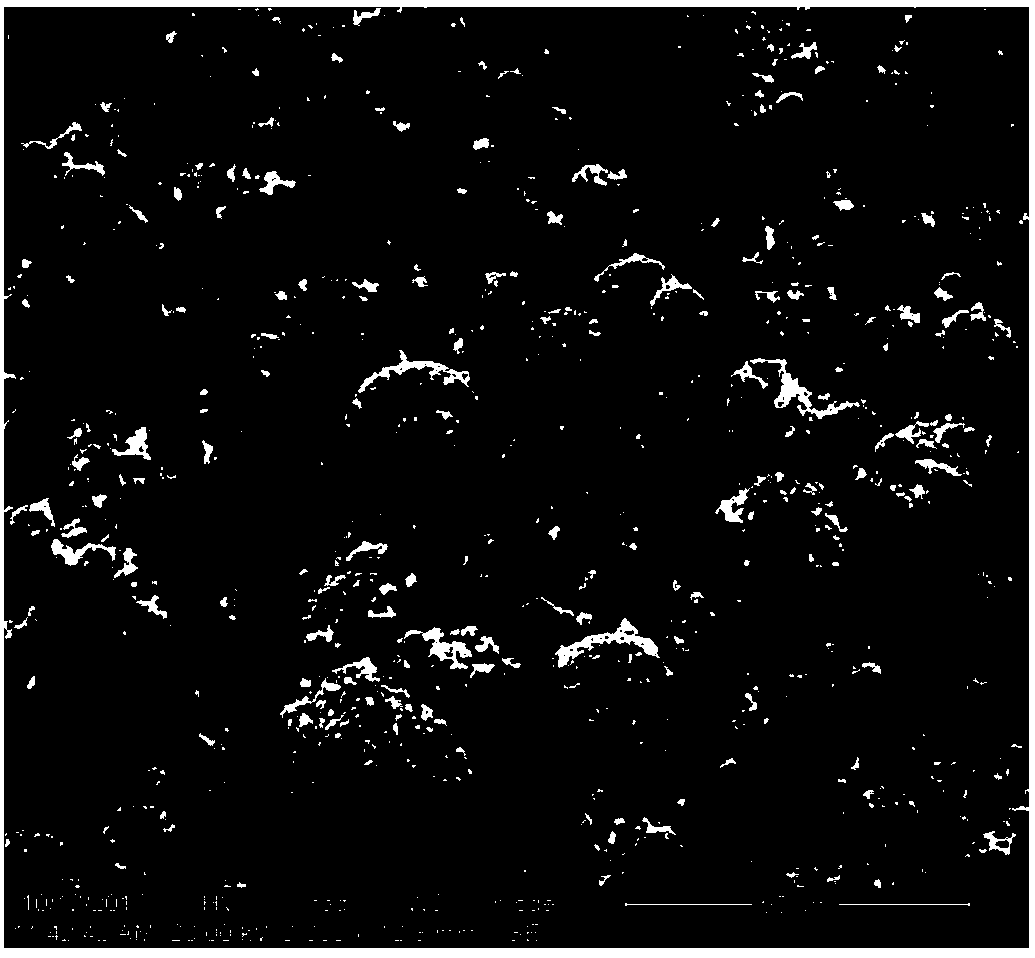

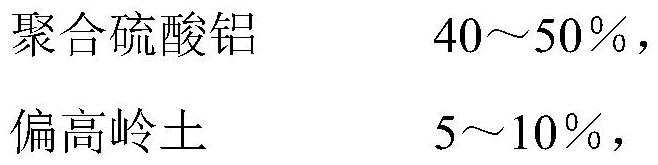

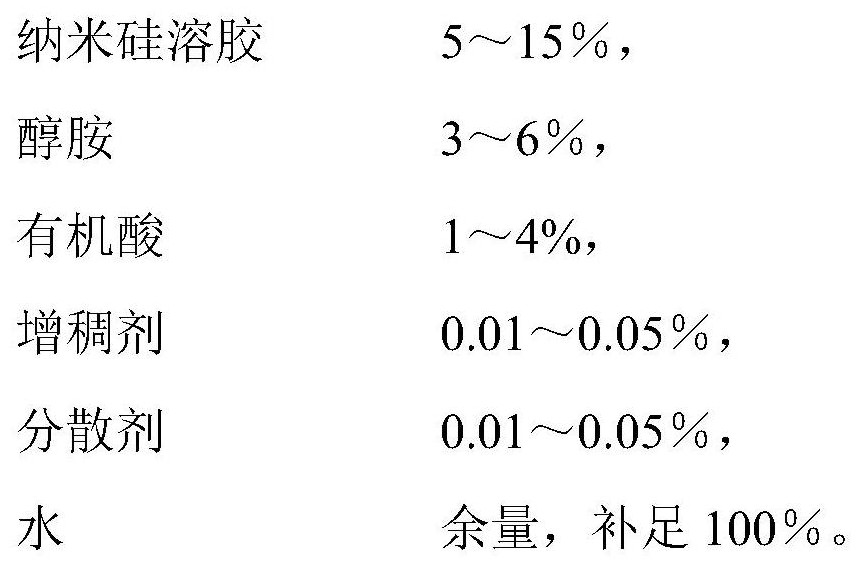

The invention relates to a high-early-strength-type alkali-free liquid accelerator and a preparation method and application thereof, and belongs to the technical field of additives of building materials. The accelerator is prepared from, by weight, 40-50% of polyaluminium sulfate, 5-10% of metakaolin, 5-15% of nanometer colloidal silica, 3-6% of alcohol amine, 1-4% of organic acid, 0.01-0.05% of athickening agent, 0.01-0.05% of a dispersion agent and the balance water. On the basis of meeting the national standard of <accelerators used for shotcrete> (GB / T35159-2017), the accelerator can effectively improve the compressive strength of cement mortar after one day, the compressive strength reaches 20 MPa or above, and the compressive strength of partial cement mortar can even reach 25 MPa or above after one day.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

Manufacturing method of porous copper foil used for lithium-ion capacitor current collector

ActiveCN105845459ASimple processReduce energy consumptionHybrid/EDL manufactureHybrid capacitor current collectorsCopper foilLithium-ion capacitor

The invention relates to the capacitor manufacturing field and discloses a manufacturing method of a porous copper foil used for a lithium-ion capacitor current collector. In the method, the copper foil is taken as a raw material and a direct current electrolysis oxidation method is used. The method comprises the following steps of A) taking an inert graphite as a cathode and taking the copper foil as an anode so as to carry out pretreatment developing hole on the copper foil; B) cleaning the processed copper foil; C) after cleaning, taking the inert graphite as the cathode and taking the copper foil as the anode so as to carry out electrolysis hole reaming on the copper foil; and D) successively performing secondary cleaning, post-treatment electrolysis and three-times cleaning on the processed copper foil and then acquiring the porous copper foil. By using the method, a technology is simple, cost is low and the method is suitable for industrial production.

Owner:西科微纳(重庆)新能源技术研究院有限公司

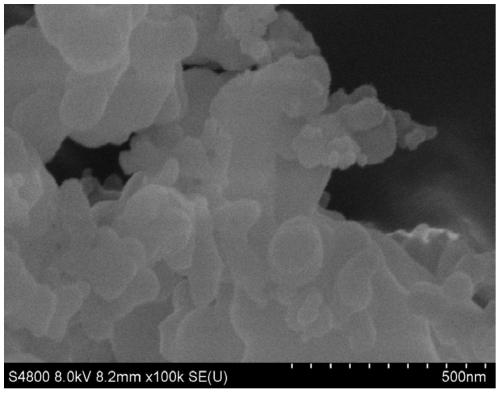

Low-surface-alkalinity lithium nickel cobalt aluminate positive electrode material and preparation method thereof

InactiveCN108417796ALow structural firmnessSmall latticeCell electrodesSecondary cellsPhosphatePyrophosphate

The invention discloses a low-surface-alkalinity lithium nickel cobalt aluminate positive electrode material and a preparation method thereof. The lithium nickel cobalt aluminate positive electrode material is obtained by performing calcining on metal hydrogen phosphate and a lithium nickel cobalt aluminate positive electrode active material in oxygen flow. By adoption of metal hydrogen phosphatewhich is decomposed into pyrophosphate in calcining, reactant activity is improved, and a reaction with the residual alkali in the lithium nickel cobalt aluminate positive electrode active material ispromoted to generate a Li<3>PO<4> coating layer; compared with phosphate, hydrogen phosphate is lower in structural firmness, lower in lattice energy and easier in reaction, so that the calcining temperature can be obviously lowered; dry method coating of the lithium nickel cobalt aluminate positive electrode active material is converted from high temperature solid phase reaction (700 DEG C) in the prior art into a medium temperature solid phase reaction (400-600 DEG C), so that reaction difficulty is greatly lowered; and in addition, simple process, low cost and high production efficiency are achieved, so that realization of large-scale industrial production can be facilitated.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

