Doped modified lithium ion battery vanadate negative electrode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, which is applied in the direction of battery electrodes, active material electrodes, negative electrodes, etc., can solve the problems of low conductivity and volume expansion of materials, achieve the expansion of intercalation channels, easy control, and increase the migration rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

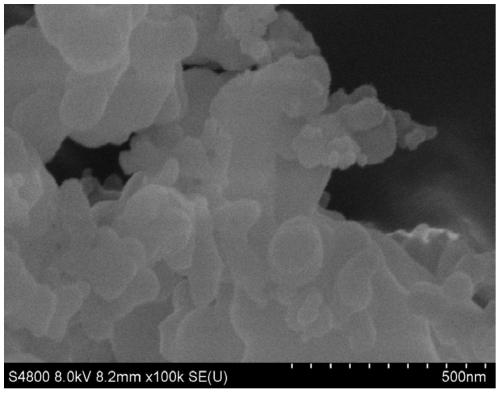

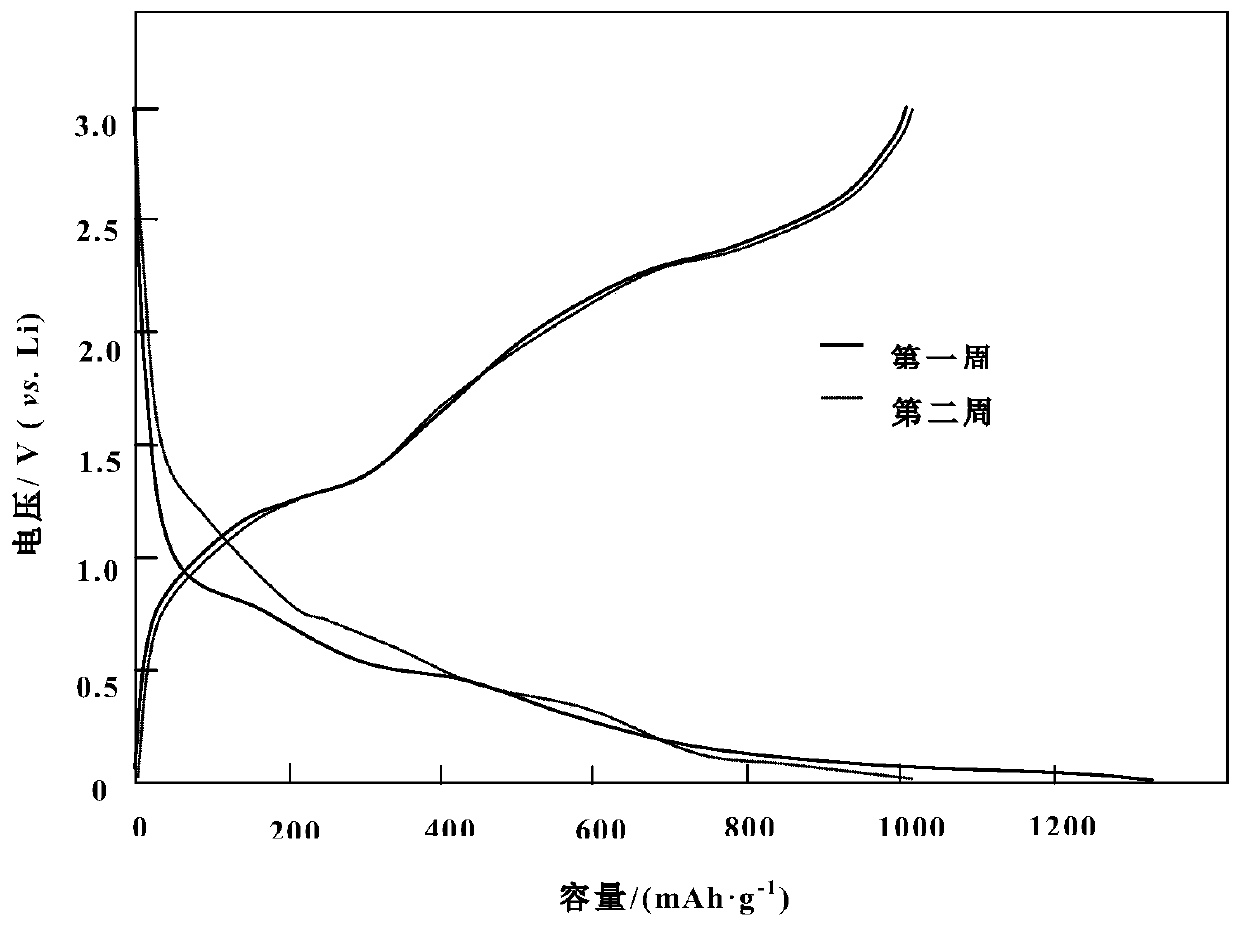

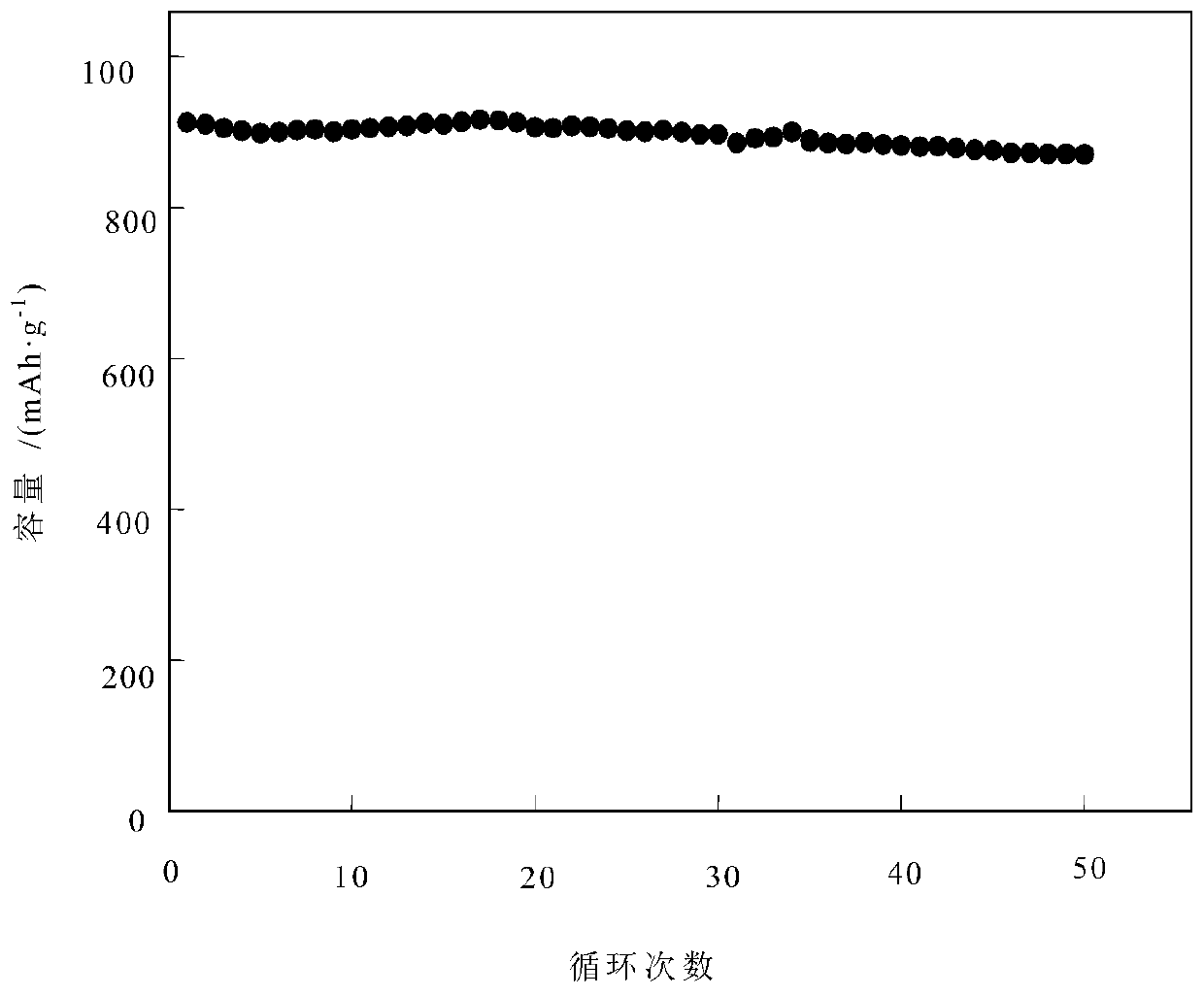

[0028] Accurately weigh 0.85molFe(OH) 3 , 0.14molSb(OH) 3 , 1.0molNH 4 VO 3 , 0.03mol NH 4 F, put it into the ball mill tank of the planetary ball mill, add deionized water, and ball mill to obtain the rheological phase mixture. While stirring, add 1.0 mol / L oxalic acid solution dropwise to the rheological phase mixture, adjust the pH value of the mixture to 5.8, and stir thoroughly. The mixture was transferred to a stainless steel high-pressure tank, and reacted at a constant temperature of 220°C for 24 hours. After taking it out and drying it, the solid mixture was ground to obtain a precursor powder. Put the