Doped silicate sodium ion battery positive electrode material and preparation method thereof

A sodium ion battery and positive electrode material technology, applied in the direction of silicate, battery electrode, alkali metal silicate, etc., can solve the problems that cannot meet the requirements of commercial energy storage batteries, and achieve the improvement of electronic conductivity and sodium ion migration rate , The preparation method is simple, the effect of long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of a sodium ion battery cathode material, comprising the following steps:

[0033] Accurately weigh 0.98 mol sodium oxalate, 0.02 mol magnesium oxalate, 1.0 mol ferrous oxalate, 1.0 mol tetraethyl orthosilicate, put them into a ball mill jar, then use an appropriate amount of deionized water as a mixing medium, and use a ball mill to fully mill for 2 hours , after drying at 110°C, the powder was pre-fired at 400°C for 4 hours under the protection of high-purity nitrogen at a heating rate of 5°C / min, and the pre-fired powder was dispersed with polyethylene glycol by mass Mix at a ratio of 1:0.2, add an appropriate amount of deionized water, adjust to a rheological state, and obtain a rheological phase precursor. The precursor was heated to 650°C at a heating rate of 5°C / min under the protection of high-purity nitrogen, and sintered for 8 hours to obtain a magnesium-doped silicate sodium-ion battery cathode material Na 1.96 Mg 0.02 FeSiO 4 .

[00...

Embodiment 2

[0038]Accurately weigh 1.94mol of sodium bicarbonate, 0.03mol of magnesium acetate, 1.0mol of ferric citrate, and 1.0mol of tetraethyl orthosilicate, put them into a ball mill jar, then use an appropriate amount of deionized water as a mixing medium, and use a ball mill to fully mill for 3 Hours, after drying at 120°C, the powder was pre-fired at 350°C for 4 hours under the protection of high-purity nitrogen at a rate of 3°C / min, and the pre-fired powder was dispersed with glucose at a mass ratio of : Mix at a ratio of 0.3, add an appropriate amount of deionized water, adjust to a rheological state, and obtain a rheological phase precursor. The precursor was heated to 700°C at a heating rate of 3°C / min under the protection of high-purity nitrogen, and sintered for 5 hours to obtain a magnesium-doped silicate sodium-ion battery cathode material Na 1.94 Mg 0.03 FeSiO 4 .

[0039] Performance Testing:

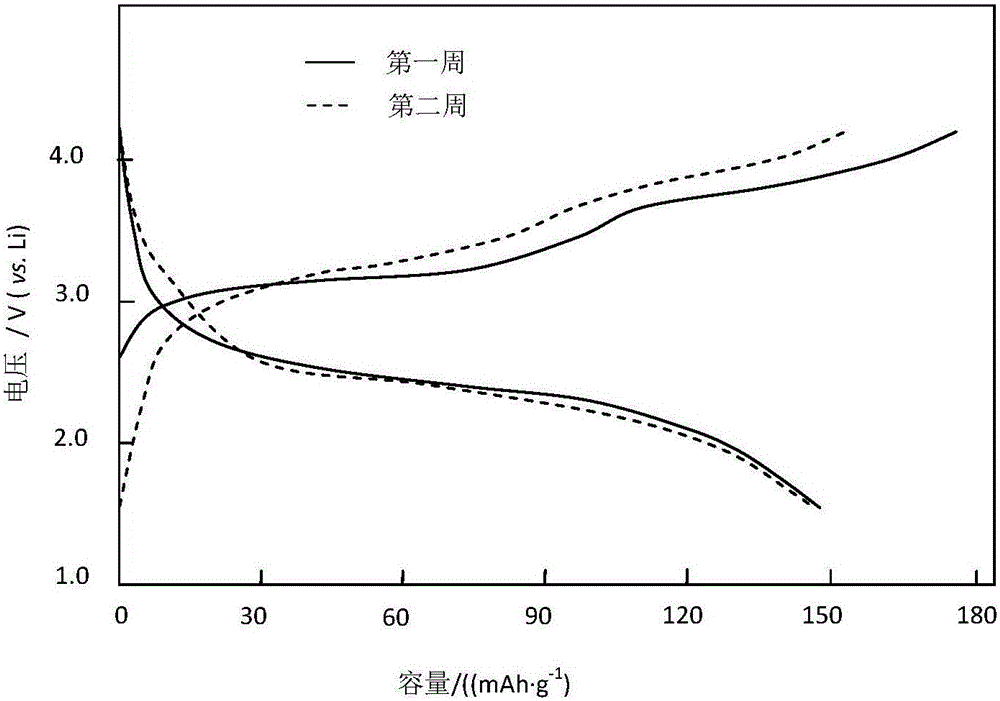

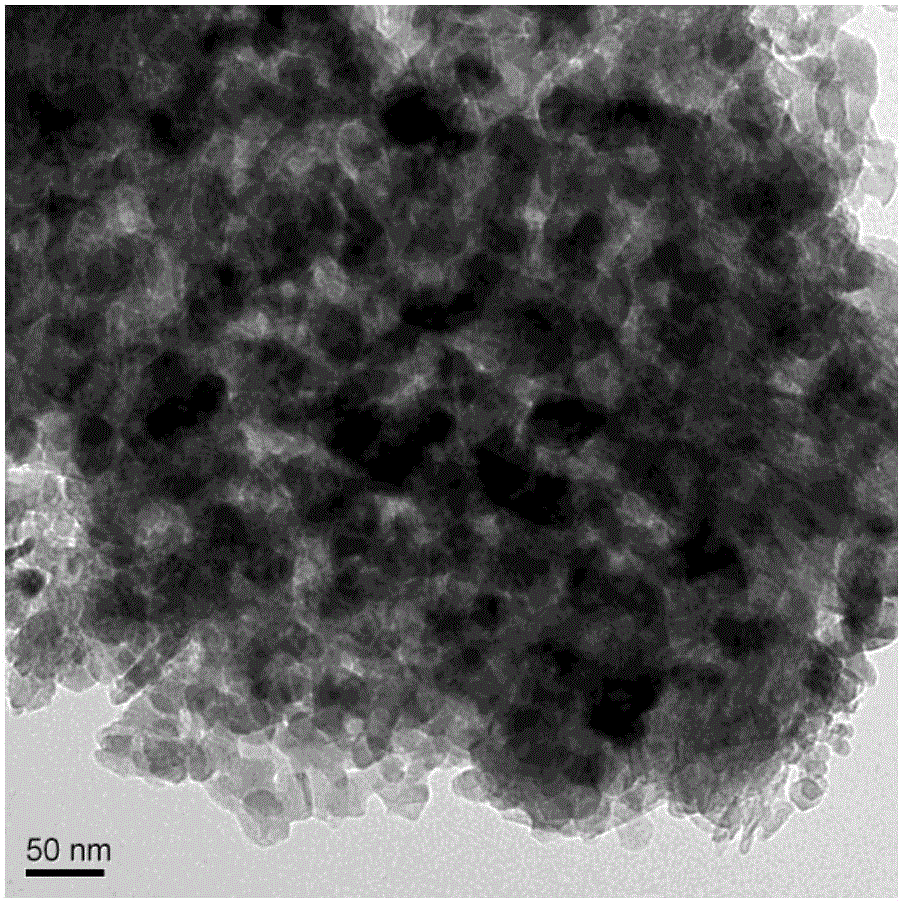

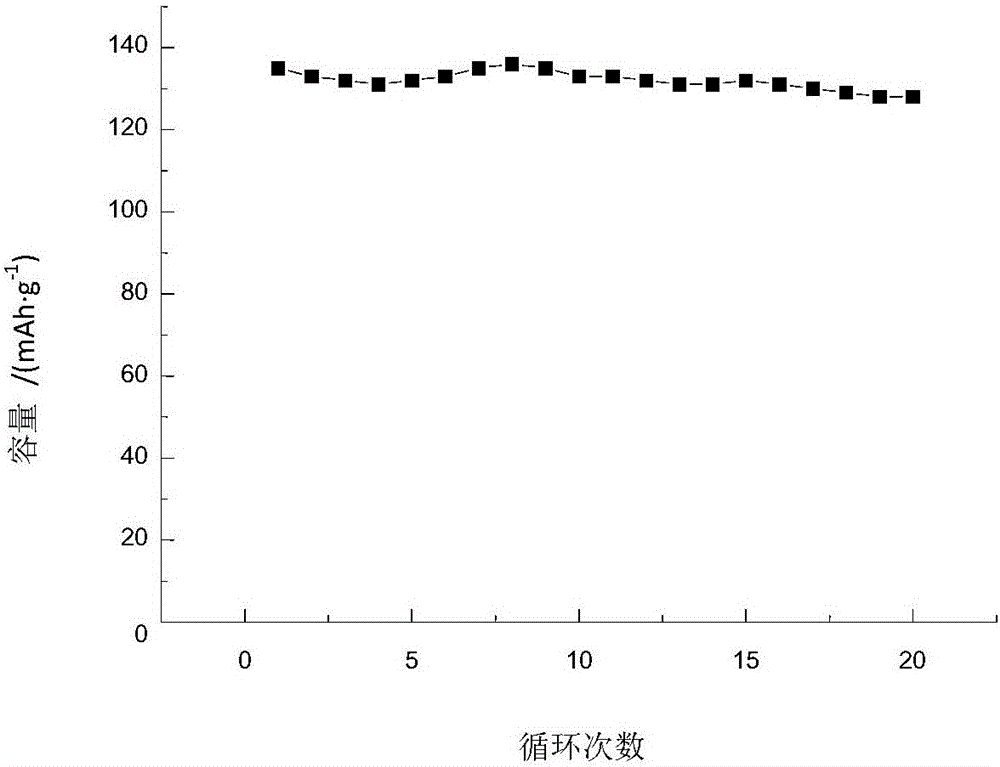

[0040] The prepared sodium ion battery cathode material Na 1.94 Mg 0.03...

Embodiment 3

[0042] Accurately weigh 1.98mol of sodium acetate, 0.01mol of magnesium hydroxide, 1.0mol of ferrous acetate, and 1.0mol of silicon dioxide, put them into a ball mill jar, then use an appropriate amount of deionized water as a mixing medium, and use a ball mill to fully mill for 4 hours. After drying at 105°C, the powder is pre-fired at 450°C for 2 hours at a heating rate of 6°C / min under the protection of high-purity nitrogen, and the pre-fired powder is dispersed with citric acid at a mass ratio of 1:0.5 Mixed in a certain ratio, adding an appropriate amount of deionized water, adjusted to a rheological state, and obtained a rheological phase precursor. The precursor was heated to 750°C at a heating rate of 6°C / min under the protection of high-purity nitrogen, and sintered for 4 hours to obtain a magnesium-doped silicate sodium-ion battery cathode material Na 1.98 Mg 0.01 FeSiO 4 .

[0043] The prepared sodium ion battery cathode material Na 1.98 Mg 0.01 FeSiO 4 Mix ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com