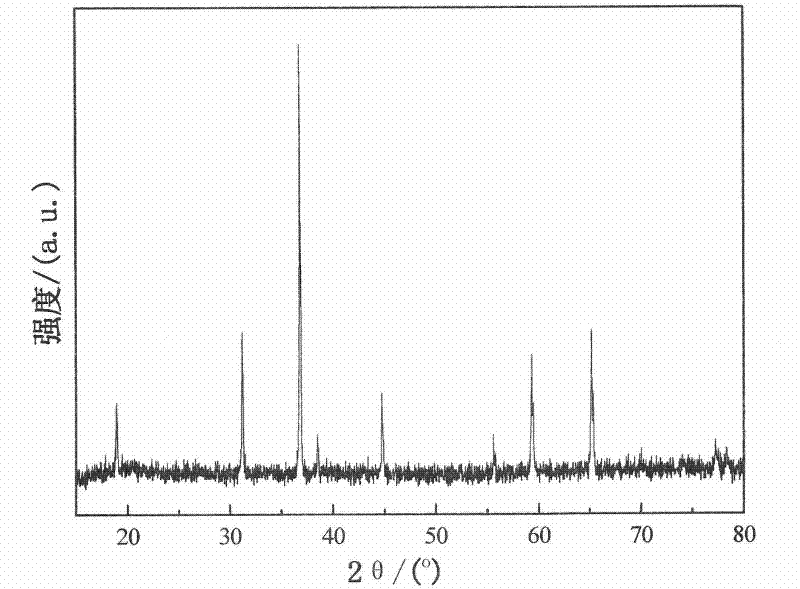

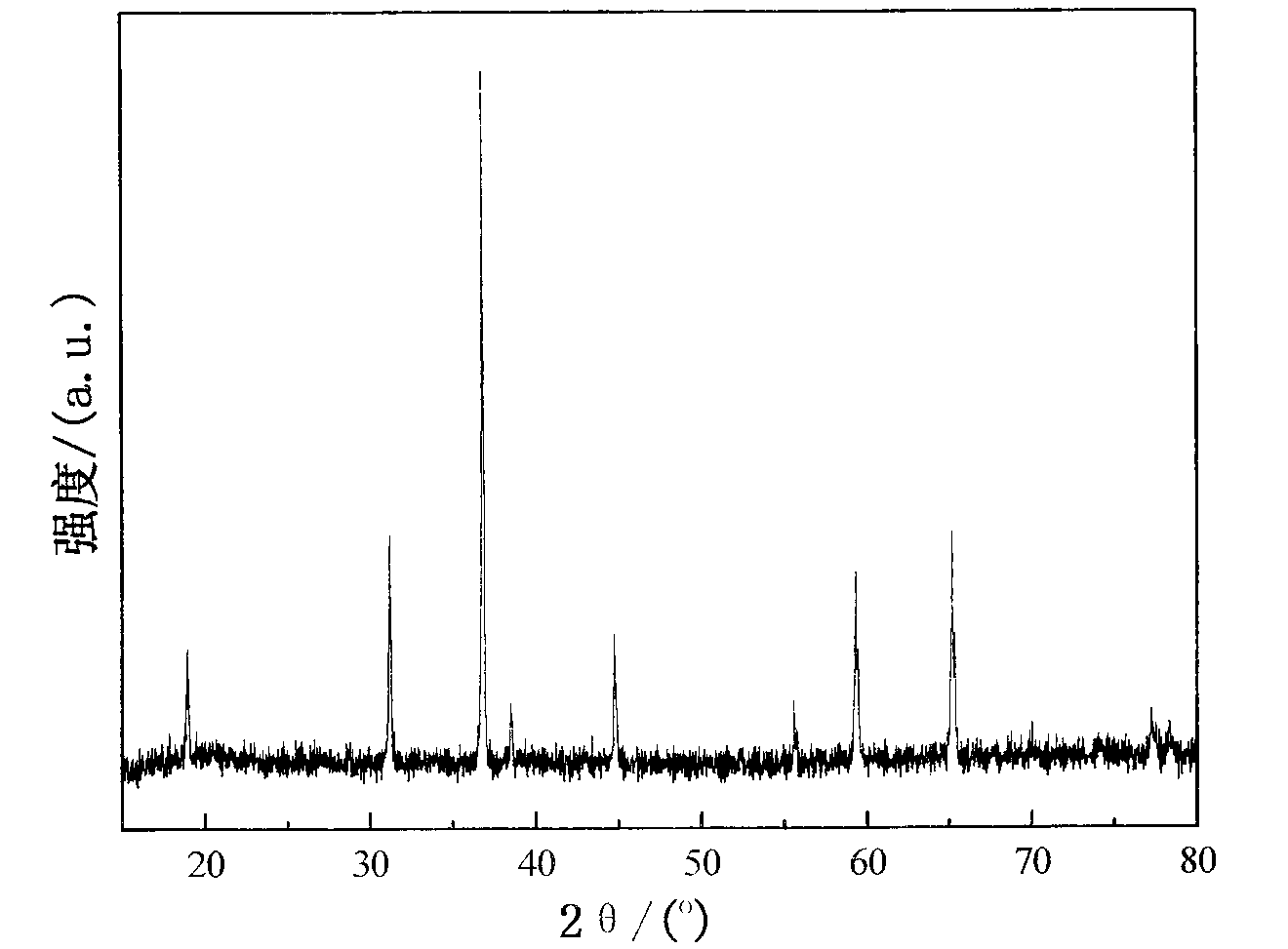

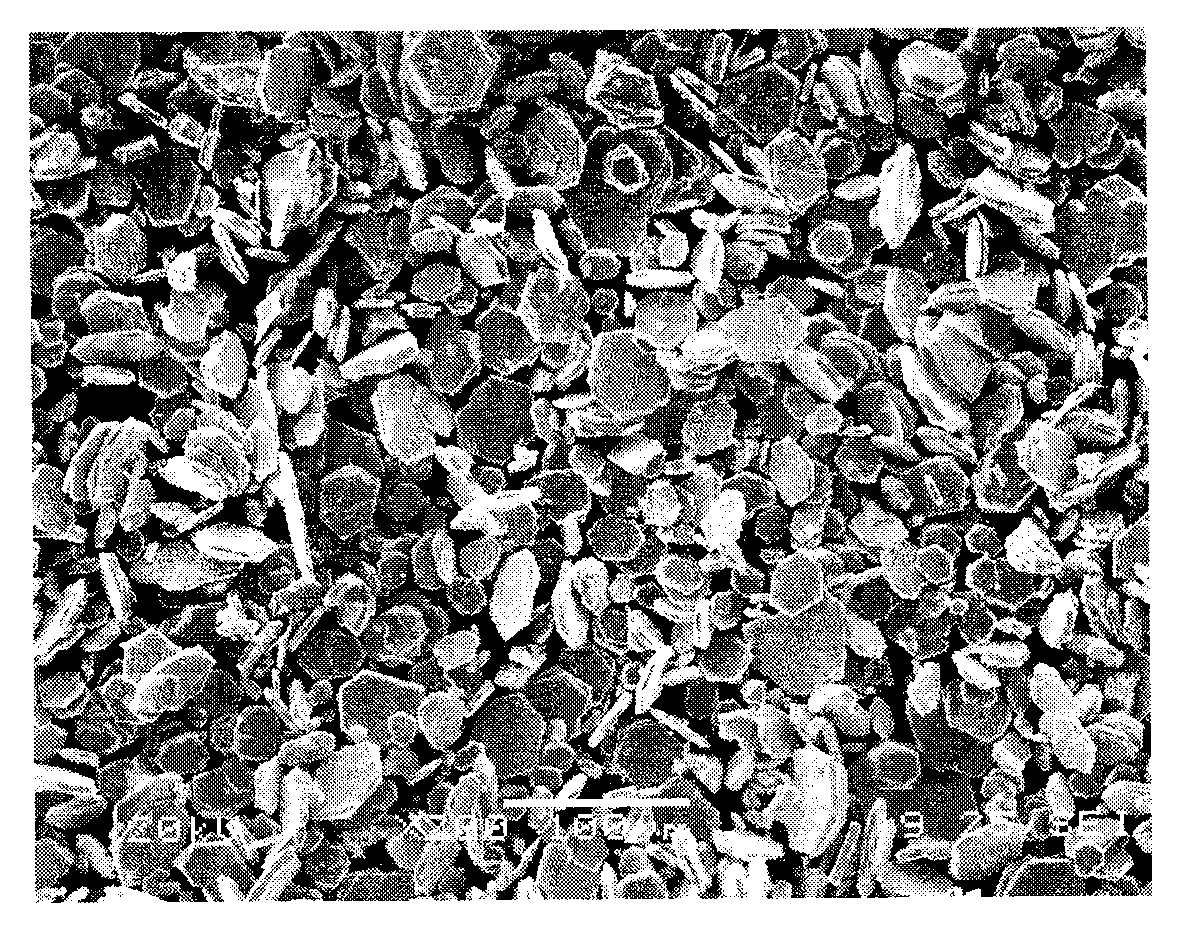

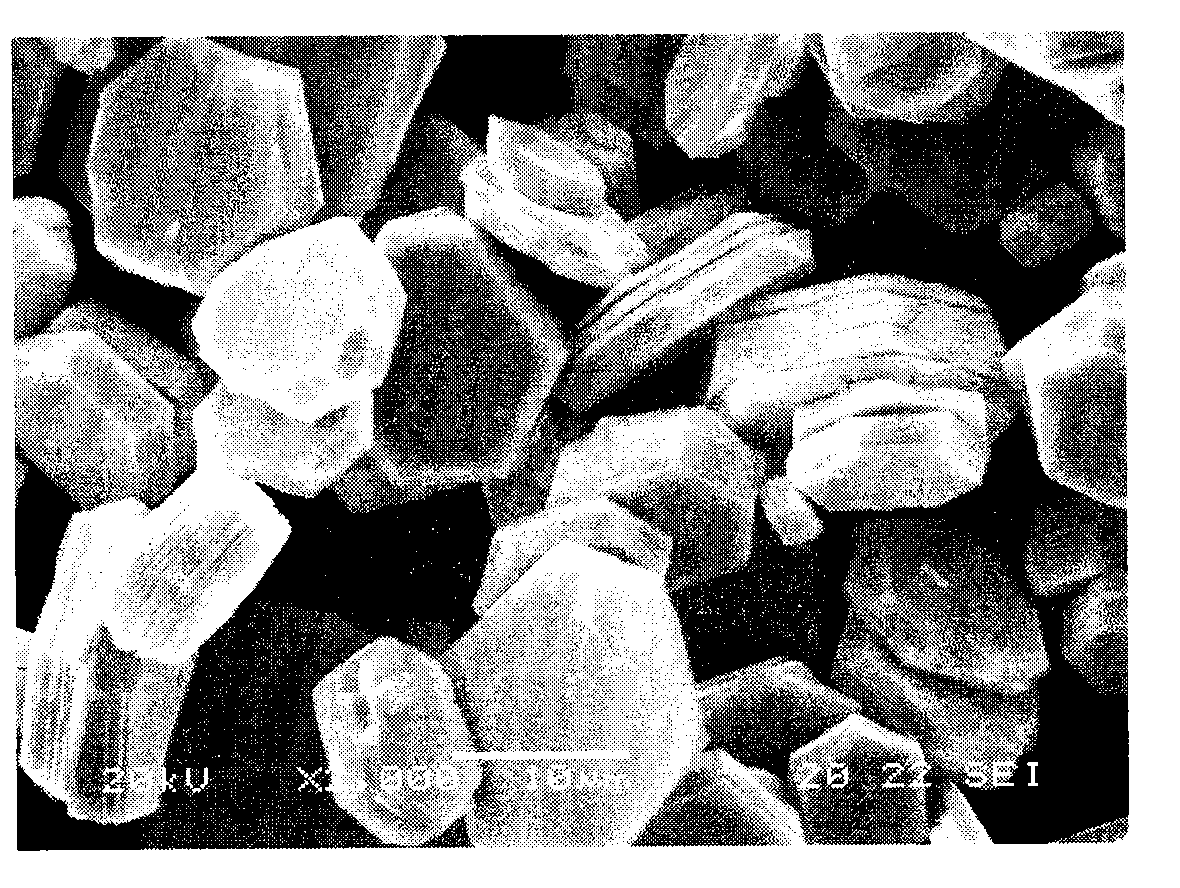

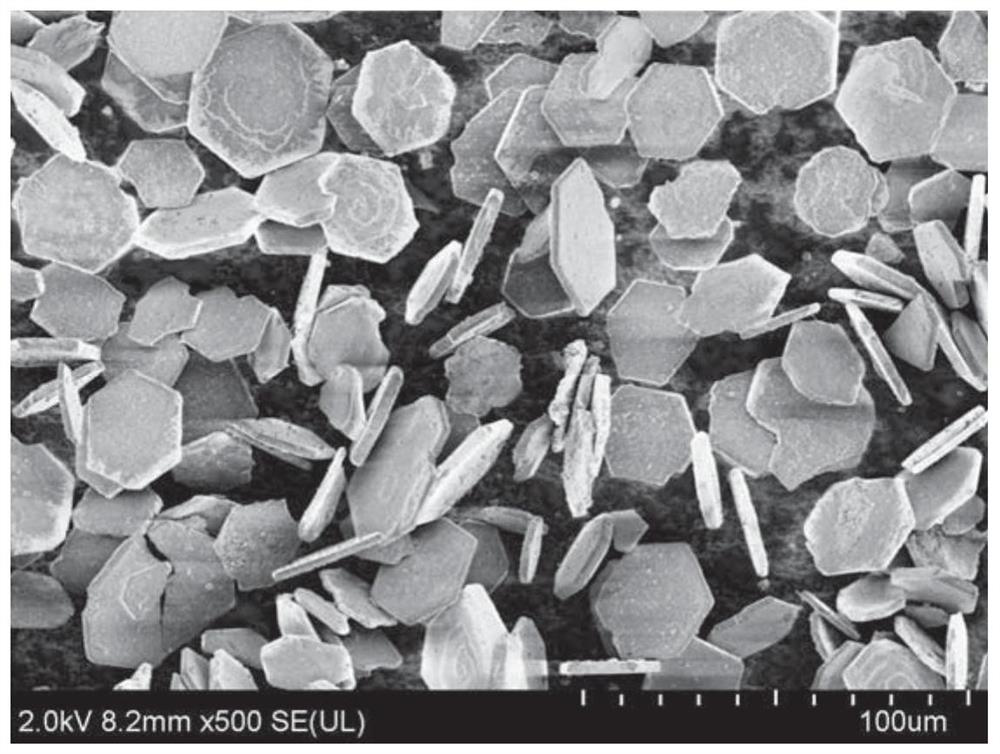

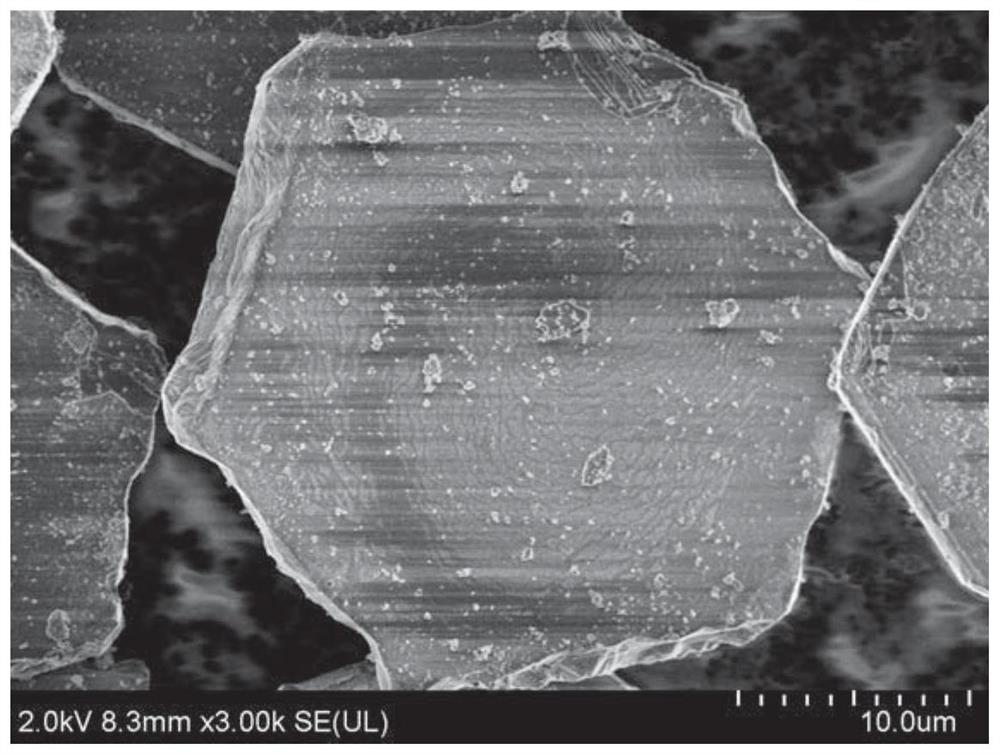

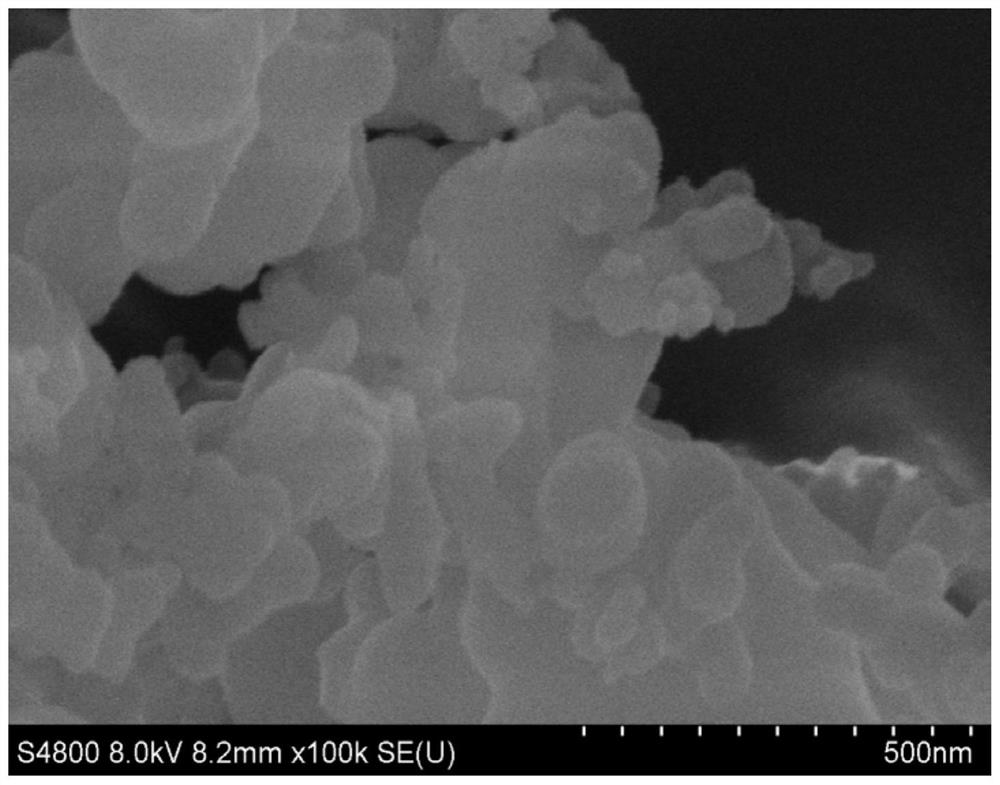

Method for preparing hexagonal plate cobaltosic oxide

ActiveCN102249348AInhibit synthesisFew reaction stepsCobalt oxides/hydroxidesCobalt(II,III) oxideFree cooling

The invention relates to a method for preparing hexagonal plate cobaltosic oxide. The method comprises the following steps of: (1) mixing materials, namely uniformly mixing a cobalt raw material, alkali saturated solution and fluxing agent, and drying to obtain a sintering material; (2) roasting, namely crushing and roasting the sintering material, and naturally cooling to obtain sinter; (3) infiltrating, namely placing the sinter in 0.1 to 2.0M hydrochloric acid, soaking, washing and filtering to obtain a cobaltosic oxide hexagonal plate wet product; and (4) drying, namely drying the cobaltosic oxide hexagonal plate wet product to obtain a hexagonal plate cobaltosic oxide product. The hexagonal plate cobaltosic oxide is directly synthesized through calcining at one time, so that the synthesis of precursor precipitate is avoided, the reaction steps, temperature and time are effectively reduced, the energy consumption and preparation cost are reduced, reaction conditions are easy to control, and the large-scale industrial production can be realized conveniently; meanwhile, the product has high purity and yield, uniform particle size and stable performance.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

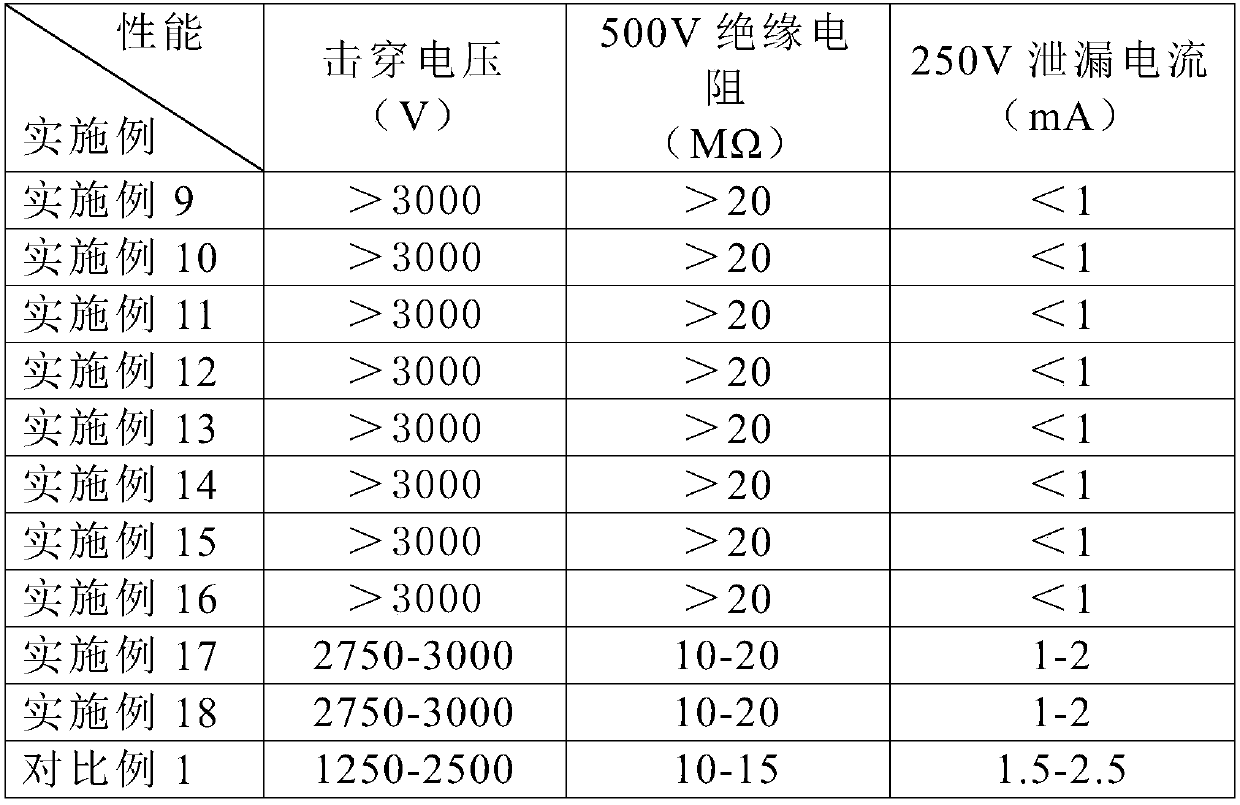

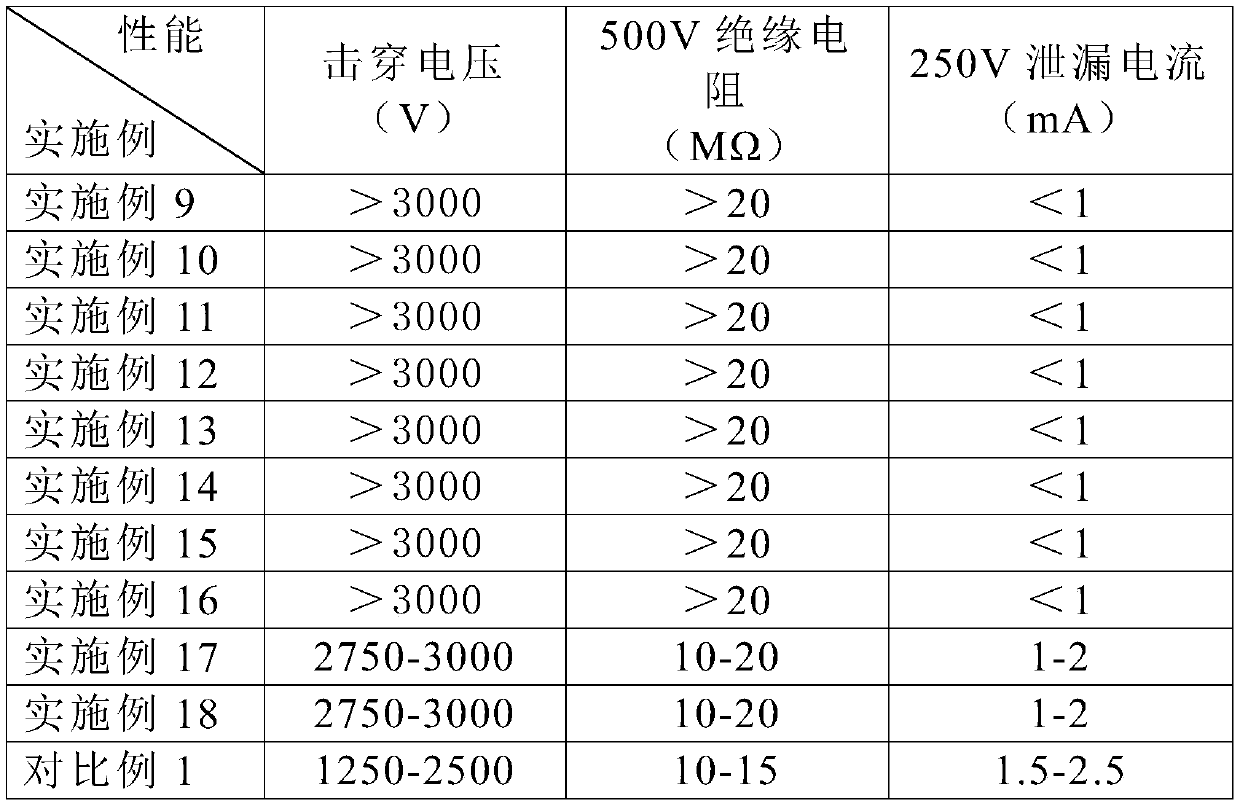

Aluminum alloy substrate thick film circuit intermediate-temperature sintering dielectric paste and preparation method thereof

InactiveCN106571172ALower melting temperatureAvoid harmQuartz/glass/vitreous enamelsInhomogenous insulation materialBreakdown strengthRare earth

