Resistance paste for thick film circuit and preparation method of resistance paste

A technology of resistance paste and thick film circuit, which is applied in the direction of circuit, conductive material dispersed in non-conductive inorganic materials, cable/conductor manufacturing, etc., can solve the problems of high price and high use cost, and reduce production cost and use Reduce cost, reduce square resistance, and realize the effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

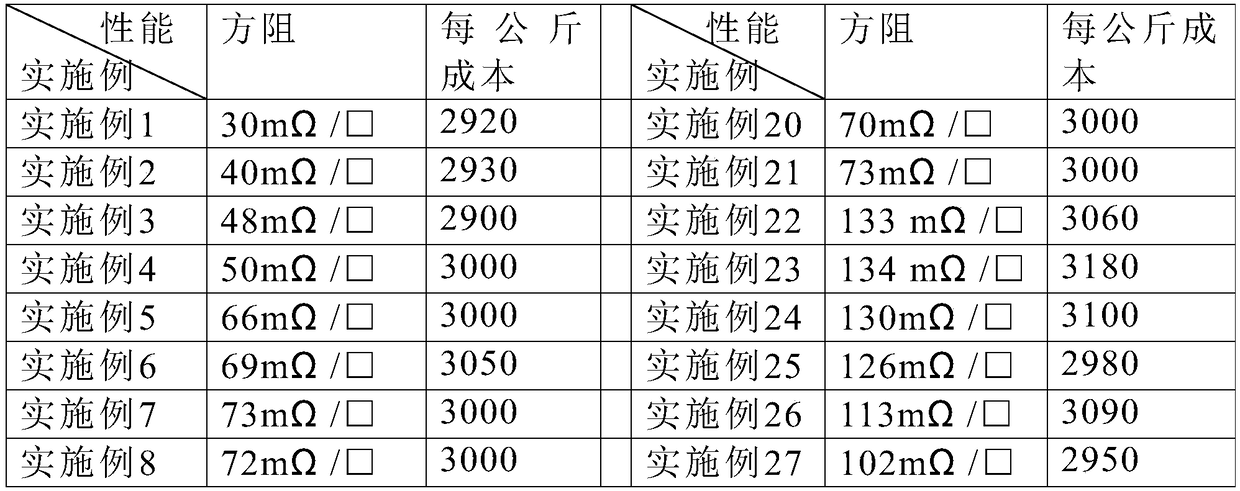

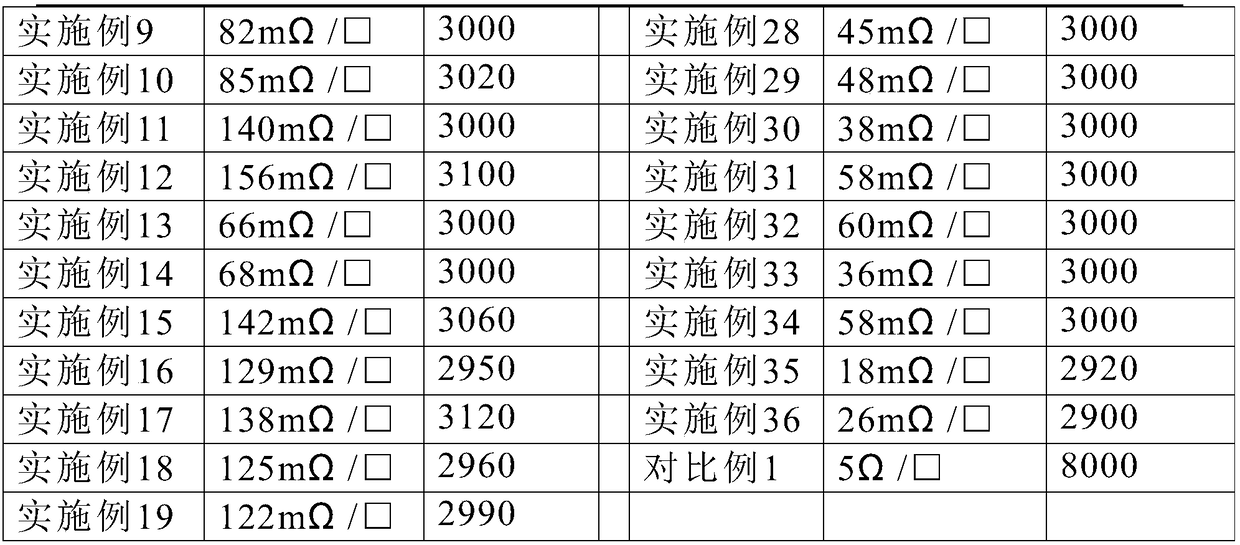

Examples

Embodiment 1

[0026] A thick film circuit resistor paste, comprising 75% solid phase and 25% organic carrier phase accounting for the total mass of the paste, wherein the solid phase includes a conductive functional phase and an inorganic glass bonding phase, and the conductive functional phase is bonded to the inorganic glass The junction phase accounts for 80% and 20% of the total mass of the solid phase respectively, and the conductive functional phase is Zn 2 SnO 4 , Ga 2 o 3 with Bi 2 o 3 complex of Zn 2 SnO 4 , Ga 2 o 3 、 Bi 2 o 3 The mass percentages are 15%, 45%, 40% respectively; the inorganic glass bonding phase is SiO 2 , B 2 o 3 , CaO, ZnO, TiO 2 Composite with NiO, SiO 2 , B 2 o 3 , CaO, ZnO, TiO 2The mass percentages of NiO and NiO are 35%, 9%, 28%, 20%, 6% and 2% respectively; the organic carrier phase is terpineol, tributyl citrate, ethyl cellulose, Span 85, 1, The complexes of 4-butyrolactone and hydrogenated castor oil account for 72%, 14%, 4%, 5%, 4% and...

Embodiment 2

[0028] Compared with Example 1, the only difference is that the thick-film circuit resistor paste of this embodiment includes 70% of the solid phase and 30% of the organic vehicle phase accounting for the total mass of the paste.

Embodiment 3

[0030] Compared with Example 1, the only difference is that the thick-film circuit resistor paste of this embodiment includes 65% of the solid phase and 35% of the organic vehicle phase accounting for the total mass of the paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com