precursor powder into a program-controlled electric furnace and heat it up to 720°C at a heating rate of 5°C / min, and keep it for 8 hours to obtain doped modified Fe 0.85 Sb 0.14 VO 4 f 0.03 Vanadate anode material.

[0029] The synthesized Fe 0.85 Sb 0.14 VO 4 f 0.03 The vanadate negative electrode material, acetylene black, and polytetrafluoroethylene are...

Embodiment 2

[0031] Accurately weigh 0.25molFe 2 o 3 , 0.05molSb 2 o 3 , 1.0molNH 4 VO 3 , 0.01mol NH 4 F, put it into the ball mill tank of the planetary ball mill, add deionized water, and ball mill to obtain the rheological phase mixture. While stirring, add 0.5 mol / L oxalic acid solution dropwise to the rheological phase mixture, adjust the pH value of the mixture to 5.1, and stir thoroughly. The mixture was transferred to a stainless steel high-pressure tank, and reacted at a constant temperature of 150°C for 60 hours. After taking it out and drying it, the solid mixture was ground to obtain a precursor powder. Put the precursor powder into a program-controlled electric furnace and heat it up to 500°C at a heating rate of 3°C / min, and keep it warm for 1 hour to obtain doped modified Fe 0.5 Sb 0.1 VO 4 f 0.01 Vanadate anode material.

[0032] The synthesized Fe 0.5 Sb 0.1 VO 4 f 0.01 The vanadate negative electrode material, acetylene black, and polytetrafluoroethylene a...

Embodiment 3

[0034] Accurately weigh 0.6mol Fe(OH) 3 , 0.19molmolSb 2 o 3 , 1.0mol NH 4 VO 3 , 0.015mol HF, put into the ball mill tank of the planetary ball mill, add an appropriate amount of deionized water, and ball mill to obtain the rheological phase mixture. While stirring, add 1.0 mol / l oxalic acid solution dropwise to the rheological phase mixture, adjust the pH value of the mixture to 5.5, and stir thoroughly. The mixture was transferred to a stainless steel high-pressure tank, and reacted at a constant temperature of 160°C for 56 hours. After taking it out and drying it, the solid mixture was ground to obtain a precursor powder. Put the precursor powder into a program-controlled electric furnace and heat it up to 600°C at a heating rate of 4°C / min, and hold it for 3 hours to obtain doped modified Fe 0.6 Sb 0.38 VO 4 f 0.015 Vanadate anode material.

[0035] The synthesized Fe 0.6 Sb 0.38 VO 4 f 0.015 The vanadate negative electrode material, acetylene black, and poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com