The invention discloses an aluminum alloy substrate thick film circuit middle-temperature sintering dielectric paste and a preparation method thereof. The preparation method is used for preparing the aluminum alloy substrate thick film circuit middle-temperature sintering dielectric paste. The aluminum alloy substrate thick film circuit middle-temperature sintering dielectric paste comprises the following materials in part by weight: 60%-80% of lead-free microcrystalline glass powders, 1%-10% of rare earth oxide and 19%-30% of organic bonding phase, wherein the lead-free microcrystalline glass powders are formed by SiO2, Bi2O3, B2O3, ZnO, K2O, SrO2 and CaO; and the organic bonding phase is a mixture formed by an organic solvent, a high-polymer thickener, a surfactant, a plasticizer, a dispersant, an antifoaming agent and a thixotropic agent. A dielectric layer formed by printing the dielectric paste on an aluminum alloy substrate has the advantages of large adhesive force, large breakdown strength and high insulation resistance, and is capable of being compatible with a thick film circuit of the aluminum alloy substrate with a resistance paste and an electrode paste.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

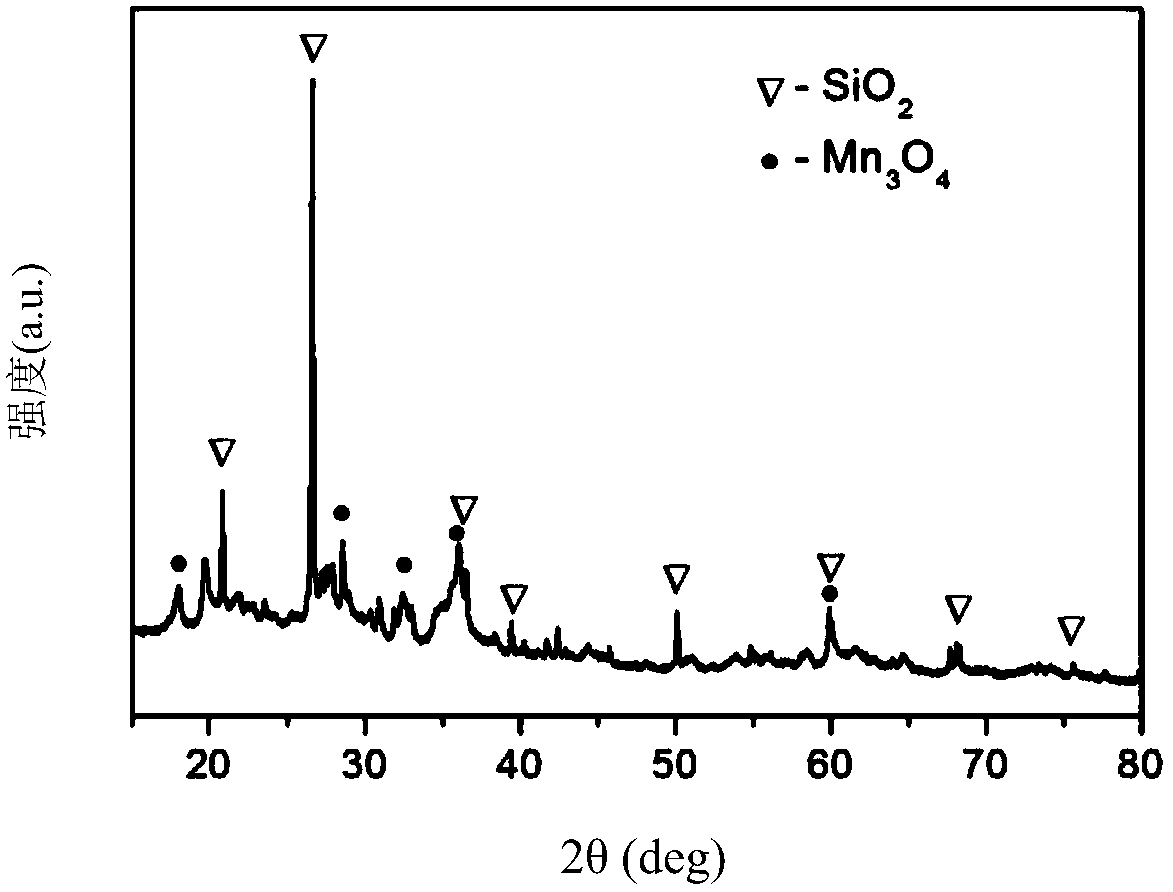

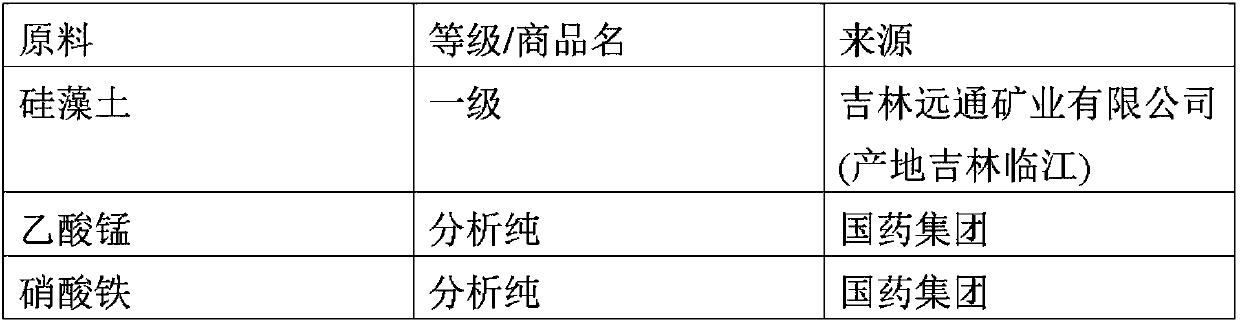

Catalyst for decomposing ozone, and preparation method of catalyst

ActiveCN107649145AEnhanced ability to decomposeEasy to makeGas treatmentDispersed particle separationMANGANESE ACETATEAcetic acid

The invention discloses a catalyst for decomposing ozone, and a preparation method of the catalyst. The catalyst is prepared from diatomaceous earth and Fe-doped manganese oxide loaded on the diatomaceous earth, wherein the mass of Mn element in the manganese oxide accounts for 2-10% of the total mass of the catalyst. The preparation method of the catalyst comprises the following steps: (1) soaking the diatomaceous earth into a mixed solution of manganese acetate and iron salt, and enabling the diatomaceous earth to be evenly dispersed in the solution, wherein the adding amount of the diatomaceous earth is 25-200g / L; (2) separating the diatomaceous earth out from the solution, drying and then calcining to obtain the catalyst.

Owner:NORTHEASTERN UNIV

Thick film circuit insulating dielectric slurry for aluminum substrates, and preparation method thereof

InactiveCN105176103AGood hardness and flexibilityLower melting temperatureQuartz/glass/vitreous enamelsElectric furnacesOrganic fluid

The present invention discloses a thick film circuit insulating dielectric slurry for aluminum substrates, and a preparation method thereof. The preparation method comprises: uniformly mixing Ba3(PO4)2, AlPO4, Zn3(PO4)2, Sn2P2O7, Rb2O, B2O3 and Nb2O5 according to a certain ratio, placing into a high temperature electric furnace, heating to a temperature of 1000-1600 DEG C according to a certain temperature increase program, carrying out thermal insulation for 1-6 h, carrying out water quenching, carrying out ball milling on the material to achieve 1-5 [mu] mu to obtain aluminum substrate thick film circuit insulating dielectric composite glass-ceramic powder, mixing the glass-ceramic powder and an organic liquid carrier comprising terpineol, tributyl citrate, ethyl cellulose, span 85 and hydrogenated castor oil according to a certain ratio, and repeatedly rolling by using a three-roller rolling mill to obtain the metal aluminum substrate thick film circuit insulating dielectric slurry. The insulating dielectric slurry has characteristics of good bonding force with the metal aluminum substrate, high breakdown voltage resistance and good insulating property, and meets the requirements of the high-power metal aluminum substrate thick film circuit insulating dielectric material.

Owner:NINGBO POLYTECHNIC

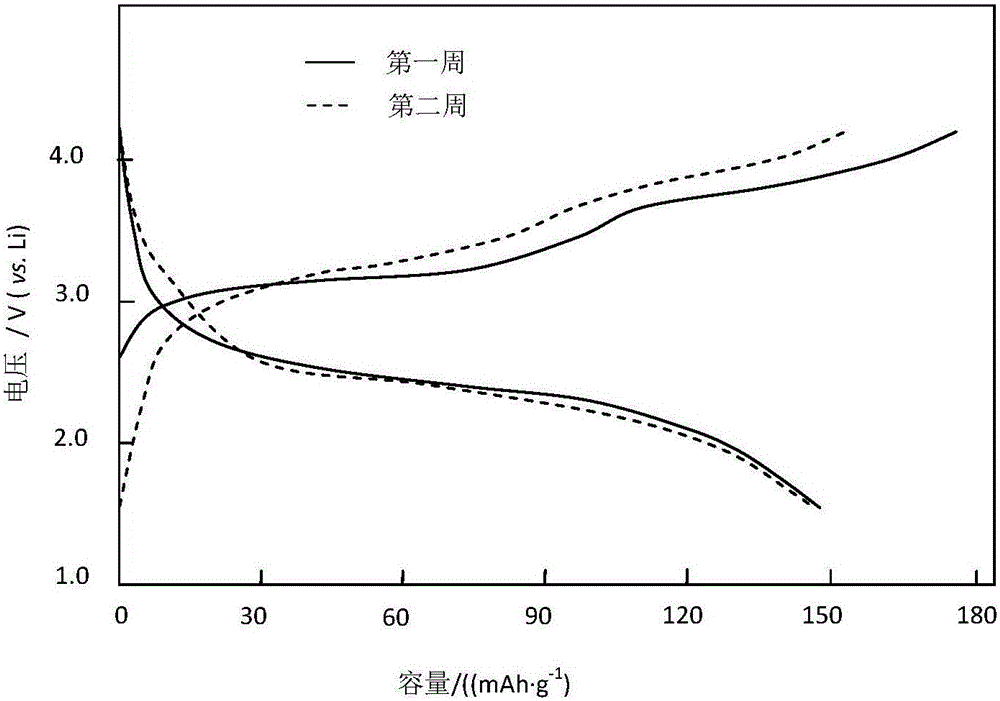

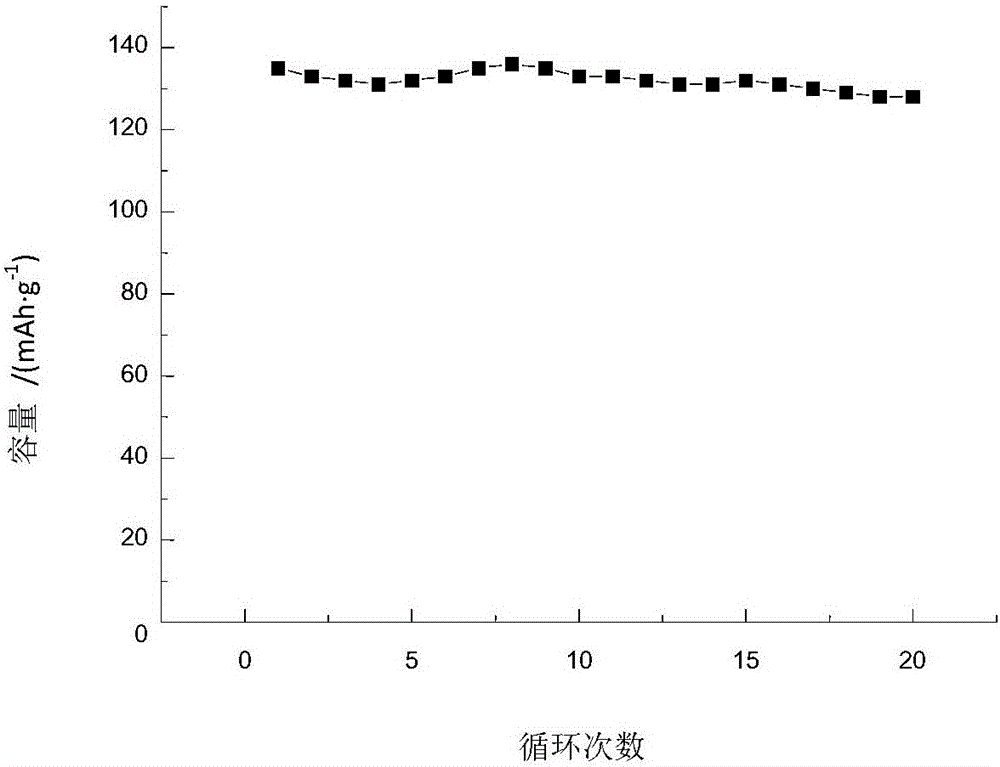

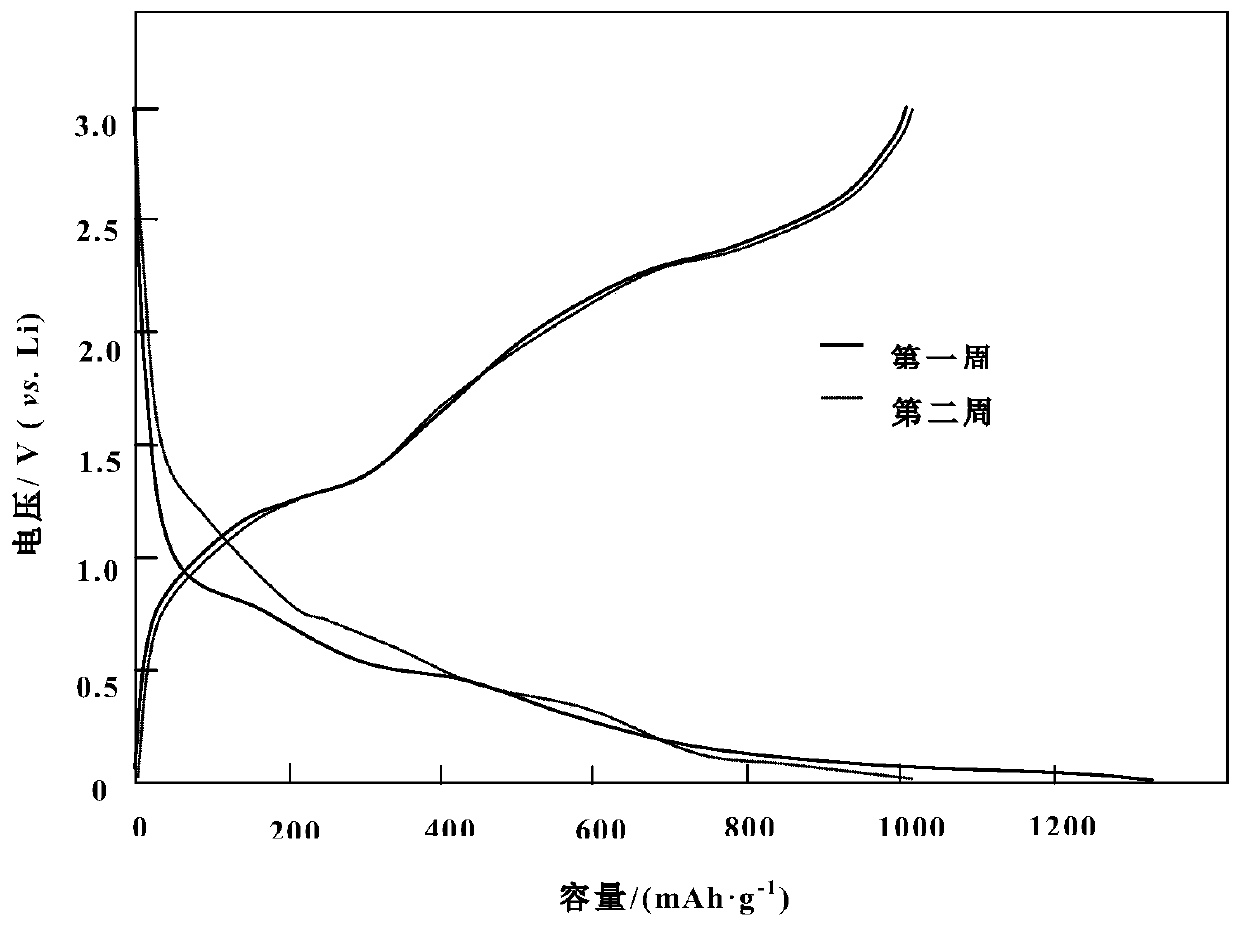

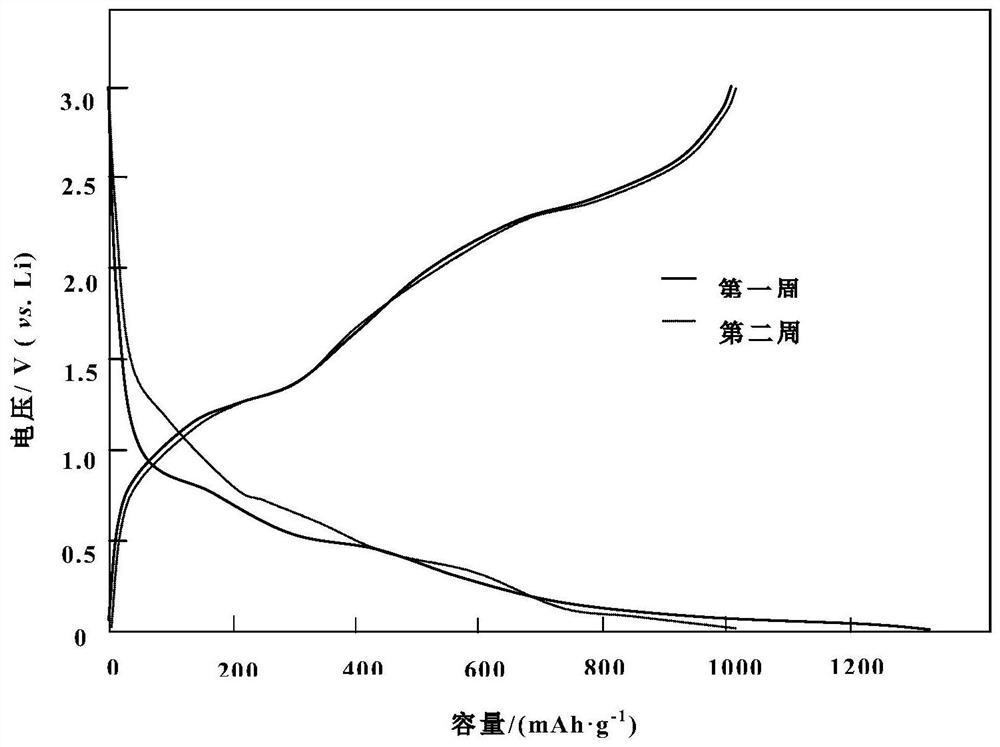

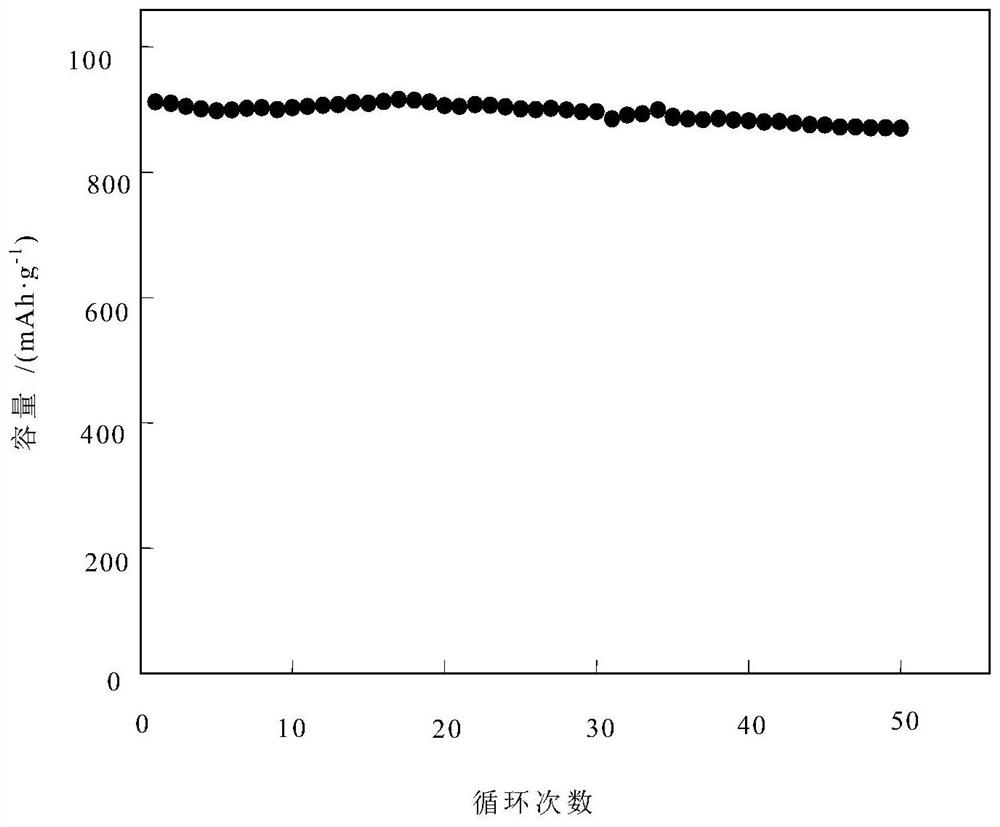

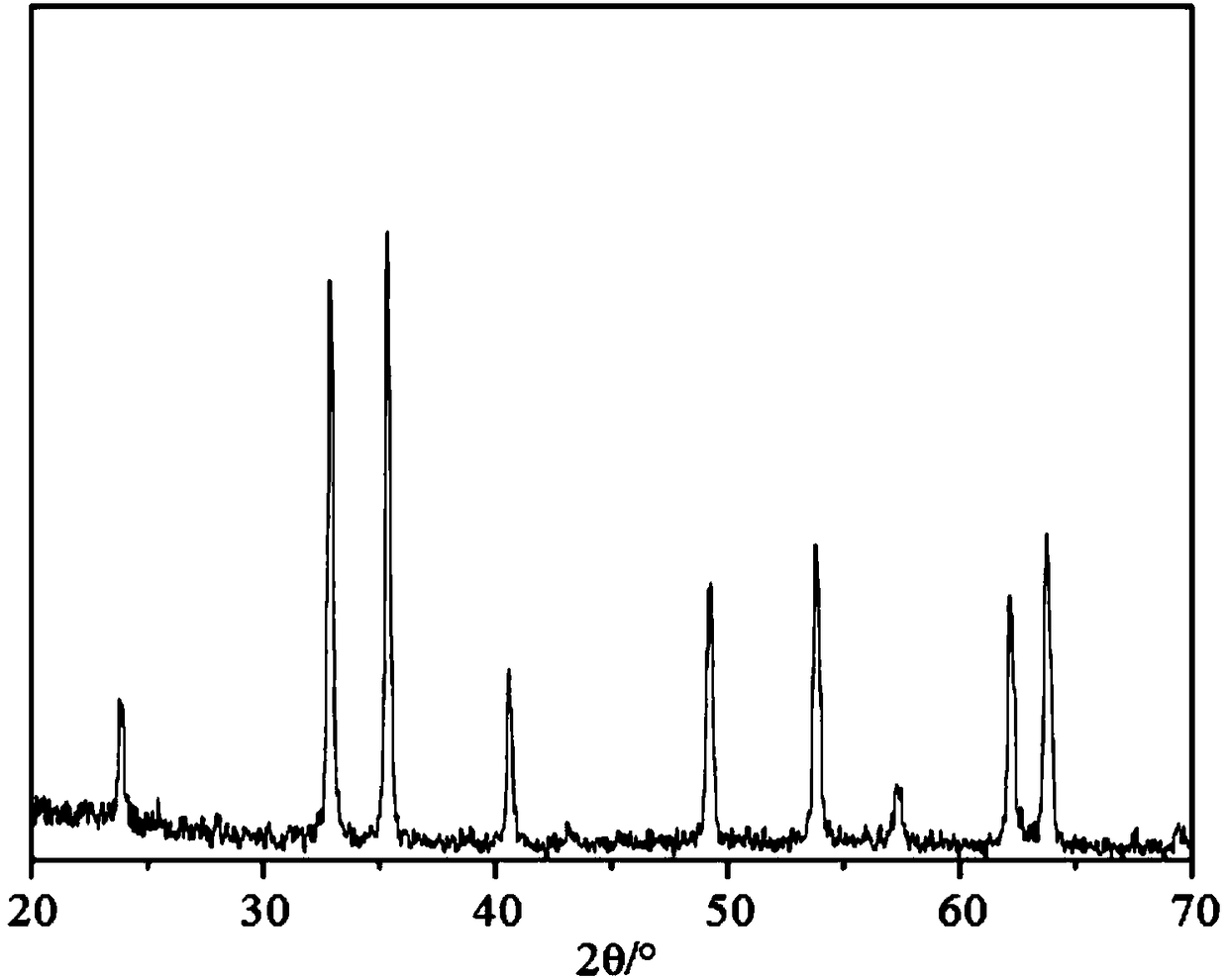

Doped silicate sodium ion battery positive electrode material and preparation method thereof

InactiveCN105819461AIncrease capacityImprove cycle performanceCell electrodesSecondary cellsSilicic acidSodium-ion battery

The invention relates to a doped silicate sodium ion battery positive electrode material and a preparation method thereof, and belongs to the field of chargeable battery positive electrode materials in energy materials. The formula of the positive electrode material is Na<2(1-x)>Mg<x>FeSiO4; x=0-0.05. The preparation method comprises the following steps: precisely weighing a sodium source compound, a magnesium source compound, an iron source compound, and a silicic acid radical source compound according to a mole ratio of Na:Mg:Fe:SiO4<2->=2(1-x):x:1:1; adding a proper amount of deionized water, evenly mixing the raw materials through ball milling, pre-burning the mixture in inert gas, grinding the obtained solid after pre-burning, then mixing the powder with a carbon source compound, adding a proper amount of deionized water to form a rheology state so as to obtain a rheology precursor; and finally burning the precursor in an inert atmosphere to obtain magnesium doped sodium silicate battery positive electrode material (Na<2(1-x)>Mg<x>FeSiO4). The positive material has a good cycle performance, and has a wide application prospect as a novel sodium ion battery positive electrode material.

Owner:NINGBO POLYTECHNIC

High-thermal-expansion-coefficient thick-film dielectric paste for stainless steel base material and preparation method thereof

InactiveCN110880376ASoftening temperature adjustmentCrystallization temperature adjustmentNon-conductive material with dispersed conductive materialCable/conductor manufactureDielectricActive agent

The invention relates to high-thermal-expansion-coefficient thick-film dielectric paste for a stainless steel base material and a preparation method thereof. The thick-film dielectric paste is characterized by comprising the following components in percentage by weight: 70-80% of lead-free microcrystalline glass powder and 20-30% of an organic bonding phase. The lead-free microcrystalline glass powder is BaO-CaO-Al2O3-SiO2-B2O3-SrO-Sm2O3-ZrO2 series microcrystalline glass powder, and the lead-free microcrystalline glass powder comprises the following components in percentage by weight: 10%-20%of BaO, 10%-15% of CaO, 5%-10% of Al2O3, 20%-30% of SiO2, 5%-20% of B2O3, 5%-10% of SrO, 5%-10% of Sm2O3 and 1%-6% of ZrO2. And the organic bonding phase comprises the following components in percentage by weight: 70%-85% of an organic solvent, 2%-10% of a polymer thickener, 0.5%-5% of a dispersing agent, 0.5%-5% of a leveling agent, 0.5%-5% of a thixotropic agent and 0.5%-5% of a surfactant. Thehigh-thermal-expansion-coefficient thick-film dielectric paste for the stainless steel base material has the characteristics of high uniformity, high stability, high solid content and the like.

Owner:广东顺德弘暻电子有限公司

Thick-film circuit resistance paste for stainless steel substrate and preparing method thereof

ActiveCN104992744AReduce production cost and use costThe preparation process is simple to operateNon-conductive material with dispersed conductive materialCable/conductor manufactureSolid phasesEthyl cellulose

The invention discloses a thick-film circuit resistance paste for a stainless steel substrate and a preparing method thereof. The thick-film circuit resistance paste is composed of two parts of a solid phase component and an organic liquid phase; the solid phase component comprises a conductive phase and a microcrystalline glass phase, the conductive phase is composed of Cu2O-GeO2 compound +Cu powder, and the microcrystalline glass phase is a SiO2-Al2O3-B2O3-CaO-ZrO2-Co2O3 compound; and the organic liquid phase is a mixed liquid phase of terpineol, tributyle citrate, ethyl cellulose, span 85, 1,4-butyrolactone and a hydrogenated castor oil. The preparing method of the thick-film circuit resistance paste comprises firstly preparing the conductive phase and the microcrystalline glass phase respectively, preparing the organic liquid phase then, finally performing mixing modulation of the conductive phase, the microcrystalline glass phase and the organic liquid phase, and then the resistance paste can be obtained.

Owner:NINGBO POLYTECHNIC

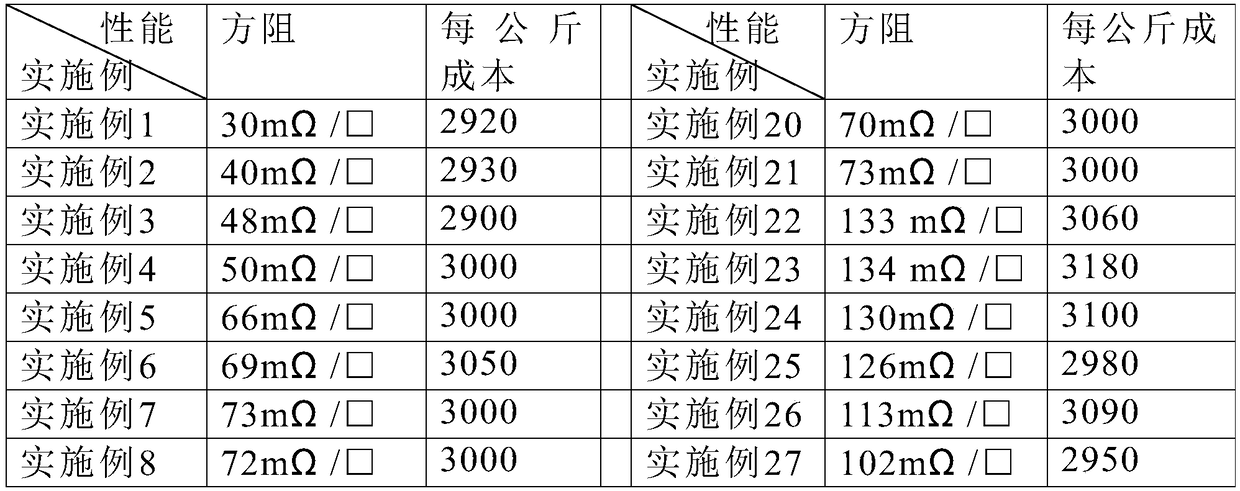

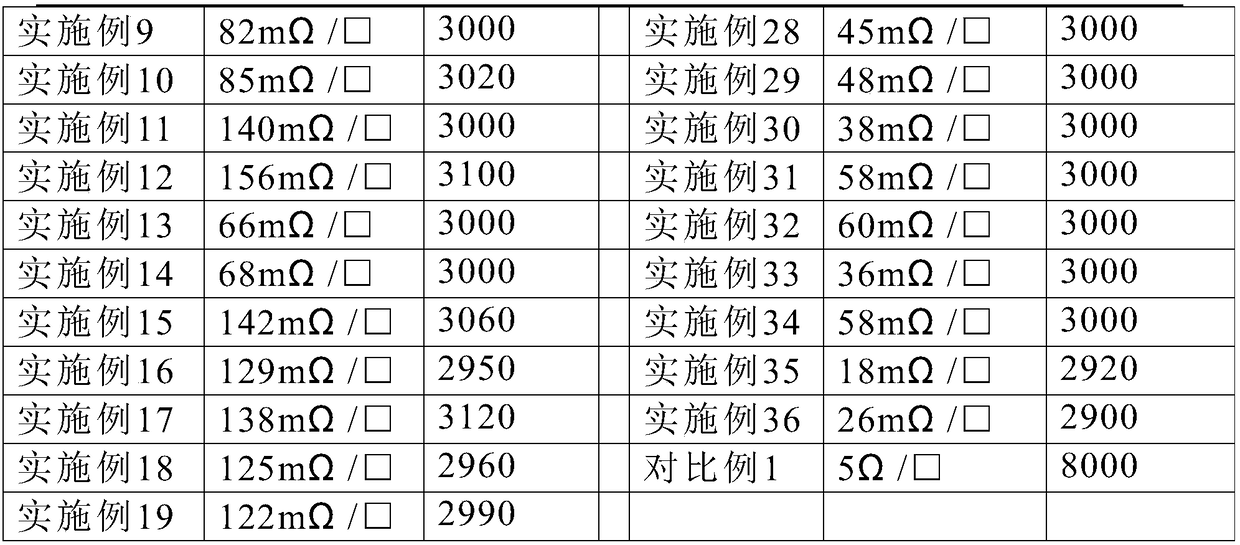

Resistance paste for thick film circuit and preparation method of resistance paste

InactiveCN108665999AMeet performance requirementsReduce square resistanceNon-conductive material with dispersed conductive materialHeating element materialsOxide compositeThin film circuits

The invention relates to resistance paste for a thick film circuit and a preparation method of the resistance paste, in particular to resistance paste for a thin film circuit of a high-power stainlesssteel substrate and a preparation method of the resistance paste and belongs to the technical field of thick film circuits. The resistance paste comprises a solid phase and an organic carrier phase,wherein the solid phase and the organic carrier phase account for 65-85% and 15-35% of total mass of the paste separately; the solid phase comprises a conductive function phase and an inorganic glassbonding phase; and the conductive function phase and the inorganic glass bonding phase account for 55-90% and 10-45% of total mass of the solid phase separately. According to the resistance paste, a cheap semiconductor oxide composite material is adopted as a conductive function phase material of the resistance paste for the thick film circuit of the high-power stainless steel substrate, so that various performance requirements of the resistance paste for the thick film circuit are met, and especially the production cost and the use cost are reduced while the square resistance is greatly reduced. Furthermore, the preparation process provided by the invention is simple in operation, easy to control and beneficial to large-scale industrial production.

Owner:NINGBO POLYTECHNIC

Amorphous glass powder, and preparation method and applications thereof

The invention discloses an amorphous glass powder, and a preparation method and applications thereof. The amorphous glass powder comprises following raw materials, by mass, 10 to 60% of BaO, 1 to 30% of Al2O3, 5 to 40% of B2O3, 5 to 40% of P2O5, 1 to 10% of MoO3, 1 to 5% of NiO, and 1 to 10% of Nd2O3. The preparation method comprises following steps: the raw materials are mixed at the ratio; the mixture is heated to 1200 to 1650 DEG C, and the temperature is kept for 0.5 to 8h; and the mixture is subjected to water quenching, and is grinded into powder with a diameter of 0.5 to 5 microns by ball milling so as to obtain the amorphous glass powder. A slurry made of the amorphous glass powder and an organic carrier possess excellent adhesiveness on stainless steel substrates; the breakdown voltage of the slurry is high, and insulating properties of the slurry are excellent; and the slurry is capable of meeting the requirements for thick film circuit insulating medium materials of high-power stainless steel substrates.

Owner:NINGBO POLYTECHNIC

Method for preparing hexagonal plate cobaltosic oxide

ActiveCN102249348BInhibit synthesisFew reaction stepsCobalt oxides/hydroxidesCobalt(II,III) oxideFree cooling

The invention relates to a method for preparing hexagonal plate cobaltosic oxide. The method comprises the following steps of: (1) mixing materials, namely uniformly mixing a cobalt raw material, alkali saturated solution and fluxing agent, and drying to obtain a sintering material; (2) roasting, namely crushing and roasting the sintering material, and naturally cooling to obtain sinter; (3) infiltrating, namely placing the sinter in 0.1 to 2.0M hydrochloric acid, soaking, washing and filtering to obtain a cobaltosic oxide hexagonal plate wet product; and (4) drying, namely drying the cobaltosic oxide hexagonal plate wet product to obtain a hexagonal plate cobaltosic oxide product. The hexagonal plate cobaltosic oxide is directly synthesized through calcining at one time, so that the synthesis of precursor precipitate is avoided, the reaction steps, temperature and time are effectively reduced, the energy consumption and preparation cost are reduced, reaction conditions are easy to control, and the large-scale industrial production can be realized conveniently; meanwhile, the product has high purity and yield, uniform particle size and stable performance.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

Sheet-shaped aluminium oxide-containing aluminium-based dielectric paste and preparation method therefor

InactiveCN106782763AImprove corrosion resistanceImprove insulation performanceMetallic oxidesHeat conductingThermal expansion

The invention discloses sheet-shaped aluminium oxide-containing aluminium-based dielectric paste and a preparation method therefor. The aluminium-based dielectric paste comprises the following components based on mass percentages: 40-70% of low-melting-point glass powder, 0-30% (not including 0) of sheet-shaped aluminium oxide powder, 20-40% of organic carrier and 0-3% of coloring agent. The aluminium-based dielectric paste has the following advantages: 1, the thermal expansion coefficient of low-melting-point glass is greater than 16*10<-6>m / K, so that an aluminum substrate can be well matched; the melting point of the low-melting-point glass powder is less than 600 DEG C, so that the low-melting-point glass powder can be sintered at an aluminium melting point; 2, by virtue of the addition of the sheet-shaped aluminium oxide powder, corrosion resistance, oxidization resistance, thermal resistance, heat-conducting property and electrical insulating performance of the dielectric layer are effectively improved; and 3, an insulating dielectric layer prepared from the insulating dielectric paste and the metal aluminium substrate are high in binding force, breakdown voltage and insulating property. The preparation method comprises the steps of preparing the low-melting-point glass powder, preparing the organic carrier and prepparing the dielectric paste.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

Composite oxide microcrystalline glass, insulating medium slurry and preparation method and application thereof

ActiveCN108682478AImprove compactnessImprove adhesionQuartz/glass/vitreous enamelsMetallic oxidesSlurryLow leakage

The invention relates to composite oxide microcrystalline glass, and an insulating medium slurry and preparation method and application thereof, and belongs to the technical field of thick film circuits. The composite oxide microcrystalline glass is SiO2-B2O3-Cs2O-P2O5-MnO2-Co2O3- Ta2O5-CeO2-Er2O3 composite oxide microcrystalline glass; the insulating medium slurry includes an organic carrier andan inorganic main phase composed of the composite oxide microcrystalline glass. The preparation method of the insulating medium slurry includes: mixing raw materials according to a ratio; heating themixture to 1100-1700 DEG C for 1-24 hours; performing water quenching, drying, and ball milling; mixing the mixture with the organic carrier in proportion; and finally using a three-roll mill to perform rolling repeatedly, and obtaining a thick film circuit insulating medium slurry. The slurry is used for a high-power thick-film circuit insulating dielectric layer of a stainless steel substrate, has a large expansion coefficient, good adhesion, high insulation and resistance, high breakdown voltage, and low leakage current.

Owner:NINGBO POLYTECHNIC

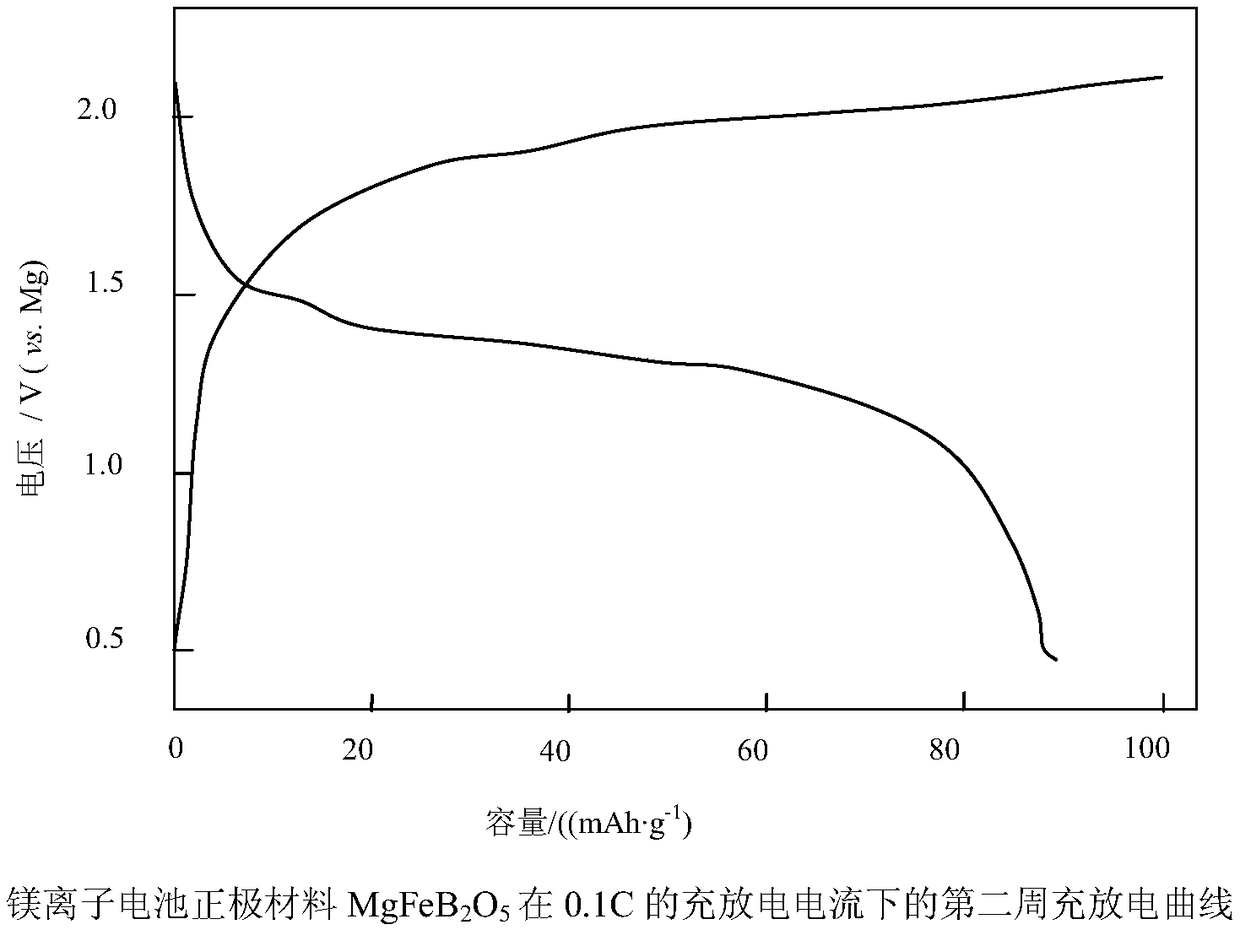

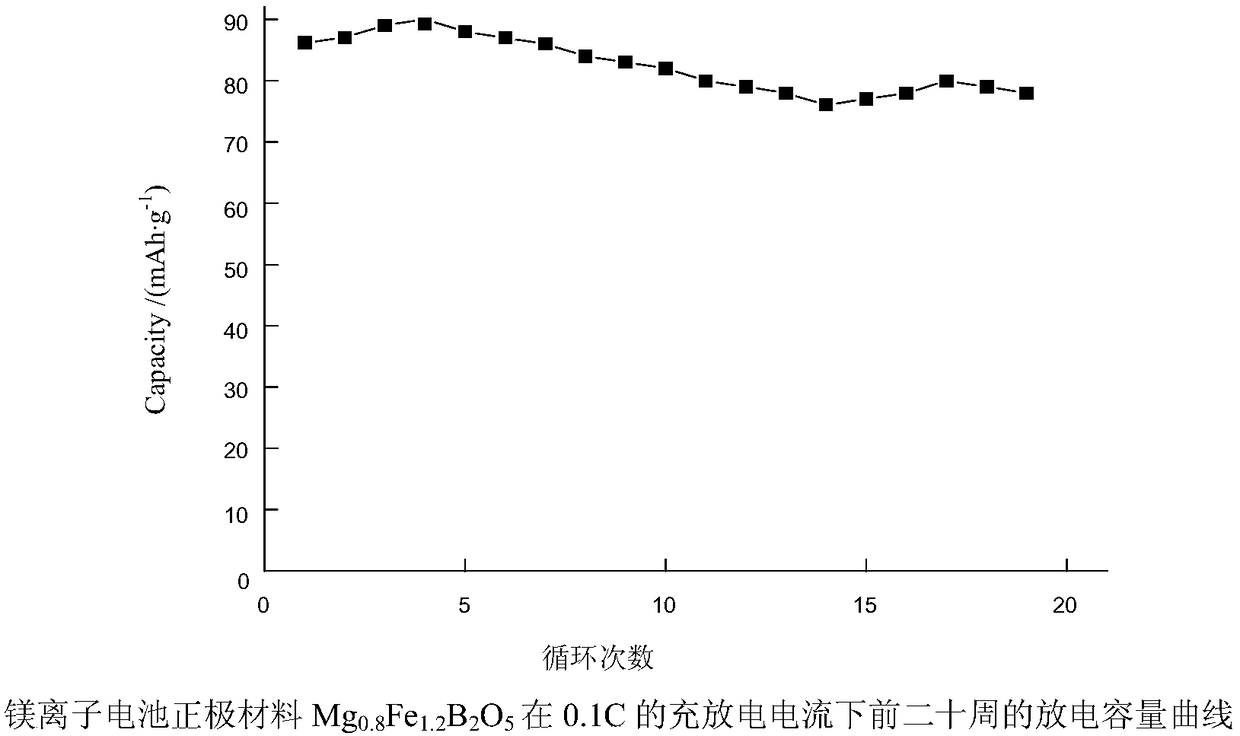

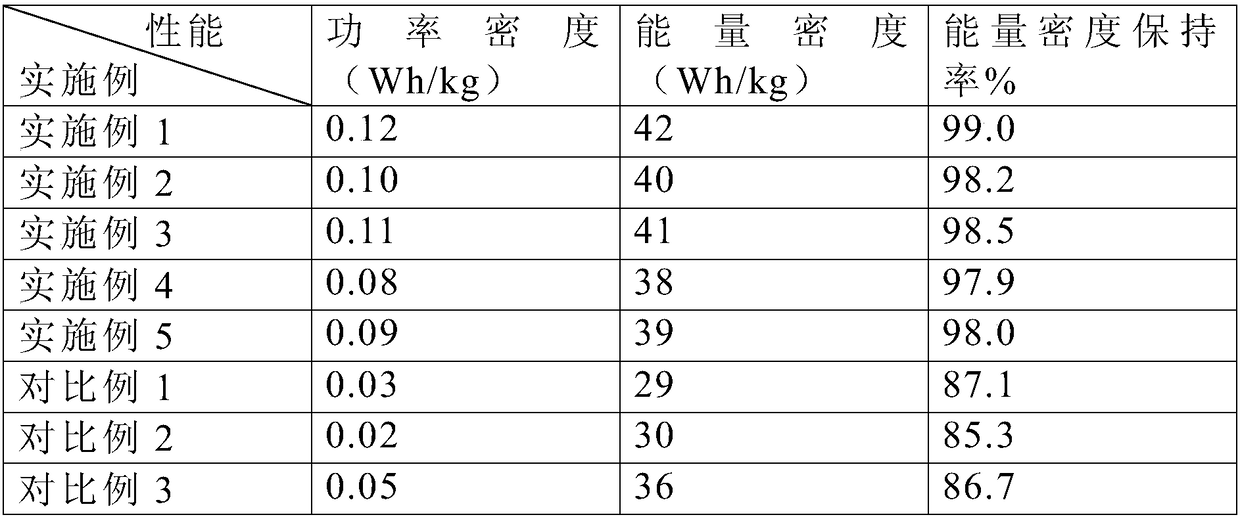

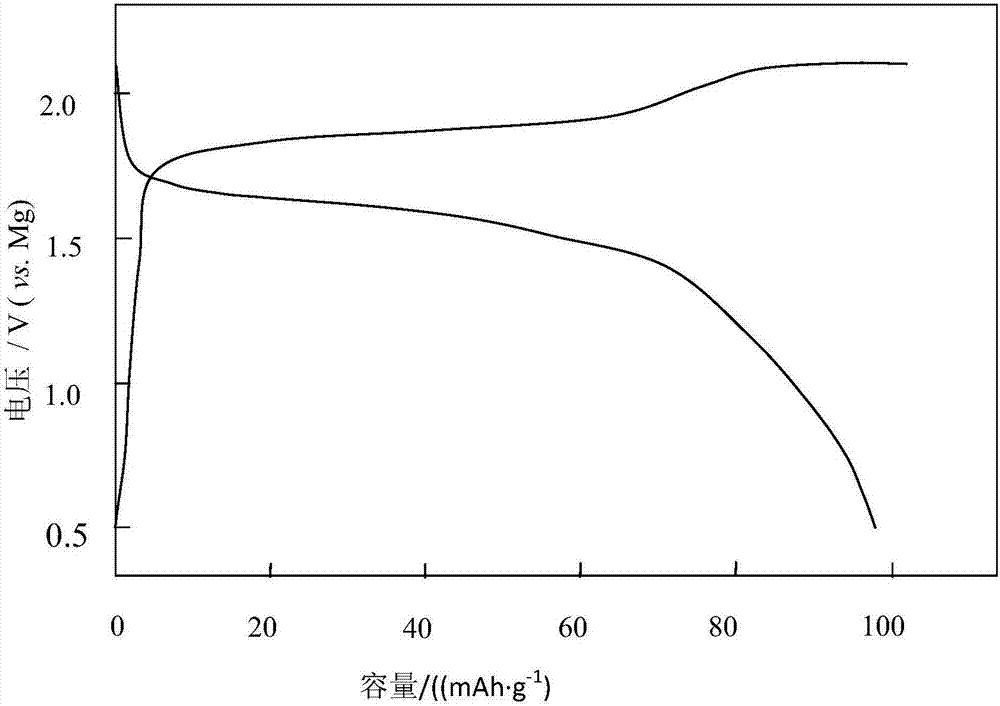

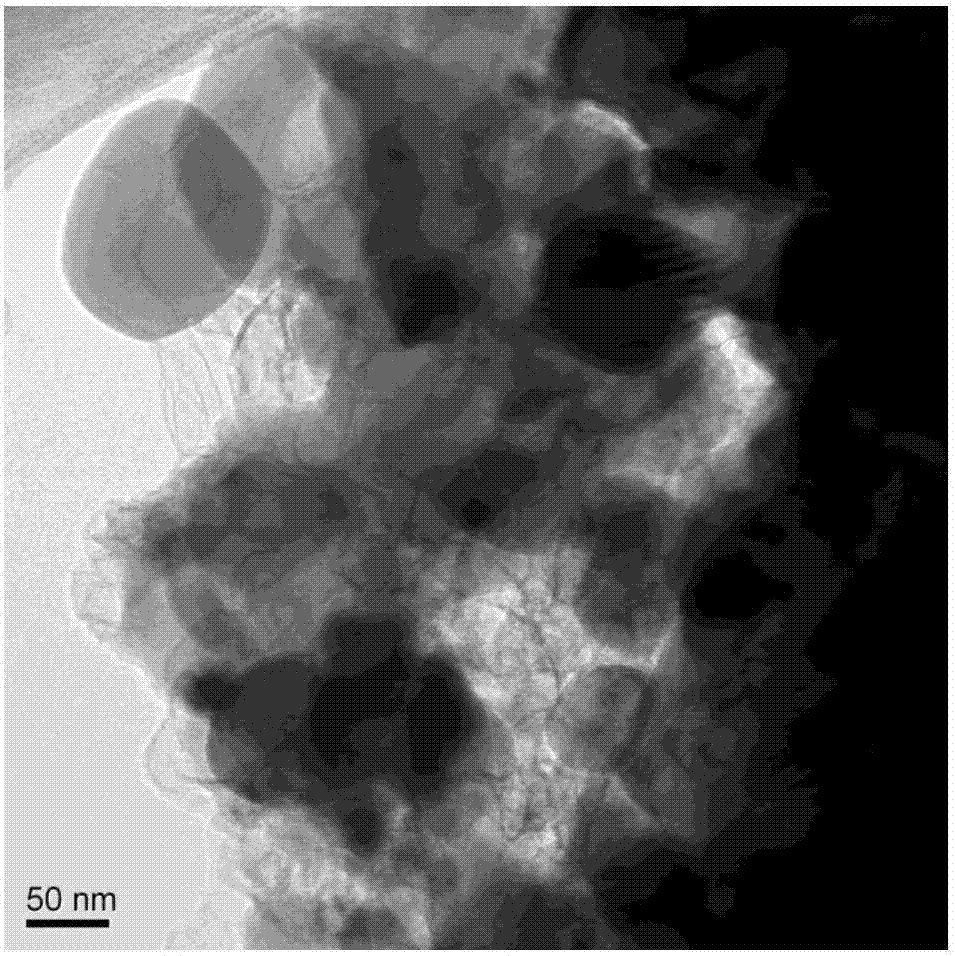

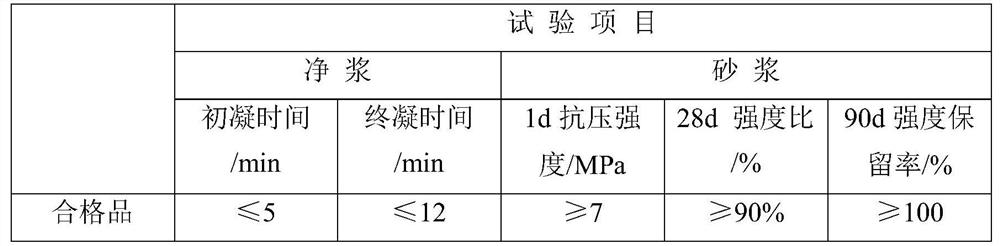

Method for preparing magnesium ion battery positive electrode material

The invention belongs to the technical field of battery materials, and concretely relates to a method for preparing a magnesium ion battery positive electrode material. The magnesium ion battery positive electrode material is carbon coated magnesium ferrous borate, wherein the magnesium ferrous borate mainly comprises a magnesium source compound, a ferrous source compound and a borate radical compound. The magnesium ferrous borate synthesized from common raw materials in the invention is a novel magnesium ion battery positive electrode material having an extremely rich source and an excellentapplication prospect. Compared with currently widely studied phosphate polyanion compound magnesium ion battery positive electrode materials, the positive electrode material in the invention achievesa higher theoretic specific capacity by replacing a phosphate radical having a large mole with a borate radical having a small mole from structural analysis. The electric conduction capability of ferrous borate is stronger than that of ferrous phosphate, the volume change rate of the ferrous borate before and after discharge is lower than that of the ferrous phosphate before and after discharge and is less than half of that of the ferrous phosphate, so the magnesium ferrous borate positive electrode material has good rate performances and a good cycle stability.

Owner:NINGBO POLYTECHNIC

Magnesium-doped positive electrode material for magnesium ion battery and preparation method thereof

ActiveCN107293747AStable structureImprove cycle lifeCell electrodesSecondary cellsAlcoholSodium-ion battery

The invention relates to a magnesium-doped positive electrode material for a magnesium ion battery and a preparation method thereof, and belongs to positive electrode materials for rechargeable batteries in energy materials. The molecular formula of the positive electrode material is Mg(1-x)AxNiSiO4, wherein A is one of doping elements Ca, Sr and Ba, and x is equal to 0.001 to 0.08. The preparation method comprises the following steps: accurately weighing a magnesium source compound, a doping element compound and a nickel source compound according to the atom mole ratio of Mg, A to Ai being (1-x): x: 1, adding an appropriate amount of deionized water, ball-milling and mixing uniformly, drying after taking out the mixture, and firing to obtain solid powder. Tetraethyl orthosilicate is weighed in proportion according to the atom mole ratio of Ni to Si being 1: 1, the solid powder, the tetraethyl orthosilicate and an appropriate amount of citric acid are sufficiently mixed in an absolute ethyl alcohol solvent, and the mixture is put in a stainless steel tank to obtain a gel substance. Then, mixed ball-milling is carried out with a carbon source compound, and sintering is carried out in an inert atmosphere for a few hours, so that the carbon coated positive electrode material Mg(1-x)AxNiSiO4 for the magnesium ion battery is obtained.

Owner:NINGBO POLYTECHNIC

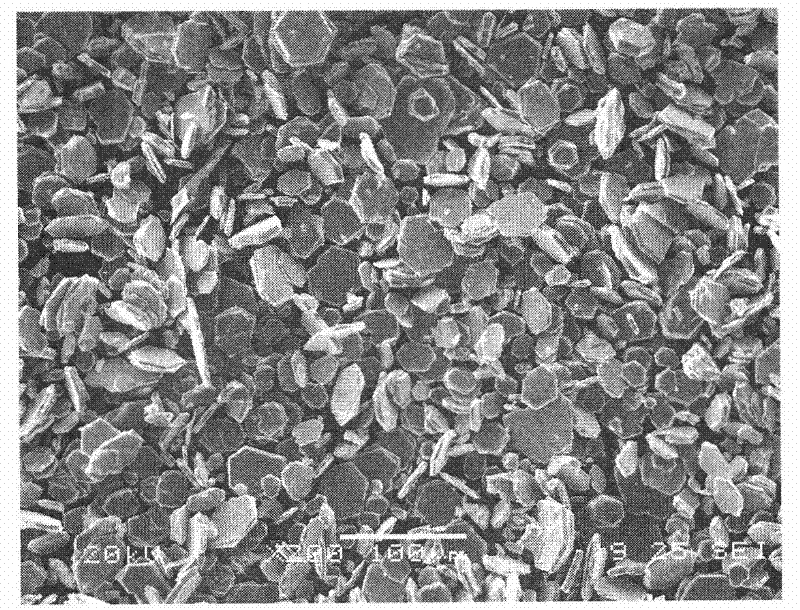

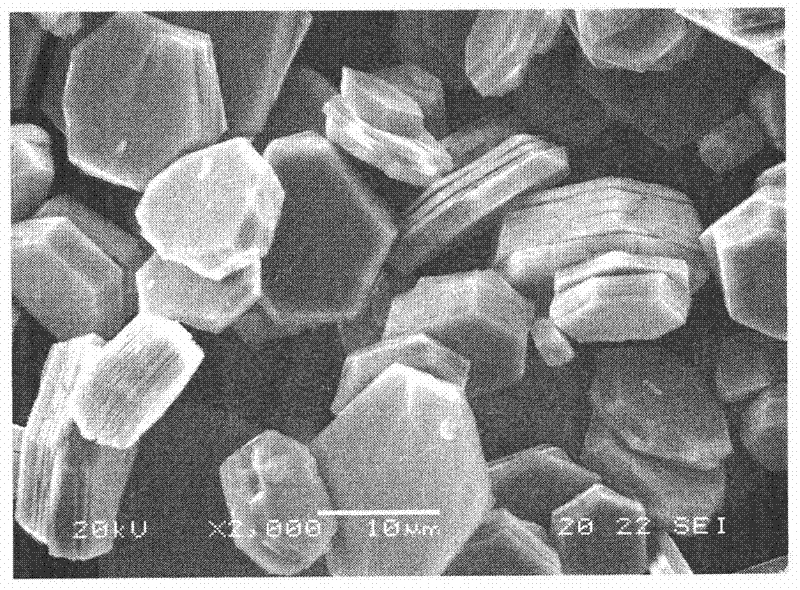

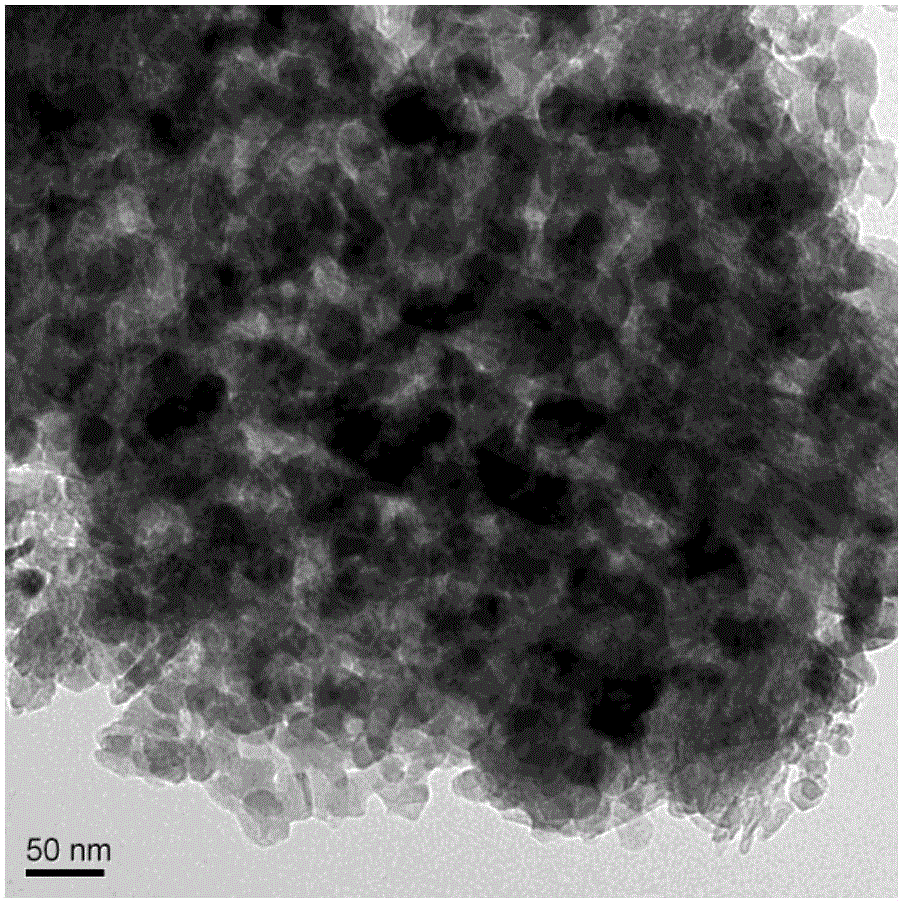

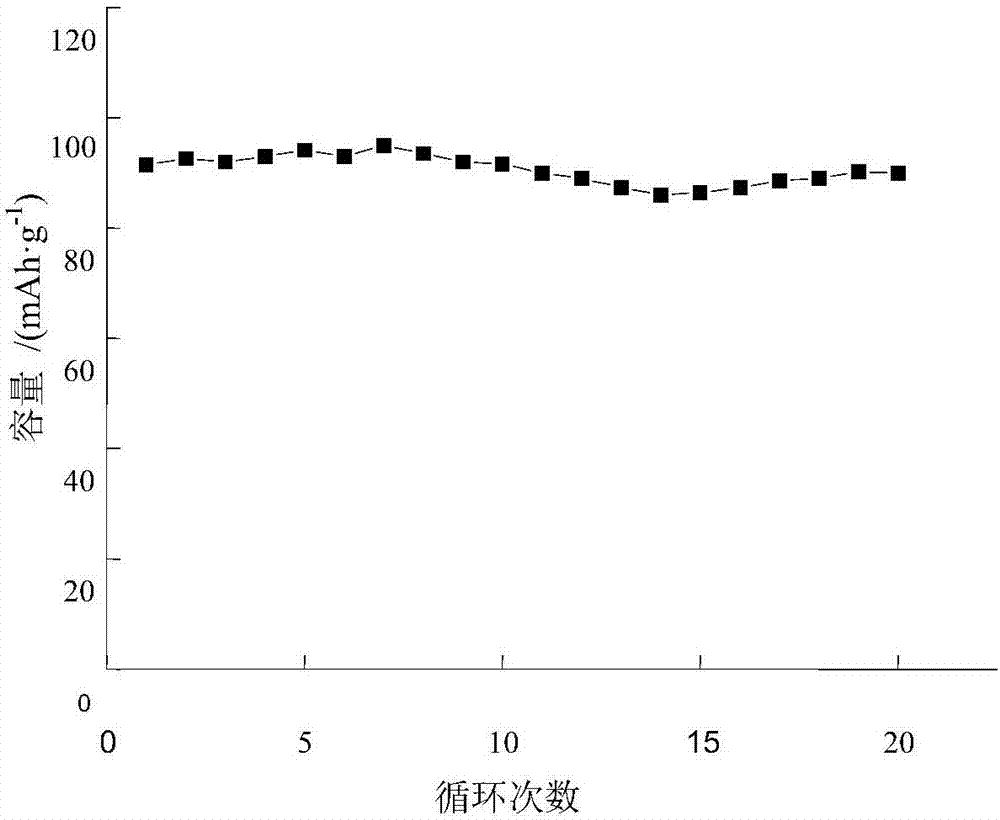

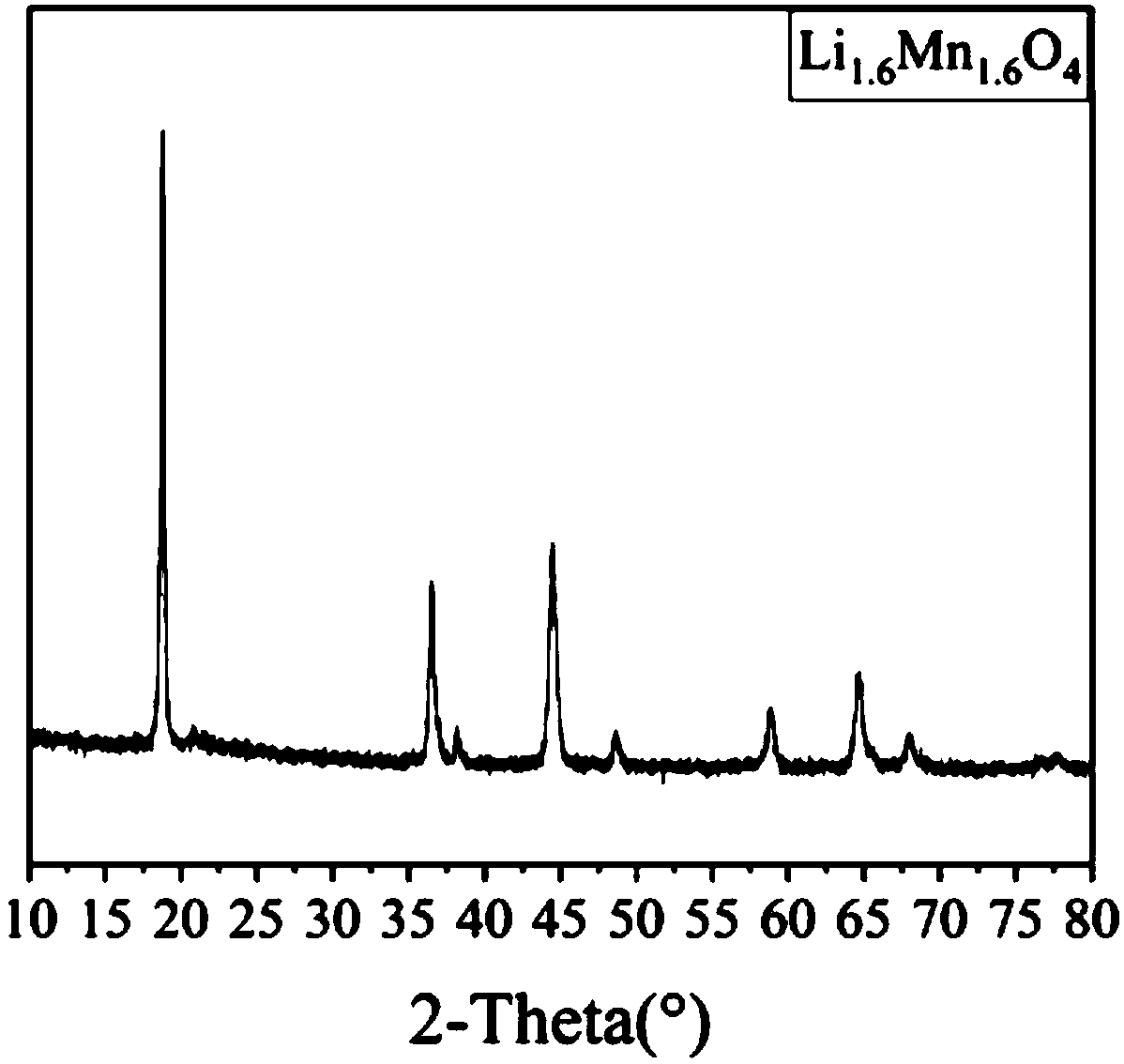

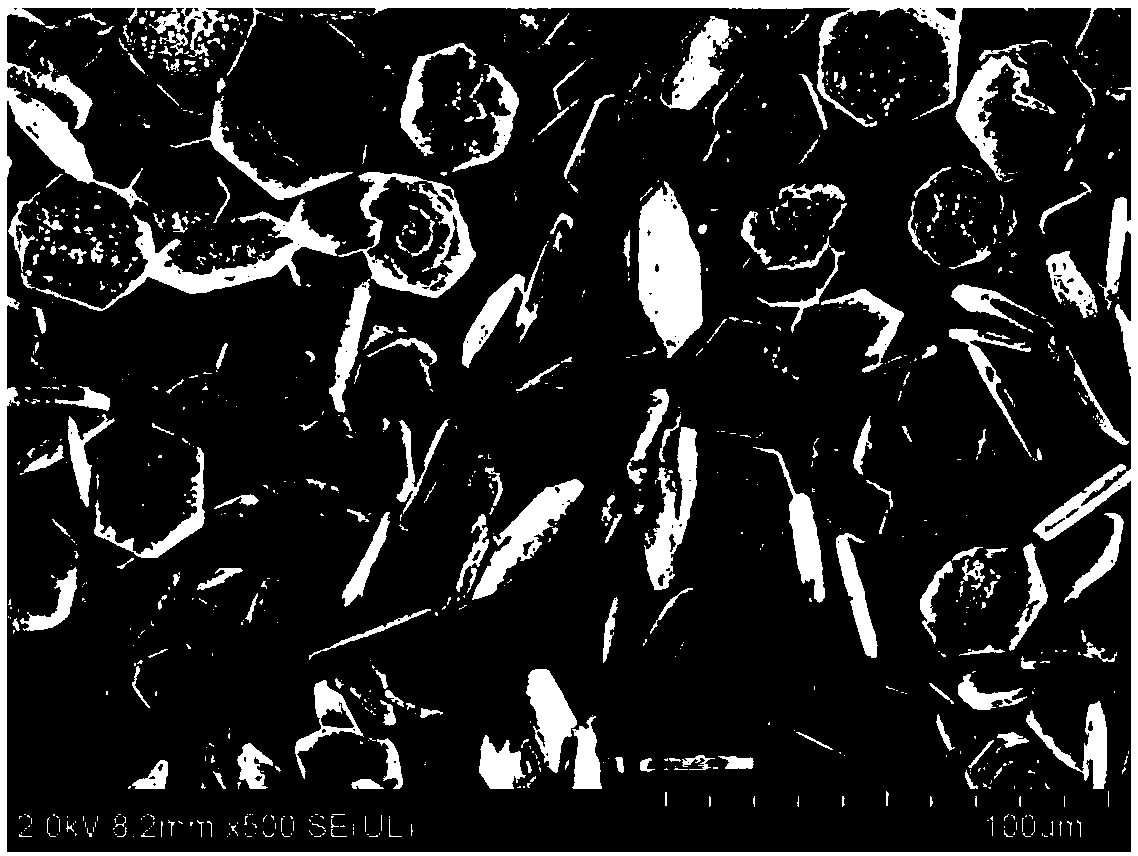

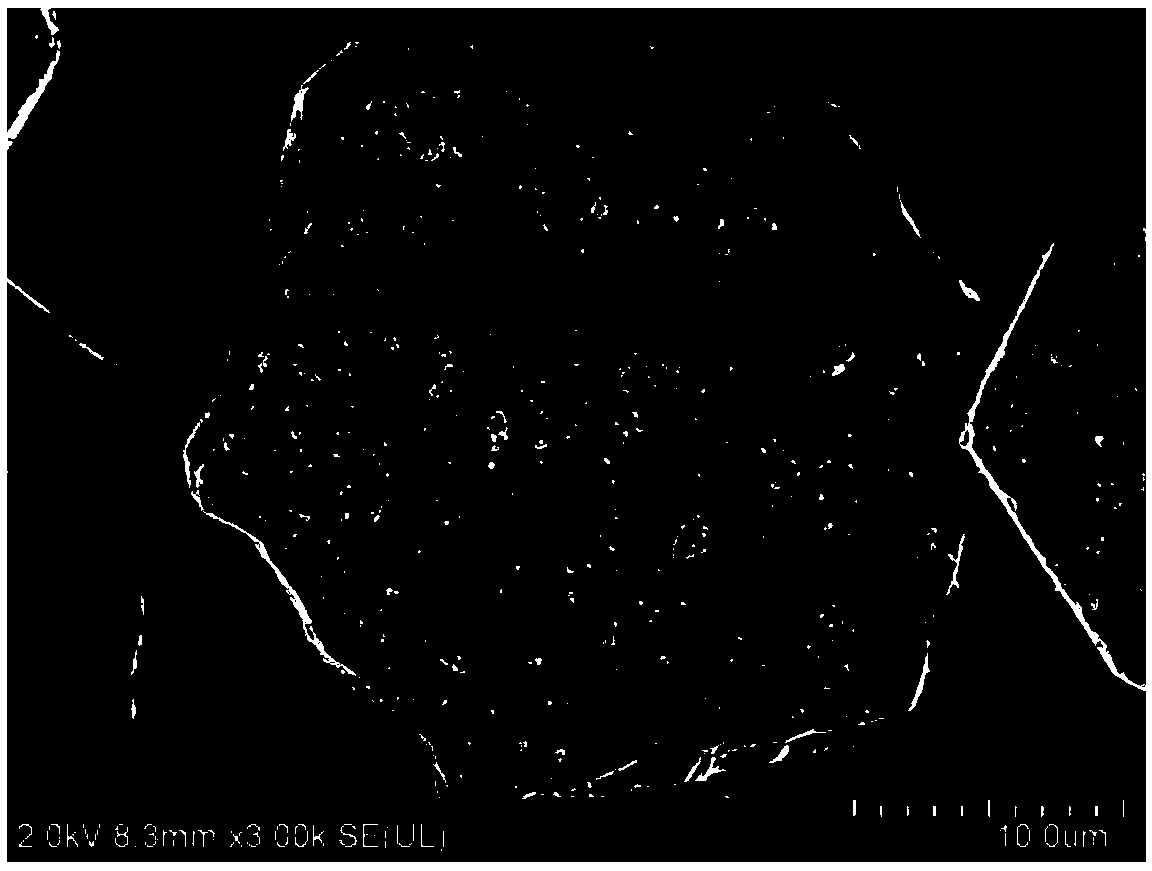

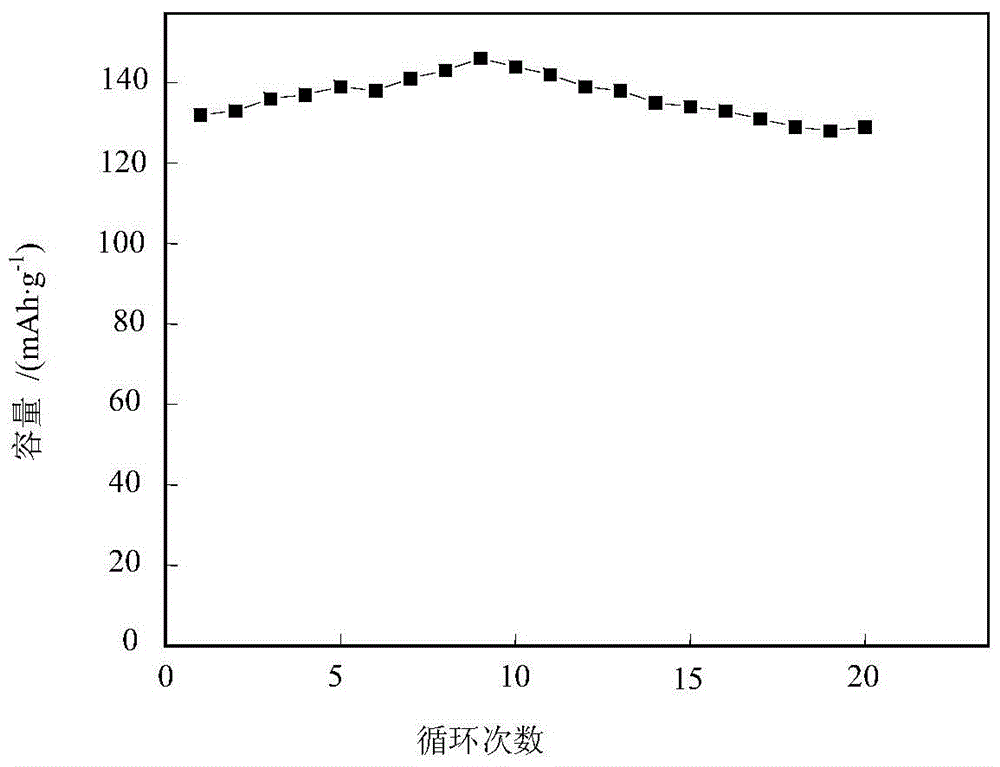

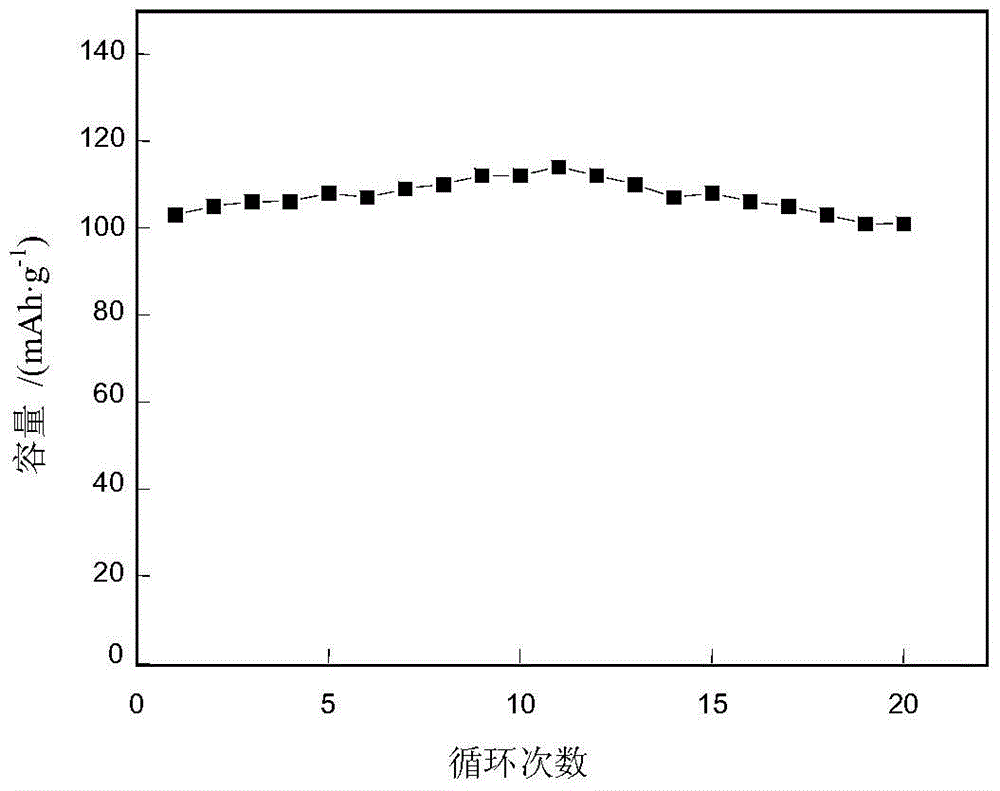

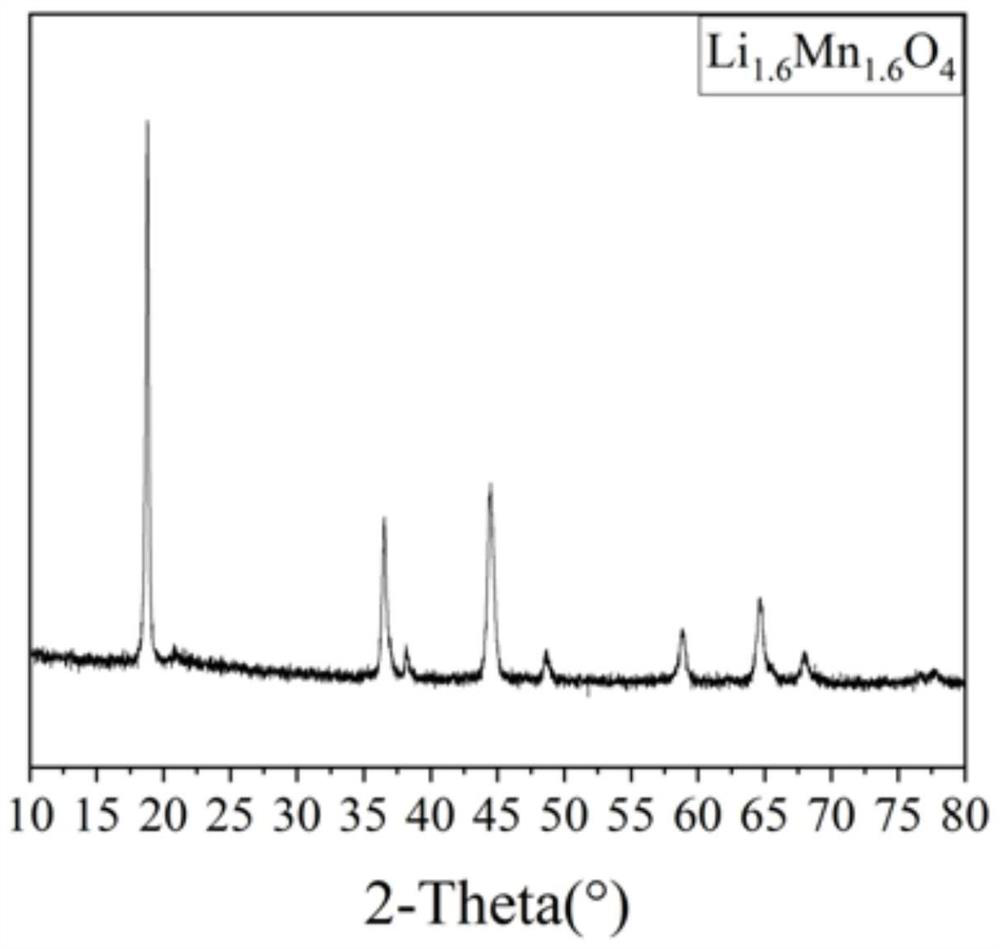

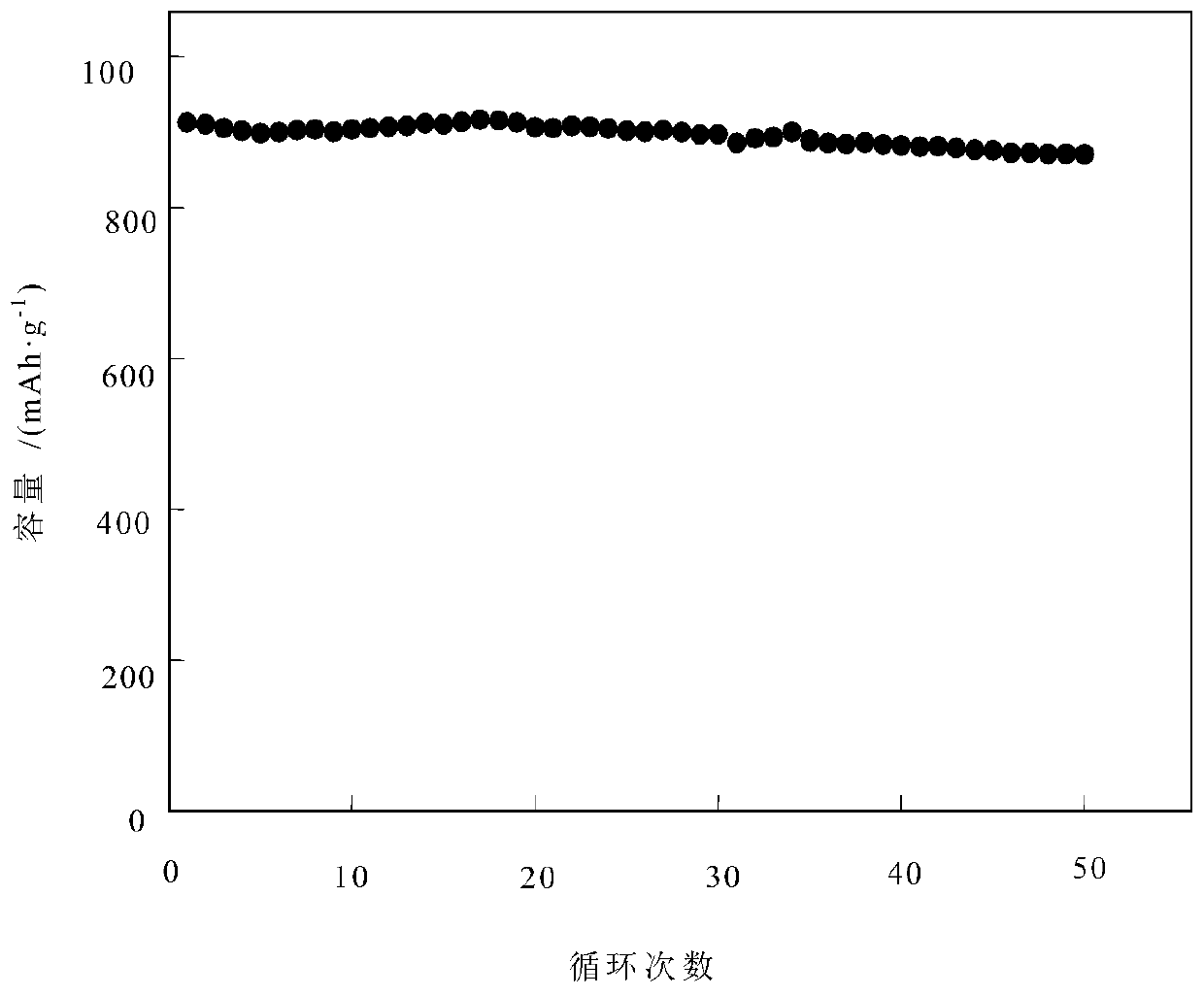

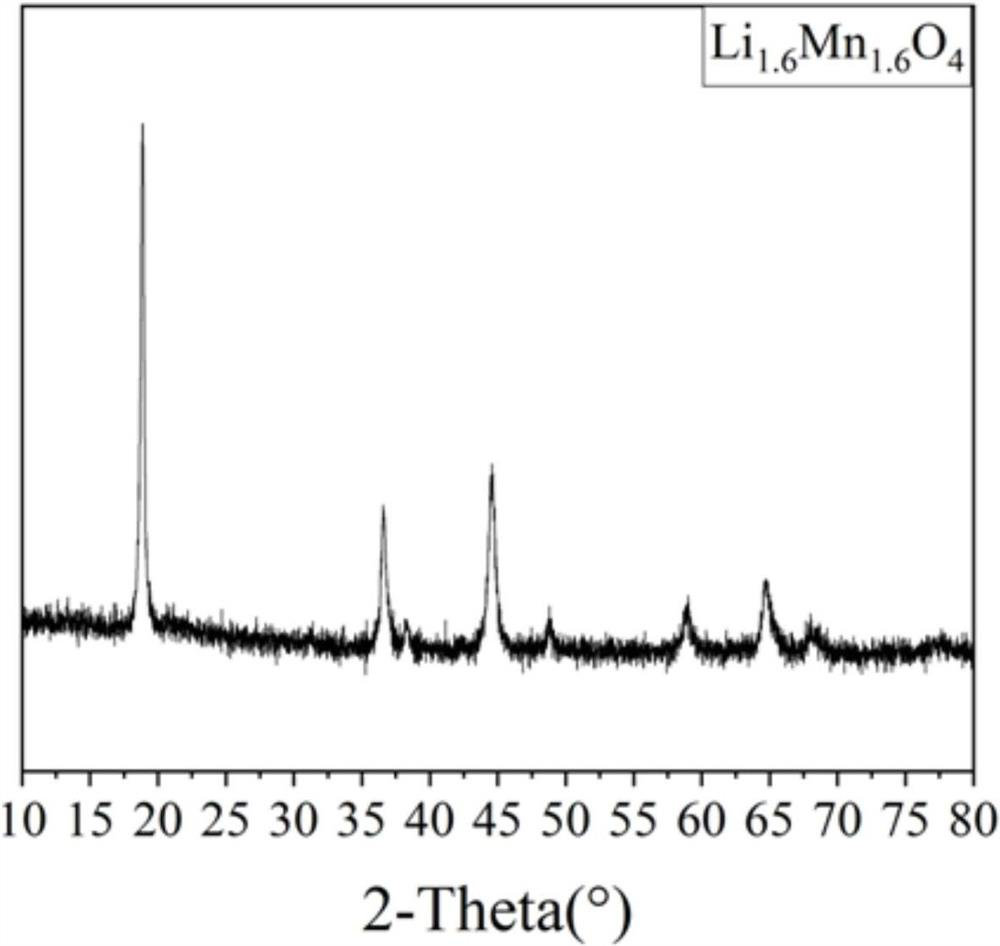

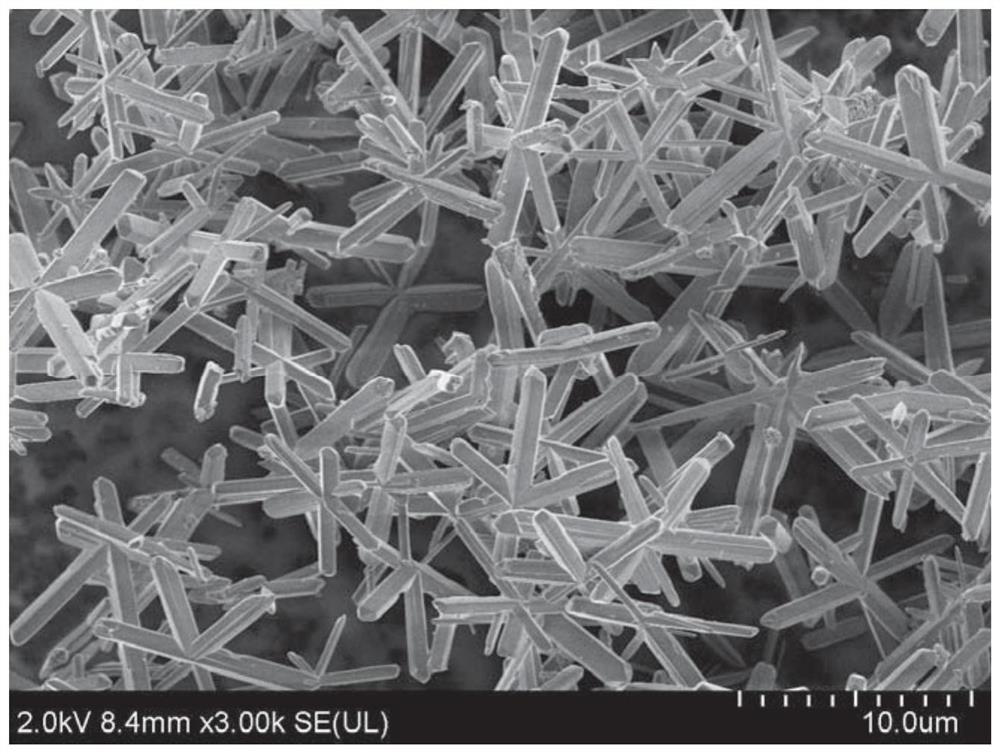

Hexagonal flaky manganese lithium ion sieve adsorbent and preparation method thereof

ActiveCN109289758AHigh purityFast purityOther chemical processesAlkali metal oxides/hydroxidesLithiumMicrowave

The invention discloses a hexagonal flaky manganese lithium ion sieve adsorbent and a preparation method thereof. The method includes: adding a manganese source and a lithium source into water, and stirring to obtain first mixed solution; adding an organic amine compound into the first mixed solution, and stirring to obtain second mixed solution; adding the second mixed solution into a microwave reactor, performing reaction for 20-45min at 150-180 DEG C, and subjecting solid and liquid in the second mixed solution to solid-liquid separation to obtain LiMnO2 particles; calcining the obtained LiMnO2 particles for 3-6h at 450-600 DEG C to obtain Li1.6Mn1.6O4 hexagonal flaky manganese lithium ion sieve adsorbent. A microwave hydrothermal reaction method is adopted for preparing the hexagonal flaky manganese lithium ion sieve adsorbent, organic amines are adopted as a reducing agent and a structural regulating agent for growth regulation, and simplicity of selected raw materials and a preparation process and high purity, high yield, particle size uniformity and stable performances of an obtained product are realized.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method of manufacturing porous aluminum foil for lithium ion capacitor current collector

InactiveCN105702481ADoes not change basic propertiesSimple processHybrid/EDL manufactureHybrid capacitor current collectorsElectrolysisGraphite

The invention relates to the field of capacitor manufacturing, and discloses a method for preparing a porous aluminum foil for a current collector of a lithium ion capacitor. The aluminum foil is used as a raw material, and a direct current electrolytic oxidation method is adopted. The steps are as follows: use inert graphite as a cathode, and use the aluminum foil as an anode pair The aluminum foil is subjected to one-step electrolysis to produce pores and expand pores; the aluminum foil after the above treatment is sequentially cleaned, post-treated and electrolyzed, and washed twice to obtain a porous aluminum foil. The method of the invention has simple process and low cost, and is suitable for industrial production.

Owner:SICHUAN MEIJIABAO NEW ENERGY TECH CO LTD

A kind of high early strength type non-alkali liquid accelerator and its preparation method and application

The invention relates to a high-early-strength non-alkali liquid quick-setting agent and its preparation method and application, belonging to the technical field of building material admixtures. The quick-setting agent is composed of the following raw materials in weight percent: 40-50% of polyaluminum sulfate, 5-10% of metakaolin, 5-15% of nano-silica sol, 3-6% of alcohol amine, 1-4 % of organic acid, 0.01-0.05% of thickener, 0.01-0.05% of dispersant, and the balance is water. On the basis of meeting the national standard "Accelerator for Shotcrete" (GB / T35159-2017), the accelerator can also effectively improve the compressive strength of cement mortar in one day, reaching more than 20MPa, and some cement mortar can resist compression in one day The strength can even reach above 25MPa.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

A kind of cathode material of magnesium ion battery and preparation method thereof

InactiveCN104143623BImprove conductivityIncrease speedCell electrodesSecondary cellsPower flowPhysical chemistry

The invention relates to a positive electrode material of a magnesium ion battery and a preparation method of the positive electrode material. The molecular formula of the positive electrode material is Mg(1-x)-SrxZnyFe(1-y)SiO4, wherein x is greater than 0 and is smaller than or equal to 0.05; y is greater than 0 and is smaller than or equal to 0.03. The preparation method comprises the following steps: adding ethanol into a magnesium source compound, a strontium source compound, a zinc source compound, an iron source compound and a silicon source compound, performing ball-milling, drying, heating to 350-500 DEG C in the presence of argon, keeping the temperature for 1-2 hours, continuously heating to 800-1,200 DEG C, and keeping the temperature for 2-8 hours, thereby obtaining the positive electrode material. The preparation process of the positive electrode material is simple to operate, easy to control and beneficial to achieving on-scale industrial production, and the positive electrode material of the magnesium ion battery is relatively high in reversible capacity and relatively high in large-current charge and discharge performance.

Owner:NINGBO POLYTECHNIC

A kind of hexagonal flake manganese series lithium ion sieve adsorbent and preparation method thereof

ActiveCN109289758BHigh purityFast purityOther chemical processesAlkali metal oxides/hydroxidesLithiumSorbent

The invention discloses a hexagonal flaky manganese lithium ion sieve adsorbent and a preparation method thereof. The method includes: adding a manganese source and a lithium source into water, and stirring to obtain first mixed solution; adding an organic amine compound into the first mixed solution, and stirring to obtain second mixed solution; adding the second mixed solution into a microwave reactor, performing reaction for 20-45min at 150-180 DEG C, and subjecting solid and liquid in the second mixed solution to solid-liquid separation to obtain LiMnO2 particles; calcining the obtained LiMnO2 particles for 3-6h at 450-600 DEG C to obtain Li1.6Mn1.6O4 hexagonal flaky manganese lithium ion sieve adsorbent. A microwave hydrothermal reaction method is adopted for preparing the hexagonal flaky manganese lithium ion sieve adsorbent, organic amines are adopted as a reducing agent and a structural regulating agent for growth regulation, and simplicity of selected raw materials and a preparation process and high purity, high yield, particle size uniformity and stable performances of an obtained product are realized.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

A kind of composite oxide glass-ceramic, insulating medium paste and preparation method and application thereof

ActiveCN108682478BImprove compactnessImprove adhesionQuartz/glass/vitreous enamelsMetallic oxidesLow leakageSlurry

The invention relates to a composite oxide glass-ceramic, an insulating dielectric slurry, a preparation method and application thereof, and belongs to the technical field of thick film circuits. The composite oxide glass-ceramic is SiO 2 -B 2 o 3 -Cs 2 O‑P 2 o 5 -MnO 2 ‑Co 2 o 3 -Ta 2 o 5 -CeO 2 -Er 2 o 3 Composite oxide glass-ceramics; the insulating dielectric slurry includes an organic carrier and an inorganic main phase composed of composite oxide glass-ceramics, and its preparation method is: mixing raw materials according to the proportion, and heating the mixture to 1100-1700°C , keep warm for 1‑24h, then water quenched, dried, ball milled, mixed with an organic carrier in proportion, and finally rolled repeatedly with a three-roll mill to obtain a thick film circuit insulation dielectric slurry, which is used for the large size of stainless steel substrates Power thick film circuit insulation dielectric layer has excellent properties such as large expansion coefficient, good adhesion, high insulation and resistance, high breakdown voltage and low leakage current.

Owner:NINGBO POLYTECHNIC

Doped modified lithium ion battery vanadate negative electrode material and preparation method thereof

ActiveCN111048778AChange the electric field distributionImprove lithium storage performanceSecondary cellsNegative electrodesElectrical batteryPhysical chemistry

The invention relates to a doped modified lithium ion battery vanadate negative electrode material and a preparation method thereof, and belongs to the field of lithium ion battery material preparation. The doped modified lithium ion battery vanadate negative electrode material is composed of an iron source compound, an antimony source compound, a vanadate source compound and a fluorine source compound according to a molar ratio of Fe:Sb:VO4<3->:F being x:y:1:z, wherein x ranges from 0.5 to 0.9, y ranges from 0.1 to 0.5, and z ranges from 0.01 to 0.1. Vanadate is used as a main body framework,iron ions and antimony ions with different ion radiuses and electronic structures and fluorine ions with a relatively small radius and relatively strong electronegativity are mutually doped, the distribution of an electric field in a unit cell is changed, a lithium ion intercalation and deintercalation channel in a crystal is expanded, the migration rate of lithium ions is improved, and the impact of lithium ions on a crystal structure due to the volume change of the crystal in the intercalation and deintercalation process is buffered, so that the lithium storage performance of the material is improved, and the cycle life of the lithium ion battery doped with the vanadate negative electrode material is greatly prolonged.

Owner:NINGBO POLYTECHNIC

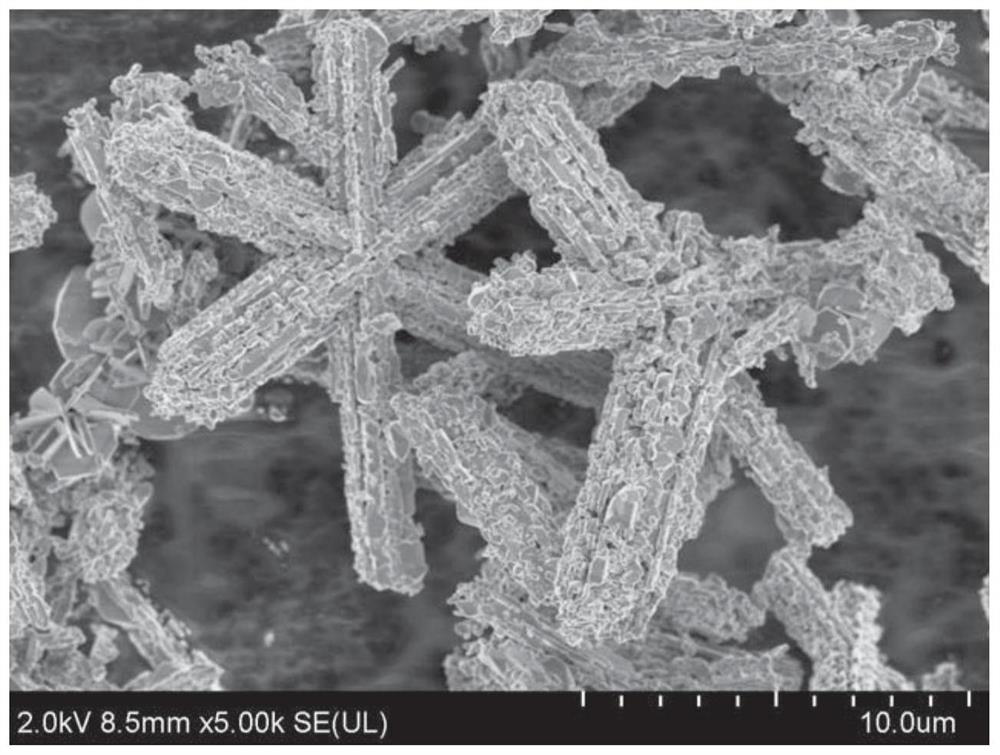

A kind of hexagonal dendritic manganese series lithium ion sieve adsorbent and preparation method thereof

ActiveCN109289757BHigh purityFast purityOther chemical processesAlkali metal oxides/hydroxidesSorbentManganese

The invention discloses a hexagonal dendritic manganese lithium ion sieve adsorbent and a preparation method thereof. The method includes: adding a manganese source and a lithium source into water, and stirring to obtain first mixed solution; adding an organic aliphatic compound into the first mixed solution, and stirring to obtain second mixed solution; adding the second mixed solution into a microwave reactor, performing reaction for 20-60min at 160-200 DEG C, and subjecting solid and liquid in the second mixed solution to solid-liquid separation to obtain LiMnO2 particles; calcining the obtained LiMnO2 particles for 4-8h at 400-600 DEG C to obtain Li1.6Mn1.6O4 hexagonal dendritic manganese lithium ion sieve adsorbent. A microwave hydrothermal reaction method is adopted for preparing thehexagonal dendritic manganese lithium ion sieve adsorbent, organic lipids are adopted as a reducing agent and a structural regulating agent for growth regulation, and simplicity of selected raw materials and a preparation process and high purity, high yield, particle size uniformity and stable performances of an obtained product are realized.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

A kind of amorphous glass powder and its preparation and application

The invention discloses an amorphous glass powder, and a preparation method and applications thereof. The amorphous glass powder comprises following raw materials, by mass, 10 to 60% of BaO, 1 to 30% of Al2O3, 5 to 40% of B2O3, 5 to 40% of P2O5, 1 to 10% of MoO3, 1 to 5% of NiO, and 1 to 10% of Nd2O3. The preparation method comprises following steps: the raw materials are mixed at the ratio; the mixture is heated to 1200 to 1650 DEG C, and the temperature is kept for 0.5 to 8h; and the mixture is subjected to water quenching, and is grinded into powder with a diameter of 0.5 to 5 microns by ball milling so as to obtain the amorphous glass powder. A slurry made of the amorphous glass powder and an organic carrier possess excellent adhesiveness on stainless steel substrates; the breakdown voltage of the slurry is high, and insulating properties of the slurry are excellent; and the slurry is capable of meeting the requirements for thick film circuit insulating medium materials of high-power stainless steel substrates.

Owner:NINGBO POLYTECHNIC

A kind of thick-film circuit resistance paste for stainless steel substrate and preparation method thereof

ActiveCN104992744BOvercoming the disadvantage of being very expensiveReduce manufacturing costNon-conductive material with dispersed conductive materialCable/conductor manufactureCITRATE ESTERTributyl citrate

The invention discloses a thick-film circuit resistor paste for stainless steel substrates and a preparation method thereof. The thick-film circuit resistor paste is composed of a solid phase component and an organic liquid phase, and the solid phase component includes a conductive phase and a microcrystalline The glass phase, the conductive phase is composed of Cu2O‑GeO2 composite + Cu powder, the glass-ceramic phase is SiO2‑Al2O3‑B2O3‑CaO‑ZrO2‑Co2O3 composite, and the organic liquid phase is terpineol, tributyl citrate, ethyl acetate Mixed liquid phase of base cellulose, span 85, 1,4-butyrolactone, hydrogenated castor oil. The preparation method is as follows: firstly, the conductive phase and the glass-ceramic phase are respectively prepared, then the organic liquid phase is prepared, and finally the conductive phase, the glass-ceramic phase and the organic liquid phase are mixed and prepared to obtain the resistance paste.

Owner:NINGBO POLYTECHNIC

A kind of doped modified lithium ion battery vanadate negative electrode material and preparation method thereof

ActiveCN111048778BImprove electrical performanceImprove reaction efficiencyNegative electrodesSecondary cellsChemical physicsElectrical battery

The invention relates to a doped modified lithium ion battery vanadate negative electrode material and a preparation method thereof, belonging to the field of lithium ion battery material preparation. The doped modified lithium ion battery vanadate negative electrode material is composed of iron source compound, antimony source compound, vanadate source compound and fluorine source compound in molar ratio Fe:Sb:VO 4 3‑ : F=x:y:1:z composition, wherein x=0.5-0.9, y=0.1-0.5, z=0.01-0.1. With vanadate as the main skeleton, ferric ions and antimony ions with different ionic radii and electronic structures and fluorine ions with smaller radii and stronger electronegativity are doped with each other to change the electric field distribution in the unit cell and expand the lithium ions in the crystal. The intercalation channel improves the migration rate of lithium ions, buffers the impact of lithium ions on the crystal structure due to crystal volume changes during the intercalation and extraction process, thereby improving the lithium storage performance of the material and greatly improving the performance of lithium-ion batteries doped with vanadate negative materials. cycle life.

Owner:NINGBO POLYTECHNIC

Method for preparing alpha iron sesquioxide

InactiveCN108128813ASimple preparation processReduced responseFerric oxidesSesquioxidePotassium ferricyanide

The invention discloses a method for preparing alpha iron sesquioxide. The method comprises the following steps: S1, preparing an aqueous solution of potassium ferricyanide; S2, carrying out a microwave hydrothermal reaction on the aqueous solution of potassium ferricyanide at a temperature of 170-220 DEG C for at least half an hour so as to obtain a solid-liquid mixture; and S3, performing solid-liquid separation on the solid-liquid mixture, and cleaning and drying a solid obtained, thereby obtaining alpha iron sesquioxide. According to the method disclosed by the invention, potassium ferricyanide serves as a raw material, the ferricyanide ion in potassium ferricyanide serves as an iron source, and nitrogen atoms in cyanogens are selectively adsorbed on the surfaces of particles due to lone pair electrons in the cyanogens, so that hexagonal flower-like crystal alpha iron sesquioxide is obtained. Compared with a traditional preparation method for regulating particle growth by using sulfate, chloride and other soluble iron sources as raw materials and adding at least one modifier, the method disclosed by the invention is simple in preparation process, and the preparation cost is reduced; the reaction conditions are easily controlled, and large-scale industrial production is realized; and meanwhile, the product is high in purity, high in yield, uniform in particle size and stablein performance.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

A kind of preparation method of porous copper foil for current collector of lithium ion capacitor

ActiveCN105845459BDo not change basic propertiesSimple processHybrid/EDL manufactureHybrid capacitor current collectorsElectrolysisCopper foil

The invention relates to the field of capacitor manufacturing, and discloses a method for preparing a porous copper foil for a lithium ion capacitor current collector. Copper foil is used as a raw material, and a direct current electrolytic oxidation method is adopted. The steps are as follows: A) using inert graphite as a cathode, and using the The copper foil is used as the anode to pretreat the copper foil to make holes; B) the copper foil after the above treatment is cleaned; C) after cleaning, the copper foil is electrolytically expanded with the inert graphite as the cathode and the copper foil as the anode. D) After the above-mentioned treated copper foil is subjected to secondary cleaning, post-treatment electrolysis, and three cleanings, the porous copper foil is produced. The method of the invention has simple process and low cost, and is suitable for industrial production.

Owner:西科微纳(重庆)新能源技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com